Tri-Polar Bot Concept -- Meet Wally

Posted by see3d

|

Re: Tri-Polar Bot Concept -- Meet Wally November 22, 2013 05:17PM |

Registered: 10 years ago Posts: 62 |

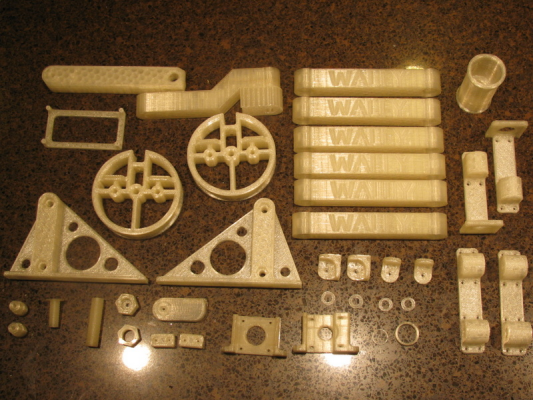

Great looking parts, Shane! I'm almost done with a set out of natural PLA. It doesn't look as cool as your blue, but it's kind of neat to see the honeycomb infill (I'll post pics when I've got a complete set). I've also got some Cotten Candy and Sky blue coming soon (hopefully today!) that's slated to turn into Walley parts.

Can you weigh all the parts? I get 871 grams, including the support material for the xy forearm (calculated...I'm still printing some of the arms). That doesn't leave a lot of room for mistakes out of a 2 lb spool from the ProtoParadigm folks...too bad their spools aren't 1Kg.

Can you weigh all the parts? I get 871 grams, including the support material for the xy forearm (calculated...I'm still printing some of the arms). That doesn't leave a lot of room for mistakes out of a 2 lb spool from the ProtoParadigm folks...too bad their spools aren't 1Kg.

|

Re: Tri-Polar Bot Concept -- Meet Wally November 22, 2013 05:44PM |

Registered: 11 years ago Posts: 48 |

I checked and my parts weighed 789 grams before support material. With support material, it was pretty close to 820 grams.

You're right: it doesn't allow for much more than 1 mistake on a large part before you'll need a second spool!

Shane

You're right: it doesn't allow for much more than 1 mistake on a large part before you'll need a second spool!

Shane

Quote

cdsteinkuehler

Can you weigh all the parts? I get 871 grams, including the support material for the xy forearm (calculated...I'm still printing some of the arms).

|

Re: Tri-Polar Bot Concept -- Meet Wally November 24, 2013 11:38AM |

Registered: 10 years ago Posts: 6 |

|

Re: Tri-Polar Bot Concept -- Meet Wally November 25, 2013 11:14PM |

Registered: 10 years ago Posts: 62 |

Quote

sgraber

I checked and my parts weighed 789 grams before support material. With support material, it was pretty close to 820 grams.

I goofed on my calculations, now that everything's printed I get about 930 grams: [github.com]

I finally got all the parts printed clean, but I don't think my layer alignment is as good as yours. That's one of the reasons I'm interested in printers like Wally and Simpson, I've had about enough of aligning parallel rods to prevent binding!

Hi-Res Photos: [plus.google.com]

|

Re: Tri-Polar Bot Concept -- Meet Wally November 26, 2013 06:18AM |

Registered: 10 years ago Posts: 62 |

Quote

sgraber

I checked and my parts weighed 789 grams before support material. With support material, it was pretty close to 820 grams.

Shane: What nozzle size are you printing with, and what's your single-wall thickness? I'm using 3mm filament with a 0.5mm nozzle, so I've got perimeter extrusion widths of 0.50mm and infill widths of 0.70mm (according to Slic3r). I'm thinking my 3 perimeters is probably a fair amount thicker than your 3 perimeters if you're using a smaller nozzle.

|

Re: Tri-Polar Bot Concept -- Meet Wally November 26, 2013 07:33AM |

Registered: 11 years ago Posts: 48 |

I'm printing with a 0.4mm orifice and my best guess at wall thickness is somewhere around 1-1.5mm with 3 perimeters. Default extrusion width is set @ 0.5mm.

Shane

Shane

Quote

cdsteinkuehler

Quote

sgraber

I checked and my parts weighed 789 grams before support material. With support material, it was pretty close to 820 grams.

Shane: What nozzle size are you printing with, and what's your single-wall thickness? I'm using 3mm filament with a 0.5mm nozzle, so I've got perimeter extrusion widths of 0.50mm and infill widths of 0.70mm (according to Slic3r). I'm thinking my 3 perimeters is probably a fair amount thicker than your 3 perimeters if you're using a smaller nozzle.

|

Re: Tri-Polar Bot Concept -- Meet Wally November 26, 2013 08:07AM |

Registered: 10 years ago Posts: 62 |

Quote

sgraber

I'm printing with a 0.4mm orifice and my best guess at wall thickness is somewhere around 1-1.5mm with 3 perimeters. Default extrusion width is set @ 0.5mm.

Thanks! I measured one of my many failed prints, and I get 1.7mm for the three perimeters. I'm guessing that's where my extra weight is coming from (or I've just got really heavy PLA!).

|

Re: Tri-Polar Bot Concept -- Meet Wally November 26, 2013 09:50AM |

Registered: 11 years ago Posts: 48 |

What's your % infill? How about solid top and bottom layers? I run 15% infill and 3 solid top/bottom layers.

Shane

Shane

Quote

cdsteinkuehler

Quote

sgraber

I'm printing with a 0.4mm orifice and my best guess at wall thickness is somewhere around 1-1.5mm with 3 perimeters. Default extrusion width is set @ 0.5mm.

Thanks! I measured one of my many failed prints, and I get 1.7mm for the three perimeters. I'm guessing that's where my extra weight is coming from (or I've just got really heavy PLA!).

|

Re: Tri-Polar Bot Concept -- Meet Wally November 26, 2013 09:57AM |

Registered: 10 years ago Posts: 62 |

Quote

sgraber

What's your % infill? How about solid top and bottom layers? I run 15% infill and 3 solid top/bottom layers.

I'm running the same. My Slic3r config file is in the github repo for reference: [github.com]

That doesn't include my filament settings (2.90mm) and extruder details (0.5mm nozzle), but it's got most everything else.

|

Re: Tri-Polar Bot Concept -- Meet Wally November 26, 2013 10:14AM |

Registered: 11 years ago Posts: 48 |

Quote

cdsteinkuehler

I'm running the same. My Slic3r config file is in the github repo for reference: [github.com]

That doesn't include my filament settings (2.90mm) and extruder details (0.5mm nozzle), but it's got most everything else.

Main differences I see:

* I use rectilinear infill (you use honeycomb)

* My external perimieter speed is 20mm/sec (yours is set @ 60%)

* The rest appears to be similar, except speeds which we each have slightly different values.

Shane

|

Re: Tri-Polar Bot Concept -- Meet Wally November 26, 2013 10:18AM |

Registered: 10 years ago Posts: 62 |

|

Re: Tri-Polar Bot Concept -- Meet Wally November 26, 2013 10:23AM |

Registered: 11 years ago Posts: 48 |

Quote

cdsteinkuehler

Hmm...I like the honeycomb infill, particularly at low infill ratios (since all layers are supported), but I wonder if that's it.

I'll slice and print a couple arms with rectilinear and see what happens.

Just slice a single WALLY arm with Honeycomb and another with Rectilinear (both @ 15%) and compare print times and filament usage (filament usage information is at the very end of the gcode file).

Shane

Edited 1 time(s). Last edit at 11/26/2013 10:24AM by sgraber.

|

Re: Tri-Polar Bot Concept -- Meet Wally November 26, 2013 10:38AM |

Registered: 10 years ago Posts: 62 |

Quote

sgraber

Just slice a single WALLY arm with Honeycomb and another with Rectilinear (both @ 15%) and compare print times and filament usage (filament usage information is at the very end of the gcode file).

Yep...already there, but I'm printing a set with the rectalinear fill to see how it comes out vs the honeycomb.

Details for quantity 2 of the "xy wall arm" part with varied nozzle size and infill type. All other settings are identical:

0.5mm Nozzle with honeycomb infill:

; filament used = 12198.5mm (80.6cm3)

0.5mm Nozzle with rectalinear infill:

; filament used = 11558.6mm (76.3cm3)

0.4mm Nozzle with rectalinear infill:

; filament used = 10394.2mm (68.7cm3)

WOW! That's over 17% difference! That totally accounts for the difference in our part weights.

It looks like I need to get a smaller nozzle and use rectalinear infill! :-)

|

Re: Tri-Polar Bot Concept -- Meet Wally November 26, 2013 10:49AM |

Registered: 11 years ago Posts: 48 |

FWIW if you want to compare your filament usage and print times, take a look at a page I setup for myself while I was making plates for printing for Smooshed:

[dl.dropboxusercontent.com]

It's a bit convoluted, but it gives you an idea...

(Edit: I need to update the print times as since making this I have tweaked the printer to print faster, thereby saving ~5-7 hrs over a 45 hr print.)

Shane

Edited 1 time(s). Last edit at 11/26/2013 10:50AM by sgraber.

[dl.dropboxusercontent.com]

It's a bit convoluted, but it gives you an idea...

(Edit: I need to update the print times as since making this I have tweaked the printer to print faster, thereby saving ~5-7 hrs over a 45 hr print.)

Shane

Edited 1 time(s). Last edit at 11/26/2013 10:50AM by sgraber.

|

Re: Tri-Polar Bot Concept -- Meet Wally November 26, 2013 12:43PM |

Registered: 12 years ago Posts: 10 |

Is Wally usable at this point? I thought the kinematics were not finished?

If he is, how does he perform compared to a good cartesian bot?

- How is layer alignment (in the Z axis)? I find that layer alignment makes a massive difference in terms of perceived quality. Is the bed movement more consistent since it's just a pivot and no rods? Or does the math mean there is rounding error?

- How is the repeatability/slop/backlash/etc (x/y axis)? Do the arms flex/bounce/etc?

If he is, how does he perform compared to a good cartesian bot?

- How is layer alignment (in the Z axis)? I find that layer alignment makes a massive difference in terms of perceived quality. Is the bed movement more consistent since it's just a pivot and no rods? Or does the math mean there is rounding error?

- How is the repeatability/slop/backlash/etc (x/y axis)? Do the arms flex/bounce/etc?

|

Re: Tri-Polar Bot Concept -- Meet Wally November 26, 2013 03:37PM |

Registered: 10 years ago Posts: 62 |

Quote

sgraber

FWIW if you want to compare your filament usage and print times, take a look at a page I setup for myself while I was making plates for printing for Smooshed:

Great page!

As expected, the rectilinear fill parts weigh in at 94 grams a pair vs. 102 grams for the honeycomb infill version. So it looks like I'll be re-slicing when I print these again, and maybe switching to a smaller nozzle. IIRC, I've got a 3mm Ubis hot-end sitting around that should have an 0.4mm nozzle.

|

Re: Tri-Polar Bot Concept -- Meet Wally November 26, 2013 03:43PM |

Registered: 10 years ago Posts: 62 |

Quote

cratos

Is Wally usable at this point? I thought the kinematics were not finished?

If he is, how does he perform compared to a good cartesian bot?

- How is layer alignment (in the Z axis)? I find that layer alignment makes a massive difference in terms of perceived quality. Is the bed movement more consistent since it's just a pivot and no rods? Or does the math mean there is rounding error?

- How is the repeatability/slop/backlash/etc (x/y axis)? Do the arms flex/bounce/etc?

Usable? I suppose it depends on your definition. Nicholas has gotten Wally printing (I saw a video on the internet, so it has to be true!), but I'm pretty sure Wally isn't ready to be dropped into a 'bot farm and start cranking out parts.

AFAIK, the kinematics have been done for a while, with the exception of maybe some tweaks to get everything working properly. There's a python processor in the github repo, but I'm going to run LinuxCNC and use a version (I have not yet) written in C.

As for mechanical details, we'll have to build a few up and see. Nicholas has indicated the mechanism is robust, and I trust him to know what he's talking about. I've got the parts printed and waiting for my Beta kit to arrive (should be this week) and will know a lot more once I start putting in bearings and tightening bolts. Meanwhile, there are three or so others with parts printed or printing, so expect some real-world feedback soon!

|

Re: Tri-Polar Bot Concept -- Meet Wally November 26, 2013 09:01PM |

Registered: 12 years ago Posts: 10 |

Of course, I too have seen it printing. Though, I am anxious to get some of my questions answered about the bed movement being more/less consistent than rods, and how accurate Wally will be able to print. There has been a lot of talk lately about how using the wrong lead screws (imperial) will cause small layer misalignments because of rounding errors. I wonder if Wally will have those same types of problems trying to line up the y movement of the bed and the other kinematics that go along with the polar movement. I cant wait to see some hard core testing.

|

Re: Tri-Polar Bot Concept -- Meet Wally November 26, 2013 09:17PM |

Registered: 10 years ago Posts: 979 |

The imperial vs metric screw talk is completely unfounded unless you have naively setup a cartesian bot. Even then I would have to really try to make it an issue. Rounding error is so much smaller than microsteps.

The only thing that I have heard that is even remotely valid is that it is advantageous to pick layer heights that are multiples of a full step. You better believe you can do that with imperial or metric screws.

All that said. Wally uses software leveling so that makes it a none issue.

The only thing that I have heard that is even remotely valid is that it is advantageous to pick layer heights that are multiples of a full step. You better believe you can do that with imperial or metric screws.

All that said. Wally uses software leveling so that makes it a none issue.

|

Re: Tri-Polar Bot Concept -- Meet Wally November 26, 2013 11:01PM |

Registered: 12 years ago Posts: 10 |

Quote

nicholas.seward

The only thing that I have heard that is even remotely valid is that it is advantageous to pick layer heights that are multiples of a full step. You better believe you can do that with imperial or metric screws.

This was specifically what I'm talking about. I'm using 1/4"-16 lead screws. 1/16in = 1.5875mm per rotation. So 200 steps = 1.5876mm. So 0.0079375mm per full step. You cant really come to a nice layer height that is a multiple of (full) steps, right? When I say nice, I mean something that goes out to less than the thousands place. Stop me if I did something wrong... But at 16x microsteppng that's 0.00049609375mm per step. At that rate, for example, a layer height of 0.254 works (512 steps). Layer height 0.1905 also works (384 steps). The other problem though, is that steps/mm is about 2015.7480314960629921259842519685. So the numbers just don't work out. The hardware cant represent a number to that precision. Now, I don't really know how/if this translates into real world 'banding' as they call it. I've yet to do any testing.

The software leveling of Wally sounds interesting. Did you make a post about it somewhere that I missed? Do you just mean to compensate for the Y movement of the bed?

|

Re: Tri-Polar Bot Concept -- Meet Wally November 26, 2013 11:18PM |

Registered: 10 years ago Posts: 979 |

@cratos: Using metric screws to make the "prefered" layer heights "nice" is reasonable. However, the controllers can handle more floating point precision than you need. Again, for any none Cartesian bot this is not an issue. Additionally, any Cartesian bot that uses software leveling (which could be any Cartesian bot) will also not have any banding issues unless you have a perfectly level bed. (I still question the cause of the banding. I am quite sure that imperial screws are a red herring but that is a topic for a whole other thread.)

It would be pretty hard to physically level the bed on Wally so I just touch off the platform at 2 (soon to be 3) places. It is surprisingly good and very easy to do. (I like this much better than using springs and screws. Those lead to a shifting platform.)

It would be pretty hard to physically level the bed on Wally so I just touch off the platform at 2 (soon to be 3) places. It is surprisingly good and very easy to do. (I like this much better than using springs and screws. Those lead to a shifting platform.)

|

Re: Tri-Polar Bot Concept -- Meet Wally November 27, 2013 01:24PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Tri-Polar Bot Concept -- Meet Wally November 27, 2013 01:36PM |

Registered: 10 years ago Posts: 979 |

|

Re: Tri-Polar Bot Concept -- Meet Wally November 30, 2013 03:15PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Tri-Polar Bot Concept -- Meet Wally November 30, 2013 03:38PM |

Registered: 10 years ago Posts: 10 |

|

Re: Tri-Polar Bot Concept -- Meet Wally November 30, 2013 04:44PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Tri-Polar Bot Concept -- Meet Wally November 30, 2013 04:47PM |

Registered: 10 years ago Posts: 979 |

|

Re: Tri-Polar Bot Concept -- Meet Wally November 30, 2013 04:50PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Tri-Polar Bot Concept -- Meet Wally November 30, 2013 04:55PM |

Registered: 11 years ago Posts: 1,049 |

I am "on the cheap" with respect to CAD sketchup TurboCAD

Did all you guys get a deal on AUTOCAD or are just lottery winners?

Got a URL for free Inventor --- I will move from my Mac to my Win machine.

Would really like an assembly drawing in PDF, would make it easier, to put WALLY together.

Did all you guys get a deal on AUTOCAD or are just lottery winners?

Got a URL for free Inventor --- I will move from my Mac to my Win machine.

Would really like an assembly drawing in PDF, would make it easier, to put WALLY together.

Quote

smooshed

Since I don't have Inventor on my workstation at the moment, I've been using Inventor View (free, but windows only) to get a handle on how Wally goes together.

Quote

cozmicray

Is there an assembly drawing out there for Wally?

or

How to make one?

Left, right, top, front line drawing?

|

Re: Tri-Polar Bot Concept -- Meet Wally November 30, 2013 05:01PM |

Registered: 10 years ago Posts: 979 |

Sorry, only registered users may post in this forum.