Polar machine questions

Posted by Miamicraft

|

Polar machine questions October 30, 2015 02:27PM |

Registered: 10 years ago Posts: 62 |

I haven't seen much development in polar machines (except Polar3d) lately and was wondering why.The mechanical design is trivial as compared to a delta machine and calibration should be no more difficult than a Prusa.

Is the problem with the controller and or firmware? The math seems pretty straight forward if you don't take into account having to vary speed and acceleration in relationship to distance from center of rotation.

r = √ ( x2 + y2 )

θ = tan-1 ( y / x )

Is the problem that the Arduino doesn't support complex math well and there are performance issues?

Is anyone working on this?

Roger

Is the problem with the controller and or firmware? The math seems pretty straight forward if you don't take into account having to vary speed and acceleration in relationship to distance from center of rotation.

r = √ ( x2 + y2 )

θ = tan-1 ( y / x )

Is the problem that the Arduino doesn't support complex math well and there are performance issues?

Is anyone working on this?

Roger

|

Re: Polar machine questions October 30, 2015 09:32PM |

Registered: 11 years ago Posts: 177 |

I suspect it has a lot to do with the "dead space" at the center of rotation

[scara3dprinter.wordpress.com]

[scara3dprinter.wordpress.com]

|

Re: Polar machine questions October 31, 2015 04:22PM |

Registered: 10 years ago Posts: 62 |

Could you please elaborate on dead spot. [polar3d.com] doesn't have one and there doesn't seam to be one in 5 axis CNC which can use similar strategies. I've done some searching and can't find anything.

Thanks,

Roger

Thanks,

Roger

|

Re: Polar machine questions October 31, 2015 07:06PM |

Registered: 11 years ago Posts: 177 |

If you watch the video they have on their website, you'll notice that nothing is printed on the center of the disk. This is because the extruder would make a mess of things right there. The result is a reduction in build volume. Its a nice machine, but I suspect thats why there aren't many more. CNC machines are a whole different ball of wax.

Edited 1 time(s). Last edit at 10/31/2015 07:06PM by Evil Monkey.

[scara3dprinter.wordpress.com]

Edited 1 time(s). Last edit at 10/31/2015 07:06PM by Evil Monkey.

[scara3dprinter.wordpress.com]

|

Re: Polar machine questions November 01, 2015 07:33PM |

Registered: 9 years ago Posts: 1,035 |

This seems to me very close to the center but I might be wrong: [youtu.be]

The Polar3D is not a true polar (bi-polar) and because of the liniar Y axis I guess it's easier to go through the center of rotation of the polar axis.

The true challenge is for the bi-polar 3D printers like the Polarworks Alta or the recently launched on Kickstarter Sculpto. I am still waiting to see a complex object printed at the centre of the printbed for the latter one.

If the bi-polar achieves the precision printing across the bed circumference then all other printers are in trouble.

But I am unaware of any bi-polar code in the open source realm. The closest is the R-360 which is, like Polar3D, uni-polar, with the other teo axes being linear.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

The Polar3D is not a true polar (bi-polar) and because of the liniar Y axis I guess it's easier to go through the center of rotation of the polar axis.

The true challenge is for the bi-polar 3D printers like the Polarworks Alta or the recently launched on Kickstarter Sculpto. I am still waiting to see a complex object printed at the centre of the printbed for the latter one.

If the bi-polar achieves the precision printing across the bed circumference then all other printers are in trouble.

But I am unaware of any bi-polar code in the open source realm. The closest is the R-360 which is, like Polar3D, uni-polar, with the other teo axes being linear.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Polar machine questions January 19, 2016 04:20PM |

Registered: 8 years ago Posts: 2 |

Hi,

I am new to the forums so please forgive any ill manners. The 3DPolar folks specifically mote that for the same x or y travel they get a larger build volume than a Cartesian coordinate system. If you look at the R-360 videos the square that is being rotated is an object that is larger and intersects the center point. I believe as long as you have the build plate properly centered there should be no troubles with that center spot. If I have an object that starts at the maximum point and intersects the centerpoint and continues through the center point the build plate would only need to rotate 180 degrees once getting to that center point to continue the object.

The R-360 rotating square build video note there is a flat base that covers the center point.

[youtu.be]

It would be interesting to add additional print heads at right angles to the initial as long as no two print heads are too close to each other at the center point at the same time you should be able to have each printing with a different material or color. This would make the build plate spin operations be more intricate and possibly/probably need to add logic so that the rotations done are working with both/all the heads you have engaged. T he might be difficult but it would make registration of the additional heads easier as all heads would use the same 0 point.

This is a project I am working on and will start with the Marlin based R-360 firmware they note out on github.

Thanks

I am new to the forums so please forgive any ill manners. The 3DPolar folks specifically mote that for the same x or y travel they get a larger build volume than a Cartesian coordinate system. If you look at the R-360 videos the square that is being rotated is an object that is larger and intersects the center point. I believe as long as you have the build plate properly centered there should be no troubles with that center spot. If I have an object that starts at the maximum point and intersects the centerpoint and continues through the center point the build plate would only need to rotate 180 degrees once getting to that center point to continue the object.

The R-360 rotating square build video note there is a flat base that covers the center point.

[youtu.be]

It would be interesting to add additional print heads at right angles to the initial as long as no two print heads are too close to each other at the center point at the same time you should be able to have each printing with a different material or color. This would make the build plate spin operations be more intricate and possibly/probably need to add logic so that the rotations done are working with both/all the heads you have engaged. T he might be difficult but it would make registration of the additional heads easier as all heads would use the same 0 point.

This is a project I am working on and will start with the Marlin based R-360 firmware they note out on github.

Thanks

|

Re: Polar machine questions January 19, 2016 04:54PM |

Registered: 8 years ago Posts: 2 |

Printing in the center is possible... it's just that it is less efficient to do so. Think about this... if you print in the center, then any movement passing through the center requires that the build plate to rotate 180 degrees, but if you move that same part towards the edge, then it only has to rotate a few degrees. Our software automatically places the part on the center of the radius to avoid that. It's merely an inconvenience... by slowing it down to print in the center. It also leaves a small "swirl" in the melted plastic as it rotates, which is visible. It's analogous to the sprue mark on an injection molded part... but it's normally flat.

If a polar printer is well calibrated, then you will not notice any other differences. I've attached three example pictures to show you the swirl.

Bill

If a polar printer is well calibrated, then you will not notice any other differences. I've attached three example pictures to show you the swirl.

Bill

|

Re: Polar machine questions January 22, 2016 12:11PM |

Registered: 8 years ago Posts: 2 |

|

Re: Polar machine questions January 22, 2016 02:24PM |

Registered: 8 years ago Posts: 2 |

The Polar3D printer is primarily a Wifi enabled device accessed via our Polar Cloud software. (We also support open source packages like Repetier-Host, Cura and Pronterface and even non open ones like Simplify3D via standard USB connections as well.) Our cloud platform was designed specifically for the class room and allows a teacher to manage several printers among several students/classes.

Bill

Bill

|

Re: Polar machine questions March 20, 2016 02:48AM |

Registered: 8 years ago Posts: 1,671 |

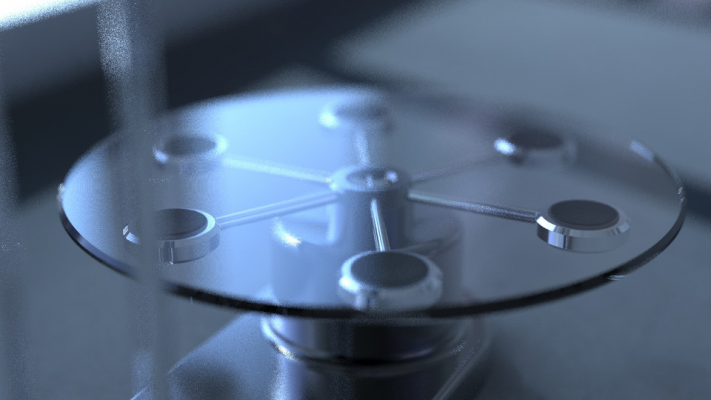

One of the first printers I designed was a Polar printer(sep 2014), long before I even knew it was called a Polar printer,

the idea came from old record player design where singles(layers of plastic) would be stacked,

I wanted it to look as much like a high-end record deck, glass platter & all,

at the time I thought it was unique concept, I had seen many 3D printers but none that worked or looked the same,

I had not seen the R-360 at the time, I put the images on GrabCad, It certainly was the first Polar machine on there.

Perhaps the serious producers where keeping theirs under wraps.

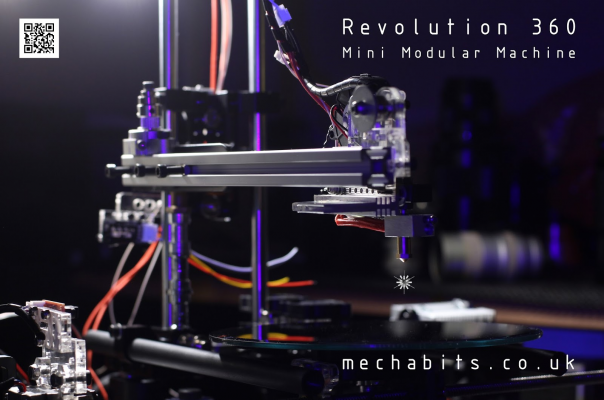

But as I knew I didnt have the skills to design the electronics/software combo the design went on the backburner,

now I see many more Polar printers surfacing, so with a little time passing the software becomes available,

so I've revisited the design/build. The first design was how I might want the item to look,

the current design has it's own personality(though you can remove the personality chip if you want

The first design led to many other designs, but the build has created a different looking beast,

Though it's continually evolving as new parts arrive, will replace the 2020 with some black 2040 vslot, probably wont use the vslots as rails, but handy to have the option.

I will have to take a look at the R-360 code and see if I can get it to control my prototype, I wonder if I should go 32bit, and if the Polar3D cloud will be open to outsiders? What I find strange about the Polar3D is that it moves the table rotary & linear, not something I wanted in my concept, but now I have the build with all these modular parts, including movement of the rotating table is easy,

I assume it was added to address the issue with the center? I wonder why it moves in X, rather than Y, if it matters?

Edited 2 time(s). Last edit at 03/20/2016 06:08AM by MechaBits.

the idea came from old record player design where singles(layers of plastic) would be stacked,

I wanted it to look as much like a high-end record deck, glass platter & all,

at the time I thought it was unique concept, I had seen many 3D printers but none that worked or looked the same,

I had not seen the R-360 at the time, I put the images on GrabCad, It certainly was the first Polar machine on there.

Perhaps the serious producers where keeping theirs under wraps.

But as I knew I didnt have the skills to design the electronics/software combo the design went on the backburner,

now I see many more Polar printers surfacing, so with a little time passing the software becomes available,

so I've revisited the design/build. The first design was how I might want the item to look,

the current design has it's own personality(though you can remove the personality chip if you want

The first design led to many other designs, but the build has created a different looking beast,

Though it's continually evolving as new parts arrive, will replace the 2020 with some black 2040 vslot, probably wont use the vslots as rails, but handy to have the option.

I will have to take a look at the R-360 code and see if I can get it to control my prototype, I wonder if I should go 32bit, and if the Polar3D cloud will be open to outsiders? What I find strange about the Polar3D is that it moves the table rotary & linear, not something I wanted in my concept, but now I have the build with all these modular parts, including movement of the rotating table is easy,

I assume it was added to address the issue with the center? I wonder why it moves in X, rather than Y, if it matters?

Edited 2 time(s). Last edit at 03/20/2016 06:08AM by MechaBits.

Sorry, only registered users may post in this forum.