2 MOTOR 3D PRINTER. 2 MOTORS FOR 3 ACCESSES.

Posted by mmiscool

|

2 MOTOR 3D PRINTER. 2 MOTORS FOR 3 ACCESSES. December 30, 2015 12:41PM |

Registered: 8 years ago Posts: 25 |

Hello,

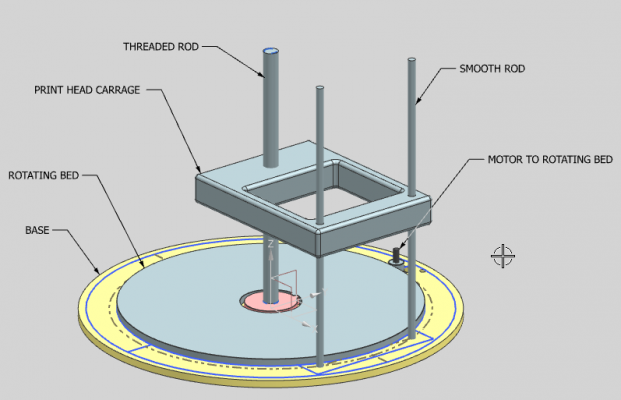

I started kicking around a concept for a supper cheap 3d printer last night.

It works with a rotating bed that when it dose a complete rotation it can move the vertical access.

I am not too familiar with all the firmware out there but this looked like it could be tweaked to be compatible.

[reprap.org]

I am attaching a few pictures of the concept.

Let me know what you think

Edited 1 time(s). Last edit at 12/30/2015 12:47PM by mmiscool.

I started kicking around a concept for a supper cheap 3d printer last night.

It works with a rotating bed that when it dose a complete rotation it can move the vertical access.

I am not too familiar with all the firmware out there but this looked like it could be tweaked to be compatible.

[reprap.org]

I am attaching a few pictures of the concept.

Let me know what you think

Edited 1 time(s). Last edit at 12/30/2015 12:47PM by mmiscool.

|

Re: 2 MOTOR 3D PRINTER. 2 MOTORS FOR 3 ACCESSES. February 08, 2016 03:40PM |

Registered: 11 years ago Posts: 471 |

|

Re: 2 MOTOR 3D PRINTER. 2 MOTORS FOR 3 ACCESSES. February 10, 2016 06:17PM |

Registered: 9 years ago Posts: 135 |

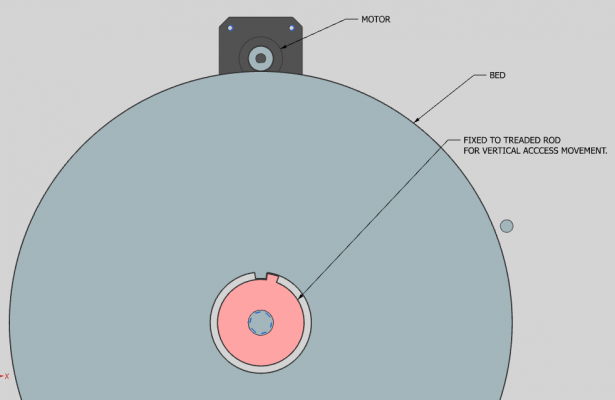

I think I see where the idea is going, the reason the plate is oddly coupled to the bed. He's relying on the z-carriage to stay in position via friction with the threaded rod while the bed goes through its printing movements, presumably uncoupled from the rod. Theoretically, it gets rid of the non-planar layer and anistropy problems, though it causes the printer to be locked into a layer height equal to the thread pitch. And as mentioned, the kinematics and slicing exist for polar printers already.

Meanwhile, in reality, any affordable thread pitch is huge compared to any kind of good layer height, spinning the bed 360o for each layer is time consuming, and friction isn't going to hold up the z-axis while there is vibration up there.

Meanwhile, in reality, any affordable thread pitch is huge compared to any kind of good layer height, spinning the bed 360o for each layer is time consuming, and friction isn't going to hold up the z-axis while there is vibration up there.

|

Re: 2 MOTOR 3D PRINTER. 2 MOTORS FOR 3 ACCESSES. February 24, 2016 05:17AM |

Admin Registered: 13 years ago Posts: 7,000 |

rotating bed has been done a few times...

[reprap.org]

[reprap.org]

Edited 2 time(s). Last edit at 02/24/2016 05:20AM by Dust.

[reprap.org]

[reprap.org]

Edited 2 time(s). Last edit at 02/24/2016 05:20AM by Dust.

|

Re: 2 MOTOR 3D PRINTER. 2 MOTORS FOR 3 ACCESSES. February 24, 2016 10:26PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: 2 MOTOR 3D PRINTER. 2 MOTORS FOR 3 ACCESSES. February 25, 2016 04:43PM |

Registered: 8 years ago Posts: 23 |

|

Re: 2 MOTOR 3D PRINTER. 2 MOTORS FOR 3 ACCESSES. February 26, 2016 08:58PM |

Registered: 13 years ago Posts: 20 |

Hey, that's a pretty clever idea, mmiscool.

I see that other people have talked about 3D printing with only 2 positioning motors (plus the extruder motor) at "3D printing with only 2 motors" ( [reprap.org] ).

But if I understand your concept, unlike those previous ideas that have the Z threaded rod rigidly attached to the rotating print bed, your initial design has a range of over 180 degrees of rotation that one motor can turn the print bed without affecting the Z threaded rod.

If I understand the concept:

One motor rotates the print bed.

During printing of one layer, normally the tooth on the print bed is nowhere near the tooth on the Z threaded rod, and we depend on the anti-backdrive-properties of the worm-gear to hold the Z threaded rod in position.

At the end of that layer, that motor rotates the print bed to exactly the position it was in the last time the tooth engaged with the Z threaded rod, turns the print bed *another* quarter turn, which causes the tooth on the print bed to push the tooth on the Z threaded rod enough to rotate that rod *another* quarter turn, which (with a standard "fine pitch" 8 mm threaded rod, which has 1 mm thread pitch) raises the print nozzle 0.25 mm, which is a standard layer height used by many people with a 0.5 mm nozzle.

(Alternatively, it could turn the print bed a half-turn every time, which with the same threaded rod raises the print nozzle 0.5 mm, which is a standard layer height used by many people with a 1.0 mm nozzle).

Then the motor rotates the print bed the opposite direction, which disengages the tooth,

turning far enough to return the part currently being printed to directly under the print nozzle.

Clever, I like it.

Does picking a layer height that tells it to turn the print bed exactly a quarter-turn between each layer restrict the build volume for a single part to a sector slightly less than 90 degrees of the print bed?

Because of symmetry, I'd be tempted to make 2 teeth a half-turn apart (or 3 teeth a third-turn apart, or 4 teeth a quarter-turn apart) (rather than just 1 tooth),

offset at various heights so the #1 tooth on the build plate only hits the #1 tooth on the Z threaded rod, and passes over or under the #2 and #3 teeth on the Z threaded rod.

I see that other people have talked about 3D printing with only 2 positioning motors (plus the extruder motor) at "3D printing with only 2 motors" ( [reprap.org] ).

But if I understand your concept, unlike those previous ideas that have the Z threaded rod rigidly attached to the rotating print bed, your initial design has a range of over 180 degrees of rotation that one motor can turn the print bed without affecting the Z threaded rod.

If I understand the concept:

One motor rotates the print bed.

During printing of one layer, normally the tooth on the print bed is nowhere near the tooth on the Z threaded rod, and we depend on the anti-backdrive-properties of the worm-gear to hold the Z threaded rod in position.

At the end of that layer, that motor rotates the print bed to exactly the position it was in the last time the tooth engaged with the Z threaded rod, turns the print bed *another* quarter turn, which causes the tooth on the print bed to push the tooth on the Z threaded rod enough to rotate that rod *another* quarter turn, which (with a standard "fine pitch" 8 mm threaded rod, which has 1 mm thread pitch) raises the print nozzle 0.25 mm, which is a standard layer height used by many people with a 0.5 mm nozzle.

(Alternatively, it could turn the print bed a half-turn every time, which with the same threaded rod raises the print nozzle 0.5 mm, which is a standard layer height used by many people with a 1.0 mm nozzle).

Then the motor rotates the print bed the opposite direction, which disengages the tooth,

turning far enough to return the part currently being printed to directly under the print nozzle.

Clever, I like it.

Does picking a layer height that tells it to turn the print bed exactly a quarter-turn between each layer restrict the build volume for a single part to a sector slightly less than 90 degrees of the print bed?

Because of symmetry, I'd be tempted to make 2 teeth a half-turn apart (or 3 teeth a third-turn apart, or 4 teeth a quarter-turn apart) (rather than just 1 tooth),

offset at various heights so the #1 tooth on the build plate only hits the #1 tooth on the Z threaded rod, and passes over or under the #2 and #3 teeth on the Z threaded rod.

|

Re: 2 MOTOR 3D PRINTER. 2 MOTORS FOR 3 ACCESSES. July 08, 2020 04:51PM |

Registered: 3 years ago Posts: 3 |

|

Re: 2 MOTOR 3D PRINTER. 2 MOTORS FOR 3 ACCESSES. July 08, 2020 05:10PM |

Admin Registered: 16 years ago Posts: 13,886 |

... we discussed different "2-motor" variants in the beginning (the wiki-page too is 10+ years old) and some were even tested -- all of this ideas died after some more development - it's simply not worth the fuzz ... a third driver+motor is much simpler to implement ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: 2 MOTOR 3D PRINTER. 2 MOTORS FOR 3 ACCESSES. July 08, 2020 08:33PM |

Registered: 8 years ago Posts: 25 |

Holly cow is this an old thread. I threw this out a few years ago.

VDX is correct that the cost of an extra motor is so low as to negate any need for such a design.

A much more interesting polar design can be seen here.

[www.youtube.com]

my latest project [autodrop3d.com]

VDX is correct that the cost of an extra motor is so low as to negate any need for such a design.

A much more interesting polar design can be seen here.

[www.youtube.com]

my latest project [autodrop3d.com]

|

Re: 2 MOTOR 3D PRINTER. 2 MOTORS FOR 3 ACCESSES. October 03, 2020 09:35AM |

Registered: 3 years ago Posts: 4 |

I bet you could do without a z axis motor on a common cartesian printer by sacrificing some bed space. suppose you had a wheel with 3-4 spokes overlapping the bed and crashed the head into a spoke each time to turn it a fraction. you could have a slip clutch on the spokes to provide some pressure against unintentional movement.

Edited 1 time(s). Last edit at 10/03/2020 09:35AM by gipetto.

Edited 1 time(s). Last edit at 10/03/2020 09:35AM by gipetto.

Sorry, only registered users may post in this forum.