How do we both encourage RepRap mutations and stay focussed?

Posted by Adrian Bowyer

|

Re: How do we both encourage RepRap mutations and stay focussed? July 02, 2012 04:20AM |

Registered: 12 years ago Posts: 1,236 |

|

Re: How do we both encourage RepRap mutations and stay focussed? July 02, 2012 04:58AM |

Registered: 11 years ago Posts: 15 |

Hi Bobc,

Its not about printing cubes at all, it is about improving 3D printing and printers. What would be pointless? Why would standards be pointless? As I was explaining earlier, you are welcome to ignore the standards, no need for you to follow them.

I am using Metric as well as Imperial as some is people reading this may not be on the metric system. I use both.

Please see my refrence earlier: Here is one definition of standard: "something considered by an authority or by general consent as a basis of comparison" Without a cube nobody can compare easily, nor classify the print envelope.

Rgrds & best

Sarel Wagner

www.microafrica.co.za

Tinkerer and designer/inventor

Its not about printing cubes at all, it is about improving 3D printing and printers. What would be pointless? Why would standards be pointless? As I was explaining earlier, you are welcome to ignore the standards, no need for you to follow them.

I am using Metric as well as Imperial as some is people reading this may not be on the metric system. I use both.

Please see my refrence earlier: Here is one definition of standard: "something considered by an authority or by general consent as a basis of comparison" Without a cube nobody can compare easily, nor classify the print envelope.

Rgrds & best

Sarel Wagner

www.microafrica.co.za

Tinkerer and designer/inventor

|

Re: How do we both encourage RepRap mutations and stay focussed? July 02, 2012 02:25PM |

Registered: 11 years ago Posts: 3 |

Hello Sarel,

I think you are a losing a lot of information with your cube standard.

I you take the paper for example, it is not classified by square size, but by paper format. This means it is both a size and a ratio. If you take an extract of the wikipedia page about paper formats :

"ISO paper sizes are all based on a single aspect ratio of square root of 2, or approximately 1:1.4142. The base A0 size of paper is defined to have an area of one m²." (http://en.wikipedia.org/wiki/Paper_size)

So, an equivalent for 3D shapes should include the aspect ratio (but considering 3 dimensions here), and the size.

But which ratio to use ? There should be several in my mind. Some people may want to print cubes, but a lot will prefer to print several pieces at a time (so a large area to fit in several pieces, with a heigh of only one piece).

A solution may be to use letters for ratios (X/Z, and Y/Z), and a number for the Z size.

As an example : if A means 1 ratio, and B means 2 ratio, a AB10 printer would be able to print a X=10cm,Y=20cm, Z=10cm volume. (this doesn't take into account the fact ratio can be lower than 1, and that integer numbers are probably not the best. Ax paper is defined with a square root).

Another solution, is to define the bed size and the height. I have a A4 bed with a 15cm heigh, so it would gives a 15A4 sized printer ? I can see that I can print as many pieces on a 20A4 printer (but they can be taller), and twice as many on a 10A3 (but limited to 10cm in height).

I really don't think theses ideas are usable enough, but it is to show that the cube shape is really not enough to define a print volume.

But finally, why is there a paper standard ? For inter-operability : you can buy a A4 sheet from one paper seller, then print it on an A4 printer from another seller, and finally put it inside an envelope that fit.

Here on the 3D printer size, I don't see anything like this : you don't feed paper on which you put ink, you only feed plastic on the bed. This could be used to defined the bed size, but the height is not important then.

Where I see a lot of interoperability problems (so where standard helps) is somewhere else. G-Code for example, as I want to use slic3r to generate G-Code for my custom made electronics board. You already have a lot of standard for electronics, like communication protocols or connectors. There is also some such compatibility issues for mechanical parts, if you want to reuse some parts.

These are only my thoughts about this subject, hoping it can helps.

I think you are a losing a lot of information with your cube standard.

I you take the paper for example, it is not classified by square size, but by paper format. This means it is both a size and a ratio. If you take an extract of the wikipedia page about paper formats :

"ISO paper sizes are all based on a single aspect ratio of square root of 2, or approximately 1:1.4142. The base A0 size of paper is defined to have an area of one m²." (http://en.wikipedia.org/wiki/Paper_size)

So, an equivalent for 3D shapes should include the aspect ratio (but considering 3 dimensions here), and the size.

But which ratio to use ? There should be several in my mind. Some people may want to print cubes, but a lot will prefer to print several pieces at a time (so a large area to fit in several pieces, with a heigh of only one piece).

A solution may be to use letters for ratios (X/Z, and Y/Z), and a number for the Z size.

As an example : if A means 1 ratio, and B means 2 ratio, a AB10 printer would be able to print a X=10cm,Y=20cm, Z=10cm volume. (this doesn't take into account the fact ratio can be lower than 1, and that integer numbers are probably not the best. Ax paper is defined with a square root).

Another solution, is to define the bed size and the height. I have a A4 bed with a 15cm heigh, so it would gives a 15A4 sized printer ? I can see that I can print as many pieces on a 20A4 printer (but they can be taller), and twice as many on a 10A3 (but limited to 10cm in height).

I really don't think theses ideas are usable enough, but it is to show that the cube shape is really not enough to define a print volume.

But finally, why is there a paper standard ? For inter-operability : you can buy a A4 sheet from one paper seller, then print it on an A4 printer from another seller, and finally put it inside an envelope that fit.

Here on the 3D printer size, I don't see anything like this : you don't feed paper on which you put ink, you only feed plastic on the bed. This could be used to defined the bed size, but the height is not important then.

Where I see a lot of interoperability problems (so where standard helps) is somewhere else. G-Code for example, as I want to use slic3r to generate G-Code for my custom made electronics board. You already have a lot of standard for electronics, like communication protocols or connectors. There is also some such compatibility issues for mechanical parts, if you want to reuse some parts.

These are only my thoughts about this subject, hoping it can helps.

|

Re: How do we both encourage RepRap mutations and stay focussed? July 02, 2012 04:17PM |

Registered: 11 years ago Posts: 15 |

Thank you for taking the time to consider my ideas Zeta. What I am talking about is not a standard at all in the sense that the system needs to adhere to a standard. A cube can hardly define a 3D printer standard. Maybe I should start every post with this: Here is one definition of standard: "something considered by an authority or by general consent as a basis of comparison" The cube only allows one printer to be compared to another, it is an indication of the 3D print envelope, no user ever needs to print this cube. It is only used as a means of classification. If we use the cube size and the full XYZ envelope we can get a ratio.

Let me use an example for XYZ Axis: 300mmx200mmx150mm and 150mm (6") will be the largest cube you are able to print. This is 3375cc (3.375 liters or 206 ci) but the print envelope is 9000cc (9 liter or 549.2 ci) The ratio here would be 2.666 cubes per print volume or 1:2.66 ratio. (no matter if we use metric or Imperial volume, we get the same ratio and it is dimensionless) So then we state it as a ratio of largest cube size (volume) printable to the maximum printing volume. This ration and the Cube and Printed volumes is an easy reference to the printers capabilities, in the example printers case: Cube volume is 3375cc to Print volume of 9000cc and the cube:print ratio is 1:2.66

This is only about classifying printers in a meaningful way. Standards can and do mean many things. The software and G-Code and many other things needs to be standardised at some point in the 3D development. That does not mean that all printers need to conform to this or any other standard but will allow some to conform.

We pay for the printers and kits or the parts when self sourcing. If we can have many sources for the same parts across a number of printers that may use some of the same parts, pricing will come down. When that happens more users will be attracted to 3D printing and more money will flow into 3D printing.

So what if some or a large number of printer models do not follow these standards? Nothing is lost. Lots are gained for these printers and users that support and follow or adhere to standards. The print bed is central to the classification and comparison of printers. If we have a few size options, and we know from the current printers what the popular sizes are, we can make many more print bed heaters in a few sizes and that will drive costs down. More suppliers can start producing them, further driving down costs and ensuring supply.

If this was easy, we would not be having these discussions and it would be 3D heaven, but its not. It is good that there are many ideas around this and we are blazing a path to some future answers and ultimately to some standards. I do not have the answers, I do have some ideas. Some ideas may work, others never do.

Rgrds in tinkering

Sarel Wagner

www.microafrica.co.za

Tinkerer and designer/inventor

Let me use an example for XYZ Axis: 300mmx200mmx150mm and 150mm (6") will be the largest cube you are able to print. This is 3375cc (3.375 liters or 206 ci) but the print envelope is 9000cc (9 liter or 549.2 ci) The ratio here would be 2.666 cubes per print volume or 1:2.66 ratio. (no matter if we use metric or Imperial volume, we get the same ratio and it is dimensionless) So then we state it as a ratio of largest cube size (volume) printable to the maximum printing volume. This ration and the Cube and Printed volumes is an easy reference to the printers capabilities, in the example printers case: Cube volume is 3375cc to Print volume of 9000cc and the cube:print ratio is 1:2.66

This is only about classifying printers in a meaningful way. Standards can and do mean many things. The software and G-Code and many other things needs to be standardised at some point in the 3D development. That does not mean that all printers need to conform to this or any other standard but will allow some to conform.

We pay for the printers and kits or the parts when self sourcing. If we can have many sources for the same parts across a number of printers that may use some of the same parts, pricing will come down. When that happens more users will be attracted to 3D printing and more money will flow into 3D printing.

So what if some or a large number of printer models do not follow these standards? Nothing is lost. Lots are gained for these printers and users that support and follow or adhere to standards. The print bed is central to the classification and comparison of printers. If we have a few size options, and we know from the current printers what the popular sizes are, we can make many more print bed heaters in a few sizes and that will drive costs down. More suppliers can start producing them, further driving down costs and ensuring supply.

If this was easy, we would not be having these discussions and it would be 3D heaven, but its not. It is good that there are many ideas around this and we are blazing a path to some future answers and ultimately to some standards. I do not have the answers, I do have some ideas. Some ideas may work, others never do.

Rgrds in tinkering

Sarel Wagner

www.microafrica.co.za

Tinkerer and designer/inventor

|

Re: How do we both encourage RepRap mutations and stay focussed? July 02, 2012 04:33PM |

Registered: 11 years ago Posts: 3 |

If the only problem you are trying to solve is comparison, how are these "complex" math easier to understand for a newbie, compared to the triplet X,Y,Z as in your example : 300mmx200mmx150mm ?

Here I can directly see that it is the same height as a 200x100x150mm, or twice as large as a 200x150x150.

I can still say that the maximum cube it can print is 150mm without thinking, as it is the smaller side length.

The only standard I can see here is that everybody uses the same unit (metrics of course ), and the same multiple (mm or preferably cm to remove meaningless zeros).

), and the same multiple (mm or preferably cm to remove meaningless zeros).

No ?

Here I can directly see that it is the same height as a 200x100x150mm, or twice as large as a 200x150x150.

I can still say that the maximum cube it can print is 150mm without thinking, as it is the smaller side length.

The only standard I can see here is that everybody uses the same unit (metrics of course

), and the same multiple (mm or preferably cm to remove meaningless zeros).

), and the same multiple (mm or preferably cm to remove meaningless zeros).No ?

|

Re: How do we both encourage RepRap mutations and stay focussed? July 02, 2012 05:01PM |

Registered: 11 years ago Posts: 15 |

One of the issues is its not a single number. How do you compare 150x150x150 to another printer of 160X160x124 or even worse to one 6"x6"x 5"? A ratio is a single number and Metric or Imperial does not matter. I know we say Metric is the standard, but many people still work in Imperial and specifications are in inches many a time.

Its not the only problem, but printing a cube of 150mm or 4" is easy to understand, and the ratio as well. Its also easy to visualise how many cubes of what size the printer can print in one go. 150mm cube and the volume ratio is 1:2.66 or 124mm cube and the volume ratio is 1:4 so now you can print 4 cubes of 124mm in one go.

This is just the first bit to get to standardising or trying to standardise the print bed. We need a few sizes of print beds to cover most users requirements. But having print beds of 120mm, 127mm 130mm, 140mm and 150mm like we currently do is all over the map.This should hopefully lead to cheaper parts and universal or more general documentation at some point.

Rgrds in volume

Sarel Wagner

www.microafrica.co.za

Tinkerer and designer/inventor

Its not the only problem, but printing a cube of 150mm or 4" is easy to understand, and the ratio as well. Its also easy to visualise how many cubes of what size the printer can print in one go. 150mm cube and the volume ratio is 1:2.66 or 124mm cube and the volume ratio is 1:4 so now you can print 4 cubes of 124mm in one go.

This is just the first bit to get to standardising or trying to standardise the print bed. We need a few sizes of print beds to cover most users requirements. But having print beds of 120mm, 127mm 130mm, 140mm and 150mm like we currently do is all over the map.This should hopefully lead to cheaper parts and universal or more general documentation at some point.

Rgrds in volume

Sarel Wagner

www.microafrica.co.za

Tinkerer and designer/inventor

|

Re: How do we both encourage RepRap mutations and stay focussed? July 02, 2012 05:44PM |

Registered: 11 years ago Posts: 3 |

|

Re: How do we both encourage RepRap mutations and stay focussed? July 03, 2012 05:14AM |

Registered: 11 years ago Posts: 15 |

Classes of printers. The print bed basically defines the printer. Surely we can agree that a printer with a bed of 10x10cm is different to one with a 20x20cm bed? All the rest of the mechanicals making up this printer will be different as the 20cm printers X and Y axis must be twice as long as the 10cm one (no matter the printer Axis configuration, XY Head and Z Bed or otherwise).

A new printer for example with X of 10cm and Y of 20cm should be able to use the already available X Axis from the 10x10cm bed printer and the Y Axis from the 20x20cm bed printer if they both of the same configuration. If we now have a number of standard bed sizes we should end up with a number of classes of printers. Have a look at the Printer family tree Printer Family tree, a different type of classification of printers is shown there, this is based on the printing configuration and technology plus popularity. From the roots we can see the growth of the different configurations.

Having for example the following classes of printers may help illustrate the concept :

Because of the many variations as shown in the Printer family tree we can already determine what style of printers is common(the design is universally accepted as efficient, many are being build/sold). If we then combine this with the Cube classification as well, we will get a list of printer types with their configurations and Bed sizes. Do not confuse this with actual printer models or manufactured printers. We are only referring to Bed size(cube) and style of printer. At a later point we may plot the actual printer models and their names against this classification if you want to do this.

We are not talking about individual printers here, merely about the print envelope and the printer Axis configuration. When we have this information we may be able to group these printers in certain classes. If there emerges a 15cm Bed class or a number of printers have a Bed no bigger than 15cm square or smaller than for example 10cm squre, they all belong to the 15cm class. If you or anybody on the Printer family tree wants to design a new 15cm class printer, and want to keep the costs down, have some modularity and commonality, then design the new printer to conform to the 15cm bed class. You are then able to use, if you want to keep costs down, some or all of the parts already designed, like the Bed and heater, or the spacings to allow the use of currently printed or designed components. Even if one of the Bed Axis is more than 15cm you may elect to use the 25cm printer class Axis for your printer as it is there already.

Now we have a new, modular printer that can use modules from different places and no custom designed part. So what if you want a new custom part, just design and buid it. Your printer design may benefit from this. It will still however only print a cube of 15cm and be classed as a 15cm printer.

Rgrds and hoping it is understandable

Sarel Wagner

www.microafrica.co.za

Tinkerer and designer/inventor

A new printer for example with X of 10cm and Y of 20cm should be able to use the already available X Axis from the 10x10cm bed printer and the Y Axis from the 20x20cm bed printer if they both of the same configuration. If we now have a number of standard bed sizes we should end up with a number of classes of printers. Have a look at the Printer family tree Printer Family tree, a different type of classification of printers is shown there, this is based on the printing configuration and technology plus popularity. From the roots we can see the growth of the different configurations.

Having for example the following classes of printers may help illustrate the concept :

- 10cm cube, 1:1ratio printer, Print volume 1000cc

- 15cm cube, 1:1 ratio printer, Print volume 3375cc

- 15cm cube, 1:3 ratio printer, Print volume 10125cc

- 25cm cube, 1:1 ratio printer, Print volume 15625cc

Because of the many variations as shown in the Printer family tree we can already determine what style of printers is common(the design is universally accepted as efficient, many are being build/sold). If we then combine this with the Cube classification as well, we will get a list of printer types with their configurations and Bed sizes. Do not confuse this with actual printer models or manufactured printers. We are only referring to Bed size(cube) and style of printer. At a later point we may plot the actual printer models and their names against this classification if you want to do this.

We are not talking about individual printers here, merely about the print envelope and the printer Axis configuration. When we have this information we may be able to group these printers in certain classes. If there emerges a 15cm Bed class or a number of printers have a Bed no bigger than 15cm square or smaller than for example 10cm squre, they all belong to the 15cm class. If you or anybody on the Printer family tree wants to design a new 15cm class printer, and want to keep the costs down, have some modularity and commonality, then design the new printer to conform to the 15cm bed class. You are then able to use, if you want to keep costs down, some or all of the parts already designed, like the Bed and heater, or the spacings to allow the use of currently printed or designed components. Even if one of the Bed Axis is more than 15cm you may elect to use the 25cm printer class Axis for your printer as it is there already.

Now we have a new, modular printer that can use modules from different places and no custom designed part. So what if you want a new custom part, just design and buid it. Your printer design may benefit from this. It will still however only print a cube of 15cm and be classed as a 15cm printer.

Rgrds and hoping it is understandable

Sarel Wagner

www.microafrica.co.za

Tinkerer and designer/inventor

|

Re: How do we both encourage RepRap mutations and stay focussed? July 03, 2012 08:25AM |

Registered: 12 years ago Posts: 21 |

HI all

Just been read the preceding conversations and thought I would throw my ideas in the ring for a good kicking

Re print size, I think a set of standard bed sizes would be a good idea, Bed size A (small) bed B (Larger) etc. This would mean standard heated beds could be made and prices would drop. A printer could then be clasiffied as a type A with 10cm Z axis. As this 'standard' worked its way in to designs, it would be simple to plan out part prints for certain sized beds. You will need a printer capable of printing A platters with a Z of 15cm to print this part set. This would also mean standardised methods of fixing the beds to the carraiges etc would emmerge.

Standard fixings for tooling would also be a good idea. Hot end 'xyz' uses fixing type '123'. If your printer has fixing type '123', this hot end would be mechanically compatible with your machine. If not an adaptor would soon be avaiable on thingiverse to convert fixing '456' to '123'. This standard could be just a set of standard sized and spaced holes on a standard plane, horizontal or vertical.

As far as the g-code standard goes this would also be good. As data is being moved from one application to another this seems a must have. It does not mean you can not have more G-codes, just that a certain set would work + the extras in this software implementation.

As for the electronics, standard connectors would be good. I tend to use 0.1' spaced pin headers for signal lines in most of the stuff I play with. They are easy, cheap and great for experimentation.

At this point in the development of 3D printing I think standards are a good idea. A standard means you have a place to start your development. If you conform to a standard fixing for your hot end, anyone with the standard fixing will know it will bolt straight on to their machine and they can then reproduce it and start using it/improving it.

If later you feel you need a new fixing, introduce this as a new standard, and if people take this up all well and good. If not, they can continue with the older standard.

A sandard should just be a solid platform to start building your own ideas from. If the standard doesn't suit you, define a new one. If it gets used, all well and good.

I think there are standards out there, they maybe just need to be defined as standards.

Just my ideas

Rob

I appologies for any spelling/grammaticcal erros. My first language IS English

Just been read the preceding conversations and thought I would throw my ideas in the ring for a good kicking

Re print size, I think a set of standard bed sizes would be a good idea, Bed size A (small) bed B (Larger) etc. This would mean standard heated beds could be made and prices would drop. A printer could then be clasiffied as a type A with 10cm Z axis. As this 'standard' worked its way in to designs, it would be simple to plan out part prints for certain sized beds. You will need a printer capable of printing A platters with a Z of 15cm to print this part set. This would also mean standardised methods of fixing the beds to the carraiges etc would emmerge.

Standard fixings for tooling would also be a good idea. Hot end 'xyz' uses fixing type '123'. If your printer has fixing type '123', this hot end would be mechanically compatible with your machine. If not an adaptor would soon be avaiable on thingiverse to convert fixing '456' to '123'. This standard could be just a set of standard sized and spaced holes on a standard plane, horizontal or vertical.

As far as the g-code standard goes this would also be good. As data is being moved from one application to another this seems a must have. It does not mean you can not have more G-codes, just that a certain set would work + the extras in this software implementation.

As for the electronics, standard connectors would be good. I tend to use 0.1' spaced pin headers for signal lines in most of the stuff I play with. They are easy, cheap and great for experimentation.

At this point in the development of 3D printing I think standards are a good idea. A standard means you have a place to start your development. If you conform to a standard fixing for your hot end, anyone with the standard fixing will know it will bolt straight on to their machine and they can then reproduce it and start using it/improving it.

If later you feel you need a new fixing, introduce this as a new standard, and if people take this up all well and good. If not, they can continue with the older standard.

A sandard should just be a solid platform to start building your own ideas from. If the standard doesn't suit you, define a new one. If it gets used, all well and good.

I think there are standards out there, they maybe just need to be defined as standards.

Just my ideas

Rob

I appologies for any spelling/grammaticcal erros. My first language IS English

|

Re: How do we both encourage RepRap mutations and stay focussed? July 03, 2012 09:40AM |

Registered: 12 years ago Posts: 1,236 |

This effort to classify 3d printers into "standard" sizes is pointless, because print objects can be any size. This is completely the opposite of 2d printers.

Standards are useful where they promote interoperability. For printer users, that means filament and Gcode, all the rest is pretty much irrelevant. Developers create from scratch, and don't build printers like assembling lego.

The problem I see with many of these proposed standards, is that they are not actually about improving printers, but trying to reduce choice for people who are confused by many different options. Helping the customer choose a printer is a job for retailers, it is not something that should be solved by creating arbitrary standards (which people are invited to ignore anyway).

Standards are useful where they promote interoperability. For printer users, that means filament and Gcode, all the rest is pretty much irrelevant. Developers create from scratch, and don't build printers like assembling lego.

The problem I see with many of these proposed standards, is that they are not actually about improving printers, but trying to reduce choice for people who are confused by many different options. Helping the customer choose a printer is a job for retailers, it is not something that should be solved by creating arbitrary standards (which people are invited to ignore anyway).

|

Re: How do we both encourage RepRap mutations and stay focussed? July 03, 2012 11:27AM |

Registered: 11 years ago Posts: 15 |

Bobc, thank you for sharing your opinion with us, twice. Do you have any other contribution to make apart from that?

EDIT: Just to make sure ya did not miss this part here it is again: Here is one definition of standard: "something considered by an authority or by general consent as a basis of comparison"

Rgrds in progress

Edited 1 time(s). Last edit at 07/03/2012 11:55AM by sarel.wagner.

Sarel Wagner

www.microafrica.co.za

Tinkerer and designer/inventor

EDIT: Just to make sure ya did not miss this part here it is again: Here is one definition of standard: "something considered by an authority or by general consent as a basis of comparison"

Rgrds in progress

Edited 1 time(s). Last edit at 07/03/2012 11:55AM by sarel.wagner.

Sarel Wagner

www.microafrica.co.za

Tinkerer and designer/inventor

|

Re: How do we both encourage RepRap mutations and stay focussed? July 03, 2012 11:48AM |

Registered: 11 years ago Posts: 15 |

@Rob, in general that is the idea to get a standard printer bed size range, something like 4" 6" 10" class for example (100mm, 150mm 250mm) and whatever the largest size cube is the printer can print will determine its class. The cube (and it does not have to be printed but can be for verification purposes) does not restrict the table size, you may have a table that is 150 x 250mm if you like. Do we need to have 30 or so different table sizes between 100mm to 300mm, I do not think so. We need to have enough different sizes but it is quite counterproductive to have tables that differ in only a few mm. That will allow designers quite some scope in selecting a printers envelope and design criteria as well as price point. It is real easy to see that the Bed size is the driver for everything mechanical.

If we then use this same logic and we apply it to other sub systems the same desirable benefits should be applicable. This can then as you say be extended to other sub systems like G-Code and Extruders etc. If we look towards the Machine tool market, we can indeed see some of this being played out. There are different classes of machine tools too, and they work in 3D.

Rgrds and many thanks

Sarel Wagner

www.microafrica.co.za

Tinkerer and designer/inventor

If we then use this same logic and we apply it to other sub systems the same desirable benefits should be applicable. This can then as you say be extended to other sub systems like G-Code and Extruders etc. If we look towards the Machine tool market, we can indeed see some of this being played out. There are different classes of machine tools too, and they work in 3D.

Rgrds and many thanks

Sarel Wagner

www.microafrica.co.za

Tinkerer and designer/inventor

|

Re: How do we both encourage RepRap mutations and stay focussed? July 05, 2012 07:48AM |

Registered: 11 years ago Posts: 15 |

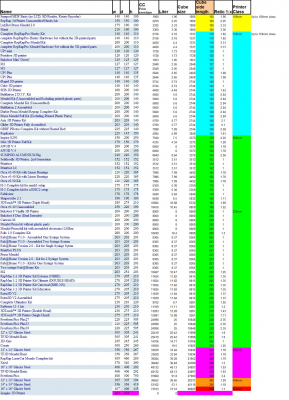

Attached is the classification I have done on the current printers as listed by 3ders here: List of printers on 3ders

My list is sorted according the biggest cube the printer can print, it is not the same order as on the 3ders site. EDIT: The Cube size is in CC and the ratio is how many cubes of that size the printer can print (Cube : Printenvelope volume)

Please comment if you like.

Rgrds in progress

Edited 3 time(s). Last edit at 07/05/2012 07:57AM by sarel.wagner.

Sarel Wagner

www.microafrica.co.za

Tinkerer and designer/inventor

My list is sorted according the biggest cube the printer can print, it is not the same order as on the 3ders site. EDIT: The Cube size is in CC and the ratio is how many cubes of that size the printer can print (Cube : Printenvelope volume)

Please comment if you like.

Rgrds in progress

Edited 3 time(s). Last edit at 07/05/2012 07:57AM by sarel.wagner.

Sarel Wagner

www.microafrica.co.za

Tinkerer and designer/inventor

|

Re: How do we both encourage RepRap mutations and stay focussed? July 08, 2012 07:16AM |

Registered: 11 years ago Posts: 15 |

If we now look at this table, we can deduce from that we need a few standard table sizes and those will cover most if not all the printers in the list.

5 square table sizes will be required. 150mm, 200mm, 250mm, 300mm, 400mm

Only one printer needs a table of 300*460mm.

Regards in progress

Sarel Wagner

www.microafrica.co.za

Tinkerer and designer/inventor

5 square table sizes will be required. 150mm, 200mm, 250mm, 300mm, 400mm

Only one printer needs a table of 300*460mm.

Regards in progress

Sarel Wagner

www.microafrica.co.za

Tinkerer and designer/inventor

|

Re: How do we both encourage RepRap mutations and stay focussed? July 08, 2012 07:14PM |

Registered: 14 years ago Posts: 177 |

I don't think standardizing print size is what we are lack of.

Just like we have A4/Letter paper size for 2D printer, we actually have a very stable standard - 1.75/3mm filament that are followed by 99% of the reprap variants.

To me - output size is like font size in 2D printer analogy. Why do we need a standard to tell the end user which font size should be used for title, sub title, paragraph etc? The font size is content driver, so does the print size - that depends on the exact object user can play with.

Maybe with so many different print sizes today first time user will have a hard time in picking a model to start with...but this is by far the easiest to pick! Car analogy: compact, SUV, van truck? It's effortless to make the decision - comparing to figuring out what engine, transmission, power, entertainment features of each cars have...

So does 3D printers - print size by far is the easiest to understand, I believe people are usually stucked with Extruder, Hotends, XYZ Bot Mechanics, Electronics, Firmware, Slicer and understanding the consequence of the choices.

Recently I am hacking the Marlin firmware to make it work on my repstrap. While I am thankful for all the contributors, maintainers who made such wonderful software, I must also mention that from software engineering perspective it's non-maintainable and non-extendable. With so many hardware variations out there the code base will soon, if not already, fall apart.

If we have Linus overseeing the firmware project like how he does for Linux kernel...I am just saying =)

Just like we have A4/Letter paper size for 2D printer, we actually have a very stable standard - 1.75/3mm filament that are followed by 99% of the reprap variants.

To me - output size is like font size in 2D printer analogy. Why do we need a standard to tell the end user which font size should be used for title, sub title, paragraph etc? The font size is content driver, so does the print size - that depends on the exact object user can play with.

Maybe with so many different print sizes today first time user will have a hard time in picking a model to start with...but this is by far the easiest to pick! Car analogy: compact, SUV, van truck? It's effortless to make the decision - comparing to figuring out what engine, transmission, power, entertainment features of each cars have...

So does 3D printers - print size by far is the easiest to understand, I believe people are usually stucked with Extruder, Hotends, XYZ Bot Mechanics, Electronics, Firmware, Slicer and understanding the consequence of the choices.

Recently I am hacking the Marlin firmware to make it work on my repstrap. While I am thankful for all the contributors, maintainers who made such wonderful software, I must also mention that from software engineering perspective it's non-maintainable and non-extendable. With so many hardware variations out there the code base will soon, if not already, fall apart.

If we have Linus overseeing the firmware project like how he does for Linux kernel...I am just saying =)

|

Re: How do we both encourage RepRap mutations and stay focussed? July 08, 2012 07:17PM |

Admin Registered: 17 years ago Posts: 179 |

|

Re: How do we both encourage RepRap mutations and stay focussed? July 09, 2012 11:51AM |

Registered: 12 years ago Posts: 1,236 |

sarel.wagner Wrote:

-------------------------------------------------------

> Bobc, thank you for sharing your opinion with us,

> twice. Do you have any other contribution to make

> apart from that?

>

> EDIT: Just to make sure ya did not miss this part

> here it is again: Here is one definition of

> standard: "something considered by an authority or

> by general consent as a basis of comparison"

>

> Rgrds in progress

Hey if you don't like my standard opinion, just ignore it

BTW, you are wasting your time and everyone else's with this. I think that has been explained several times. There are useful areas to create standards, but creating an arbitrary standard print volume doesn't help anyone. I was hoping this would turn into some sort of spoof idea to illustrate silly standards, but sadly not.

-------------------------------------------------------

> Bobc, thank you for sharing your opinion with us,

> twice. Do you have any other contribution to make

> apart from that?

>

> EDIT: Just to make sure ya did not miss this part

> here it is again: Here is one definition of

> standard: "something considered by an authority or

> by general consent as a basis of comparison"

>

> Rgrds in progress

Hey if you don't like my standard opinion, just ignore it

BTW, you are wasting your time and everyone else's with this. I think that has been explained several times. There are useful areas to create standards, but creating an arbitrary standard print volume doesn't help anyone. I was hoping this would turn into some sort of spoof idea to illustrate silly standards, but sadly not.

|

Re: How do we both encourage RepRap mutations and stay focussed? July 09, 2012 02:11PM |

Registered: 11 years ago Posts: 15 |

I love open hardware and software! Your opinion is just that, your opinion, after all you entitled to that.

I love open hardware and software! Your opinion is just that, your opinion, after all you entitled to that.On to the build platform or printer bed again. If we look at the current crop of printers we can see that a few printer bed sizes is enough to cover the range. We can have a square bed or a rectangular bed.

Square beds to satisfy most requirements:

- 150mm and 225cm square surface area

- 200mm and 400cm square surface area

- 250mm and 625cm square surface area

- 300mm and 900cm square surface area

- 400mm and 1600cm square surface area

Rectangulkar beds to satisfy the rest of the requirements:

- 150mm x 200mm and 300cm square surface area

- 200mm x 250mm and 500cm square surface area

- 200mm x 300mm and 600cm square surface area

- 250mm x 300mm and 750cm square surface area

- 250mm x 400mm and 1000cm square surface area

- 300mm x 400mm and 1200cm square surface area

- 300mm x 460mm and 1380cm square surface area

Sarel Wagner

www.microafrica.co.za

Tinkerer and designer/inventor

|

Re: How do we both encourage RepRap mutations and stay focussed? July 09, 2012 08:58PM |

Registered: 13 years ago Posts: 1,352 |

I think some1 is under the impression that bigger is better, or at least means something related to that size having some meaning.

Imo print area has no meaning. Just by itself, if has any significance, then its that bigger print area is definatelly not better. What is the point to heat 50x50 cm of 1.5Kw heated bed, just to print a 1x1cm pulley. Not to mention bigger machines will loose on rigidity and paralelism and etc, besides being slower and needing more power, bigger motors and better components, while they still lose on efficiency and maybe even speed.

So bigger isnt necesarily better, but can mean quite the opposite. That doesnt mean its worth standardising it either way, again it doesnt mean anything by itself. And i find making a standard on print area is as usefull as making a standard based on the colour of the printer's plastic parts, or if the person making it is married or not (although i recon the last one can really have some impact on the machine quality ... just not sure how ... one way or the other).

The things that do mean something are found in the real industry: for one, the highly debatable and never accepted "rigidity" (the real ppls in the real field havent accepted yet a standard for this one and we wont get it ahead of them), but there is other stuff like vibrations "class" (minor part of the above), paralelism of axes, planarity of the working area, concentricity (where it may apply), etc. These we dont even have the tooling to measure.

But we could maybe do smaller things like backlash or repeatability or etc. The trouble is that "my printer isnt your printer". So you can measure your printer backlash or repeatability, but that doesnt mean it will apply to mine, because i used cheaper components, my plastic parts were cheapest and therefore 99% air, etc. So even if some1 would buy 1 printer of each kind existing on the market and measure all it could on all of them, still that person couldnt draw any conclusion. Because the "Law of big numbers" says you need at least 40 examples to be able to take any conclusion. So you would need to at least 40 pcs of each single model of printer. Then you have to make a panel of users building them and the skills they have and quality of parts they use, and that panel has to be representative at the targeted population etc, otherwise you cant generalize. If you want to do it, good luck. However, the day you finish it, it will be already obsolete because there will be at least 10+ new models on the market that didnt existed initially.

Imo print area has no meaning. Just by itself, if has any significance, then its that bigger print area is definatelly not better. What is the point to heat 50x50 cm of 1.5Kw heated bed, just to print a 1x1cm pulley. Not to mention bigger machines will loose on rigidity and paralelism and etc, besides being slower and needing more power, bigger motors and better components, while they still lose on efficiency and maybe even speed.

So bigger isnt necesarily better, but can mean quite the opposite. That doesnt mean its worth standardising it either way, again it doesnt mean anything by itself. And i find making a standard on print area is as usefull as making a standard based on the colour of the printer's plastic parts, or if the person making it is married or not (although i recon the last one can really have some impact on the machine quality ... just not sure how ... one way or the other).

The things that do mean something are found in the real industry: for one, the highly debatable and never accepted "rigidity" (the real ppls in the real field havent accepted yet a standard for this one and we wont get it ahead of them), but there is other stuff like vibrations "class" (minor part of the above), paralelism of axes, planarity of the working area, concentricity (where it may apply), etc. These we dont even have the tooling to measure.

But we could maybe do smaller things like backlash or repeatability or etc. The trouble is that "my printer isnt your printer". So you can measure your printer backlash or repeatability, but that doesnt mean it will apply to mine, because i used cheaper components, my plastic parts were cheapest and therefore 99% air, etc. So even if some1 would buy 1 printer of each kind existing on the market and measure all it could on all of them, still that person couldnt draw any conclusion. Because the "Law of big numbers" says you need at least 40 examples to be able to take any conclusion. So you would need to at least 40 pcs of each single model of printer. Then you have to make a panel of users building them and the skills they have and quality of parts they use, and that panel has to be representative at the targeted population etc, otherwise you cant generalize. If you want to do it, good luck. However, the day you finish it, it will be already obsolete because there will be at least 10+ new models on the market that didnt existed initially.

|

Re: How do we both encourage RepRap mutations and stay focussed? July 09, 2012 11:08PM |

Registered: 14 years ago Posts: 177 |

And standard is only useful when something is depended on that.

Say we have being staying with 3mm or 1.75 filament so supply could be sourced, extruder could be built and improved base on that. Ditto for paper size.

We adopted GCode as the printing instruction so the electronics, program, slicer could work on the common thing, and play well with each others, and could be improved independently.

Or some electronics adopted polulu/sidestick so the drivers could be reused while leaving options for different CPU/heater/extruder/board design.

But print size standard would be the least we need.

Nothing is depended on it. It's not produced nor consumed by anything except user's desires. It's unbound and free-form.

Just like there is no standard for the top speed of a car, or milage, or printing speed, or power (watt),...These are the parameters that could be changed without negatively affecting the interoperability among components.

Say we have being staying with 3mm or 1.75 filament so supply could be sourced, extruder could be built and improved base on that. Ditto for paper size.

We adopted GCode as the printing instruction so the electronics, program, slicer could work on the common thing, and play well with each others, and could be improved independently.

Or some electronics adopted polulu/sidestick so the drivers could be reused while leaving options for different CPU/heater/extruder/board design.

But print size standard would be the least we need.

Nothing is depended on it. It's not produced nor consumed by anything except user's desires. It's unbound and free-form.

Just like there is no standard for the top speed of a car, or milage, or printing speed, or power (watt),...These are the parameters that could be changed without negatively affecting the interoperability among components.

|

Re: How do we both encourage RepRap mutations and stay focussed? July 26, 2012 10:20AM |

Registered: 12 years ago Posts: 82 |

Is there any mileage in wireless communication between modules? You can get some pretty cheap bluetooth chips.Quote

Adrian

For example, one could imagine an extruder with about five controls and as many sensors, all requiring electrical signals. But it would be a bad idea to specify a big multi-way extruder connector as standard, as that would hamper simple small designs.

|

Re: How do we both encourage RepRap mutations and stay focussed? August 14, 2012 11:07AM |

@sarel, standardising volume is pointless as a technical specification.

It doesn't work as a standard measurement for measuring buildable parts (as the example given, a 10x10x40 has the same build area and same ratio as a 20x20x10 machine, largest cube and multiples of therefore is a pointless metric, because it does not describe enough.)

trying to standardise volume, especially with this lets measure if with a metric you'll likely never use, is just marketting bumpf) -it serves no technical purpose, so should not be a technical standard!

I'll never replace the volume of my machine, there are no volume specific parts. however, I may wish to replace my bed. (heated/unheated/material/function -I might want a t-slotted one for tool clamps etc)

Therefore I do believe that bed size standardisation is a good thing.

What I would propose therefore is to take the lead from paper makers, (maybe not use their ration) or maybe do?

Therefore beds should be (according to my newly pulled from my anus standards).

square, in dimensions of whole inches, (or whole centimeters)

or, rectangular, in dimensions the same as paper, (e.g long side 1.44 x greater than short side), and the short side again should be measured in whole inches.

straight away there is a benefit in standardisation in that bed can be volume produced/group bought.

the beds are not model specific [for mendel, for huxley, for prussa] but size specific, square6 = 6"x6" rectangle6 = 6"x8.6"

so you end up with a standard, describer, [square] or [rectangle] and a measure of the least significant edge size.

since most of the world works in milimeters, and the Americans use imperial I'd go further to suggest that the standards should allow people to work with what is most familliar to them, or what is most obtainable to them.

e.g.

MS150 (Metric, square, 150mm edge)

IS6 (Imperial, square, 6" edge)

MR150 (Metric, rectangle, shortest edge = 150mm, longest edge = 1.44X that)

IR6 (Imperial, rectangle, shortest edge = 6", longest edge = 1.44X that)

That's a standard, it describes a build area (though speaks nothing of volume because that is not important)

it describes part dimentions

it describes units of measure (imperial vs. metric)

it describes part shape.

it all comes together as a nice easy to recognise part number as well.

This enables manufaturers to actually start to churn a product, (instead of having to wait and see what the next build size is).

it makes it much easier to go to a fabricator (I need a 6x6" piece of glass, -rather than I need a 5.54" x 7.32" piece of glass -limits dictated by the fact that the original maker/designer had that bit laying about)

it enables group buys

-both these things make it cheaper

It doesn't work as a standard measurement for measuring buildable parts (as the example given, a 10x10x40 has the same build area and same ratio as a 20x20x10 machine, largest cube and multiples of therefore is a pointless metric, because it does not describe enough.)

trying to standardise volume, especially with this lets measure if with a metric you'll likely never use, is just marketting bumpf) -it serves no technical purpose, so should not be a technical standard!

I'll never replace the volume of my machine, there are no volume specific parts. however, I may wish to replace my bed. (heated/unheated/material/function -I might want a t-slotted one for tool clamps etc)

Therefore I do believe that bed size standardisation is a good thing.

What I would propose therefore is to take the lead from paper makers, (maybe not use their ration) or maybe do?

Therefore beds should be (according to my newly pulled from my anus standards).

square, in dimensions of whole inches, (or whole centimeters)

or, rectangular, in dimensions the same as paper, (e.g long side 1.44 x greater than short side), and the short side again should be measured in whole inches.

straight away there is a benefit in standardisation in that bed can be volume produced/group bought.

the beds are not model specific [for mendel, for huxley, for prussa] but size specific, square6 = 6"x6" rectangle6 = 6"x8.6"

so you end up with a standard, describer, [square] or [rectangle] and a measure of the least significant edge size.

since most of the world works in milimeters, and the Americans use imperial I'd go further to suggest that the standards should allow people to work with what is most familliar to them, or what is most obtainable to them.

e.g.

MS150 (Metric, square, 150mm edge)

IS6 (Imperial, square, 6" edge)

MR150 (Metric, rectangle, shortest edge = 150mm, longest edge = 1.44X that)

IR6 (Imperial, rectangle, shortest edge = 6", longest edge = 1.44X that)

That's a standard, it describes a build area (though speaks nothing of volume because that is not important)

it describes part dimentions

it describes units of measure (imperial vs. metric)

it describes part shape.

it all comes together as a nice easy to recognise part number as well.

This enables manufaturers to actually start to churn a product, (instead of having to wait and see what the next build size is).

it makes it much easier to go to a fabricator (I need a 6x6" piece of glass, -rather than I need a 5.54" x 7.32" piece of glass -limits dictated by the fact that the original maker/designer had that bit laying about)

it enables group buys

-both these things make it cheaper

|

Re: How do we both encourage RepRap mutations and stay focussed? August 17, 2012 12:27AM |

Registered: 11 years ago Posts: 15 |

sarel.wagner Wrote:

-------------------------------------------------------

> @Rob, in general that is the idea to get a

> standard printer bed size range/b], something like 4"

> 6" 10" class for example (100mm, 150mm 250mm) and

> whatever the largest size cube is the printer can

> print will determine its class. The cube (and it

> does not have to be printed but can be for

> verification purposes) does not restrict the table

> size, you may have a table that is 150 x 250mm if

> you like. Do we need to have 30 or so different

> table sizes between 100mm to 300mm, I do not think

> so.

I am quoting myself here, nowhere did I say that the standard need to be volume (blue text above). The standard needs to be the table size. When however classifying the printers the volume is used.

Rgrds

Sarel Wagner

www.microafrica.co.za

Tinkerer and designer/inventor

-------------------------------------------------------

> @Rob, in general that is the idea to get a

> standard printer bed size range/b], something like 4"

> 6" 10" class for example (100mm, 150mm 250mm) and

> whatever the largest size cube is the printer can

> print will determine its class. The cube (and it

> does not have to be printed but can be for

> verification purposes) does not restrict the table

> size, you may have a table that is 150 x 250mm if

> you like. Do we need to have 30 or so different

> table sizes between 100mm to 300mm, I do not think

> so.

I am quoting myself here, nowhere did I say that the standard need to be volume (blue text above). The standard needs to be the table size. When however classifying the printers the volume is used.

Rgrds

Sarel Wagner

www.microafrica.co.za

Tinkerer and designer/inventor

Sorry, only registered users may post in this forum.