Scara with DuetWifi => Scarlette3D

Posted by frafa

|

Scara with DuetWifi => Scarlette3D September 29, 2017 06:05AM |

Registered: 8 years ago Posts: 4 |

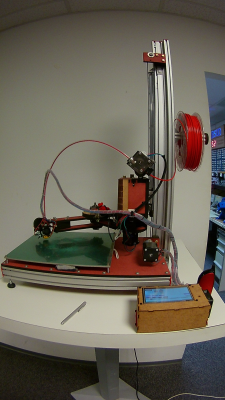

Implementation of a 3D printer based on the Scara kinematics

Video Youtube: https://youtu.be/mBF5cO8vGhI

I am "Maker" – among others – within LABSud, the FabLab in Montpellier, with a passionate interest in 3D printing.

I designed several 3D printer models notably the "I3 LABSud" derivative of the "I3 Prusa", which allowed us to equip the workshops of the Lab members.

I wanted to create a novel model, entirely based upon the experience I was able to gain inside the FabLab,

and after numerous creations I turned toward the Scara kinematics, aiming at building an Open-Source model duplicable with the means of the FabLab.

This open kinematics allows – among other features – a relatively easy re-dimensioning of a 3D printer !

After several tests to validate this kinematics, my choice went to the electronic driver "Duet Wifi" developed by David Crocker's, who provides full Open-Source boards and firmware.

When I decided to use ReprapFirmware, the support of the Scara printers was not completely finalized, but within a month he fully completed the support of the various Scara kinematics in use.

Thus was born the Scarlette 3D printer, and you can watch here its first presentation in video.

The Scara kinematics advantages are :

easy re-dimensioning of the printers;

capability to function without a tray, for example in case of a large printer fixed on a table or a wall;

relative simplicity of the mechanics;

aesthetic and open design.

And the disadvantages :

precision loss when the arm is stretched out;

Command algorithm more difficult to tune. But David Crocker's work almost entirely removed all these drawbacks !

A special thank to David Crocker's for his efficient reactiveness to improve the RepRapFirmware in order for me to complete the Scarlette 3D development

My printer was recently chosen by the YovoTogo, JUMP Lab'Orione, and Emmabuntüs associations to equip, in 2018, the future FabLab of Dapaong located in the savanna area of North Togo, and I hope to see it – later on – equip other FabLab in Africa

To make a greater use of the Scarlette 3D printer, the blueprints are available here, and you can find hereafter the list of the components used for its design :

Duet WiFi board using the RepRapFirmware ;

Display 5" Paneldue ;

Temperature sensor PT100 ;

Daughter Board for the PT100 sensor ;

"IR Sense" sensor used for Z0 & Auto-Levelling ;

Hall effect limit switch sensor for both arms ;

Nozzle E3D-V6 bowden for 3mm filament (using a size of 1.75mm could be better with a Titan extruder) ;

Titan extruder from E3D ;

Power supply DC 12V 150W ;

Extruded aluminum structure Motedis I-Type rainure 5 ;

Arm motors : Stepperonline 0.9deg Nema 17 bipolar motor 2A 4.6kg/cm 17HM19-2004S ;

Z motor : Nema 17 1.68A Planet ratio 19:1 17HS19-1684S-PG19 ;

Silicone bed Kenovo 30X30CM 750W@220V ;

Pulley GT2 16 teeth for both arms ;

Pulley GT2 20 teeth, 8mm axis, for the Z motor ;

Two 608ZZ bearings for the Z drive ;

Frame plug 220 Volts with fuse and switch with indicator light.

Remark : The red parts of the Bed are made of 8mm thick red Valcromat, trimmed with the FabLab laser cutting (co2 130 watts).

Links:

http://openhardware.eu/wordpress/scarlette3d/

https://sourceforge.net/projects/openhardware-eu/files/Scarlette3D/

https://youtu.be/mBF5cO8vGhI

https://www.duet3d.com/forum/thread.php?id=1847

https://www.duet3d.com/DuetWifi

My English is bad

it is a friend who translated this text from the French ...

Edited 4 time(s). Last edit at 09/29/2017 06:47PM by frafa.

Video Youtube: https://youtu.be/mBF5cO8vGhI

I am "Maker" – among others – within LABSud, the FabLab in Montpellier, with a passionate interest in 3D printing.

I designed several 3D printer models notably the "I3 LABSud" derivative of the "I3 Prusa", which allowed us to equip the workshops of the Lab members.

I wanted to create a novel model, entirely based upon the experience I was able to gain inside the FabLab,

and after numerous creations I turned toward the Scara kinematics, aiming at building an Open-Source model duplicable with the means of the FabLab.

This open kinematics allows – among other features – a relatively easy re-dimensioning of a 3D printer !

After several tests to validate this kinematics, my choice went to the electronic driver "Duet Wifi" developed by David Crocker's, who provides full Open-Source boards and firmware.

When I decided to use ReprapFirmware, the support of the Scara printers was not completely finalized, but within a month he fully completed the support of the various Scara kinematics in use.

Thus was born the Scarlette 3D printer, and you can watch here its first presentation in video.

The Scara kinematics advantages are :

easy re-dimensioning of the printers;

capability to function without a tray, for example in case of a large printer fixed on a table or a wall;

relative simplicity of the mechanics;

aesthetic and open design.

And the disadvantages :

precision loss when the arm is stretched out;

Command algorithm more difficult to tune. But David Crocker's work almost entirely removed all these drawbacks !

A special thank to David Crocker's for his efficient reactiveness to improve the RepRapFirmware in order for me to complete the Scarlette 3D development

My printer was recently chosen by the YovoTogo, JUMP Lab'Orione, and Emmabuntüs associations to equip, in 2018, the future FabLab of Dapaong located in the savanna area of North Togo, and I hope to see it – later on – equip other FabLab in Africa

To make a greater use of the Scarlette 3D printer, the blueprints are available here, and you can find hereafter the list of the components used for its design :

Duet WiFi board using the RepRapFirmware ;

Display 5" Paneldue ;

Temperature sensor PT100 ;

Daughter Board for the PT100 sensor ;

"IR Sense" sensor used for Z0 & Auto-Levelling ;

Hall effect limit switch sensor for both arms ;

Nozzle E3D-V6 bowden for 3mm filament (using a size of 1.75mm could be better with a Titan extruder) ;

Titan extruder from E3D ;

Power supply DC 12V 150W ;

Extruded aluminum structure Motedis I-Type rainure 5 ;

Arm motors : Stepperonline 0.9deg Nema 17 bipolar motor 2A 4.6kg/cm 17HM19-2004S ;

Z motor : Nema 17 1.68A Planet ratio 19:1 17HS19-1684S-PG19 ;

Silicone bed Kenovo 30X30CM 750W@220V ;

Pulley GT2 16 teeth for both arms ;

Pulley GT2 20 teeth, 8mm axis, for the Z motor ;

Two 608ZZ bearings for the Z drive ;

Frame plug 220 Volts with fuse and switch with indicator light.

Remark : The red parts of the Bed are made of 8mm thick red Valcromat, trimmed with the FabLab laser cutting (co2 130 watts).

Links:

http://openhardware.eu/wordpress/scarlette3d/

https://sourceforge.net/projects/openhardware-eu/files/Scarlette3D/

https://youtu.be/mBF5cO8vGhI

https://www.duet3d.com/forum/thread.php?id=1847

https://www.duet3d.com/DuetWifi

My English is bad

it is a friend who translated this text from the French ...

Edited 4 time(s). Last edit at 09/29/2017 06:47PM by frafa.

|

Re: Scara with DuetWifi => Scarlette3D September 30, 2017 03:11AM |

Registered: 10 years ago Posts: 14,672 |

I especially like the way you have anchored the belts into slots in the large wheels, to avoid needing to buy large diameter pulleys. Are the wheels made of wood? How many steps per degree does this arrangement give you, and at what microstepping?

What is the maximum radius that can be reached by the nozzle? It looks to me that you might be able to increase the bed width to 400mm or perhaps even wider. Then you could print in an area of about 400 X 200mm as well as 300 X 300.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

What is the maximum radius that can be reached by the nozzle? It looks to me that you might be able to increase the bed width to 400mm or perhaps even wider. Then you could print in an area of about 400 X 200mm as well as 300 X 300.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Scara with DuetWifi => Scarlette3D September 30, 2017 03:08PM |

Registered: 8 years ago Posts: 4 |

Hello david,

Yes I also like my pulleys (reduct 160:16), more more needs of belts closed !

5 layers of laser cut 2mm thick mdf and GT2 straps of 10mm high

I am not good in mathematics, better in mechanics: p

I think the bed could be no problem 220x400 I think.

Yes I also like my pulleys (reduct 160:16), more more needs of belts closed !

5 layers of laser cut 2mm thick mdf and GT2 straps of 10mm high

I am not good in mathematics, better in mechanics: p

I think the bed could be no problem 220x400 I think.

|

Re: Scara with DuetWifi => Scarlette3D October 05, 2017 05:18AM |

Registered: 8 years ago Posts: 76 |

salut François,

bravo! je vois que ton projet scara a bien avancé (voire terminé?)

Par contre, je n'avais pas vu le détail de tes poulies: en fait il n'y pas besoin de dents sur les poulies où la courroie est attachée (c'est pour cela que j'avais fais ce système sur mon projet auto-réplicable: les poulies GT2 ne sont pas bien imprimées en FDM)

@bientôt

Patrice

PS: faut vraiment que je passe au lab ;-)

bravo! je vois que ton projet scara a bien avancé (voire terminé?)

Par contre, je n'avais pas vu le détail de tes poulies: en fait il n'y pas besoin de dents sur les poulies où la courroie est attachée (c'est pour cela que j'avais fais ce système sur mon projet auto-réplicable: les poulies GT2 ne sont pas bien imprimées en FDM)

@bientôt

Patrice

PS: faut vraiment que je passe au lab ;-)

Sorry, only registered users may post in this forum.