Full Color 3d Printer Project

Posted by CPS

|

Re: Full Color 3d Printer Project May 22, 2014 12:46PM |

Registered: 9 years ago Posts: 3 |

Quote

ekaggrat

@gyrobot

any chance of sharing the script. the aprinter frimware supports gcode for two extruders in the following format : " g1 x100 y100 e10 u 20 " if you could share your script i could change it to that format and then use it on my dual color mixing extruder...

thanks

Hi, thank you for your interest, I have uploaded the script to Github Gcode-Filament-Mixer which has been edited to output E and U percentage extrusion rates. Please keep me informed on how you get on.

Cheers

Steve Wood AKA Gyrobot

[www.gyrobot.co.uk]

|

Re: Full Color 3d Printer Project August 21, 2014 05:03PM |

Registered: 12 years ago Posts: 14 |

Hi Gents.

I am designing and building a printer from scratch, and would like to include mixing in the design. I am surprised that they are not standard equipment by now, and I am wondering why? It might be wrapped up in a patent somewhere, and if I merrily develop it, I might get sued or something?

I am designing and building a printer from scratch, and would like to include mixing in the design. I am surprised that they are not standard equipment by now, and I am wondering why? It might be wrapped up in a patent somewhere, and if I merrily develop it, I might get sued or something?

|

Re: Full Color 3d Printer Project August 21, 2014 07:00PM |

Registered: 11 years ago Posts: 364 |

@alayax

The hardware for a mixer is a bit complex and you need a active mixer to get a good mix. After you get that right the biggest problem is getting a slicer to generate g-code for color mixing. Once you get that through you need a firmware which supports that

Yes all this is so simple ( sarcasm ) that you could do it in a day. Go figure

The hardware for a mixer is a bit complex and you need a active mixer to get a good mix. After you get that right the biggest problem is getting a slicer to generate g-code for color mixing. Once you get that through you need a firmware which supports that

Yes all this is so simple ( sarcasm ) that you could do it in a day. Go figure

|

Re: Full Color 3d Printer Project August 31, 2014 02:10PM |

Registered: 10 years ago Posts: 14,672 |

The (open-source) firmware for the RepRapPro Duet controller board, used on the Ormerod 3D printer kit, has supported gcodes for colour mixing for some months now. The syntax for a 3-filament machine would be e.g. G1 X10 Y10 E5:6:7 where 5, 6 and 7mm are the amounts of filament to be extruded.

Adrian Bower published a blog entry about what they were trying at [reprappro.com]. The blog entry doesn't describe colour mixing, it describes feeding different filaments through a single nozzle at different times.

For full colour printing, I think the main challenge is to machine a nozzle that has 3 or more filament feeds into a mixing chamber.

Edited 2 time(s). Last edit at 08/31/2014 02:14PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Adrian Bower published a blog entry about what they were trying at [reprappro.com]. The blog entry doesn't describe colour mixing, it describes feeding different filaments through a single nozzle at different times.

For full colour printing, I think the main challenge is to machine a nozzle that has 3 or more filament feeds into a mixing chamber.

Edited 2 time(s). Last edit at 08/31/2014 02:14PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Full Color 3d Printer Project September 10, 2014 08:58AM |

Registered: 9 years ago Posts: 105 |

|

Re: Full Color 3d Printer Project September 10, 2014 06:54PM |

Registered: 11 years ago Posts: 791 |

Quote

Miertam

Has anyone tried mixing laser toner into natural filament? it should become bonded at around 200C.

Thanks Mike

I tried sublimation ink and it worked fine, except the colour stayed with the filament for a long time after stopping it.

I just wiped a bit of the ink on the side of the filament and it mixes when melted. Some seems to stay inside the nozzle.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Full Color 3d Printer Project September 10, 2014 08:41PM |

Registered: 12 years ago Posts: 14 |

Thanks for that, if it is only a ridiculously complicated engineering problem rather that some IP issue, then I am all over it.

I have been developing a Design that has three (or five if I increase the diameter) filament inlets, and an active mixer. My current electronics is RAMPS 1.4, and that can only control two filament feeds at a time, so am going to have to look at upgrading the electronics soon. Just had a look at the Duet page that dc42 mentionend (http://reprap.org/wiki/Duet ) and that looks perfect for the job.

I have the stepper feeders and mixer stepper mounted on the frame, to reduce moving mass, and allow enough space to get the guide tubes into the mixing area. I am also working to incorporate a self cleaning, variable diameter nozzle, so there is really not a lot of space to play with. It is going to be a bugger to machine and assemble a reliable setup.

I had thought of mixing powders to change the properties, though not laser toner. Powders are much tricker to feed and control without compacting and clogging. It would need vibrators to make it work, and I am not keen on sending vibrations though the printhead. I am not so much fussed over colour printing as multi material, so I would mix in graphene or metallics to change the material properties. I am thinking more along the lines of highly pigmented pellets, paste or filament to add colour or "material property modifiers". If I can get the density of metals high enough it could be printed and then sintered to make a metal part. So the final part would be like "course grained Aerogel"

Right now my experimental machines's steppers won't step smoothly, so I have to solve that first before I can test any of that. No matter where I set the trim pot, they just won't turn smoothly. It is a Techzone Huxley, and I can not find the exact step motor specs to adjust the current to. If anyone knows, or knows where to find the specs, please let me know.

Has anybody thought of designing a board that has "real time electronic control" over the current? Would be handy if it needs more holding torque for a few seconds (like light CNC machining, or wiping the nozzle clean). I am better at mechanical, and not so much at electronics and code, so please feel free to tell me to stick to stuff I know about if it is not possible or practical.

Edited 1 time(s). Last edit at 09/10/2014 08:56PM by Alayax.

I have been developing a Design that has three (or five if I increase the diameter) filament inlets, and an active mixer. My current electronics is RAMPS 1.4, and that can only control two filament feeds at a time, so am going to have to look at upgrading the electronics soon. Just had a look at the Duet page that dc42 mentionend (http://reprap.org/wiki/Duet ) and that looks perfect for the job.

I have the stepper feeders and mixer stepper mounted on the frame, to reduce moving mass, and allow enough space to get the guide tubes into the mixing area. I am also working to incorporate a self cleaning, variable diameter nozzle, so there is really not a lot of space to play with. It is going to be a bugger to machine and assemble a reliable setup.

I had thought of mixing powders to change the properties, though not laser toner. Powders are much tricker to feed and control without compacting and clogging. It would need vibrators to make it work, and I am not keen on sending vibrations though the printhead. I am not so much fussed over colour printing as multi material, so I would mix in graphene or metallics to change the material properties. I am thinking more along the lines of highly pigmented pellets, paste or filament to add colour or "material property modifiers". If I can get the density of metals high enough it could be printed and then sintered to make a metal part. So the final part would be like "course grained Aerogel"

Right now my experimental machines's steppers won't step smoothly, so I have to solve that first before I can test any of that. No matter where I set the trim pot, they just won't turn smoothly. It is a Techzone Huxley, and I can not find the exact step motor specs to adjust the current to. If anyone knows, or knows where to find the specs, please let me know.

Has anybody thought of designing a board that has "real time electronic control" over the current? Would be handy if it needs more holding torque for a few seconds (like light CNC machining, or wiping the nozzle clean). I am better at mechanical, and not so much at electronics and code, so please feel free to tell me to stick to stuff I know about if it is not possible or practical.

Edited 1 time(s). Last edit at 09/10/2014 08:56PM by Alayax.

|

Re: Full Color 3d Printer Project September 11, 2014 05:38AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Alayax

Just had a look at the Duet page that dc42 mentionend (http://reprap.org/wiki/Duet ) and that looks perfect for the job.

Bear in mind that the Duet by itself controls only 4 stepper motors. To control additional extruders, you also need the DueX4 expansion board. Duet boards are available from RepRapPro and from think3dprint3d, and DuetX4 boards are available from think3dprint3d.

Quote

Alayax

Right now my experimental machines's steppers won't step smoothly, so I have to solve that first before I can test any of that. No matter where I set the trim pot, they just won't turn smoothly. It is a Techzone Huxley, and I can not find the exact step motor specs to adjust the current to. If anyone knows, or knows where to find the specs, please let me know.

The exact current should not be critical. Too low and the motor will not produce enough torque. Too high and they will get too hot. Between those two limits, any current should work. When the motor current is off, do the axes move smoothly? If not, you need to sort that out. Is it only during acceleration and high-speed movements that they won't move smoothly? If so, then the problem is more likely to be insufficient voltage than insufficient current. Try reducing the maximum acceleration and/or speed that the software commands, or increasing the supply voltage to the stepper motor chips (taking care to stay within the limits of the chips and any associated capacitors etc.).

Quote

Alayax

Has anybody thought of designing a board that has "real time electronic control" over the current? Would be handy if it needs more holding torque for a few seconds (like light CNC machining, or wiping the nozzle clean). I am better at mechanical, and not so much at electronics and code, so please feel free to tell me to stick to stuff I know about if it is not possible or practical.

The Duet board and its firmware provide software control over the stepper motor currents, using gcode commands. Normally this is only used to set the stepper motor currents from values stored in a configuration file, and to turn the motors off at the end of a job. But it could be used to do more.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Full Color 3d Printer Project October 15, 2014 03:24AM |

Registered: 12 years ago Posts: 14 |

Hi Gents

I have designed a provisional concept, and I have no doubt that is is going to need further modification. Ordinarily I keep my designs as simple as possible, but this one does very many things, so it is a complex bit of gear, more like a clock than a print head. The design includes an adjustable extruder nozzle, with a self cleaning mixer and five filament inputs. This means that at the moment the components that need to be controlled are: 2 power resistors, one thermocouple, two step motors and two magnetic contacts (or a dual direction solenoid, depending on what works better). The mixer is driven by a step motor, simply because it needs accurate alignment in order to clear the extruder holes, and also adjust the extruder diameter.

I have not allowed for heat expansion for the different moving parts yet, nor have I checked thermal properties, but I think the design will keep the heat where it is needed, and keep it away from where we don't want it.

So in total the electronics for an 5 material print head needs to control the X,Y and Z axis, as well as 5 filament feeders, and 2 print head step motors independently. That is 10 steppers total, plus drive magnets or solenoids. I think that the reprap pro duet is a good board to work with, but I don't know enough about it to know if it can control the print head and have enough the grunt to calculate mixed slice calculations? I would also like to add provision for a shaft encoder, and if at all possible machine vision. I am starting to think that it may need two sets of electronics, one to drive the printer axis and slicing, and the other just for the print head. Your input would be appreciated?

I will finish the design in the coming weeks, and machine a prototype. With my current ramps 1.4 electronics, I should be able to at least party test the mechanical parts. I will get a duet board setup when funds allow, for now I have spent more than my budget on a nc machine to machine the parts.

I also have a design for a much more efficient filament feed system as well, though that may or may not come about. The concept may be patented. I contacted the designers about a month ago to find out but have not heard back from them as yet.

The other thing is that I would like to bring this print head to market, both as a retrofit kit to existing machines and as part of a full new machine, along with a few other improvements I am working on, so I am not sure of the ethics of me getting feedback and support from the forums, and then me getting a wad of cash for it afterwards? Again your feedback would be appreciated.

I have attached a screengrab of the print head at present, hopefully to illustrate the concept without giving too much away to the competition

I have designed a provisional concept, and I have no doubt that is is going to need further modification. Ordinarily I keep my designs as simple as possible, but this one does very many things, so it is a complex bit of gear, more like a clock than a print head. The design includes an adjustable extruder nozzle, with a self cleaning mixer and five filament inputs. This means that at the moment the components that need to be controlled are: 2 power resistors, one thermocouple, two step motors and two magnetic contacts (or a dual direction solenoid, depending on what works better). The mixer is driven by a step motor, simply because it needs accurate alignment in order to clear the extruder holes, and also adjust the extruder diameter.

I have not allowed for heat expansion for the different moving parts yet, nor have I checked thermal properties, but I think the design will keep the heat where it is needed, and keep it away from where we don't want it.

So in total the electronics for an 5 material print head needs to control the X,Y and Z axis, as well as 5 filament feeders, and 2 print head step motors independently. That is 10 steppers total, plus drive magnets or solenoids. I think that the reprap pro duet is a good board to work with, but I don't know enough about it to know if it can control the print head and have enough the grunt to calculate mixed slice calculations? I would also like to add provision for a shaft encoder, and if at all possible machine vision. I am starting to think that it may need two sets of electronics, one to drive the printer axis and slicing, and the other just for the print head. Your input would be appreciated?

I will finish the design in the coming weeks, and machine a prototype. With my current ramps 1.4 electronics, I should be able to at least party test the mechanical parts. I will get a duet board setup when funds allow, for now I have spent more than my budget on a nc machine to machine the parts.

I also have a design for a much more efficient filament feed system as well, though that may or may not come about. The concept may be patented. I contacted the designers about a month ago to find out but have not heard back from them as yet.

The other thing is that I would like to bring this print head to market, both as a retrofit kit to existing machines and as part of a full new machine, along with a few other improvements I am working on, so I am not sure of the ethics of me getting feedback and support from the forums, and then me getting a wad of cash for it afterwards? Again your feedback would be appreciated.

I have attached a screengrab of the print head at present, hopefully to illustrate the concept without giving too much away to the competition

|

Re: Full Color 3d Printer Project October 15, 2014 12:53PM |

Registered: 9 years ago Posts: 50 |

|

Re: Full Color 3d Printer Project October 15, 2014 02:00PM |

Registered: 10 years ago Posts: 14,672 |

The Duet has plenty of spare I/O pins on the expansion connector, so adding extra stepper motor drivers would not be difficult. The Duet supports 4 motors, and if you add the X4 expansion board then you get 8 in total (not 7). Whatever solution you choose, I strongly recommend you avoid the older 8-bit Arduino-based solutions, because they are lacking in processor power.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Full Color 3d Printer Project October 15, 2014 05:01PM |

Registered: 9 years ago Posts: 50 |

|

Re: Full Color 3d Printer Project October 15, 2014 06:01PM |

Registered: 12 years ago Posts: 14 |

I haven't finally decided yet on whether to mount a small stepper on the extruded head yet. The alternative is the transfer the rotation via a rotary cable, like a Dremel extension cable, that is why the brass gears are shown in my screenshot . I don't think that will be accurate enough for cleaning and clearing the nozzle, so I am looking at getting small steeper to do that.something with around a 20 or 30 mm diameter. I am not a fan of moving mass, so almost all of the heavy parts are off the print head.

Initially I will make provision for five filament strands, but only drill the inputs for three, and plug one for testing using my ramps 1.4 electronics. The first iteration will only have three filament inputs, so that would bring the total stepper motors count down to eight,

So if I understand correctly, the duet boards don't use Arduino?

Regards

Leon

Initially I will make provision for five filament strands, but only drill the inputs for three, and plug one for testing using my ramps 1.4 electronics. The first iteration will only have three filament inputs, so that would bring the total stepper motors count down to eight,

So if I understand correctly, the duet boards don't use Arduino?

Regards

Leon

|

Re: Full Color 3d Printer Project October 16, 2014 03:06AM |

Registered: 10 years ago Posts: 14,672 |

The Duet board is derived from the Arduino Due design but provides more I/O including Ethernet. The firmware uses the Arduino Due core but is built in Eclipse.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Full Color 3d Printer Project October 23, 2014 03:24AM |

Registered: 9 years ago Posts: 50 |

I have recently switched filament color (ABS) while noticing that it needed lower temp, I'm not sure it isn't bad lack but..

It seems like this is an issue for all multicolored solution (I've seen till now) are there solutions I haven't read about yet?

Or all solution consists on fast injection before filament gets burn?

It seems like this is an issue for all multicolored solution (I've seen till now) are there solutions I haven't read about yet?

Or all solution consists on fast injection before filament gets burn?

|

Re: Full Color 3d Printer Project November 03, 2014 07:27PM |

Registered: 9 years ago Posts: 6 |

I still think that the injection of pigment at the print head is the way forward with colour fdl printer. Supply the head with a single filament, natural colour, and inject colour as the plastic extrudes. Ink-jet printing and the deposition of coloured dye (ink) is a mature technology, and due to the complexity of mixing plastics plus the 'inertia' that the viscosity of the plastic extrusion process means that colour mixing of filaments is so hard it's impractical.

Piezo electric injection of dye into the extruded plastic must be possible...

Have you guys considered an inkjet/j-head hybrid?

Jai

Piezo electric injection of dye into the extruded plastic must be possible...

Have you guys considered an inkjet/j-head hybrid?

Jai

|

Re: Full Color 3d Printer Project November 03, 2014 10:46PM |

Registered: 11 years ago Posts: 364 |

|

Re: Full Color 3d Printer Project November 03, 2014 11:14PM |

Registered: 11 years ago Posts: 791 |

I experimented with some sublimation ink and just wiped it on the side of some filament before printing.

It certainly colors the filament and it is all the way through to, but I didn't have any way to control it. I wanted to see if the sublimation ink would color the filament and that was very successful

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

It certainly colors the filament and it is all the way through to, but I didn't have any way to control it. I wanted to see if the sublimation ink would color the filament and that was very successful

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Full Color 3d Printer Project January 14, 2015 02:25PM |

Registered: 9 years ago Posts: 1 |

I have a very crude concept for an active mixing extruder.

6 filament paths placed radially around the main resistor. Additional resistors can be used on exterior of channels if materials require different temperatures. All paths lead into a small volume mixing chamber (cylinder shaped). Use a small neodymium cube in the chamber as the rotating mixer. Taper down the flow at the bottom of the mixing chamber to reduce the volume of colored filament between mixer and tip. Outside the mixing chamber use another neodymium ring magnet (dimetrically magnatized) as a stator. This exterior ring can be rotated with a small simple motor on OD with a couple bearings, without the need for another steper motor or aditional ramps. This should allow for a very light weight, low volume, multi-feed, and fully sealed active color mixing head.

Examples of magnets mentioned above:

Mixing cube

[www.supermagnetman.net]

Stator ring

[www.first4magnets.com]

6 filament paths placed radially around the main resistor. Additional resistors can be used on exterior of channels if materials require different temperatures. All paths lead into a small volume mixing chamber (cylinder shaped). Use a small neodymium cube in the chamber as the rotating mixer. Taper down the flow at the bottom of the mixing chamber to reduce the volume of colored filament between mixer and tip. Outside the mixing chamber use another neodymium ring magnet (dimetrically magnatized) as a stator. This exterior ring can be rotated with a small simple motor on OD with a couple bearings, without the need for another steper motor or aditional ramps. This should allow for a very light weight, low volume, multi-feed, and fully sealed active color mixing head.

Examples of magnets mentioned above:

Mixing cube

[www.supermagnetman.net]

Stator ring

[www.first4magnets.com]

|

Re: Full Color 3d Printer Project January 15, 2015 04:34AM |

Registered: 11 years ago Posts: 364 |

|

Re: Full Color 3d Printer Project January 15, 2015 12:09PM |

Registered: 12 years ago Posts: 153 |

|

Re: Full Color 3d Printer Project January 20, 2015 11:20AM |

Registered: 11 years ago Posts: 44 |

That could work for colder fluid mixing since it would lower friction at the mixing stage, but for our purposes of melting the plastics, heat from friction won't be too much of a hinder. The source of friction that we may want to reduce would be the mechanical components (to reduce wear not to reduce heat).

Edit: and also magnets would be bad for the hot end because of the extreme heat, I wouldn't think it would be a bad idea to use magnetic gears though (if they can be made precise enough)

According to ur sketches, if it would be feasible, the material between the magnetic mixing would have to be extremely insulated against heat and actively cooled as well as very permeable to a magnetic field.

The center rotating mixer cannot be a magnet due to destruction of the magnet under intense heat.

My 2 cents...(yes it's worth 2 cents!!... well maybe...?) Theoretically I guess it would be possible but you will need some serious small scale design changes and some exotic materials and it might work awesomely. And i'd say use an electromagnet to rotate the magnet in the center (i'm guessing it would have to have a magnetic counter balance up top and be super insulated and actively cooled in a very very small space to not have such of a drop off. Then again reducing friction adds serious complications and you still need the shear forces to mix the plastic together.

Edited 3 time(s). Last edit at 01/20/2015 11:33AM by CPS.

Edit: and also magnets would be bad for the hot end because of the extreme heat, I wouldn't think it would be a bad idea to use magnetic gears though (if they can be made precise enough)

According to ur sketches, if it would be feasible, the material between the magnetic mixing would have to be extremely insulated against heat and actively cooled as well as very permeable to a magnetic field.

The center rotating mixer cannot be a magnet due to destruction of the magnet under intense heat.

My 2 cents...(yes it's worth 2 cents!!... well maybe...?) Theoretically I guess it would be possible but you will need some serious small scale design changes and some exotic materials and it might work awesomely. And i'd say use an electromagnet to rotate the magnet in the center (i'm guessing it would have to have a magnetic counter balance up top and be super insulated and actively cooled in a very very small space to not have such of a drop off. Then again reducing friction adds serious complications and you still need the shear forces to mix the plastic together.

Edited 3 time(s). Last edit at 01/20/2015 11:33AM by CPS.

|

Re: Full Color 3d Printer Project January 27, 2015 04:34PM |

Registered: 11 years ago Posts: 335 |

Leak-free mixing is really the hardest part. I suspect a direct mechanical linkage to the stirrer will be required which would require a dynamic seal that does not leak at high temperatures and pressures. Alternatively we could emulate existing processes and use a long screw whose geometry forces the plastic forward. This would essentially be identical to a pellet extruder and provide reliable mixing at the cost of long switches.Quote

haskinsl

I have a very crude concept for an active mixing extruder...

The more you think about this problem the harder it seems. I suspect we will eventually decide that FDM is simply not the best process for full colour prints and pursue more promising avenues instead.

Even if you had a perfect mixing extruder, you are still forced to use a fixed number of colors per layer due to the switching time. So you end up with an enormous amount of complexity and very few advantages when compared to multiple extruders.

|

Re: Full Color 3d Printer Project January 27, 2015 05:00PM |

Registered: 12 years ago Posts: 325 |

Why not paint the extruded plastic, instead of using colored plastic? You'll never get full color anyhow with colored plastics...

Kikai Labs - colored FDM objects

This is what we tried, and it works pretty well, even though it'd need much additional engineering before it could be a product... it does work, though.

It's white plastic with magic marker paints (which could be some other painting technology, of course)...

Paucus

Kikai Labs - colored FDM objects

This is what we tried, and it works pretty well, even though it'd need much additional engineering before it could be a product... it does work, though.

It's white plastic with magic marker paints (which could be some other painting technology, of course)...

Paucus

|

Re: Full Color 3d Printer Project January 29, 2015 05:20PM |

Registered: 9 years ago Posts: 135 |

Paucus, I've been looking at Kikai labs and also at a company called Spectrom, which seems to have the same basic concept, and are very close to market with it.

As for mixing materials, a company called Mosaic Manufacturing is also getting ready to bring a splicing machine they call SEEM to market which can splice materials with different properties, though it's not what you could really call "full color" it does have potential.

As for mixing materials, a company called Mosaic Manufacturing is also getting ready to bring a splicing machine they call SEEM to market which can splice materials with different properties, though it's not what you could really call "full color" it does have potential.

|

Re: Full Color 3d Printer Project January 31, 2015 06:00PM |

Registered: 9 years ago Posts: 1 |

I think your right,

I thought about the hot end mixer using 6 filaments (cyan, magenta, yellow, white, black and another), I thought having 6 extruder motors was excessive, and I didnt like the idea of the active mixer, I had a great idea for non active mixer (not important now), I also thought that it would be better to keep things simple, so I thought have a single stepper motor to drive a gear box. This is the clever part the C,M,Y filaments would feed on a variable gearbox, using slipping gears to change the % of each of the colours. the control of this would be from a colour control file. the stepper motor from a standard stl file.

Then i realised that these colours are not readily available in ABS or PLA and i may have to colour my own filament. in that case why not just get natural and add colourant, I did some simple experiments with Ink jet inks with little success.

I then thought this is getting very cumbersome and complicated, I like simple. So I am going back to the idea of 1 extruder, retraction for three filaments (black, white other transparent or PVA, etc) with a change over carriage for stepper motor two (not quite like this but similar http://www.thingiverse.com/thing:16429 ). A single extruder and motor for neutral/transparent and a colour, injector direct to the hot end, and then i wonder about injection of all 5 colours. At least this method uses the least no of motors and only needs a simple STL file for the shape and a second colour file for the injection.

I thought about the hot end mixer using 6 filaments (cyan, magenta, yellow, white, black and another), I thought having 6 extruder motors was excessive, and I didnt like the idea of the active mixer, I had a great idea for non active mixer (not important now), I also thought that it would be better to keep things simple, so I thought have a single stepper motor to drive a gear box. This is the clever part the C,M,Y filaments would feed on a variable gearbox, using slipping gears to change the % of each of the colours. the control of this would be from a colour control file. the stepper motor from a standard stl file.

Then i realised that these colours are not readily available in ABS or PLA and i may have to colour my own filament. in that case why not just get natural and add colourant, I did some simple experiments with Ink jet inks with little success.

I then thought this is getting very cumbersome and complicated, I like simple. So I am going back to the idea of 1 extruder, retraction for three filaments (black, white other transparent or PVA, etc) with a change over carriage for stepper motor two (not quite like this but similar http://www.thingiverse.com/thing:16429 ). A single extruder and motor for neutral/transparent and a colour, injector direct to the hot end, and then i wonder about injection of all 5 colours. At least this method uses the least no of motors and only needs a simple STL file for the shape and a second colour file for the injection.

|

Re: Full Color 3d Printer Project February 01, 2015 01:43PM |

Registered: 10 years ago Posts: 219 |

Hmm,

Here is a totally different approach. You could modify the printer to have an additional axis on the effector (like a 5 axis CNC) and use an airbrush head to color the print after finishing it, or after each layer.

This would also work with delts printers.

Above picture, just an example to show what I mean....

..and yes, I too think it is easier and better to print an object with neutral color and paint it afterwards.

Another method would be to print out an object, then use a rotating device combined with a printhead to color the object afterwards. Something like they do when engraving objects:

Like this here:

[www.youtube.com]

Edited 1 time(s). Last edit at 02/01/2015 01:55PM by maboo.

Blogs:

Meine 3D Druck Abenteuer

[3dptb.blogspot.de]

FLSUN Delta Drucker für Deutschland

[flsun-deutschland.blogspot.com]

Books on 3D patents:

[goo.gl] (english)

[www.amazon.de] (deutsch)

Here is a totally different approach. You could modify the printer to have an additional axis on the effector (like a 5 axis CNC) and use an airbrush head to color the print after finishing it, or after each layer.

This would also work with delts printers.

Above picture, just an example to show what I mean....

..and yes, I too think it is easier and better to print an object with neutral color and paint it afterwards.

Another method would be to print out an object, then use a rotating device combined with a printhead to color the object afterwards. Something like they do when engraving objects:

Like this here:

[www.youtube.com]

Edited 1 time(s). Last edit at 02/01/2015 01:55PM by maboo.

Blogs:

Meine 3D Druck Abenteuer

[3dptb.blogspot.de]

FLSUN Delta Drucker für Deutschland

[flsun-deutschland.blogspot.com]

Books on 3D patents:

[goo.gl] (english)

[www.amazon.de] (deutsch)

|

Re: Full Color 3d Printer Project February 01, 2015 05:45PM |

Registered: 9 years ago Posts: 11 |

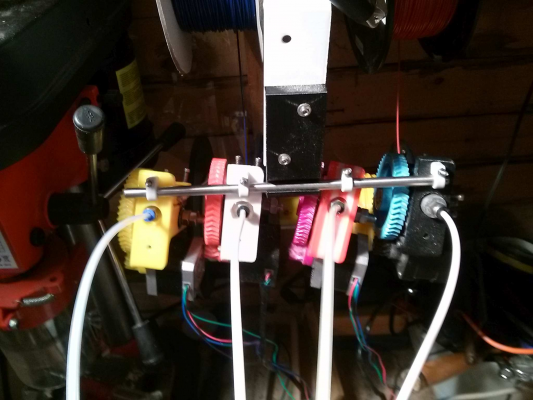

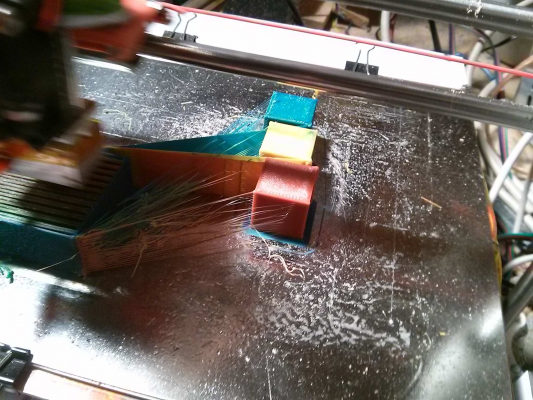

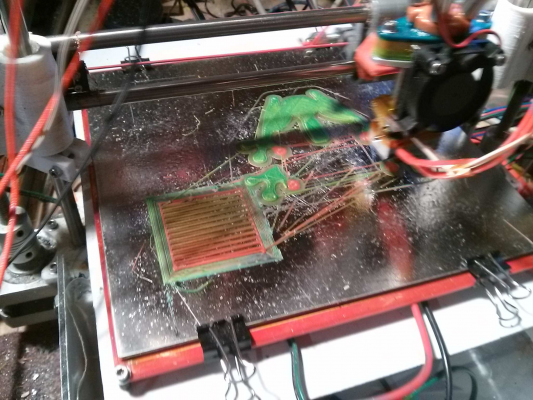

During the last months, I worked on several approaches for multicolor printing hardware.

Actually i succeeded in extruding four filaments out of one nozzle, blending then to new colors and control them via g-code ( using the BlinkM addin of marlin and a second arduino for extruder management).

Now I am the the point to look for the right slicing software. Most of the well known products do only support a few (two to four) filaments in one print. The wipe an prime tower feature of cura causes problems when printing with more than two colors (because it ist only calculated for one color change ber Layer).

Another problem seems to be turning out CSG function on complex models. This is needed to divide the model into ist different colored parts.

When loading more than three (not as small) models into repetier, it wont come back to the desktop. MeshLab can turn out CSG functions but needs a lot of time.

Importing the resulting STL into a multicolor project in slic3r lets you export an AMF model, but importing the amf.xml needs very long time (up to hours).

Could anyone recommend a toolchain for multicolor design and slicing ?

Thank you for any advice.

Coloring the frogs model was already very troublesome.

Actually i succeeded in extruding four filaments out of one nozzle, blending then to new colors and control them via g-code ( using the BlinkM addin of marlin and a second arduino for extruder management).

Now I am the the point to look for the right slicing software. Most of the well known products do only support a few (two to four) filaments in one print. The wipe an prime tower feature of cura causes problems when printing with more than two colors (because it ist only calculated for one color change ber Layer).

Another problem seems to be turning out CSG function on complex models. This is needed to divide the model into ist different colored parts.

When loading more than three (not as small) models into repetier, it wont come back to the desktop. MeshLab can turn out CSG functions but needs a lot of time.

Importing the resulting STL into a multicolor project in slic3r lets you export an AMF model, but importing the amf.xml needs very long time (up to hours).

Could anyone recommend a toolchain for multicolor design and slicing ?

Thank you for any advice.

Coloring the frogs model was already very troublesome.

|

Re: Full Color 3d Printer Project February 02, 2015 09:48AM |

Registered: 12 years ago Posts: 325 |

Take a look at this software, it uses voxels instead of breps, and it may be ideal for color: Monolith

We developed our own add-on to Slic3r for slicing in color, for applying with the magic markers on the outside of the object. It runs as a post-generation script to merge our color gcode with the object gcode made by Slic3r. This is good because you are not modifying slicer itself, but it may not be appropriate for your filament mixing.

Regards,

Marcelo

Kikai Labs

We developed our own add-on to Slic3r for slicing in color, for applying with the magic markers on the outside of the object. It runs as a post-generation script to merge our color gcode with the object gcode made by Slic3r. This is good because you are not modifying slicer itself, but it may not be appropriate for your filament mixing.

Regards,

Marcelo

Kikai Labs

|

Re: Full Color 3d Printer Project February 03, 2015 09:14PM |

Registered: 11 years ago Posts: 33 |

hi all, i have discove this project after i start it  i work with a group of 4 people caled &makers and i'm starting a bussiness with, if someone read italian here an article that talk about us and what we are going to do:&makers, we have build the hotend with 7 treaded M5 holes with the right angle, here the image, of course will need help to control 6 color mixing, i'm pretty sure to finish the hardware and test in this month, anyone is active in this project?

i work with a group of 4 people caled &makers and i'm starting a bussiness with, if someone read italian here an article that talk about us and what we are going to do:&makers, we have build the hotend with 7 treaded M5 holes with the right angle, here the image, of course will need help to control 6 color mixing, i'm pretty sure to finish the hardware and test in this month, anyone is active in this project?

i work with a group of 4 people caled &makers and i'm starting a bussiness with, if someone read italian here an article that talk about us and what we are going to do:&makers, we have build the hotend with 7 treaded M5 holes with the right angle, here the image, of course will need help to control 6 color mixing, i'm pretty sure to finish the hardware and test in this month, anyone is active in this project?

i work with a group of 4 people caled &makers and i'm starting a bussiness with, if someone read italian here an article that talk about us and what we are going to do:&makers, we have build the hotend with 7 treaded M5 holes with the right angle, here the image, of course will need help to control 6 color mixing, i'm pretty sure to finish the hardware and test in this month, anyone is active in this project?

Sorry, only registered users may post in this forum.

for start.

for start.