SCARA Arm Printer

Posted by Evil Monkey

|

SCARA Arm Printer July 31, 2014 12:17AM |

Registered: 11 years ago Posts: 177 |

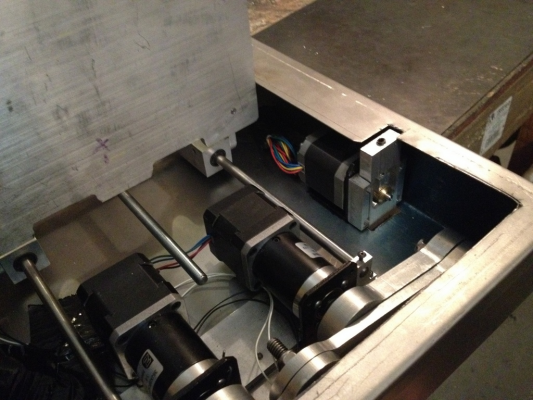

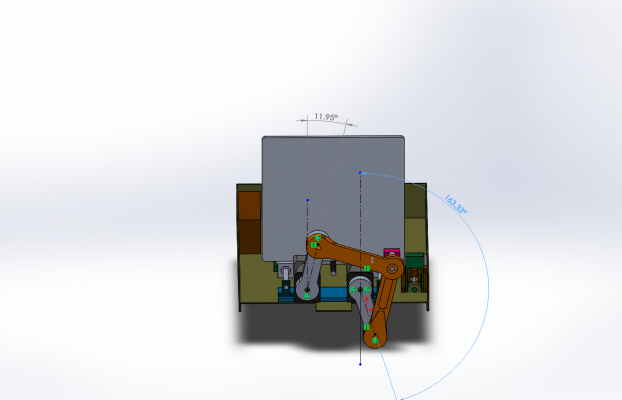

Here is a printer that I have been working on for the past few weeks. I used 51:1 geared stepper motors for the arms. There was a bit of backlash, which of course is amplified by the arm movement, so two springs were added to the shaft in order to preload the arms. It appears to be very effective. I'm using Marlin SCARA firmware and have it up and moving. The problem is that I have not been able to properly setup the firmware. Any advice on how to do so would be greatly appreciated!

|

Re: SCARA Arm Printer July 31, 2014 04:54AM |

Registered: 13 years ago Posts: 7,616 |

Quote

Evil Monkey

There was a bit of backlash, which of course is amplified by the arm movement, so two springs were added to the shaft in order to preload the arms. It appears to be very effective.

Effective, until you do substantial acceleration. Acceleration forces countermeasure these spring forces, so you can always only accelerate as fast as the spring allows.

Other than that, nice work! Are you comfortable with modifying a firmware for it?

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: SCARA Arm Printer July 31, 2014 12:09PM |

Registered: 11 years ago Posts: 177 |

I won't be able to run as fast as those machines on youtube due to inertia for sure. I am completely stumped on the firmware, programming has never been my strong point. I have been using the Marlin SCARA fork, but there aren't any good explanations online on what some variables represent. ie scara_axis_y . Homing is a real devil. I have the end stops disabled in pins.h but I don't know where the printer believes it is starting to print from. The arms will change directions without any noticeable backlash because of the springs, so that's encouraging.

|

Re: SCARA Arm Printer July 31, 2014 01:28PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: SCARA Arm Printer July 31, 2014 02:45PM |

Registered: 9 years ago Posts: 135 |

This has more in common with the Morgan than the Wally. (Though the Wally was itself a decendant of the Morgan, so I guess cousin could be accurate) The Morgans have been very practical, heck there's some small mechanical changes that could be made to the Wally to make it a more practical branch. (but that's for a different discussion)Quote

cozmicray

A Wally cousin?

|

Re: SCARA Arm Printer July 31, 2014 03:25PM |

Registered: 11 years ago Posts: 177 |

This printer has other tricks it can perform that neither Morgan or Wally can.

|

Re: SCARA Arm Printer July 31, 2014 04:31PM |

Registered: 9 years ago Posts: 135 |

I had a feeling that it woudl do that. but it's still very impressive.

Though with it folded, it kind of highlights something I didn't really look at before... Where are you planning to put the extruder/hot end? The place where the hot end normally lives on the Morgan and Wally is occupied with a big, solid bolt.

Though with it folded, it kind of highlights something I didn't really look at before... Where are you planning to put the extruder/hot end? The place where the hot end normally lives on the Morgan and Wally is occupied with a big, solid bolt.

|

Re: SCARA Arm Printer July 31, 2014 04:47PM |

Registered: 11 years ago Posts: 177 |

Like everything on this machine, it will be custom and a pain. It will be a Bowden style, as you would expect, and the hot end will be attached where the bolt currently resides. That bolt is really just a placeholder until I get the firmware sorted out. Cold end will be tucked away under the sheet metal.

|

Re: SCARA Arm Printer August 01, 2014 11:38PM |

Registered: 11 years ago Posts: 177 |

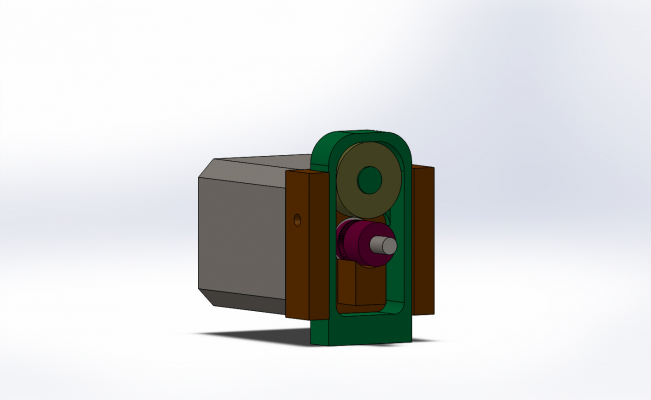

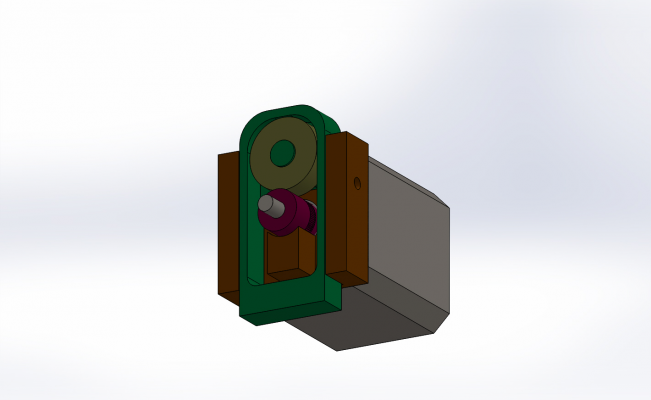

Sat down and drew up the cold end. Should fit nicely behind the sheetmetal with the big green button placed so that it can be depressed to release the filament. Plan to machine it from Aluminium.

|

Re: SCARA Arm Printer August 02, 2014 08:13PM |

Registered: 11 years ago Posts: 177 |

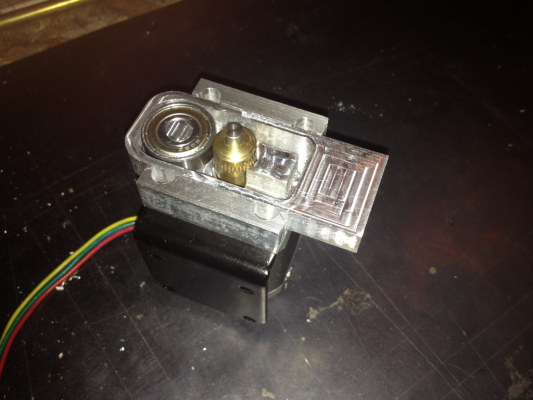

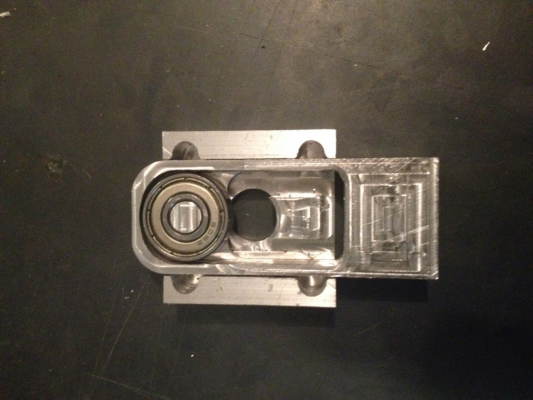

I machined what will be the extruders cold end today. Still need to drill some holes for the mounting bolts and spring, but I think it turned out quite well. The bearing holder will be turned over when in use to retain the roller bearing.

|

Re: SCARA Arm Printer August 03, 2014 08:44PM |

Registered: 10 years ago Posts: 979 |

I was trying to work up the inverse kinematics. I got a very very long expression. (There is an arctan, a sqrt along with 20 multiplications and 8 add/sub. That is only for one side.) Maybe, I did it wrong. Has anyone else worked this out. I was hoping to rough out a preprocessor so Evil Monkey could do some testing. As it stands now with the huge expression, I could fit the Wally transformation into firmware easier than this. I didn't realize how much the equal arm lengths help with the math. An ARM controller or a BBB tethered controller could handle this. You won't be able to use an AVR without some very clever firmware.

@Evil Monkey: I really love the format. (For the record, this will be a cakewalk to get accurate prints on compared to Wally. The linear Z along with the well defined arm rotations will make this require no calibration.)

I suspect that the spring can be sized to allow some insane speeds. It is a cheap and effective solution.

Can't wait to see this thing move. Have you named him/her?

Edited 1 time(s). Last edit at 08/03/2014 08:50PM by nicholas.seward.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

@Evil Monkey: I really love the format. (For the record, this will be a cakewalk to get accurate prints on compared to Wally. The linear Z along with the well defined arm rotations will make this require no calibration.)

I suspect that the spring can be sized to allow some insane speeds. It is a cheap and effective solution.

Can't wait to see this thing move. Have you named him/her?

Edited 1 time(s). Last edit at 08/03/2014 08:50PM by nicholas.seward.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

|

Re: SCARA Arm Printer August 03, 2014 09:19PM |

Registered: 11 years ago Posts: 177 |

Thank you nicholas.seward for looking into the function for this machine. I had no idea when I started building this printer that that would be the biggest problem! I had been basing the mechanism off the work posted by ttsalo, he is the person who made the SCARA firmware for Marlin as well as the Armstrong printer. Unfortunetly he does not appear to vist this forum any more.

As far as the name is concerned, I have not been calling this machine any names I would repeat in public! I am open to suggestions.

I drilled most of the bolt holes for the cold end, except for where the filament will pass through to block. Waiting for the 4mm pneumatic fittings to come in before I do that. It sits nicely behind the sheet metal, and the button for releasing the filament sits nearly flush with the front facade. The plan is to pass the tubing behind the geared stepper motors, then around to the front so that there are no sharp bends in the line, but it will still fold up flush. Filament will enter the extruder through the side.

As far as the name is concerned, I have not been calling this machine any names I would repeat in public! I am open to suggestions.

I drilled most of the bolt holes for the cold end, except for where the filament will pass through to block. Waiting for the 4mm pneumatic fittings to come in before I do that. It sits nicely behind the sheet metal, and the button for releasing the filament sits nearly flush with the front facade. The plan is to pass the tubing behind the geared stepper motors, then around to the front so that there are no sharp bends in the line, but it will still fold up flush. Filament will enter the extruder through the side.

|

Re: SCARA Arm Printer August 03, 2014 10:06PM |

Registered: 10 years ago Posts: 979 |

I just checked ttsalo's code and the Armstrong is functionally the same as yours. You will just have to tweak the parameters.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

|

Re: SCARA Arm Printer August 03, 2014 10:34PM |

Registered: 11 years ago Posts: 177 |

I have been trying with my arm lengths and base width, but it's not responding as expected. A lot of the code that would be really helpful if it was commented on. Such as which stepper is x and y on the machine (left or right?), what scara_axis_y means and the formula for steps per unit. No idea wear he got 1600, the 25 is presumably from the gear ratio he used, and 360 is a circle. The orientation and thus dimensions of the build platform are also unclear. As is which direction is x and which is considered y on the platform. I mounted end stops behind the arms now, but I keep getting errors similar to when a printer is at or near it's expected print dimensional limit. It then moves in one direction or erratically. It's causing a lot of confusion.

|

Re: SCARA Arm Printer August 03, 2014 11:11PM |

Registered: 10 years ago Posts: 979 |

Wish I could help. You will have to do some experimentation along with examining his math to figure out his intent. Just go slow and take your time. It will come.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

|

Re: SCARA Arm Printer August 04, 2014 09:39AM |

Registered: 11 years ago Posts: 177 |

|

Re: SCARA Arm Printer August 04, 2014 12:56PM |

Registered: 9 years ago Posts: 127 |

Hi,

in ttsalo´s thread [forums.reprap.org]

he wrote about his "...reduction drives (1:25 in the current design)...", so 25 might be safely assumed as the gear ratio.

BR,

Mike

in ttsalo´s thread [forums.reprap.org]

he wrote about his "...reduction drives (1:25 in the current design)...", so 25 might be safely assumed as the gear ratio.

BR,

Mike

|

Re: SCARA Arm Printer August 04, 2014 03:14PM |

Registered: 11 years ago Posts: 177 |

|

Re: SCARA Arm Printer August 04, 2014 03:30PM |

Registered: 9 years ago Posts: 127 |

Oh yes,, the motor orientation and coordinate system offset is also strange...

Did you found out whats the 1600 ? Might be steppers steps/rev times the microstepping factor ?

Oh, and I forget to tell you that I love your rigid mechanical geomtry!

I think that´s the correct way to build a proper machine !

Would you mind providing further details about your machine and electronics?

Did you found out whats the 1600 ? Might be steppers steps/rev times the microstepping factor ?

Oh, and I forget to tell you that I love your rigid mechanical geomtry!

I think that´s the correct way to build a proper machine !

Would you mind providing further details about your machine and electronics?

|

Re: SCARA Arm Printer August 04, 2014 03:52PM |

Registered: 11 years ago Posts: 177 |

Nothing too crazy behind the sheet metal. Stepper motors are Nema 17, arm ones are geared 51:1, z axis is not geared. Runs on a RAMPS 1.4. At the base there is a 160W PSU that I had laying around from a desktop computer that broke. It's enough to run the stepper motors and a hotend, but not a heated build platform unfortunately. I will take a picture of it without the front facade when I get a chance. All the parts are machined from 6061 aluminium. Build platform measures 8" x 9", big enough for a standard heated build platform if I ever come across a PSU that can support it and still fit. 8mm rods for the z axis and two 608 bearings per arm at the elbows and a brass bushing for the central pivot. I haven't made the hot end yet, so that is still to be determined.

|

Re: SCARA Arm Printer August 05, 2014 03:46PM |

Registered: 11 years ago Posts: 177 |

I think x is side to side and y is front to back, same as how a milling machine is set up. The reason I suspect this is because ttsalo says in his thread that there is a strange sine wave appearing in the x movements and if you watch the video this is the oreintation.

Edited 1 time(s). Last edit at 08/05/2014 04:36PM by Evil Monkey.

Edited 1 time(s). Last edit at 08/05/2014 04:36PM by Evil Monkey.

|

Re: SCARA Arm Printer August 05, 2014 04:11PM |

Registered: 10 years ago Posts: 1,381 |

X and Y axis determination, the longer of the two is typically designated the X-axis. If X and Y axis are of equal length, then the axis moving away from the operator is considered the Y axis. Or it's based on from where the operator faces the machine, for example, on most routers the gantry is considered the X axis, even though the Y axis is typically longer.

|

Re: SCARA Arm Printer August 05, 2014 05:43PM |

Registered: 11 years ago Posts: 177 |

Its Alive!

I got it up and moving properly.If you are the machine, the right stepper motor is X, left is Y. I loaded up a simple 1 inch cube gcode and it moved as expected. I will upload a video soon. I believe what scara_axis_y refers to is when the program starts, the machines right arm pulls back 80 mm. The platform orientation is what I thought above.

Edited 1 time(s). Last edit at 08/05/2014 06:15PM by Evil Monkey.

I got it up and moving properly.If you are the machine, the right stepper motor is X, left is Y. I loaded up a simple 1 inch cube gcode and it moved as expected. I will upload a video soon. I believe what scara_axis_y refers to is when the program starts, the machines right arm pulls back 80 mm. The platform orientation is what I thought above.

Edited 1 time(s). Last edit at 08/05/2014 06:15PM by Evil Monkey.

|

Re: SCARA Arm Printer August 05, 2014 09:33PM |

Registered: 11 years ago Posts: 177 |

|

Re: SCARA Arm Printer August 06, 2014 10:35AM |

Registered: 11 years ago Posts: 177 |

Found a couple of PSU's that would fit and run a heated build platform.

SeaSonic SS 350W ATX12V

Athena Power AP 350W

SeaSonic SS 350W ATX12V

Athena Power AP 350W

|

Re: SCARA Arm Printer August 06, 2014 11:20AM |

Registered: 9 years ago Posts: 127 |

Congratulations !

It really looks great, and smooth !

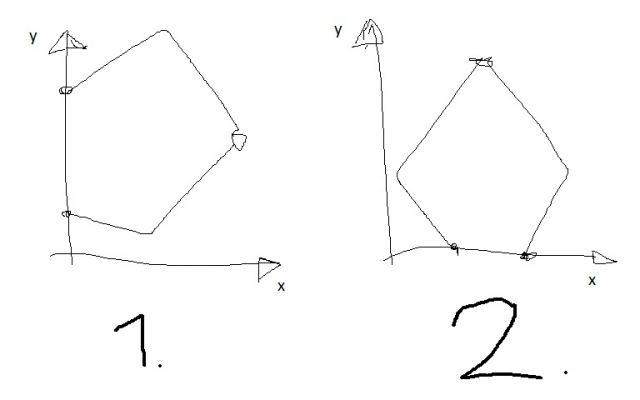

But I would not say X-axes is the one motor, Y-axes the other. Movement only in one direction, lets say x, is always a superposition of both motors because of the curved trajectory. Still I did not understand the axes direction. Here´s a (very) simple sketch...so it´s direction is like on the left side (1) ?

It really looks great, and smooth !

But I would not say X-axes is the one motor, Y-axes the other. Movement only in one direction, lets say x, is always a superposition of both motors because of the curved trajectory. Still I did not understand the axes direction. Here´s a (very) simple sketch...so it´s direction is like on the left side (1) ?

|

Re: SCARA Arm Printer August 06, 2014 11:35AM |

Registered: 11 years ago Posts: 177 |

|

Re: SCARA Arm Printer August 06, 2014 03:07PM |

Registered: 9 years ago Posts: 127 |

|

Re: SCARA Arm Printer August 06, 2014 04:52PM |

Registered: 10 years ago Posts: 979 |

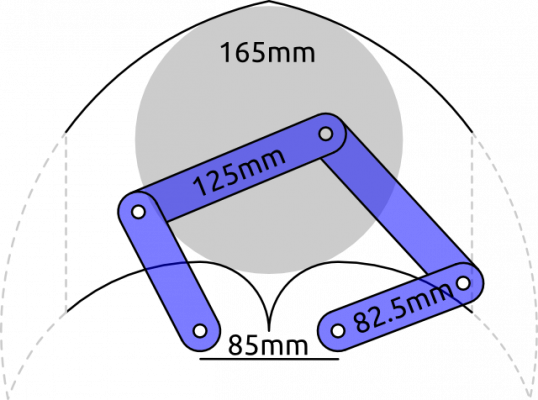

I was curious of what the print area looked like. This makes some assumptions such as the short arms can only rotate 90 degrees back and you never try to cross a singularity. 165mm is a reasonable circle. Rectangles that can fit... 250x110, 200x125, 150x132

The new Slic3r 1.2 allows for the input of arbitrary print areas so you can allow for easy layouts without worrying if it can print or not. (Too bad it is just a 2D fix. GUS requires a 3D solution.)

If you let me know where 0,0 is and what direction positive X and I can throw you an STL that you can use with Slic3r to set the print area.

Edited 1 time(s). Last edit at 08/06/2014 05:09PM by nicholas.seward.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

|

Re: SCARA Arm Printer August 06, 2014 09:02PM |

Registered: 11 years ago Posts: 177 |

Here are the firmware changes thus far:

configuration.h

scara_seg1_len 82.55

scara_seg2_len 125.07

scara_axis_spacing 85.04

(These dimensions are specific to my machine)

scara_axis_y -50

(This is an arbitrary number that I picked. By changing this number and uploading the firmware, I was able to puzzle out that when the print starts, the y stepper motor pulls the arm back, in this case 50 mm before starting)

default_axis_steps_per_unit {226.67,226.67,1133,385}

(My train of thought is as follows: When calculating steps for a normal printer the formula is (steps*microstepping^-1)/(belt pitch*pulley teeth).I'm using a 1.8 degree motor and no belt/pulley, so it's 200*16 = 3200. At this point, I can only assume that he divided in 2 for some reason. Then his formula is (1600*gear ratio)/ 360 = 226.67. I know there is an intellectual leap in there, but it seems to work. Z and A I have not changed.)

pins.h

I'm using a RAMPS, so scroll down to 34

x_min_pin -1

y_min_pin -1

(This disables the endstops. They kept giving an error. I'll deal with them later.)

I'm also interested in using the auto bed leveling feature, but have not explored it too deeply yet.

There are cutouts in the rear sheet metal to allow the steppers a larger range of motion. Currently I've just been manually pulling the arm to the center of the platform and hitting start print. It then pulls back 50 mm and then begins printing.

Edited 3 time(s). Last edit at 08/06/2014 09:06PM by Evil Monkey.

configuration.h

scara_seg1_len 82.55

scara_seg2_len 125.07

scara_axis_spacing 85.04

(These dimensions are specific to my machine)

scara_axis_y -50

(This is an arbitrary number that I picked. By changing this number and uploading the firmware, I was able to puzzle out that when the print starts, the y stepper motor pulls the arm back, in this case 50 mm before starting)

default_axis_steps_per_unit {226.67,226.67,1133,385}

(My train of thought is as follows: When calculating steps for a normal printer the formula is (steps*microstepping^-1)/(belt pitch*pulley teeth).I'm using a 1.8 degree motor and no belt/pulley, so it's 200*16 = 3200. At this point, I can only assume that he divided in 2 for some reason. Then his formula is (1600*gear ratio)/ 360 = 226.67. I know there is an intellectual leap in there, but it seems to work. Z and A I have not changed.)

pins.h

I'm using a RAMPS, so scroll down to 34

x_min_pin -1

y_min_pin -1

(This disables the endstops. They kept giving an error. I'll deal with them later.)

I'm also interested in using the auto bed leveling feature, but have not explored it too deeply yet.

There are cutouts in the rear sheet metal to allow the steppers a larger range of motion. Currently I've just been manually pulling the arm to the center of the platform and hitting start print. It then pulls back 50 mm and then begins printing.

Edited 3 time(s). Last edit at 08/06/2014 09:06PM by Evil Monkey.

Sorry, only registered users may post in this forum.