Polar Rep Rap

Posted by galaxyman7

|

Re: Polar Rep Rap March 12, 2010 07:45PM |

Registered: 14 years ago Posts: 278 |

Okay.. wiki is still a bit messy. I'm not quite sure where to start there.

Here is the tool path that I see with my current strategy:

1. Model -> STL (leverage existing tool)

2. STL -> RepRap GCode (leverage existing tool)

3. GCode -> SplineCode (under development)

4. SplineCode -> FirmwareDriver (under development)

I'll skip describing 1 and 2.

For 3, I see two strategies: A numerical strategy, where you cut it up into smaller and smaller segments until you can start running an iterative approach to satisfy the constraints. The second strategy is analytic, and the one I'm working on - this entails:

A. take GCode and create an set of N parametric functions (one for each degree of freedom, including extruder and temperature.)

B. add an additional set of parametric functions, computed using the specific polar transformation for the robot configuration.

C. Inject additional segments or wrap polar branch point angles to make all the function continuous.

D. Compute a time map function: t' = h(t) that can be used with function composition to get the optimal parametric build curve: x = X ( h(t) ), y = Y ( h(t) ), ...

E. Compute a set of parametric spline curves following the composed path to the degree of accuracy needed on each axis.

For 4, the strategy for executing splines would use some experimental firmware I've written. It accepts packets coding bytecode that set the different variables used to execute an iterative calculation for each motor spline function. These numbers then feed the motor positions, using either a step / follow or PID control, depending on the exact type of control (Stepper, servo, PID, etc.)

Here is the tool path that I see with my current strategy:

1. Model -> STL (leverage existing tool)

2. STL -> RepRap GCode (leverage existing tool)

3. GCode -> SplineCode (under development)

4. SplineCode -> FirmwareDriver (under development)

I'll skip describing 1 and 2.

For 3, I see two strategies: A numerical strategy, where you cut it up into smaller and smaller segments until you can start running an iterative approach to satisfy the constraints. The second strategy is analytic, and the one I'm working on - this entails:

A. take GCode and create an set of N parametric functions (one for each degree of freedom, including extruder and temperature.)

B. add an additional set of parametric functions, computed using the specific polar transformation for the robot configuration.

C. Inject additional segments or wrap polar branch point angles to make all the function continuous.

D. Compute a time map function: t' = h(t) that can be used with function composition to get the optimal parametric build curve: x = X ( h(t) ), y = Y ( h(t) ), ...

E. Compute a set of parametric spline curves following the composed path to the degree of accuracy needed on each axis.

For 4, the strategy for executing splines would use some experimental firmware I've written. It accepts packets coding bytecode that set the different variables used to execute an iterative calculation for each motor spline function. These numbers then feed the motor positions, using either a step / follow or PID control, depending on the exact type of control (Stepper, servo, PID, etc.)

|

Re: Polar Rep Rap March 13, 2010 12:05AM |

Admin Registered: 17 years ago Posts: 1,791 |

Would a forum for delta bots, and a forum for polar bots be possible? The Repstrappers forum already has a decent amount of discussion on delta bots, so there seems to be demand there.

We have one for delta robots already:

[dev.forums.reprap.org]

Delta Robots are parallel chain robots:

[en.wikipedia.org]

Likewise:

[en.wikipedia.org]

If you want one for polar robots I can create one.

Those are serial chain robots, as are cartesian robots like a bridgeport mill, a 'robot arm', or Mendel.

[en.wikipedia.org]

[en.wikipedia.org]

[en.wikipedia.org]

I don't mind creating a new polar-bot forum.

Does 'Polar-bots and robot arms?' sound good?

Parallel chain robots and serial chain robots have different mathematical representation. Also, you can mix and match and have a tiny polar on the end of a delta.

Edited 1 time(s). Last edit at 03/13/2010 12:12AM by SebastienBailard.

We have one for delta robots already:

[dev.forums.reprap.org]

Delta Robots are parallel chain robots:

[en.wikipedia.org]

Likewise:

[en.wikipedia.org]

If you want one for polar robots I can create one.

Those are serial chain robots, as are cartesian robots like a bridgeport mill, a 'robot arm', or Mendel.

[en.wikipedia.org]

[en.wikipedia.org]

[en.wikipedia.org]

I don't mind creating a new polar-bot forum.

Does 'Polar-bots and robot arms?' sound good?

Parallel chain robots and serial chain robots have different mathematical representation. Also, you can mix and match and have a tiny polar on the end of a delta.

Edited 1 time(s). Last edit at 03/13/2010 12:12AM by SebastienBailard.

|

Re: Polar Rep Rap March 13, 2010 12:21AM |

Admin Registered: 17 years ago Posts: 1,791 |

We have one for delta robots already

I finally moved a few of the delta threads into it.

Let me know what kind of forum you guys want for polar bot/robot arms. The name, mostly. Or I'll call it "Polar bots and Robot Arms".

Also, I'll need one volunteer to go around and get a list of names to invite into it.

Edited 1 time(s). Last edit at 03/13/2010 12:46AM by SebastienBailard.

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

I finally moved a few of the delta threads into it.

Let me know what kind of forum you guys want for polar bot/robot arms. The name, mostly. Or I'll call it "Polar bots and Robot Arms".

Also, I'll need one volunteer to go around and get a list of names to invite into it.

Edited 1 time(s). Last edit at 03/13/2010 12:46AM by SebastienBailard.

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

|

Re: Polar Rep Rap March 13, 2010 03:08AM |

Registered: 14 years ago Posts: 198 |

|

Re: Polar Rep Rap March 13, 2010 01:51PM |

Registered: 14 years ago Posts: 105 |

|

Re: Polar Rep Rap March 15, 2010 03:51AM |

Registered: 14 years ago Posts: 198 |

|

Re: Polar Rep Rap November 30, 2010 05:59PM |

Registered: 15 years ago Posts: 376 |

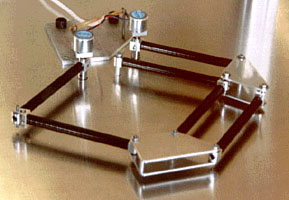

I was doing some calculations and a few sketches on CAD for a SCARA robot design similar to the configuration below.

Working on a 200mm square build envelope I calculated that to get an XY resolution of around 0.1mm using stepper motors the motors would need to be geared, but this could be achieved with toothed belts and a single intermediate gear. Something like 100:1 for the overall reduction would be about right. All components could be reprapped and a gearbox with minimal backlash could be made.

Using steppers would be easier as there would be no need for encoders and their use is already well established in the reprap community.

Working on a 200mm square build envelope I calculated that to get an XY resolution of around 0.1mm using stepper motors the motors would need to be geared, but this could be achieved with toothed belts and a single intermediate gear. Something like 100:1 for the overall reduction would be about right. All components could be reprapped and a gearbox with minimal backlash could be made.

Using steppers would be easier as there would be no need for encoders and their use is already well established in the reprap community.

|

Re: Polar Rep Rap December 01, 2010 04:37AM |

Admin Registered: 16 years ago Posts: 13,884 |

... i made some research regarding parallel kineamtics and found some documents with different concepts, some math and interesting samples ... but mostly in german ...

One result with scara robots is, that you can build a high precision system when ysing two identical scaras with joined tooltip - here the accuracy over the complete working area is much better than with a single system.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

One result with scara robots is, that you can build a high precision system when ysing two identical scaras with joined tooltip - here the accuracy over the complete working area is much better than with a single system.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Polar Rep Rap December 01, 2010 08:44AM |

Registered: 15 years ago Posts: 376 |

Yes two SCARA robots in that configuration would reduce the cantilever loading, but the downside would be the working envelope would be reduced to between the robots as it could not rotate around the primary axis too much. I'm just thinking whether ther robots would be better at 90 degrees or 180 degrees from each other.

A SCARA robot really appeals as the area above the build platform is relatively free from clutter, unlike the Reprap or Makerbot. This makes me think multiple extruder setups would be much easier. Many years ago I used to design robot cells which maily used SCARA or polar robots. A tool changer rack was often used to switch tooling heads for different pick and place objects. They used a standard interface for the electrical / air connections for each head and a cartridge rack to one side of the build platform. It was not unusual to have 6 heads on one machine.

The Z axis of the above robot looks a little complex but perhaps a table raised and lowered by a sarrus linkage would mean that virtually all the mechanical parts could be reprapped and there would be no linear guides or bearings.

A SCARA robot really appeals as the area above the build platform is relatively free from clutter, unlike the Reprap or Makerbot. This makes me think multiple extruder setups would be much easier. Many years ago I used to design robot cells which maily used SCARA or polar robots. A tool changer rack was often used to switch tooling heads for different pick and place objects. They used a standard interface for the electrical / air connections for each head and a cartridge rack to one side of the build platform. It was not unusual to have 6 heads on one machine.

The Z axis of the above robot looks a little complex but perhaps a table raised and lowered by a sarrus linkage would mean that virtually all the mechanical parts could be reprapped and there would be no linear guides or bearings.

|

Re: Polar Rep Rap December 01, 2010 09:29AM |

Admin Registered: 16 years ago Posts: 13,884 |

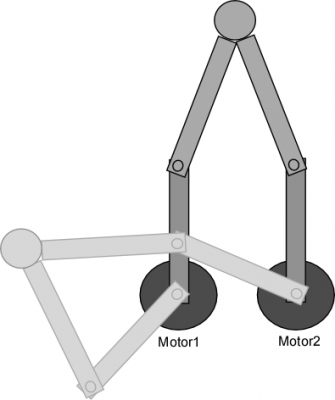

... the best 'parallel scara' design is made with only three motors when two motors sitting near each other on the 'ground-line' and two segmented arms are atached to the motors and joined in the tooltip.

So you can simply by individually turning this two motors position the tooltip in a half-circle with a max. radius of the length of the stretched arms, min. radius if both arms are folded (one to the left, the other to the right), and in a radial segment of nearly 180 degrees when rotating the motors to the corresponding sides. When rotating the complete setup you can reach the complete 360deg area defined by the length of the stretched arms.

The height (or Z) is made best with an elevated table or by moving the planar 'scaras' in Z ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

So you can simply by individually turning this two motors position the tooltip in a half-circle with a max. radius of the length of the stretched arms, min. radius if both arms are folded (one to the left, the other to the right), and in a radial segment of nearly 180 degrees when rotating the motors to the corresponding sides. When rotating the complete setup you can reach the complete 360deg area defined by the length of the stretched arms.

The height (or Z) is made best with an elevated table or by moving the planar 'scaras' in Z ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Polar Rep Rap December 01, 2010 02:43PM |

Registered: 15 years ago Posts: 376 |

Viktor

I didn't understand your exact meaning. Are there any images of such a setup?

Something like this may be nice. It keeps the motors and reduction gearboxes off the arms and has an extra linkage for stability. The inverse kinematic calculations shouldn't be too hard and it seems to leave a nice platform for the extruder.

Edited 1 time(s). Last edit at 12/01/2010 02:45PM by martinprice2004.

I didn't understand your exact meaning. Are there any images of such a setup?

Something like this may be nice. It keeps the motors and reduction gearboxes off the arms and has an extra linkage for stability. The inverse kinematic calculations shouldn't be too hard and it seems to leave a nice platform for the extruder.

Edited 1 time(s). Last edit at 12/01/2010 02:45PM by martinprice2004.

|

Re: Polar Rep Rap December 01, 2010 03:20PM |

Admin Registered: 16 years ago Posts: 13,884 |

... here a sketch of a simple setup with two max. positions - all positions inbetween and mirrored are adressible too:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Polar Rep Rap April 25, 2011 07:51AM |

Registered: 13 years ago Posts: 12 |

|

Re: Polar Rep Rap May 03, 2011 04:01AM |

Admin Registered: 16 years ago Posts: 13,884 |

... such 'parallel scara'-designs were mostly built for microassembly systems and very accurate, for 'simply' 3D-printing the software for positioning the arms has to be written first ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Polar Rep Rap June 10, 2011 12:09AM |

Registered: 12 years ago Posts: 130 |

The kinematics should be done with quaternions regular 3d matrices would work too but wouldn't be as neat, would be slower and more complicated things would be to much to handle for most processors.

At best this would go in hand with a quaternion based procedural modeling software in openscad style. REAL solids instead of polygons.

Just sayin

At best this would go in hand with a quaternion based procedural modeling software in openscad style. REAL solids instead of polygons.

Just sayin

|

Re: Polar Rep Rap September 09, 2012 09:54PM |

Registered: 11 years ago Posts: 1 |

Hello,

I am newly subscribed and doing some reading and learning. I have found this thread, which seems to be focused on using a robotic arm for 3d creations. this is of interest, but my primary interest is slightly different.

My interest is more along the lines of the following:

1. a rotating table that is driven in one constant direction by a stepper motor, fast, faster, slow, slower.... doesn't matter.

2. an overhead gantry/arm/frame that holds the thermal print head above the rotating table and and only moves along one axis....call it X-axis for this small discussion. (I am assuming that this type of system will use polar coordinates).

3. the thermal print head will move along the X-axis for the necessary r-distance, and the rotating table will rotate until the angle theta has been reached and actually aligns / lies along the the X-axis.

4. Is anyone pursuing this type of thinking? It would, by design, be limited to a specific table size (ie. 4" diameter, or 6" dia,

or 8" diameter, etc).

5. It would seem to be a very simple structure. 3 motors: one to turn the table; one to move the head along the Y-axis; and one to move the thermal head up and down:

Is anyone pursuing something along this line of thought?

regards,

spgandau

I am newly subscribed and doing some reading and learning. I have found this thread, which seems to be focused on using a robotic arm for 3d creations. this is of interest, but my primary interest is slightly different.

My interest is more along the lines of the following:

1. a rotating table that is driven in one constant direction by a stepper motor, fast, faster, slow, slower.... doesn't matter.

2. an overhead gantry/arm/frame that holds the thermal print head above the rotating table and and only moves along one axis....call it X-axis for this small discussion. (I am assuming that this type of system will use polar coordinates).

3. the thermal print head will move along the X-axis for the necessary r-distance, and the rotating table will rotate until the angle theta has been reached and actually aligns / lies along the the X-axis.

4. Is anyone pursuing this type of thinking? It would, by design, be limited to a specific table size (ie. 4" diameter, or 6" dia,

or 8" diameter, etc).

5. It would seem to be a very simple structure. 3 motors: one to turn the table; one to move the head along the Y-axis; and one to move the thermal head up and down:

Is anyone pursuing something along this line of thought?

regards,

spgandau

|

Re: Polar Rep Rap September 10, 2012 02:25AM |

Admin Registered: 16 years ago Posts: 13,884 |

... for a common cartesian XYZ-structure you'll need the same three motors too and you'll receive the same accuracy in every point of the XY-rectangle ... wereas with the polar setup you'll get different resolutions/accuracies/speeds depending on the radius, what will make the software more complicated and the resulting parts more inconsistent.

This is the main reason, why most printers (and mills) use XYZ as base structure and rotational axes or special solutions are used only as addons or lathe+mill-combinations.

More interesting could be parallel kinematics like "Rostok" or other symmetrical 3-pod or 3-wire structures ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

This is the main reason, why most printers (and mills) use XYZ as base structure and rotational axes or special solutions are used only as addons or lathe+mill-combinations.

More interesting could be parallel kinematics like "Rostok" or other symmetrical 3-pod or 3-wire structures ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Polar Rep Rap October 30, 2017 03:16PM |

Registered: 6 years ago Posts: 4 |

Sorry, only registered users may post in this forum.