Scara arm solution

Posted by idegraaf

|

Scara arm solution January 01, 2016 12:22PM |

Registered: 8 years ago Posts: 9 |

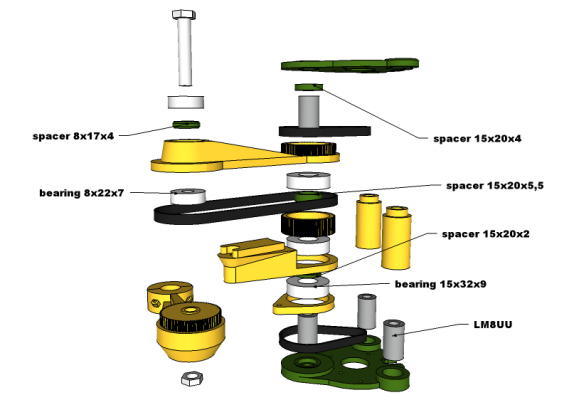

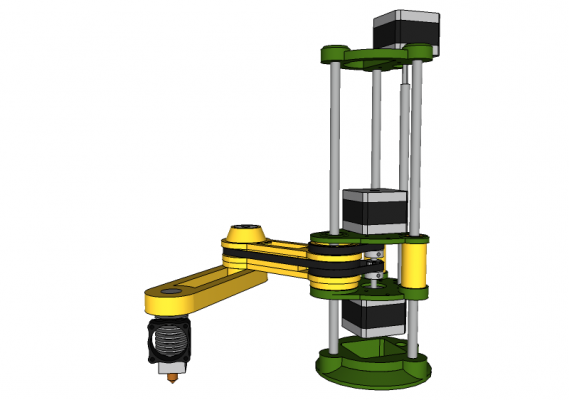

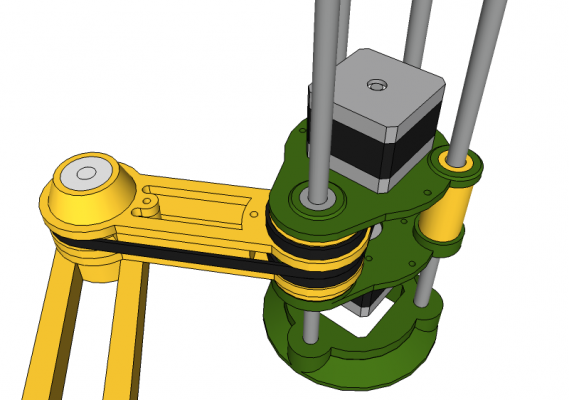

Picture says 1000 word. This arm is printable and uses just few bearing. What to you think.

Im not engineer and this is only 2-3 day work in sketchup

Im not engineer and this is only 2-3 day work in sketchup

|

Re: Scara arm solution January 04, 2016 04:18PM |

Registered: 8 years ago Posts: 76 |

|

Re: Scara arm solution January 06, 2016 03:03PM |

Registered: 9 years ago Posts: 127 |

Hi,

looks nice.

But:

What´s the size and range?

Have you calculated the expected accuracy? (Steps, angular resolution, etc.).

How do you do joint bearing and tensioning?

Arm droop is estimated?

How do you tension the belts?

What belts are you using? HTD ?

Where are the limit/position switches or encoders etc.?

Just curious...

Kind regards,

Mike

looks nice.

But:

What´s the size and range?

Have you calculated the expected accuracy? (Steps, angular resolution, etc.).

How do you do joint bearing and tensioning?

Arm droop is estimated?

How do you tension the belts?

What belts are you using? HTD ?

Where are the limit/position switches or encoders etc.?

Just curious...

Kind regards,

Mike

|

Re: Scara arm solution January 06, 2016 04:49PM |

Registered: 8 years ago Posts: 9 |

What´s the size and range?

Arm sizes is 100 & 100mm

Have you calculated the expected accuracy? (Steps, angular resolution, etc.).

No, testing and experimentation, and again ...

How do you do joint bearing and tensioning?

Arm droop is estimated?

Lets see.

How do you tension the belts?

There is the idea of tightening the belts from motors by rotating motor around one of the corner.

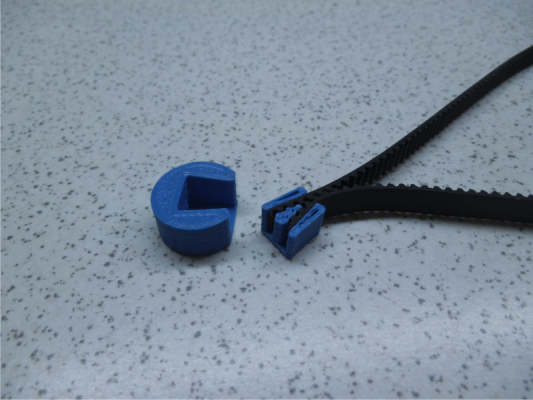

One folding point to another using self-made open belt connector.

Like this:

What belts are you using? HTD ?

GT2

Where are the limit/position switches or encoders etc.?

Not done yet.

No kidding ... it is not industrial.

Edited 4 time(s). Last edit at 01/06/2016 05:01PM by idegraaf.

Arm sizes is 100 & 100mm

Have you calculated the expected accuracy? (Steps, angular resolution, etc.).

No, testing and experimentation, and again ...

How do you do joint bearing and tensioning?

Arm droop is estimated?

Lets see.

How do you tension the belts?

There is the idea of tightening the belts from motors by rotating motor around one of the corner.

One folding point to another using self-made open belt connector.

Like this:

What belts are you using? HTD ?

GT2

Where are the limit/position switches or encoders etc.?

Not done yet.

No kidding ... it is not industrial.

Edited 4 time(s). Last edit at 01/06/2016 05:01PM by idegraaf.

|

Re: Scara arm solution January 06, 2016 08:16PM |

Registered: 11 years ago Posts: 1,049 |

Size -- I think we are asking size of printing area

area between stops or singularities?

Those don't look like standard bearings, spacers, pulleys?

Lot of machining there? You got lathe and mill?

Many use standard bearings

608ZZ Deep Groove Ball Bearings 8*22*7mm

8mm bolt as shaft

Look at eBay for ZZ type bearings that fit on standard bolts (Shafts)

Spacing two bearings wide apart on joint would make nice solid joint.

Your belts are probably continuous circle belts that should be tensioned by idler

or clamp the ends in pulley if less than 1 rev necessary.

This is Pull Pull system belts don't push so one side just pulls

Look at Wally it uses string drive

[www.youtube.com]

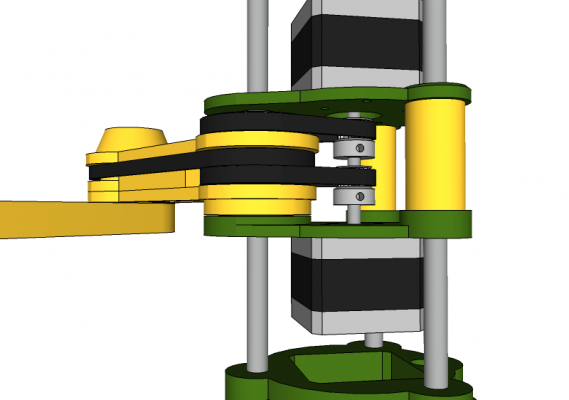

looks like 1 to 1 ratio on motor pulley to joint pulley --- it will have same resolution as motor.

small motor pulley to large pulley gets you better resolution

Good Luck

area between stops or singularities?

Those don't look like standard bearings, spacers, pulleys?

Lot of machining there? You got lathe and mill?

Many use standard bearings

608ZZ Deep Groove Ball Bearings 8*22*7mm

8mm bolt as shaft

Look at eBay for ZZ type bearings that fit on standard bolts (Shafts)

Spacing two bearings wide apart on joint would make nice solid joint.

Your belts are probably continuous circle belts that should be tensioned by idler

or clamp the ends in pulley if less than 1 rev necessary.

This is Pull Pull system belts don't push so one side just pulls

Look at Wally it uses string drive

[www.youtube.com]

looks like 1 to 1 ratio on motor pulley to joint pulley --- it will have same resolution as motor.

small motor pulley to large pulley gets you better resolution

Good Luck

|

Re: Scara arm solution January 07, 2016 09:54AM |

Registered: 9 years ago Posts: 127 |

Yeah,

Although internals and bearing contact areas are not visible, art of bearing seems to be promising.

I think GT2 is comparable with HTD, so no slip which is good.

The only thing to mention is still belt tensioning and reduction ratio (as cozmicray already meant, it will be fast but not THAT accurate,... OK acceleration might also not be perfect due to low torque). But you can calculate it.

What about an excentric belt tensioning idler, which sits inside the main arm? By Fixing it in a slightly excentrically rotated position, it presses the belt towards the outside...So you can use continuous circle belts.

Kind regards

Mike

Edited 1 time(s). Last edit at 01/07/2016 09:58AM by theothermike.

Although internals and bearing contact areas are not visible, art of bearing seems to be promising.

I think GT2 is comparable with HTD, so no slip which is good.

The only thing to mention is still belt tensioning and reduction ratio (as cozmicray already meant, it will be fast but not THAT accurate,... OK acceleration might also not be perfect due to low torque). But you can calculate it.

What about an excentric belt tensioning idler, which sits inside the main arm? By Fixing it in a slightly excentrically rotated position, it presses the belt towards the outside...So you can use continuous circle belts.

Kind regards

Mike

Edited 1 time(s). Last edit at 01/07/2016 09:58AM by theothermike.

|

Re: Scara arm solution April 10, 2016 01:51PM |

Registered: 9 years ago Posts: 10 |

Hi! A we so me idea man, I want to build one since I was a kid. What about making gears with more teeth? It will improve accuracy and reduce accumulative errors. Are the accumulative errors always the same? I mean: if we can make a scientific rule that aproximates to the value, the printer would be super accurate and fast. Looking forwards to see videos and more pics

Cheers!

Cheers!

|

Re: Scara arm solution April 11, 2016 03:16PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Scara arm solution April 11, 2016 03:27PM |

Registered: 8 years ago Posts: 9 |

|

Re: Scara arm solution April 12, 2016 04:40AM |

Registered: 9 years ago Posts: 127 |

|

Re: Scara arm solution April 12, 2016 05:17AM |

Registered: 8 years ago Posts: 9 |

|

Re: Scara arm solution January 13, 2017 06:47AM |

Registered: 7 years ago Posts: 1 |

Hello,

Thanks for the nice model and idea Idegraaf.

I see that there are more people try to use this model. On YouTube I found a russian guy with the same model working with marlin.

Youtube Movie Russian single arm scara

Blog

I am trying to make the same one. There are a few things I don`t understand.

How does marlin scara do the homing with the endstops and/or how can I test without homing? Now I don`t have control over the machine. I tried a lot things with endstops and changing some settings.

despite the explanation in the blog, it`s still hopeless.

Can some one give me some advice or help with the idea of endstops and marlin?

Thanks for the nice model and idea Idegraaf.

I see that there are more people try to use this model. On YouTube I found a russian guy with the same model working with marlin.

Youtube Movie Russian single arm scara

Blog

I am trying to make the same one. There are a few things I don`t understand.

How does marlin scara do the homing with the endstops and/or how can I test without homing? Now I don`t have control over the machine. I tried a lot things with endstops and changing some settings.

despite the explanation in the blog, it`s still hopeless.

Can some one give me some advice or help with the idea of endstops and marlin?

|

Re: Scara arm solution February 28, 2017 08:55PM |

Registered: 7 years ago Posts: 5 |

Firmware available here:

[github.com]

copy the folder "example_configurations" configuration Scara.

Adjust the settings to suit your own.

On the other firmware I have not worked Scara.

Marlin releases RC7, RC8 In parallel Scara not work!

Marlin releases RC1-RC6 work.

My site:

http://гребенюк-аа.рф/index.php/radioelectr/58-3d-printer?showall=&start=5

[github.com]

copy the folder "example_configurations" configuration Scara.

Adjust the settings to suit your own.

On the other firmware I have not worked Scara.

Marlin releases RC7, RC8 In parallel Scara not work!

Marlin releases RC1-RC6 work.

My site:

http://гребенюк-аа.рф/index.php/radioelectr/58-3d-printer?showall=&start=5

Sorry, only registered users may post in this forum.

; waiting the following, it's good to see other scara/arm projects!

; waiting the following, it's good to see other scara/arm projects!