Home

>

Developers

>

Topic

Amazing Piezoelectric Polyvinylidene Fluoride

Posted by nicholas.seward

|

Amazing Piezoelectric Polyvinylidene Fluoride May 10, 2013 01:40AM |

Registered: 10 years ago Posts: 979 |

I just came across this polymer. It exhibits a larger piezoelectric response than quartz does. It melts at 170C and it is cheap. Do a "Google Shopping" search for "Polyvinylidene Fluoride" and you will see many things that are made from it. (There is one downside. You have to "pole" it, apply a very large magnetic field, to get it to exhibit piezoelectric properties.)

Why should we care? We could use this polymer to make stepper-less RepRaps and do all sorts of other neat tricks.

Here is a short list of actuators that can use this.

This is not to mention that with a multiextruder setup you could embed this right into designs for all sorts of reasons. For example, you could make some piezo bushings for the z axis rods. You could then just throw away the z-axis motor and when you want to lower the build table you could increase the inner diameter of the bushings until you slip to the right position and then tighten it back up. etc etc etc

I haven't run the numbers to see what kind of responses we could generate with realistic electronics. I just wanted to put this out there. What do you guys think? I hope someone else can find time to experiement.

Why should we care? We could use this polymer to make stepper-less RepRaps and do all sorts of other neat tricks.

Here is a short list of actuators that can use this.

- Traveling-wave Motor

- Inchworm Motor (Linear motion)

- Rectangular Four-Quadrant Motor

- Ratcheting Piezo Motor

- etc.

This is not to mention that with a multiextruder setup you could embed this right into designs for all sorts of reasons. For example, you could make some piezo bushings for the z axis rods. You could then just throw away the z-axis motor and when you want to lower the build table you could increase the inner diameter of the bushings until you slip to the right position and then tighten it back up. etc etc etc

I haven't run the numbers to see what kind of responses we could generate with realistic electronics. I just wanted to put this out there. What do you guys think? I hope someone else can find time to experiement.

|

Re: Amazing Piezoelectric Polyvinylidene Fluoride May 10, 2013 05:22AM |

Registered: 13 years ago Posts: 406 |

I proposed this ages ago, but I do not think I got one response, (I can't be bothered to find post) my understanding is that the polymer is held at about 100v whilst it cools to polerise it, my thoughts were to have electrodes on the nozzle and build sensors/ actuators directly.

Edited 1 time(s). Last edit at 05/10/2013 05:23AM by johnrpm.

Random Precision

Edited 1 time(s). Last edit at 05/10/2013 05:23AM by johnrpm.

Random Precision

|

Re: Amazing Piezoelectric Polyvinylidene Fluoride May 10, 2013 04:48PM |

Registered: 10 years ago Posts: 979 |

johnrpm Wrote:

-------------------------------------------------------

> I proposed this ages ago, but I do not think I got

> one response, (I can't be bothered to find post)

> my understanding is that the polymer is held at

> about 100v whilst it cools to polerise it, my

> thoughts were to have electrodes on the nozzle and

> build sensors/ actuators directly.

I did a google search and a forum search and couldn't find a mention. I was thinking to myself that "this sounds too easy and perfect...there has to be a catch or everyone already knows about this". I guess right now it is just too unusual.

I found a source for filament.

I will have to do the math to see if the expected piezoelectric response generated with cheap hardware is going to be worth it. Right now I am also too busy to pursue this.

-------------------------------------------------------

> I proposed this ages ago, but I do not think I got

> one response, (I can't be bothered to find post)

> my understanding is that the polymer is held at

> about 100v whilst it cools to polerise it, my

> thoughts were to have electrodes on the nozzle and

> build sensors/ actuators directly.

I did a google search and a forum search and couldn't find a mention. I was thinking to myself that "this sounds too easy and perfect...there has to be a catch or everyone already knows about this". I guess right now it is just too unusual.

I found a source for filament.

I will have to do the math to see if the expected piezoelectric response generated with cheap hardware is going to be worth it. Right now I am also too busy to pursue this.

|

Re: Amazing Piezoelectric Polyvinylidene Fluoride May 10, 2013 05:34PM |

Registered: 13 years ago Posts: 406 |

My post was at least a year ago, it should be there somewhere,

It would not be a simple task, the electrodes would need to be at the melt point, and maybe at the platform, the cooling rate is fast so may not take poling well, also if poling is posible on the fly, it may produce the piezo material for the bead but not over the entire part, lots of work, but worth it, and at least for some time not by me.

Edit, found it, [reprap.org]

I also posted about it, but search comes up with nothing.

Edited 1 time(s). Last edit at 05/10/2013 05:44PM by johnrpm.

Random Precision

It would not be a simple task, the electrodes would need to be at the melt point, and maybe at the platform, the cooling rate is fast so may not take poling well, also if poling is posible on the fly, it may produce the piezo material for the bead but not over the entire part, lots of work, but worth it, and at least for some time not by me.

Edit, found it, [reprap.org]

I also posted about it, but search comes up with nothing.

Edited 1 time(s). Last edit at 05/10/2013 05:44PM by johnrpm.

Random Precision

|

Re: Amazing Piezoelectric Polyvinylidene Fluoride May 10, 2013 06:18PM |

Admin Registered: 13 years ago Posts: 730 |

That's a cool idea. johnrpm's thread from 2009 is here.

A couple things to note:

1) While the PVDF piezoelectric response is higher than that of quartz and other polymers, it is much less than PZT, which is a typical material for actuators.

2) If you just print out a chunky block of PVDF, the piezoelectric effect will (probably) be negligible, whether or not you pole it in the nozzle.

PVDF is said to be ferroelectric, that is, it maintains a permanent electric polarization. The permanent polarization is the source of its piezoelectric behavior. To work as an actuator, the plastic needs to be drawn into thin (25 micron) sheets, and polarized across the sheet. Here are more details from the paper "PZT and PVDF bimorph actuators" by Chilibon, Dias, Inacio, and Marat-Mendes:

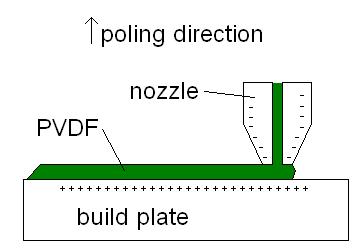

You might actually be able to do this if you printed a thin sheet while applying a high voltage between the nozzle and the (conductive) build plate, like this:

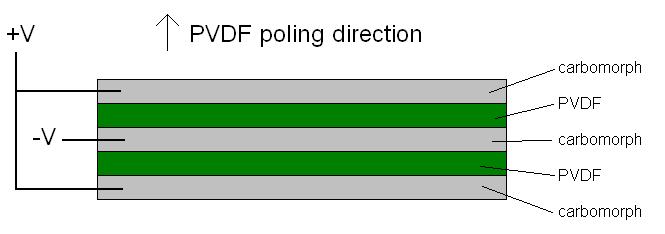

Apparently, quite a few groups have made "bimorph" bending actuators out of thin sheets of PVDF. There's an explanation and pictures of actual actuators here. You might be able to make a printed piezoelectric bimorph something like this:

where carbomorph is the conductive PCL you can read about here. What would you do with an actuator like this once you build it? Stack a bunch together and make a Compliant Linear Motion Mechanism!

A couple things to note:

1) While the PVDF piezoelectric response is higher than that of quartz and other polymers, it is much less than PZT, which is a typical material for actuators.

2) If you just print out a chunky block of PVDF, the piezoelectric effect will (probably) be negligible, whether or not you pole it in the nozzle.

PVDF is said to be ferroelectric, that is, it maintains a permanent electric polarization. The permanent polarization is the source of its piezoelectric behavior. To work as an actuator, the plastic needs to be drawn into thin (25 micron) sheets, and polarized across the sheet. Here are more details from the paper "PZT and PVDF bimorph actuators" by Chilibon, Dias, Inacio, and Marat-Mendes:

Quote

Chilibon

Ferroelectric polymers are produced by a variety of techniques, where in the case of PVDF the material is mechanically drawn and polarized in order to form a useful transducer material. The drawing techniques include extrusion and stretching and while processing the film material is subjected to a strong electrical polarization field. Without drawing, PVDF shows a very weak piezoelectric behaviour and the higher the molecular orientation the stronger the resultant response of the polarized film.

You might actually be able to do this if you printed a thin sheet while applying a high voltage between the nozzle and the (conductive) build plate, like this:

Apparently, quite a few groups have made "bimorph" bending actuators out of thin sheets of PVDF. There's an explanation and pictures of actual actuators here. You might be able to make a printed piezoelectric bimorph something like this:

where carbomorph is the conductive PCL you can read about here. What would you do with an actuator like this once you build it? Stack a bunch together and make a Compliant Linear Motion Mechanism!

|

Re: Amazing Piezoelectric Polyvinylidene Fluoride May 10, 2013 07:08PM |

Registered: 13 years ago Posts: 406 |

|

Re: Amazing Piezoelectric Polyvinylidene Fluoride May 11, 2013 10:43AM |

Registered: 10 years ago Posts: 979 |

You could theoretically stretch it during deposition if you have an elastic layer on the top of the build plate. PVDF would need to permanently bond to it (or at least for the build phase). I can see that this isn't going to be easy by any stretch (pun intended). I think the moral of the story will be that a lot of work would be required for a response that is much less than PZT. Side note: using selective laser sintering on PZT could be a possibility. I found a lot of papers on this but the conclusions weren't accessible. This might be something to bring back up once RepRap starts producing some powder based printers specificly SLS machines.

|

Re: Amazing Piezoelectric Polyvinylidene Fluoride May 11, 2013 09:21PM |

Registered: 16 years ago Posts: 174 |

@nicholas.seward, you can certainly produce PZT via laser sintering.

You can also produce other high-grade ceramics like superconductors(!) using laser sintering, though it looks like a fairly complicated process.

As far as PZT goes it looks like there has been more success using PZT mixed with photopolymer slurry and a stereolithography type process.

You can also produce other high-grade ceramics like superconductors(!) using laser sintering, though it looks like a fairly complicated process.

As far as PZT goes it looks like there has been more success using PZT mixed with photopolymer slurry and a stereolithography type process.

|

Re: Amazing Piezoelectric Polyvinylidene Fluoride May 14, 2013 12:05PM |

Admin Registered: 13 years ago Posts: 730 |

Quote

johnrpm

could the bead be stretched (as in the above info) during deposition?

I think so... The polymer molecules are going to get somewhat aligned as they are extruded, and then when the bead is deposited it gets kind of stretched and flattened out too. I think that just depositing a single thin layer using a normal extruder might provide enough alignment. And you wouldn't need fancy electrodes at the tip if you just apply a voltage between the nozzle and the plate.

So, it might, might, just be possible to get positive results on a standard setup without doing too much additional modification. It looks like you can buy 3mm PVDF welding rod off-the-shelf. Still would be a lot of work...

Quote

nicholas.seward

This might be something to bring back up once RepRap starts producing some powder based printers specificly SLS machines.

I bring this link up every time someone mentions SLS and RepRap

. There is a very nice writeup on a fully-functional SLS wax printer on the RepRap wiki here: [reprap.org]. I think this project is a great starting place for doing more ambitious SLS printers - metals, ceramics, etc.

. There is a very nice writeup on a fully-functional SLS wax printer on the RepRap wiki here: [reprap.org]. I think this project is a great starting place for doing more ambitious SLS printers - metals, ceramics, etc.

|

Re: Amazing Piezoelectric Polyvinylidene Fluoride May 15, 2013 05:34AM |

Registered: 13 years ago Posts: 406 |

|

Re: Amazing Piezoelectric Polyvinylidene Fluoride July 31, 2016 01:41AM |

Admin Registered: 13 years ago Posts: 730 |

Here is an update for this old thread with links to some more recent experiments on poling and 3D printing PVDF:

In-situ poling of PVDF for 3D printing

Electric poling-assisted additive manufacturing process for PVDF polymer-based piezoelectric device applications

In-situ poling of PVDF for 3D printing

Electric poling-assisted additive manufacturing process for PVDF polymer-based piezoelectric device applications

Sorry, only registered users may post in this forum.