Home

>

Developers

>

Topic

THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF…

Posted by Lalo

|

THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… October 21, 2011 04:32PM |

Registered: 12 years ago Posts: 10 |

Dear Friends:

I think this Open Source project probably could have a future if this Rep Rap system is more like inkjet printing with a line of printing with many nozzles, or better, an area of printing; so we could to obtain one layer at a time. With this the printing can be faster. Also, the quality could be improved if the base where we build the prototype have a circular motion for to do manufacture of prototype with circular symmetry, and if the paddle is similar to the Contour Crafting, so we could to create on the outside a surface with better quality.

Another idea that I have is that also we could to use a robotic arm like a 3d printer, in a similar way with the Contour Crafting method, only that now we would to use a minor robotic arm for to buid prototypes in minor scale, using in a similar way a side trowel with a paddle that help to obtain a better surface with a better precision. This could be more fast if first we construct the shell of the prototype, and after we can fill with a special nozzle with a fast rate.

Thanks and have a nice day,

Eduardo

I think this Open Source project probably could have a future if this Rep Rap system is more like inkjet printing with a line of printing with many nozzles, or better, an area of printing; so we could to obtain one layer at a time. With this the printing can be faster. Also, the quality could be improved if the base where we build the prototype have a circular motion for to do manufacture of prototype with circular symmetry, and if the paddle is similar to the Contour Crafting, so we could to create on the outside a surface with better quality.

Another idea that I have is that also we could to use a robotic arm like a 3d printer, in a similar way with the Contour Crafting method, only that now we would to use a minor robotic arm for to buid prototypes in minor scale, using in a similar way a side trowel with a paddle that help to obtain a better surface with a better precision. This could be more fast if first we construct the shell of the prototype, and after we can fill with a special nozzle with a fast rate.

Thanks and have a nice day,

Eduardo

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… October 21, 2011 06:08PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Eduardo,

... please avoid flooding the forum with the same posts in different sub-categories - i've deleted the other threads

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

... please avoid flooding the forum with the same posts in different sub-categories - i've deleted the other threads

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… October 21, 2011 07:30PM |

Registered: 12 years ago Posts: 4 |

I am certainly no expert, but I think your first idea has already been done. It is called polymer thermojet, and I admit that ZCorp's Z450/Z510/Z650 are some a rather impressive machines. Also, don't forget the Open3DP project, but they are still in the process of creating an open inkjet printer. However, I think even ZCorp would agree that they are not in the same market space as FDM. Meaning, the FDM technique is great for light production ready parts whereas inkjet based parts are mostly used for presentation of what the future product would look like.

I would agree that the current multi-head approach is not an ideal approach, and there is allot of work going on here. I personally have been working on a multi-head changer (currently the ability of 10 heads) and it does work, but very slight extruder head movements on each loading is causing some big headaches and head changing is too slow due to the z-axis acme screw. Because of this, I am forced to make minor tweets every time a new head is loaded which is got me trying to rethink the homing technique. We currently calibrate the bed in reference to the gantry, but ideally with a multi-head changer you want to calibrate the bed in reference to the extruder nozzle itself which would eliminate the minor movements on each extruder head change. One big advantage I have found with a multi-head changer design, however, is that individual heads can be readied while the current extruder is still working which in theory could be a big time savings in some cases.

On your second idea, articulated robot, parallel / delta manipulator designs have all been tried, but there are numerous reasons why CNC mills are not just giant articulated robot arms. Linear actuator designs might not be the space age design of the day, but they are cheap, proven, and reliable designs. Meaning, why fix something that is not broken?

I would agree that the current multi-head approach is not an ideal approach, and there is allot of work going on here. I personally have been working on a multi-head changer (currently the ability of 10 heads) and it does work, but very slight extruder head movements on each loading is causing some big headaches and head changing is too slow due to the z-axis acme screw. Because of this, I am forced to make minor tweets every time a new head is loaded which is got me trying to rethink the homing technique. We currently calibrate the bed in reference to the gantry, but ideally with a multi-head changer you want to calibrate the bed in reference to the extruder nozzle itself which would eliminate the minor movements on each extruder head change. One big advantage I have found with a multi-head changer design, however, is that individual heads can be readied while the current extruder is still working which in theory could be a big time savings in some cases.

On your second idea, articulated robot, parallel / delta manipulator designs have all been tried, but there are numerous reasons why CNC mills are not just giant articulated robot arms. Linear actuator designs might not be the space age design of the day, but they are cheap, proven, and reliable designs. Meaning, why fix something that is not broken?

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… October 22, 2011 04:21AM |

Registered: 13 years ago Posts: 7,616 |

"... will have a future only if ..."

What a nonsense. There's no point in discussing stuff under such a headline.

What a nonsense. There's no point in discussing stuff under such a headline.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… October 25, 2011 03:19PM |

Admin Registered: 17 years ago Posts: 179 |

Crappy title and not well thought out.

If we made the thing from bamboo and tin cans it would have a bigger future because it would be more easily replicated by poor people. Putting RepRaps in areas with limited resources is a Good Idea because those people are going to be more focused on what they have and will innovate out of necessity.

This is not about toys for rich, white guys.

Vik :v)

If we made the thing from bamboo and tin cans it would have a bigger future because it would be more easily replicated by poor people. Putting RepRaps in areas with limited resources is a Good Idea because those people are going to be more focused on what they have and will innovate out of necessity.

This is not about toys for rich, white guys.

Vik :v)

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… October 26, 2011 02:10AM |

Admin Registered: 13 years ago Posts: 730 |

I have an informal design challenge. I've been thinking about it for a while and here is as good a place to post it as any. Vik's comment inspired me.

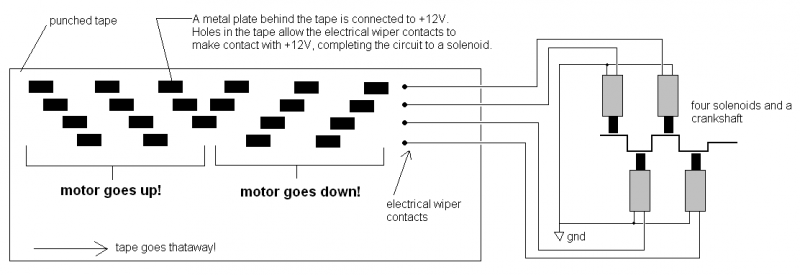

Summary - The VORBAT Challenge: Build a reprap entirely from scrap without any electronics other than hand-wound coils. The instructions are stored in a punched paper tape, which plays back trajectories directly to the motors, as in a player piano, early CNC machine tool, or Jacquard loom.

Details - Now I know design challenges have a checkered history of success around here (informal or not (this is not meant to be a knock at the Vertical X Axis contest [www.reprap.org] which is chugging along nicely)) but to add sure-fire publicity to my challenge I am going to name it after Vik. It is the VORBAT Challenge. Which stands for Vik Oliver's Reprap Bamboo And Tincan Challenge! (not meant to be a knock at Vik, either, and if he is annoyed at the name I will change it )

)

First we're going to imagine the tools and materials used by people who work in a shop like this:

[hackaday.com]

Let's say basic hand tools - hacksaw, hand drill, hammers, files, screwdrivers, various scrap sheet steel and steel barstock (hopefully including some threaded rod), plastic and glass bottles, all kinds of wood, bits and pieces of old appliances and automobiles, paper, fabric, and lots of insulated wire (imagine it unwound from an automobile alternator or ignition coil), and 12V batteries. Also bamboo and tin cans.

Let's say also a source of plastic filament is at hand - farfetched I know, but suppose it is produced locally from recycled bottles/bags and/or fermented from potatoes, or substituted by wax-impregnated string, or molten glass, or extruded clay or whatever. Just go with me on this one.

Now we are going to make a reprap.

Well sure, you say. We'll carve some brackets, we'll cut up some rod, we'll magically obtain a kit with some steppers and electronics and an extruder and we're off to the races; it's called a RepStrap, no big deal...

NO. That doesn't count. Now, this next part is going to be hard for any of you electrical engineer types to stomach, but hear me out on this; you will still get to have a lot of fun on this project. You cannot use a microprocessor. You cannot use a PC. You cannot use an SD card or an LCD or a transistor (not a single one!) or an LED or any piece of electronics that can't be built with wire and steel (but hand-built relays are OK).

How will you make a motor? You will make four hand-wound solenoids and make a stepper motor like this: [reprap.org]

How will you control motors? With a punch tape like a player piano. See the uploaded picture. It's all there (well, mostly).

How will you make the extruder heater? With a big wirewound copper heating coil.

How will you control extruder heater? I don't know... How about open loop? How a about a bimetal thermostat? [en.wikipedia.org]

How will you make gears? Your first set will have to be carved by hand. Or you can use belts and pulleys.

What is left for those EE's to do? We'll need a computer-science-type to write a GCODE to PunchTape compiler. We'll need someone else to make an automatic punch-tape puncher with an arduino, some motors and a hole punch. (see I told you there was still fun for the EEs). In fact, any bored EE/CS types can run some numbers right now. Take your favorite STL file and its associated GCODE, make some assumptions about the tape and hole dimensions and so on, and calculate how big the tape would be. Is this even feasible?

If you imagine something like this working, it would open up several cottage industries:

1. making and maintaining printers

2. making stuff with the printers

3. making feedstock material

4. creating and maintaining libraries of punched tapes

This is old school, people. The automatic loom folks had it done a hundred years ago and they didn't even use electricity [en.wikipedia.org] . Same with the player piano [en.wikipedia.org] . Computer Numerical Control [en.wikipedia.org] was invented in the 50's and all they had was a box of relays and some vacuum tubes. You guys with your new fangled computers and lasers and 3D printers should have this done in a couple of weeks. Any takers?

Summary - The VORBAT Challenge: Build a reprap entirely from scrap without any electronics other than hand-wound coils. The instructions are stored in a punched paper tape, which plays back trajectories directly to the motors, as in a player piano, early CNC machine tool, or Jacquard loom.

Details - Now I know design challenges have a checkered history of success around here (informal or not (this is not meant to be a knock at the Vertical X Axis contest [www.reprap.org] which is chugging along nicely)) but to add sure-fire publicity to my challenge I am going to name it after Vik. It is the VORBAT Challenge. Which stands for Vik Oliver's Reprap Bamboo And Tincan Challenge! (not meant to be a knock at Vik, either, and if he is annoyed at the name I will change it

)

)First we're going to imagine the tools and materials used by people who work in a shop like this:

[hackaday.com]

Let's say basic hand tools - hacksaw, hand drill, hammers, files, screwdrivers, various scrap sheet steel and steel barstock (hopefully including some threaded rod), plastic and glass bottles, all kinds of wood, bits and pieces of old appliances and automobiles, paper, fabric, and lots of insulated wire (imagine it unwound from an automobile alternator or ignition coil), and 12V batteries. Also bamboo and tin cans.

Let's say also a source of plastic filament is at hand - farfetched I know, but suppose it is produced locally from recycled bottles/bags and/or fermented from potatoes, or substituted by wax-impregnated string, or molten glass, or extruded clay or whatever. Just go with me on this one.

Now we are going to make a reprap.

Well sure, you say. We'll carve some brackets, we'll cut up some rod, we'll magically obtain a kit with some steppers and electronics and an extruder and we're off to the races; it's called a RepStrap, no big deal...

NO. That doesn't count. Now, this next part is going to be hard for any of you electrical engineer types to stomach, but hear me out on this; you will still get to have a lot of fun on this project. You cannot use a microprocessor. You cannot use a PC. You cannot use an SD card or an LCD or a transistor (not a single one!) or an LED or any piece of electronics that can't be built with wire and steel (but hand-built relays are OK).

How will you make a motor? You will make four hand-wound solenoids and make a stepper motor like this: [reprap.org]

How will you control motors? With a punch tape like a player piano. See the uploaded picture. It's all there (well, mostly).

How will you make the extruder heater? With a big wirewound copper heating coil.

How will you control extruder heater? I don't know... How about open loop? How a about a bimetal thermostat? [en.wikipedia.org]

How will you make gears? Your first set will have to be carved by hand. Or you can use belts and pulleys.

What is left for those EE's to do? We'll need a computer-science-type to write a GCODE to PunchTape compiler. We'll need someone else to make an automatic punch-tape puncher with an arduino, some motors and a hole punch. (see I told you there was still fun for the EEs). In fact, any bored EE/CS types can run some numbers right now. Take your favorite STL file and its associated GCODE, make some assumptions about the tape and hole dimensions and so on, and calculate how big the tape would be. Is this even feasible?

If you imagine something like this working, it would open up several cottage industries:

1. making and maintaining printers

2. making stuff with the printers

3. making feedstock material

4. creating and maintaining libraries of punched tapes

This is old school, people. The automatic loom folks had it done a hundred years ago and they didn't even use electricity [en.wikipedia.org] . Same with the player piano [en.wikipedia.org] . Computer Numerical Control [en.wikipedia.org] was invented in the 50's and all they had was a box of relays and some vacuum tubes. You guys with your new fangled computers and lasers and 3D printers should have this done in a couple of weeks. Any takers?

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… October 26, 2011 05:18AM |

Registered: 13 years ago Posts: 7,616 |

Quote

calculate how big the tape would be. Is this even feasible?

A rough estimate for one hour of printing. Assuming the stepper runs at 30 mm/s, which is considered to be slow these days, and forwards the carriage at 8 steps/mm, the value typical for half-stepping, you have

1 hour * 60 * 60 = 3600 seconds 3600 seconds * 30 mm/second * 8 steps/mm = 864000 steps

If you manage to do one punch every 5 mm of paper, you have a trail of 4320 m, which has to be run at roughly 1 mph (extremly fast) through the sensor. 4320 m at 50 mm wide, this is just short of 20 kilograms, using typewriter paper (90 g/m^2). To print a Prusa Mendel set, which takes some 20 hours, AFAIK, almost half a metric ton of paper is required.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… October 26, 2011 06:46AM |

Admin Registered: 16 years ago Posts: 13,884 |

... when i started college in 1982 some of the Profs were busy converting their Fortran77-programs from puncher-cards to floppies or diskdrives.

My advisor had a cabinet full of cards - converted some hundred kilobytes on a handfull of floppies!

Check the byte-space needed for a common print and check the price of a SD-card with 2GB capacity

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

My advisor had a cabinet full of cards - converted some hundred kilobytes on a handfull of floppies!

Check the byte-space needed for a common print and check the price of a SD-card with 2GB capacity

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… October 26, 2011 10:31AM |

Admin Registered: 13 years ago Posts: 730 |

Well, OK. So on first glance it looks like this would take a prohibitive amount of paper (thanks Traumflug!  )

)

But let me ask you this: How much paper would it take to store one single layer? There are many useful parts that are composed from many repetitions of only a few different layers.

For example, look at the Prusa parts [reprap.org]

"y-motor-bracket" could be done with one or two unique layers.

"pulley" could be done in three or four.

"x-end-motor" maybe in ten.

Of course if you want to do "pla-bushing" you're in trouble.

Suppose maybe you can fit a layer on a little roll of "cash register paper" (2.25 inch by 150 feet) (?)

Then you take ten little rolls, each with a different layer, and you add a master roll, which controls the sequences of layers and the numbers of times they are repeated. I bet you can store some pretty complicated parts on eleven little rolls of paper.

There are other weirder ways to do "low tech data compression" but I can post those later.

Also - if you want to save time on rewinding the punch tape, you can just play it forward and play it backward and you'll end up where you started.

)

)But let me ask you this: How much paper would it take to store one single layer? There are many useful parts that are composed from many repetitions of only a few different layers.

For example, look at the Prusa parts [reprap.org]

"y-motor-bracket" could be done with one or two unique layers.

"pulley" could be done in three or four.

"x-end-motor" maybe in ten.

Of course if you want to do "pla-bushing" you're in trouble.

Suppose maybe you can fit a layer on a little roll of "cash register paper" (2.25 inch by 150 feet) (?)

Then you take ten little rolls, each with a different layer, and you add a master roll, which controls the sequences of layers and the numbers of times they are repeated. I bet you can store some pretty complicated parts on eleven little rolls of paper.

There are other weirder ways to do "low tech data compression" but I can post those later.

Also - if you want to save time on rewinding the punch tape, you can just play it forward and play it backward and you'll end up where you started.

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… October 26, 2011 11:03AM |

Registered: 12 years ago Posts: 10 |

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… October 26, 2011 11:18AM |

Registered: 12 years ago Posts: 187 |

MattMoses Wrote:

-------------------------------------------------------

> But let me ask you this: How much paper would it

> take to store one single layer?

It depends on how large the layer is.

Using Traumflug's 8 steps/mm and 1 punch per 5mm of paper.

It works out at 40mm of paper per 1mm on a layer.

Just get your layer size then times it by 40 to get the mm of paper per layer.

My Reprap blog

jds-reprap.blogspot.com

-------------------------------------------------------

> But let me ask you this: How much paper would it

> take to store one single layer?

It depends on how large the layer is.

Using Traumflug's 8 steps/mm and 1 punch per 5mm of paper.

It works out at 40mm of paper per 1mm on a layer.

Just get your layer size then times it by 40 to get the mm of paper per layer.

My Reprap blog

jds-reprap.blogspot.com

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… October 26, 2011 03:36PM |

Admin Registered: 17 years ago Posts: 179 |

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… October 26, 2011 06:05PM |

Registered: 13 years ago Posts: 632 |

But then when the said poor person is ready to design a new part that he/she needs to become the village supplier of trinkets and corner the market on thumb screw holders, does he/she need to contract with a 3D designer who has a computer to do the design and then with a EE to translate the design into punch cards? Would the cost of such a process equal the cost to buy motors and electronics from abroad? Perhaps binary design on punch cards from the beginning is simpler than I am thinking?

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… October 26, 2011 08:47PM |

Admin Registered: 13 years ago Posts: 730 |

Vik - Did you post pictures of the cam setup at one point long ago? It sounds vaguely familiar. The Solar Sinter guy (Markus Kayser) used cams to control one of his machines and it is really a lot of fun to watch [www.markuskayser.com]

While cams are simpler, punchtape has the advantage that it is a true digital medium and hence has a higher tolerance to errors in copying (i.e. a hole in the tape that is slightly mis-placed or mis-shapen it is still interpreted as a hole) whereas minor analog imperfections incurred during the copying of a cam are passed on to the next generation, and accumulate over time.

bryanandaimee - Looking at the recycling shops seen in this video [blog.thingiverse.com] I get the impression that the cost of buying *anything* from abroad is impossibly high. What if there was a systematic way to build repraps from junked electronics? (as an aside a good source of magnet wire might be the deflection yokes in old CRT TVs)

It seems like these shops have a lot of human-power. What if people just write their gcode by hand, layer by layer? Machinists wrote gcode by hand for decades before CAD/CAM became widespread. Transcribing gcode to punchtape is tedious but could be done manually if you have enough time. EEs, PCs, and programmers can speed up the process but they are optional

While cams are simpler, punchtape has the advantage that it is a true digital medium and hence has a higher tolerance to errors in copying (i.e. a hole in the tape that is slightly mis-placed or mis-shapen it is still interpreted as a hole) whereas minor analog imperfections incurred during the copying of a cam are passed on to the next generation, and accumulate over time.

bryanandaimee - Looking at the recycling shops seen in this video [blog.thingiverse.com] I get the impression that the cost of buying *anything* from abroad is impossibly high. What if there was a systematic way to build repraps from junked electronics? (as an aside a good source of magnet wire might be the deflection yokes in old CRT TVs)

It seems like these shops have a lot of human-power. What if people just write their gcode by hand, layer by layer? Machinists wrote gcode by hand for decades before CAD/CAM became widespread. Transcribing gcode to punchtape is tedious but could be done manually if you have enough time. EEs, PCs, and programmers can speed up the process but they are optional

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… October 26, 2011 10:51PM |

Registered: 13 years ago Posts: 1,352 |

VORBAT challenge in the Cameroon context.

We use 1 kiddo for X axis, another kiddo for Y axis, and a third kiddo for Z axis. The last one can be a young female, because it has to work only now and then. We make the design with a pencil on the bed and ask them to move to those directions. We put the bed directly on top of the fire. Note the temperature control is automatic because the X and Y kiddos will just have to raise it when their fingers get hot. Extruder can be an adult with some recycled plastic and a lighter in the other hand. Here is a smile which by coincidence it looks just like how this will work

I reckon this way is slightly more realistic and might get results faster than the half of metric ton of paper made into punch cards, which would have to be re-written all over again after each rain season.

I hope i made someone smile, thats what i was going for

Edited 1 time(s). Last edit at 10/26/2011 10:55PM by NoobMan.

We use 1 kiddo for X axis, another kiddo for Y axis, and a third kiddo for Z axis. The last one can be a young female, because it has to work only now and then. We make the design with a pencil on the bed and ask them to move to those directions. We put the bed directly on top of the fire. Note the temperature control is automatic because the X and Y kiddos will just have to raise it when their fingers get hot. Extruder can be an adult with some recycled plastic and a lighter in the other hand. Here is a smile which by coincidence it looks just like how this will work

I reckon this way is slightly more realistic and might get results faster than the half of metric ton of paper made into punch cards, which would have to be re-written all over again after each rain season.

I hope i made someone smile, thats what i was going for

Edited 1 time(s). Last edit at 10/26/2011 10:55PM by NoobMan.

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… October 27, 2011 11:08PM |

Admin Registered: 13 years ago Posts: 730 |

With a few reasonable compromises, the VORBAT paper punchtape requirements become feasible, at least from a proof-of-principle standpoint.

The key assumption is that you have a model that can be built up from repetitions of a small number of unique layers.

How much do you need for layer storage? Suppose our layer is a 75mm square. Coarse resolution is acceptable for this project, so let us assume an extruded filament width of 1mm. That gives 75 * 75 = 5625mm of extruded filament per layer. Let us use 2 steps per mm (coarser than Traumflug's 8 steps per mm but for this project 2 steps/mm is ok). So we need 11,250 steps per layer. Supposing we need 5mm of punchtape per step, we need 56250mm (185ft) of tape to store one layer.

How wide does the tape need to be? We need 4 rows of holes for X, 4 for Y, and 4 for the extruder. The Z-axis is controlled by the layer coordination tape (the master tape). Let us say 5mm again for the row spacing. So the punchtape width must be at least 12*5 = 60mm (2.36 inch).

So one layer will easily fit on a 3-1/8 inch by 230 foot roll of paper tape. This is a common size for cash register paper (do a search for "thermal paper rolls").

How fast does the paper have to feed through the reader? Assuming the extruder moves at Traumflug's value of 30mm/s, the paper will have to feed at 300mm/s. That is reasonable.

Now, it is cheating of course to use off-the-shelf thermal paper in a true VORBAT. But for debugging and proof-of-principle it would work well.

Advantage 1) Thermal paper is cheap and available.

Advantage 2) It can be found in the right size.

Advantage 3) You can make a quick optical reader that goes direct from optosensor to Mosfet to stepper, so you don't have to mess with making electrical contacts.

Advantage 4) You can hack a thermal printer to automatically print out your converted Gcode directly on the tape!

After an optical version is working we could work on making an electromechanical one. See [hackaday.com] for some info on thermal printer hacks.

The key assumption is that you have a model that can be built up from repetitions of a small number of unique layers.

How much do you need for layer storage? Suppose our layer is a 75mm square. Coarse resolution is acceptable for this project, so let us assume an extruded filament width of 1mm. That gives 75 * 75 = 5625mm of extruded filament per layer. Let us use 2 steps per mm (coarser than Traumflug's 8 steps per mm but for this project 2 steps/mm is ok). So we need 11,250 steps per layer. Supposing we need 5mm of punchtape per step, we need 56250mm (185ft) of tape to store one layer.

How wide does the tape need to be? We need 4 rows of holes for X, 4 for Y, and 4 for the extruder. The Z-axis is controlled by the layer coordination tape (the master tape). Let us say 5mm again for the row spacing. So the punchtape width must be at least 12*5 = 60mm (2.36 inch).

So one layer will easily fit on a 3-1/8 inch by 230 foot roll of paper tape. This is a common size for cash register paper (do a search for "thermal paper rolls").

How fast does the paper have to feed through the reader? Assuming the extruder moves at Traumflug's value of 30mm/s, the paper will have to feed at 300mm/s. That is reasonable.

Now, it is cheating of course to use off-the-shelf thermal paper in a true VORBAT. But for debugging and proof-of-principle it would work well.

Advantage 1) Thermal paper is cheap and available.

Advantage 2) It can be found in the right size.

Advantage 3) You can make a quick optical reader that goes direct from optosensor to Mosfet to stepper, so you don't have to mess with making electrical contacts.

Advantage 4) You can hack a thermal printer to automatically print out your converted Gcode directly on the tape!

After an optical version is working we could work on making an electromechanical one. See [hackaday.com] for some info on thermal printer hacks.

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… October 28, 2011 06:07AM |

Registered: 13 years ago Posts: 7,616 |

An optical sensor requires semiconductors. To some extent I get the impression, getting printable semiconductors to work is closer than getting a punch tape up to speed.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… October 28, 2011 12:31PM |

Registered: 12 years ago Posts: 10 |

I think that if in the Rep Rap project want to do a system for rapid manufacture, then we do not have to discover the boiled water. We have to take systems that are already working and to do reverse engineering, because what we want to create must be accessible to most people, easier, practical and cheaper than currently exists.

As you said, probably the system multi –nozzles printer inkjet system is very complicated to do, but I think we could take the idea of contour crafting with a robotic arm to make the outline design (layer profiles and possibly some hatching patterns, in a similar way like the SIS method: [www-bcf.usc.edu]) of the prototype that we want to build, exploiting the property that gives its shovel to define very good surfaces, and use another nozzles filler faster internal parts. It makes no sense and is more expensive, inefficient and time consuming to try to create a prototype with high definition for the inner part. The conceptual idea is first to create the shell and then fill it with more speed. As if you are creating its mold mold. Also, this system could be used to create cast metal molds. Probably not a good method to create high definition small parts in detail, but at some scale could be very useful for creating machines and tools.

Pictures in anex

On the other hand, if you want a design on a smaller scale, has created its own 3D Printer - High Resolution – Homemade,

[www.youtube.com]

this technology work with Digital Light Processing (DLP), curing the polymers with UV light:

[www.makepartsfast.com]

and I think that we could use the same technique for to do Sintering and/or casting of metals using Leds or Lasers.

Thanks and have a good day,

As you said, probably the system multi –nozzles printer inkjet system is very complicated to do, but I think we could take the idea of contour crafting with a robotic arm to make the outline design (layer profiles and possibly some hatching patterns, in a similar way like the SIS method: [www-bcf.usc.edu]) of the prototype that we want to build, exploiting the property that gives its shovel to define very good surfaces, and use another nozzles filler faster internal parts. It makes no sense and is more expensive, inefficient and time consuming to try to create a prototype with high definition for the inner part. The conceptual idea is first to create the shell and then fill it with more speed. As if you are creating its mold mold. Also, this system could be used to create cast metal molds. Probably not a good method to create high definition small parts in detail, but at some scale could be very useful for creating machines and tools.

Pictures in anex

On the other hand, if you want a design on a smaller scale, has created its own 3D Printer - High Resolution – Homemade,

[www.youtube.com]

this technology work with Digital Light Processing (DLP), curing the polymers with UV light:

[www.makepartsfast.com]

and I think that we could use the same technique for to do Sintering and/or casting of metals using Leds or Lasers.

Thanks and have a good day,

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… October 31, 2011 01:19PM |

Registered: 12 years ago Posts: 3 |

I think the VORBAT Challenge is quite cool/fun concept, but would actually agree more with NoobMan’s methodology. I don’t mean burning them all alive, but don’t use motors don’t use some crazy complex punch tape CNC’esk method.

It looks like they could knock up some chunky gears, a sturdy frame, maybe they can get some threaded rod but I bet would be easier to use some belt driven system, maybe a ratchet for the Z axis.

Then have a few guys working the machine, some one turning the generator to power hotend. A couple people controlling the X and Y axis (by hand), keep the extruder stationery so the filament can be fed in by hand.

And then keep time from essentially a product song book, i.e. 10 turns right, 5 turns left, pause etc..

It looks like they could knock up some chunky gears, a sturdy frame, maybe they can get some threaded rod but I bet would be easier to use some belt driven system, maybe a ratchet for the Z axis.

Then have a few guys working the machine, some one turning the generator to power hotend. A couple people controlling the X and Y axis (by hand), keep the extruder stationery so the filament can be fed in by hand.

And then keep time from essentially a product song book, i.e. 10 turns right, 5 turns left, pause etc..

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… November 01, 2011 01:13PM |

Registered: 13 years ago Posts: 1,352 |

I was really joking about exploiting children for reprap purposes, even if my humor is really bad.

If someone wants to promote reprap in distant locations away from power grid, and wants to make a challenge for that purpose, then instead make something that can produce a little juice by itself.

Sunpower is nice but i think was already done, plus it aint anything to design about that unless some1 makes fotovoltaic cells printable on reprap.

Wind mill or water mill design, that would be better areas. Say it should be very sturdy design, still reprap printable, and designed to also power a reprap by itself. Also would include electronics, probably minus battery pack - as a temporary accumulator / buffer, maybe just link to one already existant on an automobile, should be a fair assumption that a car would be nearby since i dont see any1 running into the wild with a reprap and some filament carried on the backpack.

So it ends up with two things, a water mill and a wind mill both capable of producing electricity enough to run a reprap machine, and as such, those might be adopted, documented on wiki, and considered a first choice when somebody needs something like that, in time could improve, etc. Which at least could have a potential future. Better than just going into the past.

If someone wants to promote reprap in distant locations away from power grid, and wants to make a challenge for that purpose, then instead make something that can produce a little juice by itself.

Sunpower is nice but i think was already done, plus it aint anything to design about that unless some1 makes fotovoltaic cells printable on reprap.

Wind mill or water mill design, that would be better areas. Say it should be very sturdy design, still reprap printable, and designed to also power a reprap by itself. Also would include electronics, probably minus battery pack - as a temporary accumulator / buffer, maybe just link to one already existant on an automobile, should be a fair assumption that a car would be nearby since i dont see any1 running into the wild with a reprap and some filament carried on the backpack.

So it ends up with two things, a water mill and a wind mill both capable of producing electricity enough to run a reprap machine, and as such, those might be adopted, documented on wiki, and considered a first choice when somebody needs something like that, in time could improve, etc. Which at least could have a potential future. Better than just going into the past.

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… November 03, 2011 09:31AM |

Registered: 12 years ago Posts: 35 |

I realise it's a bit more manual than the punchtape method, but how about if each layer were to be milled/routed by hand, at say 10 times the size, in MDF/ hardwood/floorboards etc. You could then use a pantograph arrangement to plot the extruder around the bed. Use a foot-pedel to turn the extruder feed (spinnng/pottery wheel style), and maybe let air out of a set of bellows to drop the bed away from the nozzle?

The disadvantages are that it requires an operator or 2, and of course the master-plates for each layer take up a lot of space (Unless the layers were drawn on paper, in a book. Then the operator just has to trace it!).

The disadvantages are that it requires an operator or 2, and of course the master-plates for each layer take up a lot of space (Unless the layers were drawn on paper, in a book. Then the operator just has to trace it!).

|

Re: this Rep Rap Project will have a future only if… November 03, 2011 11:48AM |

Registered: 13 years ago Posts: 8 |

Lalo, i see that most people here forget the original statement you were trying to make. I will try to answer your questions as clear as i can.

Reprap has a future. It is here, and growing fast. Improvements are being made on a daily basis. The main focus is still on the FFF way of producing smallish objects out of threads of molten plastics, but other groups are looking at different machines.

They just have not gotten their project up to the point where everybody can build and use one. If people want to join their cause, it is possible to contact them, and offer expertise, or try to build the machine themselves with some of the same principles in mind. Whoever makes it easy enough that people get interested in making it, and improving it from that point.

Your idea would be a good way to produce some parts, and i look forward to your first explanations and examples of such a machine. I'm glad you are taking the lead on this, as there is no such effort going on till now as far as i know. I'm sure that when you show us how, a lot of people will build it. Your machine will become a force to reckon with within the project.

That is how the Mendel design came to be. It was designed to be much easier than the Darwin, so people started building it. Then the Prusa design came along, building on the then renamed "Sells" Mendel, and improving its build and print time, so it can be built in a weekend. It also lowered its cost. This is where we are now, and the interest in the project is growing a lot, because we provide usable results, and a clear way to get there.

So what im saying is: Your idea is good, it should surely be investigated. But that will only be to provide an alternative, as the RepRap project is living its future already. Your idea would just alter it, as soon as you publish the build info. Then it could grow even faster, and reach more people. That would surely be a Good Thing.

Remember, the layered look of most objects are:

-optional, there are low layer skinned projects around where you cannot even see the individual layers with the naked eye.

-subject to fashion, imagine a ribbed AppPhone, and the fashion shift it would make

-beautiful, dont you think?

P.S. Using only capital letters in the title is like SCREAMING!! Thank you for not doing that again.

The VORBAT challenge looks like a Rube Goldberg machine to me, as this would then still not be a feasible way to get more production into the hands of people with less means to spend hundreds of Euro's on new materials. I propose a way to look at what the people have available locally, and try to make the things we need out of that. There are landfills at almost all locations filled with plastics and all kind of materials, use those. There have been many things that have been thrown out because they dont fulfill their original function anymore, but could do lots more.

Like the project that makes a lathe with a VW motor block as a basis. These can be found anywhere in the world, and can be used even if badly damaged.

Using this as a basis there are tutorials to make lots more tools, of which a RepStrap could be one. This would not only bring the use of 3D printing to people, but a lot of means to personally produce. OpenSourceMachine

From that basis it would even be possible to set up a complete system like the Global Village Construction Set and pave the way to live in a open way.

I think any effort used on this challenge would be better directed into these areas, but that is only my opinion, others may, and hopefully will differ.

Reprap has a future. It is here, and growing fast. Improvements are being made on a daily basis. The main focus is still on the FFF way of producing smallish objects out of threads of molten plastics, but other groups are looking at different machines.

They just have not gotten their project up to the point where everybody can build and use one. If people want to join their cause, it is possible to contact them, and offer expertise, or try to build the machine themselves with some of the same principles in mind. Whoever makes it easy enough that people get interested in making it, and improving it from that point.

Your idea would be a good way to produce some parts, and i look forward to your first explanations and examples of such a machine. I'm glad you are taking the lead on this, as there is no such effort going on till now as far as i know. I'm sure that when you show us how, a lot of people will build it. Your machine will become a force to reckon with within the project.

That is how the Mendel design came to be. It was designed to be much easier than the Darwin, so people started building it. Then the Prusa design came along, building on the then renamed "Sells" Mendel, and improving its build and print time, so it can be built in a weekend. It also lowered its cost. This is where we are now, and the interest in the project is growing a lot, because we provide usable results, and a clear way to get there.

So what im saying is: Your idea is good, it should surely be investigated. But that will only be to provide an alternative, as the RepRap project is living its future already. Your idea would just alter it, as soon as you publish the build info. Then it could grow even faster, and reach more people. That would surely be a Good Thing.

Remember, the layered look of most objects are:

-optional, there are low layer skinned projects around where you cannot even see the individual layers with the naked eye.

-subject to fashion, imagine a ribbed AppPhone, and the fashion shift it would make

-beautiful, dont you think?

P.S. Using only capital letters in the title is like SCREAMING!! Thank you for not doing that again.

The VORBAT challenge looks like a Rube Goldberg machine to me, as this would then still not be a feasible way to get more production into the hands of people with less means to spend hundreds of Euro's on new materials. I propose a way to look at what the people have available locally, and try to make the things we need out of that. There are landfills at almost all locations filled with plastics and all kind of materials, use those. There have been many things that have been thrown out because they dont fulfill their original function anymore, but could do lots more.

Like the project that makes a lathe with a VW motor block as a basis. These can be found anywhere in the world, and can be used even if badly damaged.

Using this as a basis there are tutorials to make lots more tools, of which a RepStrap could be one. This would not only bring the use of 3D printing to people, but a lot of means to personally produce. OpenSourceMachine

From that basis it would even be possible to set up a complete system like the Global Village Construction Set and pave the way to live in a open way.

I think any effort used on this challenge would be better directed into these areas, but that is only my opinion, others may, and hopefully will differ.

|

Re: this Rep Rap Project will have a future only if… November 05, 2011 11:42AM |

Registered: 12 years ago Posts: 10 |

Dear Sikko, thans Thanks for reading my letter and your reply.

I was actually screaming because this is a Babel tower, and nobody listens. I had already given up, until you respond. I'm not a specialist in this area of technology, I'm from another area, but from my experience I know that does not have to reinvent the wheel if you want to develop a technology as sophisticated as a 3D printer, if we want that this technology may be possible in the future, and anyone can use it. You can take the experience of other projects such as the personal computer. They did not begin building an abacus, then move on to the computer of bulbs, etc.. They took the microprocessor to make it smaller, and gathered all the advances like graphical user interface, mouse, etc. I think that the people of the Open Source Machine and Open Source Ecology projets, knew this, and began in the most advanced of the technology, and took the best of each one doing reverse engineering.

Thank you and have a nice day,

I was actually screaming because this is a Babel tower, and nobody listens. I had already given up, until you respond. I'm not a specialist in this area of technology, I'm from another area, but from my experience I know that does not have to reinvent the wheel if you want to develop a technology as sophisticated as a 3D printer, if we want that this technology may be possible in the future, and anyone can use it. You can take the experience of other projects such as the personal computer. They did not begin building an abacus, then move on to the computer of bulbs, etc.. They took the microprocessor to make it smaller, and gathered all the advances like graphical user interface, mouse, etc. I think that the people of the Open Source Machine and Open Source Ecology projets, knew this, and began in the most advanced of the technology, and took the best of each one doing reverse engineering.

Thank you and have a nice day,

|

Re: this Rep Rap Project will have a future only if… November 06, 2011 12:45AM |

Admin Registered: 17 years ago Posts: 179 |

I don't mean to be rude, but in the Open Source world saying "You project will only work if..." or "I'd use your software but..." generally gets ignored.

People who actually care will say "how do I change the program to..." or "is anybody working on..."

Again, no offence intended.

Vik :v)

People who actually care will say "how do I change the program to..." or "is anybody working on..."

Again, no offence intended.

Vik :v)

|

Re: this Rep Rap Project will have a future only if… November 07, 2011 07:50AM |

Registered: 12 years ago Posts: 10 |

|

Re: this Rep Rap Project will have a future only if… November 08, 2011 02:57PM |

Registered: 13 years ago Posts: 8 |

Lalo Wrote:

-------------------------------------------------------

> I was actually screaming because this is a Babel tower, and nobody listens.

Lots of people listen, but its difficult to reply to somebody just screaming : "YOU ARE DOING IT WRONG! YOU SHOULD BE LIKE A PROFESSIONAL" We are trying another way, and we are doing well. In my vision even because we are not trying to be professional.

> things that you are doing could be made in a professional way, to make things work.

And here we go again, im trying not to repeat myself, but it already works. There are thousands of RepRap's being made, and more are printing now, delivering high quality items that exactly fulfill their maker's needs.

Doing things "Professional" means "lowest quality people will accept" most of the time. Because we do not need to be professional, we can be just as good as we want to be.

If there are professionals developing items of actual worth in a faster rate, show me which ones. The "Professional" way has been tried and tested, and seems to lead to stagnation and low cost over quality. Innovation lately has been very slow lately in the commercial range, more like incremental upgrades dependent on price drops of fabrication. Invention is being discouraged by the stiffling effect of patents, and lawsuits in general.

RepRap is not a product, it is a project.

People who use it are not consumers, they are individuals with a need, to which RepRap offers a solution. Some people seem to think it needs to be perfect from the beginning, but we offer real change today, not some shady vision of the future.

Im glad we are not "Professionals" here, and do this because we have passion for it.

OSHW is following in the footsteps of OSS, where people who can afford the best, end up with projects using open solutions, and just the consumers stay with the products, not caring how bad they have become.

They try to save a penny, and while doing that they end up paying much more than they are saving, just in small increments.

Be glad that we can take things in our own hands now, and are no longer bound by the ideas of big companies and their PR agency's. Make! Create! Express yourself! Live.

We will get to your idea at some point, and maybe you will be the one showing us. If it has merits, there will always be somebody running with it. So make a prototype, and make our jaw's drop. Lots of people will jump in. Try it out.

-------------------------------------------------------

> I was actually screaming because this is a Babel tower, and nobody listens.

Lots of people listen, but its difficult to reply to somebody just screaming : "YOU ARE DOING IT WRONG! YOU SHOULD BE LIKE A PROFESSIONAL" We are trying another way, and we are doing well. In my vision even because we are not trying to be professional.

> things that you are doing could be made in a professional way, to make things work.

And here we go again, im trying not to repeat myself, but it already works. There are thousands of RepRap's being made, and more are printing now, delivering high quality items that exactly fulfill their maker's needs.

Doing things "Professional" means "lowest quality people will accept" most of the time. Because we do not need to be professional, we can be just as good as we want to be.

If there are professionals developing items of actual worth in a faster rate, show me which ones. The "Professional" way has been tried and tested, and seems to lead to stagnation and low cost over quality. Innovation lately has been very slow lately in the commercial range, more like incremental upgrades dependent on price drops of fabrication. Invention is being discouraged by the stiffling effect of patents, and lawsuits in general.

RepRap is not a product, it is a project.

People who use it are not consumers, they are individuals with a need, to which RepRap offers a solution. Some people seem to think it needs to be perfect from the beginning, but we offer real change today, not some shady vision of the future.

Im glad we are not "Professionals" here, and do this because we have passion for it.

OSHW is following in the footsteps of OSS, where people who can afford the best, end up with projects using open solutions, and just the consumers stay with the products, not caring how bad they have become.

They try to save a penny, and while doing that they end up paying much more than they are saving, just in small increments.

Be glad that we can take things in our own hands now, and are no longer bound by the ideas of big companies and their PR agency's. Make! Create! Express yourself! Live.

We will get to your idea at some point, and maybe you will be the one showing us. If it has merits, there will always be somebody running with it. So make a prototype, and make our jaw's drop. Lots of people will jump in. Try it out.

|

Re: THIS REP RAP PROJECT WILL HAVE A FUTURE ONLY IF… November 11, 2011 03:56PM |

Registered: 12 years ago Posts: 10 |

Dear Friend Sicko, certainly I don´t want to cause annoyance or insult or disrespect anyone, nor reduce the value of your effort and creativity. I´m sorry, I apologize, probably we had a culture crash.

But, in my opinion, if your idea was to create a toy for a personal use, I totally agree with you. But if the idea was to create a 3D printer to solve the problem of access to technology in underdeveloped world, I think that's necessary to create a more advanced technology to the existing actually, but not only that, but must also be able to be used by anyone, anywhere.

I think that this is the idea because I read the following article (annexed in attachment):

3-D Printing of Open Source Appropriate Technologies for Self-Directed Sustainable Development.

I really believe in this project, so I'm trying to participate.

My research area is about Nanotechnology Computational Modeling, therefore I have not experience in robotic area, but I have experience according as it does in my technology area. According to my own experience with the application of scientific method, we need first to take the references of previous work and from them we began our research, trying to improve what is already done, and brings it closer to a technological application. We did not start from zero, because otherwise we run the risk of repeating what is done, and so we will not progress. Just as Einstein said about the Science, but also could be applied to Technology:

Creating a new theory is not like destroying an old barn and erecting a skyscraper in its place. It is rather like climbing a mountain, gaining new and wider views, discovering unexpected connections between our starting point and its rich environment. But the point from which we started out still exists and can be seen, although it appears smaller and forms a tiny part of our broad view gained by the mastery of the obstacles on our adventurous way up.

We must learn to use a scientific method, otherwise it becomes a Babel tower, where everybody talks and nobody listens. What Einstein meant is that science (and technology) are created by additions of ideas and constructive criticisms, where each person can contribute with a right part of your idea. For example, the Classical Dynamic from Newton was not invalid for the General Relativity from Einsten, only was corrected or improved for high speeds and intense gravity. Therefore, I think that we need to learn to listen all people, and take the best that everyone can contribute to create a collective intelligence. We have to overcome the traditional method of struggle of ideas, and the dichotomy of true against false, for a constructive thinking.

Therefore, we need build on past experience to make it feasible in the near future this Open Source technology for everyone.

This guy has achieved a breakthrough: [www.youtube.com]

Thanks and have a nice day

But, in my opinion, if your idea was to create a toy for a personal use, I totally agree with you. But if the idea was to create a 3D printer to solve the problem of access to technology in underdeveloped world, I think that's necessary to create a more advanced technology to the existing actually, but not only that, but must also be able to be used by anyone, anywhere.

I think that this is the idea because I read the following article (annexed in attachment):

3-D Printing of Open Source Appropriate Technologies for Self-Directed Sustainable Development.

I really believe in this project, so I'm trying to participate.

My research area is about Nanotechnology Computational Modeling, therefore I have not experience in robotic area, but I have experience according as it does in my technology area. According to my own experience with the application of scientific method, we need first to take the references of previous work and from them we began our research, trying to improve what is already done, and brings it closer to a technological application. We did not start from zero, because otherwise we run the risk of repeating what is done, and so we will not progress. Just as Einstein said about the Science, but also could be applied to Technology:

Creating a new theory is not like destroying an old barn and erecting a skyscraper in its place. It is rather like climbing a mountain, gaining new and wider views, discovering unexpected connections between our starting point and its rich environment. But the point from which we started out still exists and can be seen, although it appears smaller and forms a tiny part of our broad view gained by the mastery of the obstacles on our adventurous way up.

We must learn to use a scientific method, otherwise it becomes a Babel tower, where everybody talks and nobody listens. What Einstein meant is that science (and technology) are created by additions of ideas and constructive criticisms, where each person can contribute with a right part of your idea. For example, the Classical Dynamic from Newton was not invalid for the General Relativity from Einsten, only was corrected or improved for high speeds and intense gravity. Therefore, I think that we need to learn to listen all people, and take the best that everyone can contribute to create a collective intelligence. We have to overcome the traditional method of struggle of ideas, and the dichotomy of true against false, for a constructive thinking.

Therefore, we need build on past experience to make it feasible in the near future this Open Source technology for everyone.

This guy has achieved a breakthrough: [www.youtube.com]

Thanks and have a nice day

Sorry, only registered users may post in this forum.