Multi-resin printing with the Peachy Printer

Posted by dudesom

|

Re: Multi-resin printing with the Peachy Printer September 29, 2013 08:35PM |

Registered: 10 years ago Posts: 100 |

dudesom Wrote:

-------------------------------------------------------

> I hear ya about the uncertainty of it all. I hope

> that they will release the specs before production

> so that diy'ers like you and I can build one

> independently.

Sorry to burst your bubble, but I signed up for the KS kit. I am still waiting for my first 3D printer to arrive, either a RigidBot Big, or Wally Beta. My KS filament extruder kit will likely get here before any printers... LOL

I have done many scratch built tech projects over the last 50 years, but they were all original ideas. I like helping others succeed with their original ideas rather than reinvent their wheel on my own. I love the open source community efforts that everyone can contribute to, either with brainstorming, or implementation variations. I get my biggest kicks from coming up with ideas and posting them so that they are then public domain and can't be patented after that. Nothing burns me more than some corporation patenting some trivial and obvious solution that I could think up in a few minutes or hours...

-------------------------------------------------------

> I hear ya about the uncertainty of it all. I hope

> that they will release the specs before production

> so that diy'ers like you and I can build one

> independently.

Sorry to burst your bubble, but I signed up for the KS kit. I am still waiting for my first 3D printer to arrive, either a RigidBot Big, or Wally Beta. My KS filament extruder kit will likely get here before any printers... LOL

I have done many scratch built tech projects over the last 50 years, but they were all original ideas. I like helping others succeed with their original ideas rather than reinvent their wheel on my own. I love the open source community efforts that everyone can contribute to, either with brainstorming, or implementation variations. I get my biggest kicks from coming up with ideas and posting them so that they are then public domain and can't be patented after that. Nothing burns me more than some corporation patenting some trivial and obvious solution that I could think up in a few minutes or hours...

|

Re: Multi-resin printing with the Peachy Printer September 29, 2013 08:40PM |

Registered: 12 years ago Posts: 80 |

|

Re: Multi-resin printing with the Peachy Printer September 30, 2013 08:57PM |

Registered: 10 years ago Posts: 26 |

The fact that the resin is contains by the raft really helps solve the

problem of the linear beings gumming up. if we use nylon rods no corrosion ether

The surface of the water will keep the hole thing floating nice and flat in a very still room.

so we may not need to have liner bearings per say .. more like just thin holes that make point contact like this.

I

>I<

I

Having worked with the peachy alot ( i hate that im the only one right now)

I can tell you that there is a huge advantage to having the peachy stay close to the resin

its not resolution at all .. the peachy has alot of that to spare, its laser focus! , with the cheap

mirrors currently on the peachy its hard to get thin walls at a distance. having said that we will probably find a

quality mirror suppler

The pick posted by tyoung87 is Great

tyoung87, two days ago I did the same thing ... read thrue this form and compiled the ideas in the ways they might work best. Its been rendering for a while now.

... my animation is missing the floating peachy part tho! so ill do that one next..

enjoy!

[youtu.be]

problem of the linear beings gumming up. if we use nylon rods no corrosion ether

The surface of the water will keep the hole thing floating nice and flat in a very still room.

so we may not need to have liner bearings per say .. more like just thin holes that make point contact like this.

I

>I<

I

Having worked with the peachy alot ( i hate that im the only one right now)

I can tell you that there is a huge advantage to having the peachy stay close to the resin

its not resolution at all .. the peachy has alot of that to spare, its laser focus! , with the cheap

mirrors currently on the peachy its hard to get thin walls at a distance. having said that we will probably find a

quality mirror suppler

The pick posted by tyoung87 is Great

tyoung87, two days ago I did the same thing ... read thrue this form and compiled the ideas in the ways they might work best. Its been rendering for a while now.

... my animation is missing the floating peachy part tho! so ill do that one next..

enjoy!

[youtu.be]

|

Re: Multi-resin printing with the Peachy Printer September 30, 2013 11:00PM |

Registered: 12 years ago Posts: 80 |

I think I understand now where you are coming from Rylan. If you really think it would help, then help us out by giving us some dimensions to work with. What's the ideal peachy height above the print resin surface? What is the scan area like this?

Another avenue for a z-guide would be a sarrus linkage. Also, we could put the smooth rods on the outside of the build reservoir.

We could also use printable linear bearings instead of hardware, as Prusa used with his varient of the Mendel. There are options if we're willing to look.

When it's all said and done I think these 2 additions should be compatible, but perhaps not codependent, so that one can work without the other. While we wait for details to come along, I choose to design and model the multi-resin raft. Perhaps, when we have more details, we can further design a float for the peachy.

Another avenue for a z-guide would be a sarrus linkage. Also, we could put the smooth rods on the outside of the build reservoir.

We could also use printable linear bearings instead of hardware, as Prusa used with his varient of the Mendel. There are options if we're willing to look.

When it's all said and done I think these 2 additions should be compatible, but perhaps not codependent, so that one can work without the other. While we wait for details to come along, I choose to design and model the multi-resin raft. Perhaps, when we have more details, we can further design a float for the peachy.

|

Re: Multi-resin printing with the Peachy Printer October 01, 2013 12:14AM |

Registered: 10 years ago Posts: 100 |

I had my suspicions about the Laser focus being distance dependent. It is vey hard to get a perfectly parallel Laser beam from a diode. On top of that, the ones used for a Blue Ray DVD players need to have a very small spot size, so they converge the beam to a focus point at the surface of the disk.

The Peachy does not need such a small spot size though, but it would need some optics to get the beam small enough and reasonably well collimated.

If the Peachy is so close to the surface that it swings a 45 degree angle, the beam would be spread out into an oblong circle that was 1.4 times as long in one dimension pointing back towards the Laser. The energy would also be spread over a larger area. I would think making a straight vertical wall would have some interesting layering issues. In order to control this effect, the resin has to be a strong absorber of the Laser energy, so that it can not penetrate the surface much to harden it.

Camera quality glass first surface mirrors are usually pretty good. I used them in my View Magic 3-D Viewers years ago. I even had to make my own glass cutting bot to get the tolerances that I needed. However, the vacuum deposited aluminum reflective surface has to be protected by another clear glass deposited overcoat. That does mean that there can be two reflective surfaces very close to each other. If the thickness of the coating is just right, it could interfere with the Laser beam wavelength. As you move the beam to a larger angle to the surface, the interference characteristics could also change.

Without understanding the technical specs of the Laser and resin you are currently working with, it is hard to make specific mirror suggestions.

Floating the Peachy is a good idea for making life a lot simpler for the software and Laser hardware. I think the issues would be the mirrors creating a moving mass that would rock the Peachy raft or jiggle the water. A dual 4 bar linkage (like the Z axis of Wally), from the top of the container might stabilize it enough to not be a problem. Some of the half Sarrus mechanisms that are under considerations are also a possibility. Having only rotating members might reduce any stiction better than sliding members.

The Peachy does not need such a small spot size though, but it would need some optics to get the beam small enough and reasonably well collimated.

If the Peachy is so close to the surface that it swings a 45 degree angle, the beam would be spread out into an oblong circle that was 1.4 times as long in one dimension pointing back towards the Laser. The energy would also be spread over a larger area. I would think making a straight vertical wall would have some interesting layering issues. In order to control this effect, the resin has to be a strong absorber of the Laser energy, so that it can not penetrate the surface much to harden it.

Camera quality glass first surface mirrors are usually pretty good. I used them in my View Magic 3-D Viewers years ago. I even had to make my own glass cutting bot to get the tolerances that I needed. However, the vacuum deposited aluminum reflective surface has to be protected by another clear glass deposited overcoat. That does mean that there can be two reflective surfaces very close to each other. If the thickness of the coating is just right, it could interfere with the Laser beam wavelength. As you move the beam to a larger angle to the surface, the interference characteristics could also change.

Without understanding the technical specs of the Laser and resin you are currently working with, it is hard to make specific mirror suggestions.

Floating the Peachy is a good idea for making life a lot simpler for the software and Laser hardware. I think the issues would be the mirrors creating a moving mass that would rock the Peachy raft or jiggle the water. A dual 4 bar linkage (like the Z axis of Wally), from the top of the container might stabilize it enough to not be a problem. Some of the half Sarrus mechanisms that are under considerations are also a possibility. Having only rotating members might reduce any stiction better than sliding members.

|

Re: Multi-resin printing with the Peachy Printer October 01, 2013 05:06AM |

Registered: 10 years ago Posts: 7 |

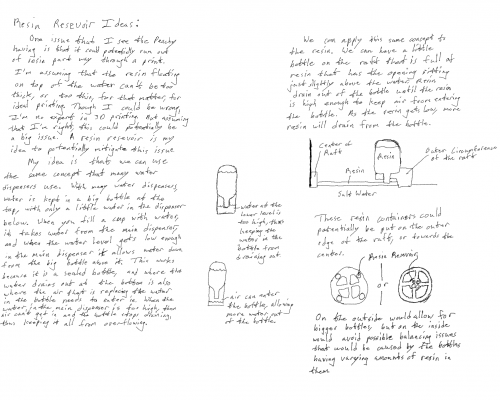

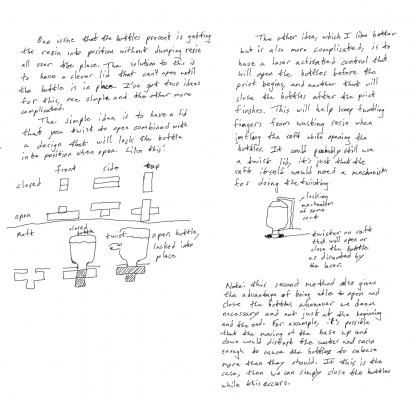

Alright, I've separated out the resin reservoir idea and added on to it. I wrote it up with notes and drawings, so hopefully you can understand my handwriting. So here it is:

|

Re: Multi-resin printing with the Peachy Printer October 01, 2013 05:15AM |

Registered: 10 years ago Posts: 7 |

Also, I do agree with rylangrayston, the whole thing shouldn't really move that much. The rods would probably be more of something that keeps it generally lined up with the base by preventing it from floating off or twisting. I imagine that nylon rods should work quite well. If they don't, another idea could be to make it so that instead of the base of the rods being the base of the container and the raft lining up with it through holes on the edges of the raft, it could rather have the base of the rods be situated on the raft and have the rods line up with holes in the ceiling of the container. This would keep the rods from being submerged in the salt water and still give the same benefit.

|

Re: Multi-resin printing with the Peachy Printer October 01, 2013 05:59AM |

Registered: 13 years ago Posts: 7,616 |

Quote

Alright, I've separated out the resin reservoir idea and added on to it.

Nice idea. During the printing process, the resin level doesn't lower, though, it rises.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Multi-resin printing with the Peachy Printer October 01, 2013 08:35AM |

Registered: 12 years ago Posts: 80 |

I really like the feed mechanism for the resin reservoirs. They might have to be really small to fit on the raft, though

Personally, I was just thinking of having really deep floating rafts that would be able to carry a lot of resin. The only thing this depends on is the large movement of either the water level rising or the print bed lowering (my current favorite solution).

Personally, I was just thinking of having really deep floating rafts that would be able to carry a lot of resin. The only thing this depends on is the large movement of either the water level rising or the print bed lowering (my current favorite solution).

|

Re: Multi-resin printing with the Peachy Printer October 01, 2013 12:22PM |

Registered: 10 years ago Posts: 7 |

You could always make it so that the bottles aren't actually on the raft, but rather are somewhere up above it with hoses running down to it. This would just bring in the problem of the hoses limiting the movement of the raft. This could be fixed by making it so that the bottles, which are now somewhere up above the raft, still twist and turn in the same way as the raft, thus keeping the hoses from wrapping around the the plastic rod that turns the wheel.

I guess a lot of this would depend on whether or not the thickness of the resin layer on the water affects the printing. Essentially, can the resin layer be too thick? Since the laser is shining from above, it would seem like thickness should have an affect, but again, I could be wrong on that.

Edited 1 time(s). Last edit at 10/01/2013 12:27PM by tyoung87.

I guess a lot of this would depend on whether or not the thickness of the resin layer on the water affects the printing. Essentially, can the resin layer be too thick? Since the laser is shining from above, it would seem like thickness should have an affect, but again, I could be wrong on that.

Edited 1 time(s). Last edit at 10/01/2013 12:27PM by tyoung87.

|

Re: Multi-resin printing with the Peachy Printer October 01, 2013 12:43PM |

Registered: 10 years ago Posts: 7 |

|

Re: Multi-resin printing with the Peachy Printer October 01, 2013 01:00PM |

Registered: 10 years ago Posts: 100 |

|

Re: Multi-resin printing with the Peachy Printer October 01, 2013 03:09PM |

Registered: 10 years ago Posts: 7 |

I agree that it should be kept as simple as possible. This idea is based on the assumption that the resin layer being too thick would cause issues. If this is not the case then this would needlessly over complicate things. But if it is the case then this could be a viable solution. With no way of testing, ideas must stem from assumptions. Just working with what I've got.

|

Re: Multi-resin printing with the Peachy Printer October 01, 2013 03:12PM |

Registered: 12 years ago Posts: 80 |

|

Re: Multi-resin printing with the Peachy Printer October 01, 2013 05:56PM |

Registered: 10 years ago Posts: 26 |

|

Re: Multi-resin printing with the Peachy Printer October 01, 2013 07:20PM |

Registered: 10 years ago Posts: 14 |

Here is my first attempt at a design for a floating peachy.

On a different subject, I'm actually leaning away from using mirrors at all. If a laser is hanging by a slight cantilevered connection, and two magnets are attached to the laser, then coils could use magnetic repulsion to push the laser into position, The natural hanging position would be less than my X,Y zero position. I would preload some voltage on the coils to get it to the actual 0,0 position.

Just a thought, the mass of the laser means it would have a lower top speed but it would be operating at full power. And the laser doesn't move fast in UV curing anyway. Two mirrors could drop the power anywhere from 20 to 50%. And this way, with no mirrors and more power (resin cures faster), you can scan faster than normal. I'll have to test this. Just thinking out loud.

On a different subject, I'm actually leaning away from using mirrors at all. If a laser is hanging by a slight cantilevered connection, and two magnets are attached to the laser, then coils could use magnetic repulsion to push the laser into position, The natural hanging position would be less than my X,Y zero position. I would preload some voltage on the coils to get it to the actual 0,0 position.

Just a thought, the mass of the laser means it would have a lower top speed but it would be operating at full power. And the laser doesn't move fast in UV curing anyway. Two mirrors could drop the power anywhere from 20 to 50%. And this way, with no mirrors and more power (resin cures faster), you can scan faster than normal. I'll have to test this. Just thinking out loud.

|

Re: Multi-resin printing with the Peachy Printer October 01, 2013 10:34PM |

Registered: 12 years ago Posts: 80 |

|

Re: Multi-resin printing with the Peachy Printer October 02, 2013 01:56AM |

Registered: 10 years ago Posts: 7 |

|

Re: Multi-resin printing with the Peachy Printer October 04, 2013 05:23PM |

Registered: 11 years ago Posts: 15 |

|

Re: Multi-resin printing with the Peachy Printer October 04, 2013 10:15PM |

Registered: 10 years ago Posts: 14 |

|

Re: Multi-resin printing with the Peachy Printer November 10, 2013 08:07PM |

Registered: 10 years ago Posts: 3 |

Originally my goal was to keep everything fixed besides the rotational movement of the multi-resin container/raft and the 3D-model to be printed fixture. I wanted to use dudesome's idea to move the fixture to the bottom by putting it in a container within the lower resin/water tank in the saltwater so that by letting water drop out of this container (where the fixture floats upon) the fixture would loose height and the host would count the falling drops (remark: there no longer is a upper container) by which the fixture holding the 3D model is sunk layer by layer. Unfortunately the problem is that saltwater and resin will fall into the middlecontainer too. >=> We ultimately need a permeable membrane that only lets the 3D-model pass! Impossible!?

So the fixture to the lower mobility design failed. Advantages of such a system are that the mirrors are fixed and at constant distance as well as that multi-resin printing comes for free in such a design (as we are capable of moving the fixture for printing anyway, so for avoiding the wall of the rotating multi-resin raft this obstacle/container-wall avoiding movement were already available).

Then I thought of flipping the design, such that we print bottom up. Here the laser beam has to pass through glass or any other medium that is used for preventing the resin from falling to ground onto the laser - which is positioned at the bottom in this approach.

A problem here is to fix the model to the fixture that itself is fixed at the 3D-printer sky-plate.

Here is a short animation that shows the benefits, one being that the mirrors are at a fixed distance, giving maximum workspace/printing volume. The center of mass would be quite low too. THe z-axis movement has to be controlled via weights that float in water in a not shown outer shell or using a pressure column or a stepper motor.

[youtu.be]

Result: The design of the initial Peachy Printer is difficult to top - it solves several problems in a smart way. The different distance of the mirrors to the print piece is not too much a problem - this might complicat the software but saves extra hardware complification.

What about using the approach of Spelljammer where we replace the mirrors with an x-y- belt driven positioning system. The laser should have very little mass, the laser light has almost no inertia, thus backwards repulsion will be neglectable. Or better, why not keep the simple DC audio card method of Rylans team? This is really a great system! A dc audio won't be so much more expensive - will it?

So the fixture to the lower mobility design failed. Advantages of such a system are that the mirrors are fixed and at constant distance as well as that multi-resin printing comes for free in such a design (as we are capable of moving the fixture for printing anyway, so for avoiding the wall of the rotating multi-resin raft this obstacle/container-wall avoiding movement were already available).

Then I thought of flipping the design, such that we print bottom up. Here the laser beam has to pass through glass or any other medium that is used for preventing the resin from falling to ground onto the laser - which is positioned at the bottom in this approach.

A problem here is to fix the model to the fixture that itself is fixed at the 3D-printer sky-plate.

Here is a short animation that shows the benefits, one being that the mirrors are at a fixed distance, giving maximum workspace/printing volume. The center of mass would be quite low too. THe z-axis movement has to be controlled via weights that float in water in a not shown outer shell or using a pressure column or a stepper motor.

[youtu.be]

Result: The design of the initial Peachy Printer is difficult to top - it solves several problems in a smart way. The different distance of the mirrors to the print piece is not too much a problem - this might complicat the software but saves extra hardware complification.

What about using the approach of Spelljammer where we replace the mirrors with an x-y- belt driven positioning system. The laser should have very little mass, the laser light has almost no inertia, thus backwards repulsion will be neglectable. Or better, why not keep the simple DC audio card method of Rylans team? This is really a great system! A dc audio won't be so much more expensive - will it?

|

Re: Multi-resin printing with the Peachy Printer November 13, 2013 02:49PM |

Registered: 11 years ago Posts: 15 |

@Radagast:

Would be similar to the Muve 1, but with the gantry on top?

I think you can see that he has got a ringing issue in some of the photos.

[www.muve3d.net]

Edited 1 time(s). Last edit at 11/13/2013 02:50PM by Nahoj.

Would be similar to the Muve 1, but with the gantry on top?

I think you can see that he has got a ringing issue in some of the photos.

[www.muve3d.net]

Edited 1 time(s). Last edit at 11/13/2013 02:50PM by Nahoj.

|

Re: Multi-resin printing with the Peachy Printer December 28, 2013 04:17PM |

Registered: 10 years ago Posts: 1 |

Maybe U can lift the resin easily with two balloons connected. One ballon is inside the salt water, the other ballon is outside the tank. When U compress the outside ballon then the inside ballon increase, so the water level incresase. If U stop compressing the outside ballon then the original level will be restored.

|

Re: Multi-resin printing with the Peachy Printer December 31, 2013 06:42PM |

Registered: 10 years ago Posts: 5 |

the balloon on the outside (that you sqeeze) would steal water from the print side as your print side gets full (causing an error in the z axis).Quote

hygy

Maybe U can lift the resin easily with two balloons connected. One ballon is inside the salt water, the other ballon is outside the tank. When U compress the outside ballon then the inside ballon increase, so the water level incresase. If U stop compressing the outside ballon then the original level will be restored.

Instead, maybe use a syringe. start print with syringe full of water, push water in to raise the level, pull back out before laser starts up again.

Edited 1 time(s). Last edit at 12/31/2013 06:42PM by ert485.

Sorry, only registered users may post in this forum.

As for this project, I do appreciate your help, even if you do not build one.

As for this project, I do appreciate your help, even if you do not build one.