... sourcing parts for a parallel SCARA

Posted by VDX

|

... sourcing parts for a parallel SCARA December 05, 2019 03:15PM |

Admin Registered: 16 years ago Posts: 13,886 |

Hi all,

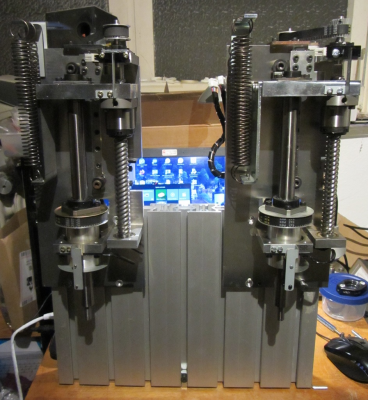

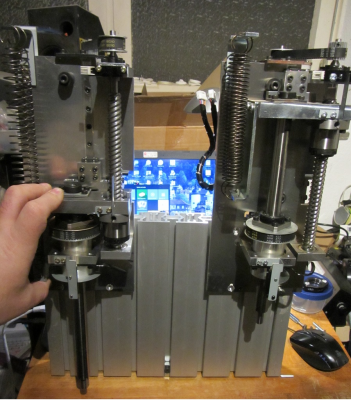

... got some interesting parts from a friend, perfectly suited for building a parallel SCARA

This are Z+A axes from industrial dispensers, so two of them with synchronized moving in Z and rotating the "arm-shoulders" are the "core" of the parallel SCARA:

The steppers are Vexta 5-phase types, so will replace them wit 2-pase-steppers, for lack of 5-ph-drivers ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

... got some interesting parts from a friend, perfectly suited for building a parallel SCARA

This are Z+A axes from industrial dispensers, so two of them with synchronized moving in Z and rotating the "arm-shoulders" are the "core" of the parallel SCARA:

The steppers are Vexta 5-phase types, so will replace them wit 2-pase-steppers, for lack of 5-ph-drivers ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: ... sourcing parts for a parallel SCARA December 19, 2019 07:22AM |

Registered: 8 years ago Posts: 1,671 |

you'll be balancing pens in no time [www.youtube.com]

|

Re: ... sourcing parts for a parallel SCARA December 19, 2019 04:47PM |

Admin Registered: 16 years ago Posts: 13,886 |

... not my intention - but will allow a 4DOF parallel SCARA, if allowed for "skewing" the working plane between the two "shoulders"

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: ... sourcing parts for a parallel SCARA December 21, 2019 04:54AM |

Registered: 5 years ago Posts: 155 |

|

Re: ... sourcing parts for a parallel SCARA December 21, 2019 03:31PM |

Admin Registered: 16 years ago Posts: 13,886 |

... hmmm ... could be a variant too -- have a Duet2 Ethernet lying around ... have to swap all 5-phase steppers for bipolar ones then ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: ... sourcing parts for a parallel SCARA December 21, 2019 04:09PM |

Registered: 5 years ago Posts: 155 |

RRF 3 is possible for Duet 2 Ethernet. I have created a RRF 2 version already for parallel Scara which is tested by user bondus, but without your idea of screwing.

Please tell me when you are sure whether want to implement it. I don't want to waste time if you don't use it. But I will implement it if you want to use it.

The current documentation is in [duet3d.dozuki.com]

and the current RRF 2 firmware is in [github.com]

Please tell me when you are sure whether want to implement it. I don't want to waste time if you don't use it. But I will implement it if you want to use it.

The current documentation is in [duet3d.dozuki.com]

and the current RRF 2 firmware is in [github.com]

|

Re: ... sourcing parts for a parallel SCARA December 21, 2019 05:29PM |

Admin Registered: 16 years ago Posts: 13,886 |

... actually simple plain movement would be OK - the "skewing" is only a theoretical option ... should be much easier with a separate tilt+pan unit on the table ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: ... sourcing parts for a parallel SCARA December 21, 2019 05:49PM |

Registered: 5 years ago Posts: 155 |

Then you can use the RRF2 version and in January I'll migrate to RRF3 and make a push to the official RRF. I have a Duet 2 and 3 and will test with both.

The skewing has the disadvantate that it tilts only into specific directions. I am not sure whether it's worth using or better implement separate axes at the hotend/tool point. The skewing angle changes with position, which makes kinematic more complex. But I already thought about two Z axis actuators to support calibration in respect to the print bed.

The skewing has the disadvantate that it tilts only into specific directions. I am not sure whether it's worth using or better implement separate axes at the hotend/tool point. The skewing angle changes with position, which makes kinematic more complex. But I already thought about two Z axis actuators to support calibration in respect to the print bed.

Sorry, only registered users may post in this forum.