SAPE Single Arm Printer Experiment

Posted by Solidus Labs

|

SAPE Single Arm Printer Experiment June 02, 2014 12:49PM |

Registered: 10 years ago Posts: 56 |

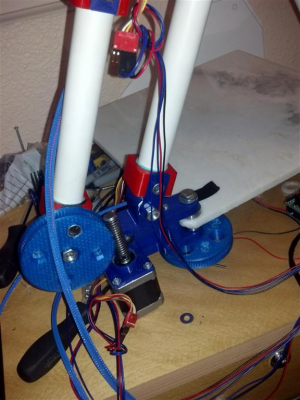

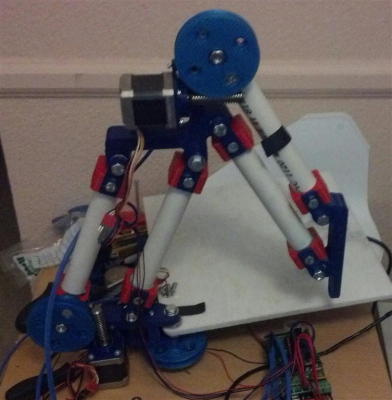

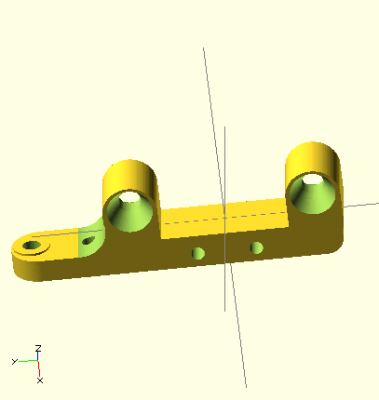

Getting started on a new single arm project. Firmware is finished and I have an early prototype built. I am using my worm wheel/gear design from my gdr project. I focused on an extremely low vitamin design. Only 2 bearings for movement, bolts, PVC and printed parts.

Short homing test video:

http://youtu.be/ICIe5_Wij5g

Short homing test video:

http://youtu.be/ICIe5_Wij5g

|

Re: SAPE Single Arm Printer Experiment June 02, 2014 04:15PM |

Registered: 10 years ago Posts: 56 |

A few shots:

Bearing:

Bearing:

|

Re: SAPE Single Arm Printer Experiment June 02, 2014 04:24PM |

Registered: 11 years ago Posts: 979 |

Love it. I imagine everything is pretty rigid in the plane of the arm. Quick shoulder accelerations are probably out. You can beef up the arm, go slow, or rotate the table instead.

Edited 1 time(s). Last edit at 06/02/2014 04:34PM by nicholas.seward.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

Edited 1 time(s). Last edit at 06/02/2014 04:34PM by nicholas.seward.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

|

Re: SAPE Single Arm Printer Experiment June 02, 2014 05:23PM |

Registered: 10 years ago Posts: 100 |

|

Re: SAPE Single Arm Printer Experiment June 02, 2014 09:10PM |

Registered: 11 years ago Posts: 364 |

|

Re: SAPE Single Arm Printer Experiment June 02, 2014 09:18PM |

Registered: 10 years ago Posts: 1,381 |

Very cool!

Am I the only one that see's it evolving into a backhoe Remotely, and pragmatically dig holes in the yard, scale it up and dig a pond, or a basement, switch the backhoe out for the 3d cement extruder to finish the job! Mount a chair to it for a flight simulator

Remotely, and pragmatically dig holes in the yard, scale it up and dig a pond, or a basement, switch the backhoe out for the 3d cement extruder to finish the job! Mount a chair to it for a flight simulator  The worm gear will be inherently safe if you loose power too.

The worm gear will be inherently safe if you loose power too.

Am I the only one that see's it evolving into a backhoe

Remotely, and pragmatically dig holes in the yard, scale it up and dig a pond, or a basement, switch the backhoe out for the 3d cement extruder to finish the job! Mount a chair to it for a flight simulator

Remotely, and pragmatically dig holes in the yard, scale it up and dig a pond, or a basement, switch the backhoe out for the 3d cement extruder to finish the job! Mount a chair to it for a flight simulator  The worm gear will be inherently safe if you loose power too.

The worm gear will be inherently safe if you loose power too.

|

Re: SAPE Single Arm Printer Experiment June 02, 2014 09:54PM |

Registered: 10 years ago Posts: 100 |

Too Funny!

I just finished rebuilding my DIY tractor backhoe attachment last week. I never though about putting a seat on the bucket and running the joysticks out to the seat and taking it for a joy ride.

I just finished rebuilding my DIY tractor backhoe attachment last week. I never though about putting a seat on the bucket and running the joysticks out to the seat and taking it for a joy ride.

Quote

A2

Very cool!

Am I the only one that see's it evolving into a backhoeRemotely, and pragmatically dig holes in the yard, scale it up and dig a pond, or a basement, switch the backhoe out for the 3d cement extruder to finish the job! Mount a chair to it for a flight simulator

The worm gear will be inherently safe if you loose power too.

|

Re: SAPE Single Arm Printer Experiment June 03, 2014 12:58AM |

Registered: 10 years ago Posts: 56 |

LOL Epcot did that with a roller coaster simulator and really big kuka arms.

kuka

kuka

Quote

see3d

Too Funny!

I just finished rebuilding my DIY tractor backhoe attachment last week. I never though about putting a seat on the bucket and running the joysticks out to the seat and taking it for a joy ride.

Quote

A2

Very cool!

Am I the only one that see's it evolving into a backhoeRemotely, and pragmatically dig holes in the yard, scale it up and dig a pond, or a basement, switch the backhoe out for the 3d cement extruder to finish the job! Mount a chair to it for a flight simulator

The worm gear will be inherently safe if you loose power too.

|

Re: SAPE Single Arm Printer Experiment June 03, 2014 02:16AM |

Registered: 10 years ago Posts: 1,381 |

This is a great "thing" that you have created.

Some one clever could modify it to feed a person who is unable to feed them selves There is software that in real time can give feed back of topology of a dynamic environment (the hungry human) to avoid collision. Or place reflective markers near the mouth to identify the target.

There is software that in real time can give feed back of topology of a dynamic environment (the hungry human) to avoid collision. Or place reflective markers near the mouth to identify the target.

Scalable KinectFusion

[www.youtube.com]

LazeeEye

[www.kickstarter.com]

Edited 1 time(s). Last edit at 06/03/2014 02:21AM by A2.

Some one clever could modify it to feed a person who is unable to feed them selves

There is software that in real time can give feed back of topology of a dynamic environment (the hungry human) to avoid collision. Or place reflective markers near the mouth to identify the target.

There is software that in real time can give feed back of topology of a dynamic environment (the hungry human) to avoid collision. Or place reflective markers near the mouth to identify the target.Scalable KinectFusion

[www.youtube.com]

LazeeEye

[www.kickstarter.com]

Edited 1 time(s). Last edit at 06/03/2014 02:21AM by A2.

|

Re: SAPE Single Arm Printer Experiment June 05, 2014 01:37PM |

Registered: 9 years ago Posts: 135 |

|

Re: SAPE Single Arm Printer Experiment June 05, 2014 09:55PM |

Registered: 9 years ago Posts: 210 |

|

Re: SAPE Single Arm Printer Experiment June 07, 2014 03:09PM |

Registered: 10 years ago Posts: 56 |

The inverse kinematics coordinate translation is all done in the controller (ramps 1.4) . After writing the software for my GDR, the SAPE was not much more difficult. The Simpson style printer (grounded delta) is inherently more stable because of its geometry but it has the same singularities and it relies heavily on symmetry. Symmetry is a cold hearted bitch that will rob you of 6 months of your life leaving only emptiness in your soul.Quote

Feign

This does look awesome, though I'm guessing the programming to keep it level and on a g-code designated path will be a bit painful.

Also, while it looks awesome and easy to make, your Simpson-style printer looks much more stable.

|

Re: SAPE Single Arm Printer Experiment June 07, 2014 03:11PM |

Registered: 10 years ago Posts: 56 |

|

Re: SAPE Single Arm Printer Experiment June 07, 2014 06:15PM |

Registered: 9 years ago Posts: 210 |

Really awesome, thanks for the video and please keep us updated!

A robot arm that can print would offer many interesting possibilities, you could have it rotate 360 degree to move to a new print surface after finishing an object, or have it moving around. Then if you could scale up the design, you could have it print walls or houses!

A robot arm that can print would offer many interesting possibilities, you could have it rotate 360 degree to move to a new print surface after finishing an object, or have it moving around. Then if you could scale up the design, you could have it print walls or houses!

|

Re: SAPE Single Arm Printer Experiment June 07, 2014 07:59PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: SAPE Single Arm Printer Experiment May 17, 2015 06:12PM |

Registered: 9 years ago Posts: 14 |

|

Re: SAPE Single Arm Printer Experiment May 17, 2015 08:15PM |

Registered: 9 years ago Posts: 210 |

Not what you asked but I just had to share it  I just bought the small (tiny) kit for a servo driven robot arm, the meArm. For 33£ / 50€ I simply could not resist! The plans are on thingieverse and there are also bigger 3D printed versions of it (see comments). The design of the arm seems to be rather smart, the servos / steppers are on the base not on the arm etc.

I just bought the small (tiny) kit for a servo driven robot arm, the meArm. For 33£ / 50€ I simply could not resist! The plans are on thingieverse and there are also bigger 3D printed versions of it (see comments). The design of the arm seems to be rather smart, the servos / steppers are on the base not on the arm etc.

Not clue if a reprap firmware for these types of kinematic arms exist, but a GCode converter most likely. Maybe the links to the software for the meArm helps you find one. Not even sure how you call a robot arm like this? Is that still a parallel manipulator?

I just bought the small (tiny) kit for a servo driven robot arm, the meArm. For 33£ / 50€ I simply could not resist! The plans are on thingieverse and there are also bigger 3D printed versions of it (see comments). The design of the arm seems to be rather smart, the servos / steppers are on the base not on the arm etc.

I just bought the small (tiny) kit for a servo driven robot arm, the meArm. For 33£ / 50€ I simply could not resist! The plans are on thingieverse and there are also bigger 3D printed versions of it (see comments). The design of the arm seems to be rather smart, the servos / steppers are on the base not on the arm etc.Not clue if a reprap firmware for these types of kinematic arms exist, but a GCode converter most likely. Maybe the links to the software for the meArm helps you find one. Not even sure how you call a robot arm like this? Is that still a parallel manipulator?

|

Re: SAPE Single Arm Printer Experiment May 27, 2015 06:05PM |

Registered: 9 years ago Posts: 1,035 |

|

Re: SAPE Single Arm Printer Experiment June 01, 2015 05:31AM |

Registered: 9 years ago Posts: 14 |

Quote

Dejay

Not what you asked but I just had to share itI just bought the small (tiny) kit for a servo driven robot arm, the meArm. For 33£ / 50€ I simply could not resist! The plans are on thingieverse and there are also bigger 3D printed versions of it (see comments). The design of the arm seems to be rather smart, the servos / steppers are on the base not on the arm etc.

Not clue if a reprap firmware for these types of kinematic arms exist, but a GCode converter most likely. Maybe the links to the software for the meArm helps you find one. Not even sure how you call a robot arm like this? Is that still a parallel manipulator?

Thanks for the reply, I've seen that robot before. I'm building another one I found on thingiverse. I'm just looking for the firmware, or a way to convert the gcode. I'll keep looking!

|

Re: SAPE Single Arm Printer Experiment June 01, 2015 04:32PM |

Registered: 9 years ago Posts: 210 |

Well if you can program a bit you could try adapt something like marlin. Or just use the gcode interpreter in marlin.

The inverse kinematic code for the meArm is here: [github.com]

Afaik controlling servos is simpler than steppers, so instead of generating step signals until you reach the destination over time, you just set the position you want your servo to be at:

If you've never programmed before it might seem like a daunting task but it's not black magic. You can start simple and add more functionality as you learn. Reading code written by others is always a bit of work through. But rewarding Writing code is much more fun of course! Hope this helps.

Writing code is much more fun of course! Hope this helps.

Afaik the problem with robot arms is jerk and backlash though. Limiting acceleration of the servos (starting and ending a move slow) could help though. And servos aren't precise enough (not enough steps / mm) and not repeatable enough.

I have this crazy idea that you could improve the precision though by using computer vision to track the precise location of the effector and using some kind of algorithm to compensate for backlash and jerk and arm droop. Maybe you could use an IMU for this as well. After all our human arms are highly imprecisely manufactured as well but we "learn" to use them precisely. If you could teach a robot that then you could safe a lot on "precision manufacturing". This would also be an important step for reprap "reproducability" by creating less precise but 3D printable linkages. That's just crazy talk though

Edited 1 time(s). Last edit at 06/01/2015 04:35PM by Dejay.

The inverse kinematic code for the meArm is here: [github.com]

int b = sqrt ((x * x) + (z * z)); // b = distance from the origin to the start of the gripper //Serial.write(b); float q1 = atan2( x, z ); // q1 = angle between the horizontal and the line b //Serial.print(q1,4); float q2 = acos((bic_sq - for_sq + (b * b))/(2 * bicep * b)); // q1 = angle between line b and the bicep //Serial.print(q2,4); float abi = q1 + q2; // abi = angle between horizontal and the bicep //Serial.print(abi,4); float afo = acos((bic_sq + for_sq - (b * b))/(2 * bicep * forearm)); // afo = angle between bicep and forearm

Afaik controlling servos is simpler than steppers, so instead of generating step signals until you reach the destination over time, you just set the position you want your servo to be at:

myservo0.write(abi); // sets the servo position according to the scaled value myservo3.write(afo); // sets the servo position according to the scaled value

If you've never programmed before it might seem like a daunting task but it's not black magic. You can start simple and add more functionality as you learn. Reading code written by others is always a bit of work through. But rewarding

Writing code is much more fun of course! Hope this helps.

Writing code is much more fun of course! Hope this helps.Afaik the problem with robot arms is jerk and backlash though. Limiting acceleration of the servos (starting and ending a move slow) could help though. And servos aren't precise enough (not enough steps / mm) and not repeatable enough.

I have this crazy idea that you could improve the precision though by using computer vision to track the precise location of the effector and using some kind of algorithm to compensate for backlash and jerk and arm droop. Maybe you could use an IMU for this as well. After all our human arms are highly imprecisely manufactured as well but we "learn" to use them precisely. If you could teach a robot that then you could safe a lot on "precision manufacturing". This would also be an important step for reprap "reproducability" by creating less precise but 3D printable linkages. That's just crazy talk though

Edited 1 time(s). Last edit at 06/01/2015 04:35PM by Dejay.

|

Re: SAPE Single Arm Printer Experiment June 16, 2015 11:47PM |

Registered: 9 years ago Posts: 14 |

Quote

Dejay

Well if you can program a bit you could try adapt something like marlin. Or just use the gcode interpreter in marlin.

The inverse kinematic code for the meArm is here: [github.com]

int b = sqrt ((x * x) + (z * z)); // b = distance from the origin to the start of the gripper //Serial.write(b); float q1 = atan2( x, z ); // q1 = angle between the horizontal and the line b //Serial.print(q1,4); float q2 = acos((bic_sq - for_sq + (b * b))/(2 * bicep * b)); // q1 = angle between line b and the bicep //Serial.print(q2,4); float abi = q1 + q2; // abi = angle between horizontal and the bicep //Serial.print(abi,4); float afo = acos((bic_sq + for_sq - (b * b))/(2 * bicep * forearm)); // afo = angle between bicep and forearm

Afaik controlling servos is simpler than steppers, so instead of generating step signals until you reach the destination over time, you just set the position you want your servo to be at:

myservo0.write(abi); // sets the servo position according to the scaled value myservo3.write(afo); // sets the servo position according to the scaled value

If you've never programmed before it might seem like a daunting task but it's not black magic. You can start simple and add more functionality as you learn. Reading code written by others is always a bit of work through. But rewardingWriting code is much more fun of course! Hope this helps.

Afaik the problem with robot arms is jerk and backlash though. Limiting acceleration of the servos (starting and ending a move slow) could help though. And servos aren't precise enough (not enough steps / mm) and not repeatable enough.

I have this crazy idea that you could improve the precision though by using computer vision to track the precise location of the effector and using some kind of algorithm to compensate for backlash and jerk and arm droop. Maybe you could use an IMU for this as well. After all our human arms are highly imprecisely manufactured as well but we "learn" to use them precisely. If you could teach a robot that then you could safe a lot on "precision manufacturing". This would also be an important step for reprap "reproducability" by creating less precise but 3D printable linkages. That's just crazy talk though

Thanks for the reply, I've only adjusted settings in Marlin, but have never programmed anything on my own. I will keep looking and researching. Would it be possible to input the inverse kinetic code of a similar robot in place of something that is already in an existing Marlin?

And I like your idea! I was thinking about calibrating an arm similar to how a CMM is calibrated.

|

Re: SAPE Single Arm Printer Experiment June 17, 2015 12:03AM |

Registered: 9 years ago Posts: 210 |

I think generally you probably want to search for "arduino sketch" or program to control your robot. Not firmware. Reprap firmware are just arduino programs. Maybe this helps you to find what you are looking for. What is the name / model of the robot you want to use? And what controller do you want to use?

Sorry, only registered users may post in this forum.