Full Color 3d Printer Project

Posted by CPS

|

Re: Full Color 3d Printer Project March 06, 2013 10:24PM |

|

Re: Full Color 3d Printer Project March 06, 2013 11:02PM |

Registered: 11 years ago Posts: 482 |

I don't see how the system could make a true color print, like 16-bit color, without the ability to change print color instantly (nanoliter mixing).

The reason is, most people will have a file, with colors, and gradients, and they will not want to design it only to change gradually on a Z-axis or per-layer basis.

Therefore the best solution is some kind of high temperature dye injected at the tip of the nozzle with plastic in nanoliter volumes. This way you can get as much or as little colors, imparted even to clear materials. How it would actually reduce to practice...is beyond me. But it smells of something like an inkjet nozzle ?

The reason is, most people will have a file, with colors, and gradients, and they will not want to design it only to change gradually on a Z-axis or per-layer basis.

Therefore the best solution is some kind of high temperature dye injected at the tip of the nozzle with plastic in nanoliter volumes. This way you can get as much or as little colors, imparted even to clear materials. How it would actually reduce to practice...is beyond me. But it smells of something like an inkjet nozzle ?

|

Re: Full Color 3d Printer Project March 07, 2013 01:45AM |

Registered: 11 years ago Posts: 44 |

1nanoliter (why necessarily nanoliter needed?)= 100µm x 100µm x 100µm (a 22" monitor @ 1080p would be a 248µm x 248µm for comparison) and btw inkjet uses picoliter volumes but we aren't 3d printing with just ink, with using inkjet you also have to guarentee that it will mix homogeneously with the plastic which is probably why current color 3d printers use resins.

I'm thinking printing with colors as using a paintbrush (mix then apply) instead of using a inkjet printer (droplets very close to each other)(bad analogy probably but o well, let me know if you don't understand). Gradients should still be possible and probably just as easy/easier than using inkjet nozzle (uncalculated example, turn motor for red filament 10rpm - 0.1rpm per second, and turn blue motor 10rpm + 0.1rpm/second, assuming 20rpm=total output for nozzle = 2 dimension gradient (i think, technical term idk, can be applied for all 5 colors))

yea true 16bit color would be difficult without custom careful design of the color of the filaments. (color properties can be calculated to print out an approximation, perfection is probably way off budget)

what would be the math to limitations with mixing for nozzle and software?

I'm thinking printing with colors as using a paintbrush (mix then apply) instead of using a inkjet printer (droplets very close to each other)(bad analogy probably but o well, let me know if you don't understand). Gradients should still be possible and probably just as easy/easier than using inkjet nozzle (uncalculated example, turn motor for red filament 10rpm - 0.1rpm per second, and turn blue motor 10rpm + 0.1rpm/second, assuming 20rpm=total output for nozzle = 2 dimension gradient (i think, technical term idk, can be applied for all 5 colors))

yea true 16bit color would be difficult without custom careful design of the color of the filaments. (color properties can be calculated to print out an approximation, perfection is probably way off budget)

what would be the math to limitations with mixing for nozzle and software?

|

Re: Full Color 3d Printer Project March 07, 2013 02:00AM |

Registered: 11 years ago Posts: 44 |

Does anyone have any pcb designs of stepper motor drivers and controller boards (don't know about servo motors yet, possibly could use those?, dc motor probably enough for mixer because it will probably be enough to mix it same speed maybe/maybe not) and considering the price of some of the price of the pre-made ones for simpler repraps, I don't want to empty my bank account just for the electronics

yes i know how to make pcb's (haven't tried multi-layer yet, but is a possibility, anyone have experience especially with 3+ layer pcb's?, just curious ) and solder through-hole and smt components (will have to order components probably, and most order quantities are 1k+ so i'll have plenty extra )

)

yes i know how to make pcb's (haven't tried multi-layer yet, but is a possibility, anyone have experience especially with 3+ layer pcb's?, just curious ) and solder through-hole and smt components (will have to order components probably, and most order quantities are 1k+ so i'll have plenty extra

)

)

|

Re: Full Color 3d Printer Project March 07, 2013 03:12AM |

Registered: 11 years ago Posts: 482 |

CPS Wrote:

-------------------------------------------------------

> Does anyone have any pcb designs of stepper motor

> drivers and controller boards (don't know about

> servo motors yet, possibly could use those?, dc

> motor probably enough for mixer because it will

> probably be enough to mix it same speed

> maybe/maybe not) and considering the price of some

> of the price of the pre-made ones for simpler

> repraps, I don't want to empty my bank account

> just for the electronics

>

> yes i know how to make pcb's (haven't tried

> multi-layer yet, but is a possibility, anyone have

> experience especially with 3+ layer pcb's?, just

> curious ) and solder through-hole and smt

> components (will have to order components

> probably, and most order quantities are 1k+ so

> i'll have plenty extra )

)

Wow, just buy it . RAMPS is dirt cheap, and works spectacular. I highly recommend stepstick A4988 drivers. You can also control servos. IMO, all these are sufficient, and all the math is there. The problem is effective mixing/volumes.

. RAMPS is dirt cheap, and works spectacular. I highly recommend stepstick A4988 drivers. You can also control servos. IMO, all these are sufficient, and all the math is there. The problem is effective mixing/volumes.

The nanoliter calculation is the volume mixing - a latency. 1nL would go through before color changes from say red to white. That is the ideal, meaning, you can print anything, since a 0.1 mm layer height with the futuristic impossibly small 0.1mm or so nozzle size would give you near invisibly small color changes, you could "turn on a dime."

Its good to aim high at first. I love the idea of painting the out side of the filament as it comes out. We can keep brainstorming for now.

How small do you think we have to lay down filament before the colors blend together? Since a Retina display may have 128 micron pixels, with 40 submicron pixels, technically thats similar to how an inkjet mimicks color without mixing too. I think that is a more practical vision of color in the future 3D printer - 4 base colors, in this case CYMK would be placed so close that you cant see the color separations. now, practically, FFF seems impossibly slow, if we need to get to 0.1mm and we are at 0.35mm, it doesn't seem that far away, though the factor 3 is really 3^4 power times more force needed, and 3^3 power more print time to get desired prints out, its a start.

-------------------------------------------------------

> Does anyone have any pcb designs of stepper motor

> drivers and controller boards (don't know about

> servo motors yet, possibly could use those?, dc

> motor probably enough for mixer because it will

> probably be enough to mix it same speed

> maybe/maybe not) and considering the price of some

> of the price of the pre-made ones for simpler

> repraps, I don't want to empty my bank account

> just for the electronics

>

> yes i know how to make pcb's (haven't tried

> multi-layer yet, but is a possibility, anyone have

> experience especially with 3+ layer pcb's?, just

> curious ) and solder through-hole and smt

> components (will have to order components

> probably, and most order quantities are 1k+ so

> i'll have plenty extra

)

)Wow, just buy it

. RAMPS is dirt cheap, and works spectacular. I highly recommend stepstick A4988 drivers. You can also control servos. IMO, all these are sufficient, and all the math is there. The problem is effective mixing/volumes.

. RAMPS is dirt cheap, and works spectacular. I highly recommend stepstick A4988 drivers. You can also control servos. IMO, all these are sufficient, and all the math is there. The problem is effective mixing/volumes.The nanoliter calculation is the volume mixing - a latency. 1nL would go through before color changes from say red to white. That is the ideal, meaning, you can print anything, since a 0.1 mm layer height with the futuristic impossibly small 0.1mm or so nozzle size would give you near invisibly small color changes, you could "turn on a dime."

Its good to aim high at first. I love the idea of painting the out side of the filament as it comes out. We can keep brainstorming for now.

How small do you think we have to lay down filament before the colors blend together? Since a Retina display may have 128 micron pixels, with 40 submicron pixels, technically thats similar to how an inkjet mimicks color without mixing too. I think that is a more practical vision of color in the future 3D printer - 4 base colors, in this case CYMK would be placed so close that you cant see the color separations. now, practically, FFF seems impossibly slow, if we need to get to 0.1mm and we are at 0.35mm, it doesn't seem that far away, though the factor 3 is really 3^4 power times more force needed, and 3^3 power more print time to get desired prints out, its a start.

|

Re: Full Color 3d Printer Project March 07, 2013 04:06AM |

Registered: 11 years ago Posts: 44 |

Where is a RAMPS board that supports 10+ motors along with temperature control, etc. And how much is it including all boards for the motors and such. Each stepstick driver is $9.50 on amazon = $95 (maybe i'm missing bulk pricing idk) just for the drivers (doesn't look like RAMPS board has enough pins). Still seems making pcb would be much cheaper (not hard to do either).

There is 100µm nozzles i believe (or somewhere close to that).

laying down tiny 1-color dots on moving filament on the scale of a 3d build would slow it down, and if you color the side of the filament, won't some of the filament (still molten) maybe swirl and wouldn't you have to rotate the inkjet or something to make sure you are on the outside of the print?

Are we still talking about the process as being: filaments ->melting->mixing->extruding out a 100µm hole or are you thinking of another idea?

Reason for cyan/yellow/magenta/white/black I was saying for cyan/yellow/magenta/white for making all colors but black, and use black for actual black prints (cyan+yellow+magenta not a perfect black, either is black, but black would be closer wouldn't it?)

Hmm is there a way to get a separate motor to help force the mix'ed filament out of the nozzle(cant think of any atm, but this is a type bunch of maybe useful ideas and smash them together and make something out of it forum)?

Is there any software that can accommodate color mixing or at least be adaptable to doing so (preferably putting color additive values to match the desired output color)

The separate part for the not-so-perfect-mixing intermediates I think is a viable solution (yet if it can switch fast enough, won't need but color change "on a dime" shouldn't be required in order for it to work)

Any thoughts about the 2nd head for infill (among other things), so moving parts can be printed?

Anyone have any experience with the conductive filament (seems way too high resistance but idk)?

Please feel free to ask/correct/add/discuss about anything (relevant please) I try to read and respond to everything when I'm able, i'm really interested in getting this "perfected" and having a working base design

Edited 1 time(s). Last edit at 03/07/2013 04:08AM by CPS.

There is 100µm nozzles i believe (or somewhere close to that).

laying down tiny 1-color dots on moving filament on the scale of a 3d build would slow it down, and if you color the side of the filament, won't some of the filament (still molten) maybe swirl and wouldn't you have to rotate the inkjet or something to make sure you are on the outside of the print?

Are we still talking about the process as being: filaments ->melting->mixing->extruding out a 100µm hole or are you thinking of another idea?

Reason for cyan/yellow/magenta/white/black I was saying for cyan/yellow/magenta/white for making all colors but black, and use black for actual black prints (cyan+yellow+magenta not a perfect black, either is black, but black would be closer wouldn't it?)

Hmm is there a way to get a separate motor to help force the mix'ed filament out of the nozzle(cant think of any atm, but this is a type bunch of maybe useful ideas and smash them together and make something out of it forum)?

Is there any software that can accommodate color mixing or at least be adaptable to doing so (preferably putting color additive values to match the desired output color)

The separate part for the not-so-perfect-mixing intermediates I think is a viable solution (yet if it can switch fast enough, won't need but color change "on a dime" shouldn't be required in order for it to work)

Any thoughts about the 2nd head for infill (among other things), so moving parts can be printed?

Anyone have any experience with the conductive filament (seems way too high resistance but idk)?

Please feel free to ask/correct/add/discuss about anything (relevant please) I try to read and respond to everything when I'm able, i'm really interested in getting this "perfected" and having a working base design

Edited 1 time(s). Last edit at 03/07/2013 04:08AM by CPS.

|

Re: Full Color 3d Printer Project March 07, 2013 01:31PM |

Registered: 11 years ago Posts: 482 |

the firmware will do the mixing. the software has to slice VRML format to give it a simple RGB gcode.

As for nozzles, you you can buy a ruby nozzle for 100 micron diameter. However it is useless in two ways. 1) the nozzle is designed to fit inside a larger holder, which blocks the tip from being able to touch anything. 2) You can not extrude beloe 0.35mm diameter. Someone has extruded 0.25mm, but it requires so much pressure they machine crashes and needs to be cleaned. As the system approached 0.1mm, it becomes exponentially harder to extrude (based on flow equations, proportionate to the fourth power of inverse diameter!)

I would not worry about this electronic control so much. I am not aware of a 10 motor control, but I'm sure many people would buy it . We are planning to design one but lack the PCB expertise to do it. Still I think it is easy based on arduino mega + i/o expansion.

. We are planning to design one but lack the PCB expertise to do it. Still I think it is easy based on arduino mega + i/o expansion.

As for nozzles, you you can buy a ruby nozzle for 100 micron diameter. However it is useless in two ways. 1) the nozzle is designed to fit inside a larger holder, which blocks the tip from being able to touch anything. 2) You can not extrude beloe 0.35mm diameter. Someone has extruded 0.25mm, but it requires so much pressure they machine crashes and needs to be cleaned. As the system approached 0.1mm, it becomes exponentially harder to extrude (based on flow equations, proportionate to the fourth power of inverse diameter!)

I would not worry about this electronic control so much. I am not aware of a 10 motor control, but I'm sure many people would buy it

. We are planning to design one but lack the PCB expertise to do it. Still I think it is easy based on arduino mega + i/o expansion.

. We are planning to design one but lack the PCB expertise to do it. Still I think it is easy based on arduino mega + i/o expansion.

|

Re: Full Color 3d Printer Project March 07, 2013 02:19PM |

Registered: 11 years ago Posts: 44 |

|

Re: Full Color 3d Printer Project March 07, 2013 02:27PM |

Registered: 11 years ago Posts: 482 |

CPS Wrote:

-------------------------------------------------------

> Xeed 3d printer uses a 0.2mm nozzle:

> [www.lpfrg.com]

>

> What do you suggest?

"€5,460"

But like I said, going from 0.35 mm to 0.1 mm isn't going to be impossible, its a matter of incremental improvements.

a 200 micron layer thickness though, is 4 human hairs thick. Color mixing can not be done here.

Practically how about this: A nozzle that takes filament of 4 colors, then extrudes through to 4X 0.05 mm nozzles, and all the exits are joined together to make a ~ 0.2 mm nozzle. The output would be unmixed, but the naked eye almost can't tell.

Likewise, if flow rate is a problem you could amplify this, i.e. 0.35 mm nozzle with 5 subpixel nozzles. Then we are talking some advanced microfluidics and still a decent backpressure normal filastruders can't handle. This is part of the reason for the higher price tag.

Also, what is up with these specifications...

200 mm / minute speed ??

400 watt? What are they doing there.

[www.lpfrg.com]

Also just noticed "We are working hard to finalize the design. We are taking pre-orders with 50% down payment. Contact us at: info ‘at’ lpfrg.com" May be they have not done the 0.2mm yet, I don't see pictures of anything but the machine... hmmmm

You'll note the finalized product before it, Creatr has a "0.35 mm" nozzle.

Edited 5 time(s). Last edit at 03/07/2013 02:37PM by Simba.

-------------------------------------------------------

> Xeed 3d printer uses a 0.2mm nozzle:

> [www.lpfrg.com]

>

> What do you suggest?

"€5,460"

But like I said, going from 0.35 mm to 0.1 mm isn't going to be impossible, its a matter of incremental improvements.

a 200 micron layer thickness though, is 4 human hairs thick. Color mixing can not be done here.

Practically how about this: A nozzle that takes filament of 4 colors, then extrudes through to 4X 0.05 mm nozzles, and all the exits are joined together to make a ~ 0.2 mm nozzle. The output would be unmixed, but the naked eye almost can't tell.

Likewise, if flow rate is a problem you could amplify this, i.e. 0.35 mm nozzle with 5 subpixel nozzles. Then we are talking some advanced microfluidics and still a decent backpressure normal filastruders can't handle. This is part of the reason for the higher price tag.

Also, what is up with these specifications...

200 mm / minute speed ??

400 watt? What are they doing there.

[www.lpfrg.com]

Also just noticed "We are working hard to finalize the design. We are taking pre-orders with 50% down payment. Contact us at: info ‘at’ lpfrg.com" May be they have not done the 0.2mm yet, I don't see pictures of anything but the machine... hmmmm

You'll note the finalized product before it, Creatr has a "0.35 mm" nozzle.

Edited 5 time(s). Last edit at 03/07/2013 02:37PM by Simba.

|

Re: Full Color 3d Printer Project March 07, 2013 03:50PM |

Registered: 11 years ago Posts: 44 |

yea way too expensive I know, especially half of it down and you won't know if/when u'll get it (

On ebay, 0.25mm nozzle: [www.ebay.com]

Assembled hot end 0.25mm (says 0.2mm also but idk): [www.ebay.com]

Color mixing before going into the exit nozzle on the hot end, wouldn't it not matter how big the hole is

On ebay, 0.25mm nozzle: [www.ebay.com]

Assembled hot end 0.25mm (says 0.2mm also but idk): [www.ebay.com]

Color mixing before going into the exit nozzle on the hot end, wouldn't it not matter how big the hole is

|

Re: Full Color 3d Printer Project March 09, 2013 02:58PM |

Registered: 12 years ago Posts: 313 |

CPS Wrote:

-------------------------------------------------------

> Where is a RAMPS board that supports 10+ motors

> along with temperature control, etc. And how much

> is it including all boards for the motors and

> such. Each stepstick driver is $9.50 on amazon =

> $95 (maybe i'm missing bulk pricing idk) just for

> the drivers (doesn't look like RAMPS board has

> enough pins). Still seems making pcb would be much

> cheaper (not hard to do either).

Worrying about the electronics at this stage is like counting your chickens before they have even evolved from dinosaurs.

-------------------------------------------------------

> Where is a RAMPS board that supports 10+ motors

> along with temperature control, etc. And how much

> is it including all boards for the motors and

> such. Each stepstick driver is $9.50 on amazon =

> $95 (maybe i'm missing bulk pricing idk) just for

> the drivers (doesn't look like RAMPS board has

> enough pins). Still seems making pcb would be much

> cheaper (not hard to do either).

Worrying about the electronics at this stage is like counting your chickens before they have even evolved from dinosaurs.

|

Re: Full Color 3d Printer Project March 09, 2013 03:06PM |

Registered: 11 years ago Posts: 44 |

|

Re: Full Color 3d Printer Project March 14, 2013 02:16AM |

Registered: 11 years ago Posts: 44 |

|

Re: Full Color 3d Printer Project March 16, 2013 10:33PM |

Registered: 11 years ago Posts: 38 |

Rather than using markers before the filament is extruded ...

What if you had a cluster of markers on the x-carriage each of which is connected to a solenoid which raises and lowers it.

You would print a white substrate layer and then "go over" the printed layer with the necessary marker colors.

As the markers have a felt tip your tolerances on the raising and lowering of the markers probably don't need to be accurate to the micron level. With careful design you should be even able to drive N markers off a pair on motors (one to select and one to lower).By the way the Azteeg X3 (with v1.5 shield) has 4 MOSFET PWM switched outputs available + 6 motor driver outputs.

Sounds like a good project for someone!

Edited 3 time(s). Last edit at 03/17/2013 06:36PM by buildrob.

What if you had a cluster of markers on the x-carriage each of which is connected to a solenoid which raises and lowers it.

You would print a white substrate layer and then "go over" the printed layer with the necessary marker colors.

As the markers have a felt tip your tolerances on the raising and lowering of the markers probably don't need to be accurate to the micron level. With careful design you should be even able to drive N markers off a pair on motors (one to select and one to lower).By the way the Azteeg X3 (with v1.5 shield) has 4 MOSFET PWM switched outputs available + 6 motor driver outputs.

Sounds like a good project for someone!

Edited 3 time(s). Last edit at 03/17/2013 06:36PM by buildrob.

|

Re: Full Color 3d Printer Project March 17, 2013 07:46PM |

Registered: 11 years ago Posts: 44 |

Not using markers at all.

BTW it only has 5 independent motor driver outputs (the 2 Z axis aren't independently controllable)

Need more than 6 motor driver outputs, need 10+; I can make the pcb, if I knew the circuit and BOM. (ofc compatible software)

I have thought about 5-axis later on(6th axis won't be used as long as it is being built up layer by layer), but I believe infill would solve most, if not all, of the limitations of using a 3-axis system.

Edited 3 time(s). Last edit at 03/17/2013 08:26PM by CPS.

BTW it only has 5 independent motor driver outputs (the 2 Z axis aren't independently controllable)

Need more than 6 motor driver outputs, need 10+; I can make the pcb, if I knew the circuit and BOM. (ofc compatible software)

I have thought about 5-axis later on(6th axis won't be used as long as it is being built up layer by layer), but I believe infill would solve most, if not all, of the limitations of using a 3-axis system.

Edited 3 time(s). Last edit at 03/17/2013 08:26PM by CPS.

|

Re: Full Color 3d Printer Project March 18, 2013 05:24AM |

Registered: 11 years ago Posts: 38 |

The Azteeg X3 base board has 5 independent motor drivers (XYZE1E2) and the v1.1 expansion board (which now comes standard as far as I understand) now adds the connectors for 3 more motor controllers - which is actually 8 independent axis not 6 as I originally said (although they don't include the Polulo style headers for the ones on the expansion board).

The question is: do you need to drive all axis simultaneously? If not then you could multiplex through the different extrusion axes. I think they used tricks like this because they had full dual extruder support on boards - not sure how successfully.

[Edit: just checked the Azteeg X3 product page and it is three extra motor axis on the shield not two - which brings the total to 8 independent motor axis - this could get you to 5 hotends & thermistors if you didn't bother with a heated bed.]

Edited 6 time(s). Last edit at 03/18/2013 07:28AM by buildrob.

The question is: do you need to drive all axis simultaneously? If not then you could multiplex through the different extrusion axes. I think they used tricks like this because they had full dual extruder support on boards - not sure how successfully.

[Edit: just checked the Azteeg X3 product page and it is three extra motor axis on the shield not two - which brings the total to 8 independent motor axis - this could get you to 5 hotends & thermistors if you didn't bother with a heated bed.]

Edited 6 time(s). Last edit at 03/18/2013 07:28AM by buildrob.

|

Re: Full Color 3d Printer Project March 18, 2013 07:04AM |

Registered: 11 years ago Posts: 44 |

bare minimum i guess: has to be able to at least run at least XY (for diagonal movement, cant print tiny right angles lol)+ 4 extruders (for color options, maybe 5 not positive) at the same time, i'm not sure if Z axis has be available at the same time as well. The other extruder head with infill should be able to be multiplexed without printed part design issues

Anyone have success in multiplexing extruders for 3d printing?

Edited 1 time(s). Last edit at 03/18/2013 07:14AM by CPS.

Anyone have success in multiplexing extruders for 3d printing?

Edited 1 time(s). Last edit at 03/18/2013 07:14AM by CPS.

|

Re: Full Color 3d Printer Project March 21, 2013 12:04AM |

Registered: 11 years ago Posts: 482 |

Hi CPS and others

Great discussion. I'm starting to dislike the marker idea a bit now.

This is totally incidental, but we are having a 10-stepper controller ramps being made now. I'll let you know when it is done, but it is only for steppers + endstops. You'd have to add an expansion or we have to make revisions to include the standard pieces like heater fets and thermistors.

Edited 1 time(s). Last edit at 03/21/2013 12:04AM by Simba.

Great discussion. I'm starting to dislike the marker idea a bit now.

This is totally incidental, but we are having a 10-stepper controller ramps being made now. I'll let you know when it is done, but it is only for steppers + endstops. You'd have to add an expansion or we have to make revisions to include the standard pieces like heater fets and thermistors.

Edited 1 time(s). Last edit at 03/21/2013 12:04AM by Simba.

|

Re: Full Color 3d Printer Project March 21, 2013 02:20AM |

Registered: 11 years ago Posts: 44 |

Yea i don't really like the marker idea either for various reasons

YAY good news =) how long till you think it will be done (i can etch and assemble, any1 tried using silver or graphene ink for pcb's yet?) Aww why no heatbed + thermistors 2 important things that's needed on every awesome 3d printer pcb, looking forward to it though.

YAY good news =) how long till you think it will be done (i can etch and assemble, any1 tried using silver or graphene ink for pcb's yet?) Aww why no heatbed + thermistors 2 important things that's needed on every awesome 3d printer pcb, looking forward to it though.

|

Re: Full Color 3d Printer Project March 21, 2013 02:26AM |

Registered: 11 years ago Posts: 482 |

CPS Wrote:

-------------------------------------------------------

> Yea i don't really like the marker idea either for

> various reasons

>

> YAY good news =) how long till you think it will

> be done (i can etch and assemble, any1 tried using

> silver or graphene ink for pcb's yet?) Aww why no

> heatbed + thermistors 2 important things that's

> needed on every awesome 3d printer pcb, looking

> forward to it though.

Because I wanted to keep the PCB design simple for the first run... also keeps costs down for many people who just want a stepper controller for robotics. The price to add features like FETs and thermistors is practically proprtionate with a small expansion board. ...And at this rate, we'll have samples in 1-2 weeks, I will let you know about the production run.

-------------------------------------------------------

> Yea i don't really like the marker idea either for

> various reasons

>

> YAY good news =) how long till you think it will

> be done (i can etch and assemble, any1 tried using

> silver or graphene ink for pcb's yet?) Aww why no

> heatbed + thermistors 2 important things that's

> needed on every awesome 3d printer pcb, looking

> forward to it though.

Because I wanted to keep the PCB design simple for the first run... also keeps costs down for many people who just want a stepper controller for robotics. The price to add features like FETs and thermistors is practically proprtionate with a small expansion board. ...And at this rate, we'll have samples in 1-2 weeks, I will let you know about the production run.

|

Re: Full Color 3d Printer Project March 21, 2013 02:38AM |

Registered: 11 years ago Posts: 44 |

|

Re: Full Color 3d Printer Project March 22, 2013 11:09AM |

Registered: 11 years ago Posts: 482 |

|

Re: Full Color 3d Printer Project March 22, 2013 03:58PM |

Registered: 11 years ago Posts: 369 |

o gawd ... and this PDF u made was 3 months ago ... and it looks so fantastic !

most of you have already build at least 1 machine, as for me, i have only finish one unit of X axis LOL (but it is over 600mm long).

i do think the AT2560 can do much more, however, that will require some re-design (i just tried KiCad, and it is so much more fun then my stiffy veroboards), maybe a docking board that allows a single AT2560 to interface with 2 or more ramps boards. i have yet to really look at how a arduino talks to a ramps, maybe by then, i could put some time into making such a docker.

as the number of diff feed materials increase, i think it will be nice to have a dedicated daughter board that uses K-thermocouples and digital PWM heaters, the daughter board feeds data to the main AT2560 board, so there is a 2 way comms there. i believe i read somewhere, feed materials have diff melt temps for diff colors.

to simplify the entire main machine build, i think the color mixer should be a seperate add on entity. a daughter board that reads color info and commands the color mix portion of the machine. the extra data stream with color information will do whatever it needs with the color mixer "head", and the print side of things still works like a .... basic 3dprinter. i cant imagine how the user will input the color data, overlay a real picture of the object?

just picking numbers off the top of my head here w/o actually knowing arduino/ramps well :

each XYZ+filament = 1 EN, 1DIR, 1 step = 12 channels

sensor + heater bed on/off =2

sensor + nozzle heater on/off =2

XYZ limit switches = 6

so we are really only using 22++ channels yes? (i am def wrong in this i think lol)

instead of having a massive increase in channel use involving multiple colors, you could multiplex color data over say, 1EN 1DIR 1step and 1 COLOR DATA CHANNEL, so a sub MCU will pick the filament "channel" based on the 4th color selection data (instead of have 6 x full set of channels of stepper drives). this multiplexing can be in the region of 1kHz? so practically, you can make a color mixer that accepts 10 colors with 10 extrusion drives, 10x stepsticks, etc but just 1 clever multiplexer and bingo.

as for the temperature control, the idea i had is borrowed from precision soldering machines, kinda hard to explain here. but seeing that you have a whole mechanical fab in your uni. it should be a breeze compared to my 3 sq foot lab HAHAHA ... i need a bloody 5in1 lathe to do what u did to the hexagonal mixer, that is really a nice turn in printing advancements, have you tried using those mini burring heads as a mixer? the smaller the buffer/heating chamber, the faster the print head can follow the printing color information, unless .... you wanna ultrasonically shoot the plastics like a inkjet head? i wonder, at wat frequency does PLA/ABS change state ... do you have facilities to try that?

... i need a bloody 5in1 lathe to do what u did to the hexagonal mixer, that is really a nice turn in printing advancements, have you tried using those mini burring heads as a mixer? the smaller the buffer/heating chamber, the faster the print head can follow the printing color information, unless .... you wanna ultrasonically shoot the plastics like a inkjet head? i wonder, at wat frequency does PLA/ABS change state ... do you have facilities to try that?

cheerio

CPS Wrote:

-------------------------------------------------------

> What do you think about this:

> [www.reprap.org]

> ColourMixingReport-jmc.pdf

Edited 2 time(s). Last edit at 03/22/2013 04:57PM by redreprap.

______________________________________

__my mixed bag blog || aka --> [http] || ___ so 3D printing is everywhere ... dont worry, hospitals can now 3Dprint body parts, they will charge you $1million excluding surgical fees ... you will die paying your debts. thats their aim ___ if every patent expires tomorrow, everybody will surely get a 3dprinter and make EVERYTHING ! ____ there is a "DIY-DTG" t shirt printing forum, you can mod an EPSON printer to PRINT like a pro. ___ CNCzone? overly commercialized it seems ___ my country? they will be taxing you for every cm of road you use and track you to your grave using GPS and its government authorized, now they will fire all the traffic wardens instead.___ EEVBLOG? there is only 1 way to do things --> take it apart like a pro

most of you have already build at least 1 machine, as for me, i have only finish one unit of X axis LOL (but it is over 600mm long).

i do think the AT2560 can do much more, however, that will require some re-design (i just tried KiCad, and it is so much more fun then my stiffy veroboards), maybe a docking board that allows a single AT2560 to interface with 2 or more ramps boards. i have yet to really look at how a arduino talks to a ramps, maybe by then, i could put some time into making such a docker.

as the number of diff feed materials increase, i think it will be nice to have a dedicated daughter board that uses K-thermocouples and digital PWM heaters, the daughter board feeds data to the main AT2560 board, so there is a 2 way comms there. i believe i read somewhere, feed materials have diff melt temps for diff colors.

to simplify the entire main machine build, i think the color mixer should be a seperate add on entity. a daughter board that reads color info and commands the color mix portion of the machine. the extra data stream with color information will do whatever it needs with the color mixer "head", and the print side of things still works like a .... basic 3dprinter. i cant imagine how the user will input the color data, overlay a real picture of the object?

just picking numbers off the top of my head here w/o actually knowing arduino/ramps well :

each XYZ+filament = 1 EN, 1DIR, 1 step = 12 channels

sensor + heater bed on/off =2

sensor + nozzle heater on/off =2

XYZ limit switches = 6

so we are really only using 22++ channels yes? (i am def wrong in this i think lol)

instead of having a massive increase in channel use involving multiple colors, you could multiplex color data over say, 1EN 1DIR 1step and 1 COLOR DATA CHANNEL, so a sub MCU will pick the filament "channel" based on the 4th color selection data (instead of have 6 x full set of channels of stepper drives). this multiplexing can be in the region of 1kHz? so practically, you can make a color mixer that accepts 10 colors with 10 extrusion drives, 10x stepsticks, etc but just 1 clever multiplexer and bingo.

as for the temperature control, the idea i had is borrowed from precision soldering machines, kinda hard to explain here. but seeing that you have a whole mechanical fab in your uni. it should be a breeze compared to my 3 sq foot lab HAHAHA

... i need a bloody 5in1 lathe to do what u did to the hexagonal mixer, that is really a nice turn in printing advancements, have you tried using those mini burring heads as a mixer? the smaller the buffer/heating chamber, the faster the print head can follow the printing color information, unless .... you wanna ultrasonically shoot the plastics like a inkjet head? i wonder, at wat frequency does PLA/ABS change state ... do you have facilities to try that?

... i need a bloody 5in1 lathe to do what u did to the hexagonal mixer, that is really a nice turn in printing advancements, have you tried using those mini burring heads as a mixer? the smaller the buffer/heating chamber, the faster the print head can follow the printing color information, unless .... you wanna ultrasonically shoot the plastics like a inkjet head? i wonder, at wat frequency does PLA/ABS change state ... do you have facilities to try that?

cheerio

CPS Wrote:

-------------------------------------------------------

> What do you think about this:

> [www.reprap.org]

> ColourMixingReport-jmc.pdf

Edited 2 time(s). Last edit at 03/22/2013 04:57PM by redreprap.

______________________________________

__my mixed bag blog || aka --> [http] || ___ so 3D printing is everywhere ... dont worry, hospitals can now 3Dprint body parts, they will charge you $1million excluding surgical fees ... you will die paying your debts. thats their aim ___ if every patent expires tomorrow, everybody will surely get a 3dprinter and make EVERYTHING ! ____ there is a "DIY-DTG" t shirt printing forum, you can mod an EPSON printer to PRINT like a pro. ___ CNCzone? overly commercialized it seems ___ my country? they will be taxing you for every cm of road you use and track you to your grave using GPS and its government authorized, now they will fire all the traffic wardens instead.___ EEVBLOG? there is only 1 way to do things --> take it apart like a pro

|

Re: Full Color 3d Printer Project March 23, 2013 03:41PM |

Registered: 11 years ago Posts: 482 |

|

Re: Full Color 3d Printer Project March 23, 2013 07:20PM |

Registered: 13 years ago Posts: 486 |

|

Re: Full Color 3d Printer Project March 24, 2013 03:26AM |

Registered: 13 years ago Posts: 486 |

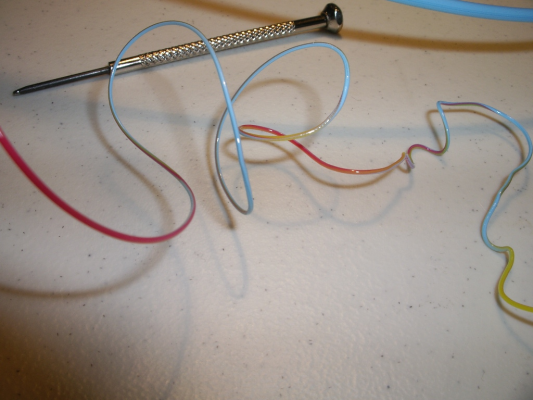

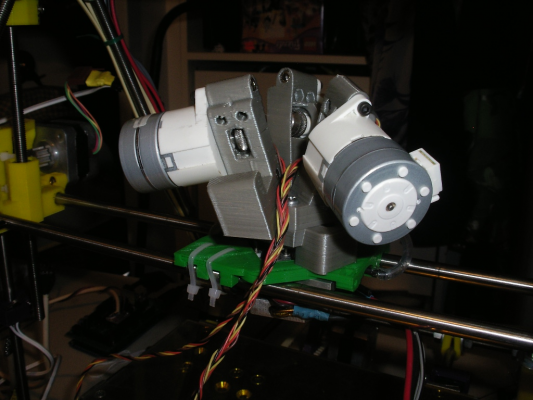

Here is some filament from the first test of my 3 colour feed to one nozzle extruder:

From 3 colour extruder:

Edited 1 time(s). Last edit at 03/24/2013 03:27AM by Greg Frost.

From 3 colour extruder:

Edited 1 time(s). Last edit at 03/24/2013 03:27AM by Greg Frost.

|

Re: Full Color 3d Printer Project March 24, 2013 04:56AM |

Registered: 11 years ago Posts: 44 |

|

Re: Full Color 3d Printer Project April 15, 2013 11:19PM |

Registered: 11 years ago Posts: 2 |

Have you all seen RichRap's 3-colour mixing extruder head? One nozzle. 3 filaments. It's on Thingiverse.

3-Way Mixing Extruder and Colour Blending Nozzle

Jason

3-Way Mixing Extruder and Colour Blending Nozzle

Jason

|

Re: Full Color 3d Printer Project April 15, 2013 11:48PM |

Registered: 11 years ago Posts: 369 |

hey that looks fun, so what did he do to his heating chamber? have space for 3 filaments at the same time? and taper it into 1?

______________________________________

__my mixed bag blog || aka --> [http] || ___ so 3D printing is everywhere ... dont worry, hospitals can now 3Dprint body parts, they will charge you $1million excluding surgical fees ... you will die paying your debts. thats their aim ___ if every patent expires tomorrow, everybody will surely get a 3dprinter and make EVERYTHING ! ____ there is a "DIY-DTG" t shirt printing forum, you can mod an EPSON printer to PRINT like a pro. ___ CNCzone? overly commercialized it seems ___ my country? they will be taxing you for every cm of road you use and track you to your grave using GPS and its government authorized, now they will fire all the traffic wardens instead.___ EEVBLOG? there is only 1 way to do things --> take it apart like a pro

______________________________________

__my mixed bag blog || aka --> [http] || ___ so 3D printing is everywhere ... dont worry, hospitals can now 3Dprint body parts, they will charge you $1million excluding surgical fees ... you will die paying your debts. thats their aim ___ if every patent expires tomorrow, everybody will surely get a 3dprinter and make EVERYTHING ! ____ there is a "DIY-DTG" t shirt printing forum, you can mod an EPSON printer to PRINT like a pro. ___ CNCzone? overly commercialized it seems ___ my country? they will be taxing you for every cm of road you use and track you to your grave using GPS and its government authorized, now they will fire all the traffic wardens instead.___ EEVBLOG? there is only 1 way to do things --> take it apart like a pro

|

Re: Full Color 3d Printer Project April 26, 2013 02:14PM |

Registered: 11 years ago Posts: 44 |

Sorry, only registered users may post in this forum.