Home

>

Developers

>

Topic

Printable ceramic hot end

Posted by Igor Lobanov

|

Printable ceramic hot end January 08, 2012 06:28PM |

Registered: 12 years ago Posts: 43 |

Dear All,

I've only just started building my own first Prusa, so my observations might be incorrect, but it seems that the most "vitamin-hungry" part of the RepRap as it is now is the extruder and hot end in particular. On the other hand, apparently, lots of progress has been made by the community in the area of clay/paste extruding. Those devices are perfectly capable of working with ceramics and epoxies.

On the other hand there are quite a few of ceramic materials out there that exhibit interesting heat conductivity properties. I mean that there are good heat insulators as well, as good heat conductors with healthy working temperatures range. Consequently it is probably possible (and feasible) to produce hot end for a platic extruder using those ceramics.

It looks like by having printable hot ends RepRap could be even more self-reproducible. However, I did a brief research only and haven't found any work in this direction. Is it something that already has been tried and rejected for some reason or it's just something that needs to be done?

Best regards,

Igor

I've only just started building my own first Prusa, so my observations might be incorrect, but it seems that the most "vitamin-hungry" part of the RepRap as it is now is the extruder and hot end in particular. On the other hand, apparently, lots of progress has been made by the community in the area of clay/paste extruding. Those devices are perfectly capable of working with ceramics and epoxies.

On the other hand there are quite a few of ceramic materials out there that exhibit interesting heat conductivity properties. I mean that there are good heat insulators as well, as good heat conductors with healthy working temperatures range. Consequently it is probably possible (and feasible) to produce hot end for a platic extruder using those ceramics.

It looks like by having printable hot ends RepRap could be even more self-reproducible. However, I did a brief research only and haven't found any work in this direction. Is it something that already has been tried and rejected for some reason or it's just something that needs to be done?

Best regards,

Igor

|

Re: Printable ceramic hot end January 09, 2012 05:17AM |

Registered: 13 years ago Posts: 7,616 |

RepRap is pretty much focussed on extruding thermoplastics only. Hooking up a silicone extruder, epoxy extruder od a milling spindle would be almost trivial, but interest in doing such things is apparently low.

Also, people are apparently exhausted by "it prints!". They're more exited by printing octopusses or a feminine body model than by designing technical parts

OK, the above is a bit exaggerated, but not entirely untrue.

Also, people are apparently exhausted by "it prints!". They're more exited by printing octopusses or a feminine body model than by designing technical parts

OK, the above is a bit exaggerated, but not entirely untrue.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Printable ceramic hot end January 09, 2012 06:20AM |

Registered: 12 years ago Posts: 43 |

|

Re: Printable ceramic hot end January 09, 2012 08:22AM |

Admin Registered: 17 years ago Posts: 7,879 |

|

Re: Printable ceramic hot end January 09, 2012 09:52AM |

Registered: 12 years ago Posts: 43 |

@nophead

There may be no de jure standard build, but de facto standard Prusa build is definitely as it described on the wiki. Similar thing is for electronics and extruders with a bit of variety. I know it as I'd spent ages shopping around for printed parts and electronics kit. Whenever someone offering you a set of printed parts for Prusa, you can expect it to be the same as described.

On the other hand, I see what you mean. There's no release process, and no releasing body for specifications, as it is for, say, open source software. I believe the key reason is that the community is relatively small and even in terms of skills, i.e. little or no 'casual users' around.

There may be no de jure standard build, but de facto standard Prusa build is definitely as it described on the wiki. Similar thing is for electronics and extruders with a bit of variety. I know it as I'd spent ages shopping around for printed parts and electronics kit. Whenever someone offering you a set of printed parts for Prusa, you can expect it to be the same as described.

On the other hand, I see what you mean. There's no release process, and no releasing body for specifications, as it is for, say, open source software. I believe the key reason is that the community is relatively small and even in terms of skills, i.e. little or no 'casual users' around.

|

Re: Printable ceramic hot end January 09, 2012 10:28AM |

Registered: 13 years ago Posts: 601 |

I'm interested in trying a cast plaster hot end. Not the nozzle, just the insulator. Vik Oliver made a wiki page about a similar experiment he did back in 2006, but there's no conclusion on how well it worked, and a lot has changed with hot ends since then.

my extruder is kaput, but when i get the new one installed i'll print out a form and give it a try. I'd like to have a working backup on hand for the next time the hot end fails.

edit: here's the wiki page

[reprap.org]

Edited 1 time(s). Last edit at 01/09/2012 10:55AM by Buback.

my extruder is kaput, but when i get the new one installed i'll print out a form and give it a try. I'd like to have a working backup on hand for the next time the hot end fails.

edit: here's the wiki page

[reprap.org]

Edited 1 time(s). Last edit at 01/09/2012 10:55AM by Buback.

|

Re: Printable ceramic hot end January 09, 2012 11:00AM |

Registered: 12 years ago Posts: 43 |

|

Re: Printable ceramic hot end January 09, 2012 12:00PM |

Registered: 13 years ago Posts: 601 |

well i have very little experience with plaster, but from recent reading i've learned that gypsum plaster (plaster of paris) will break down back into powder around 200C (i think  )

)

Vic used cement and pearlite, with wire reinforcement. I may start there, with fiberglass fabric instead of wire, and a ptfe liner.

Another option that I've heard about but know little about is dental plaster. it sets very quickly, but generates a lot of heat which might melt or distort printed PLA forms. it also might not stand up to ABS temps, which i think are a bare minimum for an extruder hot end these days.

)

)Vic used cement and pearlite, with wire reinforcement. I may start there, with fiberglass fabric instead of wire, and a ptfe liner.

Another option that I've heard about but know little about is dental plaster. it sets very quickly, but generates a lot of heat which might melt or distort printed PLA forms. it also might not stand up to ABS temps, which i think are a bare minimum for an extruder hot end these days.

|

Re: Printable ceramic hot end January 09, 2012 12:06PM |

Admin Registered: 17 years ago Posts: 7,879 |

@Igor,

If you look at all the Prusa parts for sale you will see a wide variation. Some with PLA bushings, some with Josef's new linear bearing parts, some with Greg Frosts alternative linear bearing parts and extruder, different z-couplings, different vertex styles and so on. And then there is the Prusa version 2 where nearly all the parts have changed in some way and it needs a different bill of materials and assembly instructions.

There are less variations of the Sell's Mendel but there are two versions of the X axis and the extruder parts. You will see both for sale.

[www.hydraraptor.blogspot.com]

If you look at all the Prusa parts for sale you will see a wide variation. Some with PLA bushings, some with Josef's new linear bearing parts, some with Greg Frosts alternative linear bearing parts and extruder, different z-couplings, different vertex styles and so on. And then there is the Prusa version 2 where nearly all the parts have changed in some way and it needs a different bill of materials and assembly instructions.

There are less variations of the Sell's Mendel but there are two versions of the X axis and the extruder parts. You will see both for sale.

[www.hydraraptor.blogspot.com]

|

Re: Printable ceramic hot end January 09, 2012 12:40PM |

Registered: 12 years ago Posts: 43 |

@Buback,

I've found very interesting ceramic materials online, including those with very high working temperature ranges. For example, on cotronics.com. However, it doesn't look like there's a way to buy those in retail amounts, not in the UK anyway. Haven't spoken with them yet, though. Will try at some point once my reprap is operational and I manage to build a claystruder.

@nophead,

That's correct, but it's still 'Prusa with linear bearings' or 'Prusa with new z-couplings', only changes to the standard are highlighted. The same will happen with Prusa 2.

I've found very interesting ceramic materials online, including those with very high working temperature ranges. For example, on cotronics.com. However, it doesn't look like there's a way to buy those in retail amounts, not in the UK anyway. Haven't spoken with them yet, though. Will try at some point once my reprap is operational and I manage to build a claystruder.

@nophead,

That's correct, but it's still 'Prusa with linear bearings' or 'Prusa with new z-couplings', only changes to the standard are highlighted. The same will happen with Prusa 2.

|

Re: Printable ceramic hot end March 06, 2014 08:30PM |

Registered: 10 years ago Posts: 1 |

|

Re: Printable ceramic hot end March 07, 2014 05:45PM |

Registered: 13 years ago Posts: 601 |

I've had too many ideas and too many project (not to mention life and job) so this one never got past the modeling stage.

Is there any interest still? it seems that there are a number of machinists selling good reliable hot ends now. And you would still have to drill and .4mm hole in a threaded rod to make the nozzle, even if you had cast the heat break. Back then there were a lot of people with failed ptfe-style hot ends that had an extra nozzle that they could recycle.

Is there any interest still? it seems that there are a number of machinists selling good reliable hot ends now. And you would still have to drill and .4mm hole in a threaded rod to make the nozzle, even if you had cast the heat break. Back then there were a lot of people with failed ptfe-style hot ends that had an extra nozzle that they could recycle.

|

Re: Printable ceramic hot end March 11, 2014 10:33PM |

Registered: 13 years ago Posts: 632 |

|

Re: Printable ceramic hot end March 14, 2014 11:32AM |

Registered: 11 years ago Posts: 334 |

There are a few clay extruders out there if you look, I would love to play with one someday but considering the fact that I don't have a kiln it may be a while. A mold may be a better way of producing a hotend barrel. I am not so sure I would try to make a heater out of ceramic. You could possibly print a mold out of PLA. From a quick search through the internet I would recommend porcelain.

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

|

Re: Printable ceramic hot end March 14, 2014 05:37PM |

Admin Registered: 13 years ago Posts: 730 |

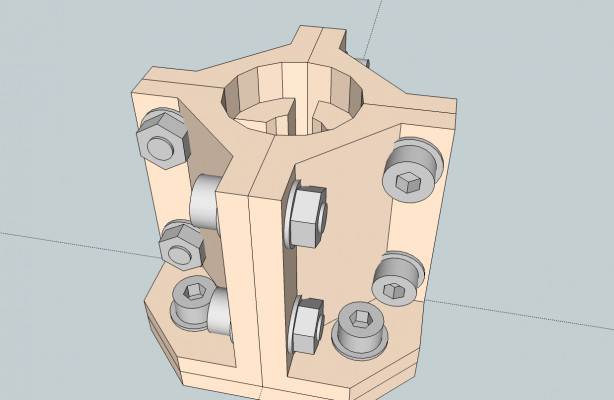

I made this proof-of-principle hot end with an electroformed copper nozzle and a cast plaster heat break.

|

Re: Printable ceramic hot end March 18, 2014 11:40AM |

Registered: 13 years ago Posts: 601 |

I found some old files from when i was designing a plaster cast for an extruder. I don't remember much about what i was doing, but i thought i'd put the files up here for those who want to experiment.

I'm assuming that the bottom hole was to screw in either the nozzle itself, or a threaded rod of the right diameter, so that you had interior threads that you could screw the nozzle into after it dried.

You would also want a ptfe insert, but it doesn't look like i got around to a jig piece that would hold that in the center while casting.

Sketchup file is below.

I'm assuming that the bottom hole was to screw in either the nozzle itself, or a threaded rod of the right diameter, so that you had interior threads that you could screw the nozzle into after it dried.

You would also want a ptfe insert, but it doesn't look like i got around to a jig piece that would hold that in the center while casting.

Sketchup file is below.

Sorry, only registered users may post in this forum.