New polar concept/design

Posted by Gomez.Marcos

|

Re: New polar concept/design December 21, 2013 12:58AM |

Registered: 10 years ago Posts: 979 |

Quote

Gomez.Marcos

...

it was difficult to understand the movement, i think that is only needed pulley friction in the effector, right?

...

how much print volume give your GUS arms??

...

Yep, only the effector needs friction.

GUS arms can do whatever you want. The ones I use can actuate a distance from about 25mm to 325mm. You can design them however you want.

I didn't check your math but I would suggest 25 microns as a good target. That agrees with my earlier statement that you need a mechanical advantage of 5-10.

|

Re: New polar concept/design December 21, 2013 01:29AM |

Registered: 10 years ago Posts: 226 |

I actually have 40-50 microns WITHOUT MECHANICAL ADVANTAGE

it would reach 8-10 microns with just 5 MA

EDIT:

I made graphics...I would need 10MA for a 35 to 10 microns

Edited 1 time(s). Last edit at 12/21/2013 04:23AM by Gomez.Marcos.

it would reach 8-10 microns with just 5 MA

EDIT:

I made graphics...I would need 10MA for a 35 to 10 microns

Edited 1 time(s). Last edit at 12/21/2013 04:23AM by Gomez.Marcos.

|

Re: New polar concept/design December 21, 2013 06:23AM |

Registered: 10 years ago Posts: 1,381 |

@Gomez.Marcos

I see why you are confused, I didn't construct a complete assembly using 2 arms.

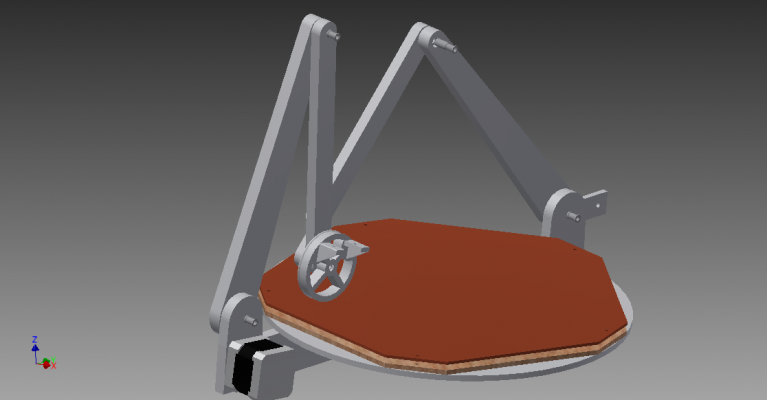

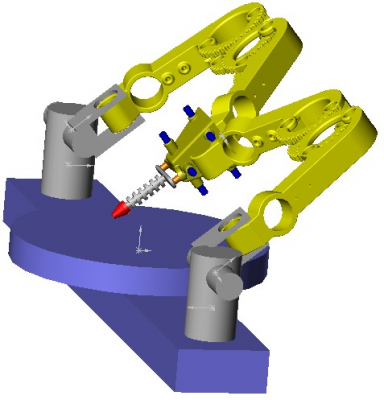

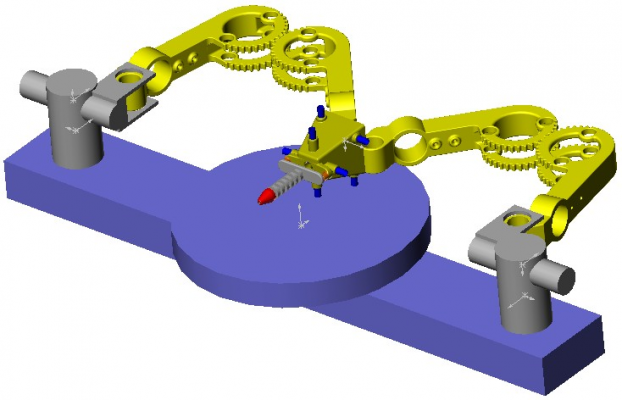

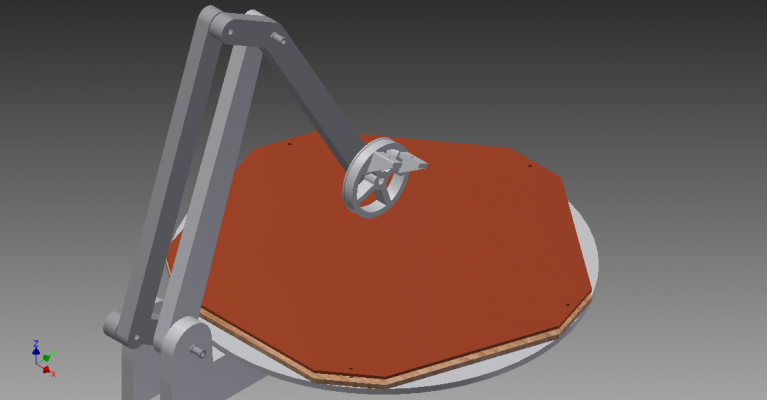

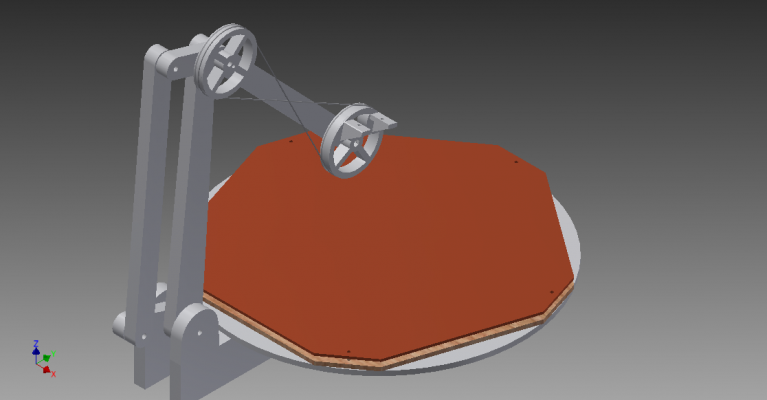

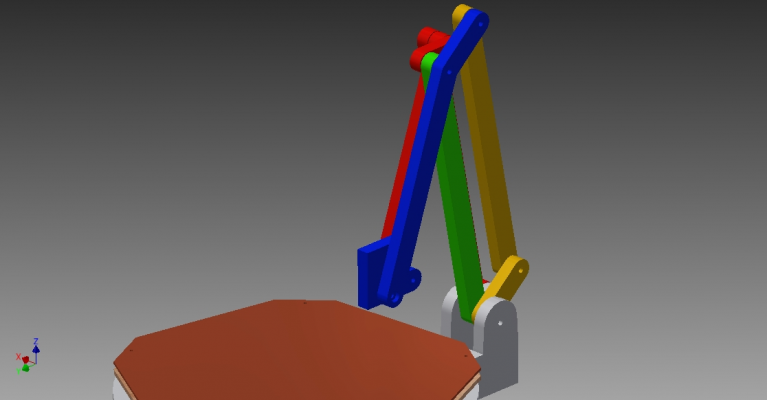

Here is a picture with two arms.

The idea is you mount a scanner on the end effector,

rotate the table, and swing the arms down parallel to the table.

This allows you to scan 360 degree, and you can scan the top of your object,

which no other 3d printer/scanner combination can do, that I'm aware of.

And we can use this configuration to do minor surgery!!!!

Lets say I have a minor tumor on my cheek, and I'm in a 3rd world country with no surgeon to help me.

1. Place markers on my face, it can be a piece of tape.

This is so the computer an find an orientation.

2. You scan my face.

3. You then program a sequence for the robot to exercise the tumor.

Or a surgeon from another country performs the surgery remotely, and/or with preprogrammed automated sequences.

4. You would have a quick change tool holder/turret with medical devices.

5. When the surgery is done the patient gets a smiley face sticker to take home

Edited 4 time(s). Last edit at 12/21/2013 07:01AM by A2.

I see why you are confused, I didn't construct a complete assembly using 2 arms.

Here is a picture with two arms.

The idea is you mount a scanner on the end effector,

rotate the table, and swing the arms down parallel to the table.

This allows you to scan 360 degree, and you can scan the top of your object,

which no other 3d printer/scanner combination can do, that I'm aware of.

And we can use this configuration to do minor surgery!!!!

Lets say I have a minor tumor on my cheek, and I'm in a 3rd world country with no surgeon to help me.

1. Place markers on my face, it can be a piece of tape.

This is so the computer an find an orientation.

2. You scan my face.

3. You then program a sequence for the robot to exercise the tumor.

Or a surgeon from another country performs the surgery remotely, and/or with preprogrammed automated sequences.

4. You would have a quick change tool holder/turret with medical devices.

5. When the surgery is done the patient gets a smiley face sticker to take home

Edited 4 time(s). Last edit at 12/21/2013 07:01AM by A2.

|

Re: New polar concept/design December 21, 2013 10:23AM |

Registered: 10 years ago Posts: 226 |

|

Re: New polar concept/design December 23, 2013 12:21AM |

Registered: 10 years ago Posts: 226 |

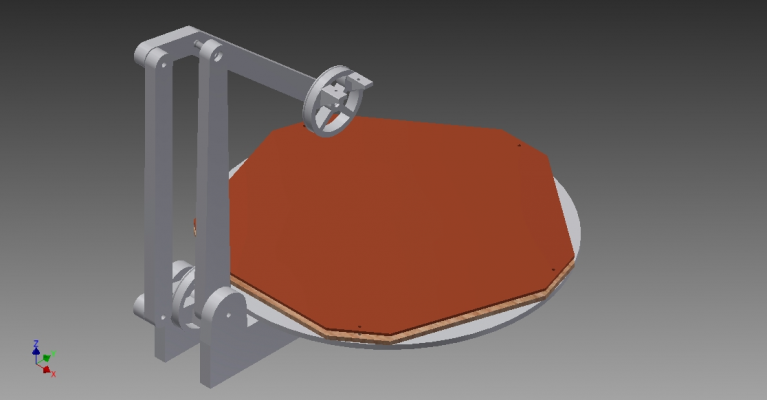

I get to that:

I like it, but ekaggrat´s arm looks great and with less parts

I'm going to implement it on the printer

EDIT:

is going to need a motor for effector's level correction :/

Edited 1 time(s). Last edit at 12/23/2013 04:03AM by Gomez.Marcos.

I like it, but ekaggrat´s arm looks great and with less parts

I'm going to implement it on the printer

EDIT:

is going to need a motor for effector's level correction :/

Edited 1 time(s). Last edit at 12/23/2013 04:03AM by Gomez.Marcos.

|

Re: New polar concept/design December 23, 2013 09:53AM |

Registered: 11 years ago Posts: 364 |

|

Re: New polar concept/design December 23, 2013 01:47PM |

Registered: 10 years ago Posts: 226 |

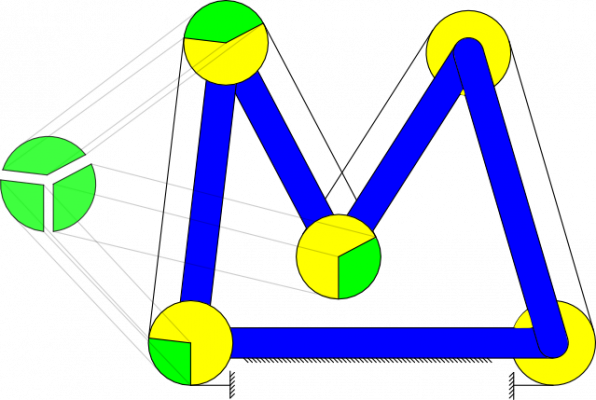

after thinking lots, i realize that the effector's angle change is exactly like the arm's angle, so if I attach the string to the angle arm axis is going to auto correct it... please someone correct me if im wrong

SOLVED?:

OR

I'm not thinking clear, I'm going to give a rest

Edited 3 time(s). Last edit at 12/23/2013 03:05PM by Gomez.Marcos.

SOLVED?:

OR

I'm not thinking clear, I'm going to give a rest

Edited 3 time(s). Last edit at 12/23/2013 03:05PM by Gomez.Marcos.

|

Re: New polar concept/design December 23, 2013 03:03PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: New polar concept/design December 23, 2013 03:09PM |

Registered: 10 years ago Posts: 226 |

|

Re: New polar concept/design December 23, 2013 07:25PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: New polar concept/design December 23, 2013 10:06PM |

Registered: 10 years ago Posts: 226 |

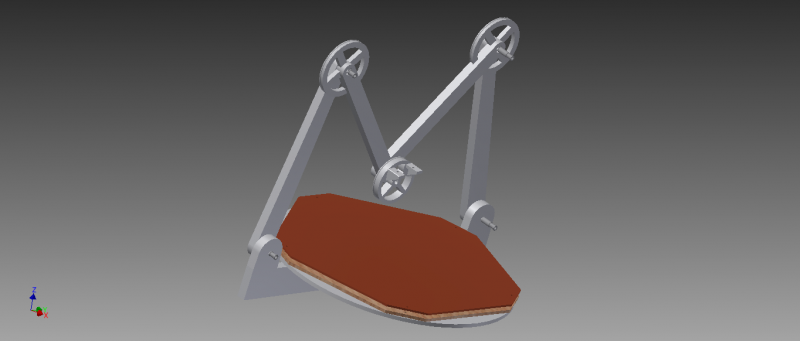

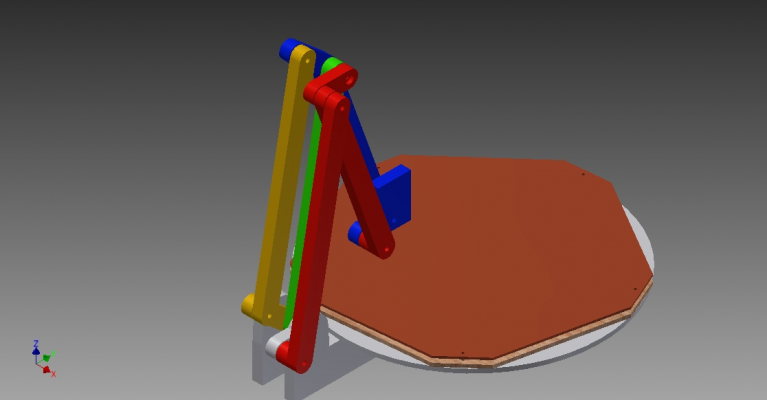

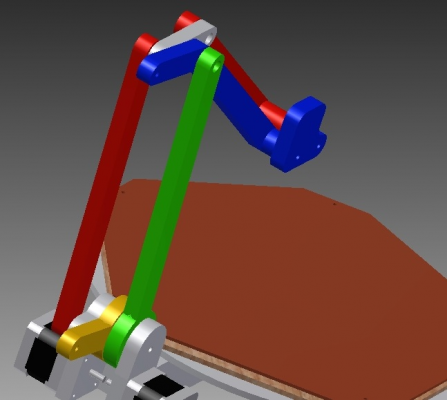

More of the same was the solution

now with colors to understand the mess

now with colors to understand the mess

|

Re: New polar concept/design December 26, 2013 04:41PM |

Registered: 10 years ago Posts: 226 |

|

Re: New polar concept/design December 26, 2013 07:05PM |

Registered: 10 years ago Posts: 979 |

@Gomez.Marcos: Make sure you design so that the torque on the driven gears will remain in the same direction. (The center of gravity needs to stay on one side of the grounded pivots.) This is needed so that you don't get any backlash between the worm and its gear. It seems that the design that you have will agree with this requirement.

|

Re: New polar concept/design December 26, 2013 07:42PM |

Registered: 10 years ago Posts: 226 |

|

Re: New polar concept/design December 26, 2013 07:51PM |

Registered: 10 years ago Posts: 979 |

@Gomez.Marcos: Just change the design so that you are never >90 degrees on that green arm. It is just a slight change of the design and shouldn't greatly change your working envelope.

I don't necessarily recommend this link but your design will live and die by the quality of your worm gears so I would buy some professionally milled ones. If you have a better source I am very curious. Good luck.

I will see if I can do some calculations but I would go for at least 20 or 30 teeth on your worm gear.

I don't necessarily recommend this link but your design will live and die by the quality of your worm gears so I would buy some professionally milled ones. If you have a better source I am very curious. Good luck.

I will see if I can do some calculations but I would go for at least 20 or 30 teeth on your worm gear.

|

Re: New polar concept/design December 26, 2013 11:42PM |

Registered: 10 years ago Posts: 226 |

|

Re: New polar concept/design December 26, 2013 11:53PM |

Registered: 10 years ago Posts: 979 |

@Gomez.Marcos: No argument here. However, where is everything going to go. Pulley's big enough will probably start to impinge on your build volume. (Just an idea but you could sink the pulleys under the table and curve the first arms to go around the platform.)

Note: string is cheap but a belt will require less calibration. (For the record, I would probably go with string.)

Super crazy idea: you could counterbalance each arms so that the arms would be in equilibrium everywhere. This will add inertia to the system but will allow your pulleys to be smaller than they had to be without the counterbalancing. With the counterbalances you only need the mechanical advantage to get the resolution you need. You won't have to use the MA for raw movement.

Note: string is cheap but a belt will require less calibration. (For the record, I would probably go with string.)

Super crazy idea: you could counterbalance each arms so that the arms would be in equilibrium everywhere. This will add inertia to the system but will allow your pulleys to be smaller than they had to be without the counterbalancing. With the counterbalances you only need the mechanical advantage to get the resolution you need. You won't have to use the MA for raw movement.

|

Re: New polar concept/design December 27, 2013 01:08AM |

Registered: 10 years ago Posts: 226 |

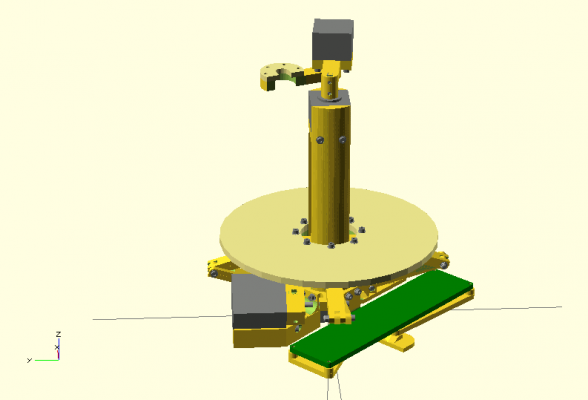

I have managed to get everything right there in a compact zone

EDIT: your crazy ideas are really difficult to see for me

Edited 1 time(s). Last edit at 12/27/2013 01:11AM by Gomez.Marcos.

|

Re: New polar concept/design December 27, 2013 01:24AM |

Registered: 10 years ago Posts: 979 |

@Gomez.Marcos: Wally which needs less mechanical advantage than you need has a 12.5mm drive pulley and 100mm large pulleys. You need to do better than that and I don't think you can make the drive pulley that much smaller unless you have it machined. 12.5mm is on the edge of acceptability when it comes to printed pulleys.

I think if I was doing this basic design that I would probably use a compound pulley design. I think two 1:5 ratios for a grand total of a 1:25 mechanical advantage would be about what I would go for.

EDIT: I would go with the worm drive if you want to drive from the shoulders. All the tricks to get string to work here would be a turn off to most.

However, I would personally go with the two sided approach and drive the elbows. (This is mainly because of all the tricks I see that would have to be done to get the one sided approach workable would take away from the elegance in my opinion. This is also because it is 4DOF ready and there elbow pulleys can be huge and not hurt anything.)

Edited 1 time(s). Last edit at 12/27/2013 01:26AM by nicholas.seward.

I think if I was doing this basic design that I would probably use a compound pulley design. I think two 1:5 ratios for a grand total of a 1:25 mechanical advantage would be about what I would go for.

EDIT: I would go with the worm drive if you want to drive from the shoulders. All the tricks to get string to work here would be a turn off to most.

However, I would personally go with the two sided approach and drive the elbows. (This is mainly because of all the tricks I see that would have to be done to get the one sided approach workable would take away from the elegance in my opinion. This is also because it is 4DOF ready and there elbow pulleys can be huge and not hurt anything.)

Edited 1 time(s). Last edit at 12/27/2013 01:26AM by nicholas.seward.

|

Re: New polar concept/design December 27, 2013 02:17AM |

Registered: 10 years ago Posts: 226 |

I have left the two sided because the string in tension to make it a 4DOF was not going to work, because the length of the string around the effector constantly changes

the one sided have no big precision differences, and have bigger print volume

about compound pulley is not bad idea... it would be on an adjustable bolt that tense it

EDIT:

recalculating... one sided have lots of precision losses, you have reason one more time

Edited 1 time(s). Last edit at 12/27/2013 03:05AM by Gomez.Marcos.

the one sided have no big precision differences, and have bigger print volume

about compound pulley is not bad idea... it would be on an adjustable bolt that tense it

EDIT:

recalculating... one sided have lots of precision losses, you have reason one more time

Edited 1 time(s). Last edit at 12/27/2013 03:05AM by Gomez.Marcos.

|

Re: New polar concept/design December 31, 2013 08:46PM |

Registered: 10 years ago Posts: 979 |

|

Re: New polar concept/design January 01, 2014 06:46PM |

Registered: 10 years ago Posts: 226 |

|

Re: New polar concept/design January 01, 2014 07:02PM |

Registered: 10 years ago Posts: 979 |

|

Re: New polar concept/design January 01, 2014 08:58PM |

Registered: 10 years ago Posts: 226 |

|

Re: New polar concept/design January 02, 2014 01:53AM |

Registered: 10 years ago Posts: 979 |

Does this clear it up. You can see that no matter what position the arms are in that the length of string from the tie off to the bottom of the effector pulley is constant.

|

Re: New polar concept/design January 02, 2014 05:41PM |

Registered: 10 years ago Posts: 979 |

|

Re: New polar concept/design January 02, 2014 06:58PM |

Registered: 10 years ago Posts: 226 |

great designs, but delta's relation between print height and printer height is really big

I was seeing new posibilities because of precision problems and found this

youTube

that reminded me the reprap lewis

I'm going to try something similar with posibility of 3D scanner

Sorry, only registered users may post in this forum.