Home

>

Developers

>

Topic

Annoucing our dual extruder design release

Posted by Dglass3D

|

Annoucing our dual extruder design release July 15, 2013 02:44PM |

Registered: 10 years ago Posts: 5 |

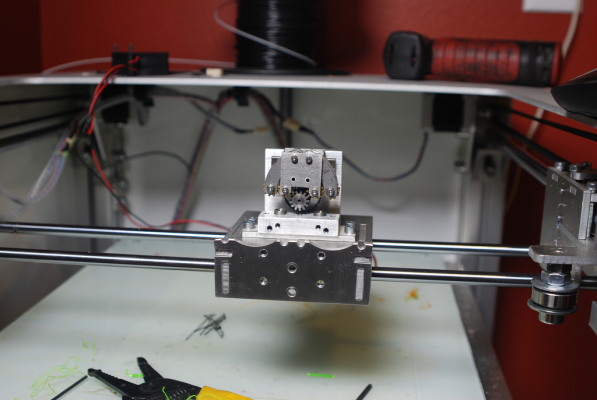

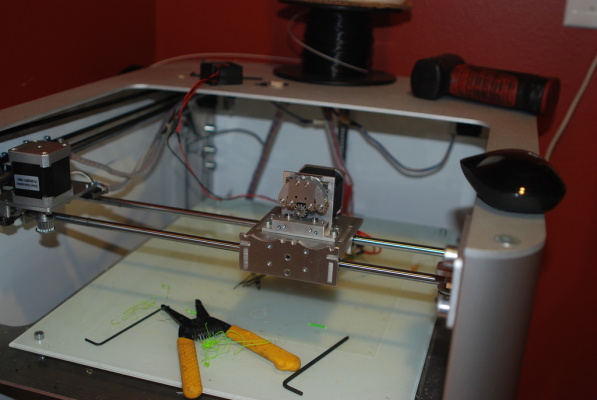

Alright we'll just take the cat out of the bag and show off our work that we are looking at kickstarting soon. We want to make sure we hit on all the key components that the end user is looking to have. This is a very simple design that should only require minor software tweaks to be compatible with most of the current 3D printers out there.

Comments and concerns are welcome as our goal is to make the most practical and durable dual extruder for any size print bed and the availability to stack two together allowing four extruders in the footprint of two.

Dglass 3D Blog

My brother and I purchased our first printer in January and quickly noticed that the quality of the build was low and we often had to re-calibrate everything to have quality prints. We weren't happy with the constant tinkering. We have been following posts on this site and have found many helpful answers.

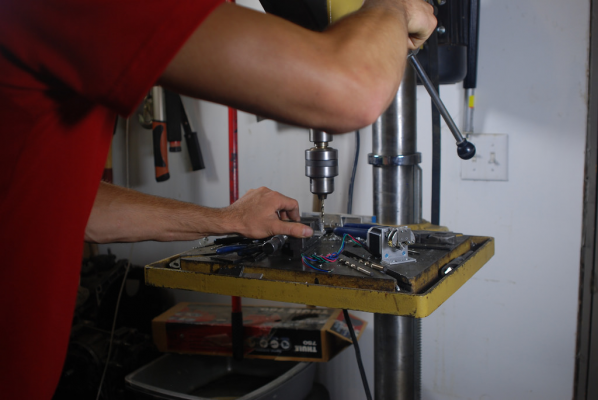

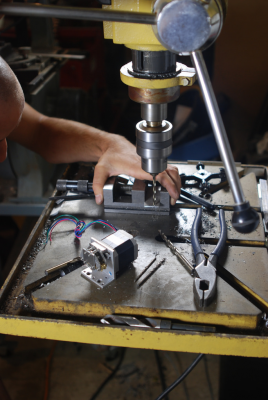

Our goal was to create a device that allows for more extruders in a similar sized footprint while also maintaining an ease of use. Our head has constant tension to keep the plastic in grip and after solving many problems and making revisions we are at the point where we are confident in the design but it needs a few more tweaks. We are definitely part of the DIY group as we created several prototypes in our garage using the equipment we have available.

We also want to help the community take steps forward that benefit everyone with a focus on well made precision parts. We can only meet our goal with feedback and questions from the DIY printer users so we can ensure this is a worthwhile endeavor.

Edited 4 time(s). Last edit at 07/15/2013 03:54PM by Dglass3D.

Comments and concerns are welcome as our goal is to make the most practical and durable dual extruder for any size print bed and the availability to stack two together allowing four extruders in the footprint of two.

Dglass 3D Blog

My brother and I purchased our first printer in January and quickly noticed that the quality of the build was low and we often had to re-calibrate everything to have quality prints. We weren't happy with the constant tinkering. We have been following posts on this site and have found many helpful answers.

Our goal was to create a device that allows for more extruders in a similar sized footprint while also maintaining an ease of use. Our head has constant tension to keep the plastic in grip and after solving many problems and making revisions we are at the point where we are confident in the design but it needs a few more tweaks. We are definitely part of the DIY group as we created several prototypes in our garage using the equipment we have available.

We also want to help the community take steps forward that benefit everyone with a focus on well made precision parts. We can only meet our goal with feedback and questions from the DIY printer users so we can ensure this is a worthwhile endeavor.

Edited 4 time(s). Last edit at 07/15/2013 03:54PM by Dglass3D.

|

Re: Annoucing our dual extruder design release July 15, 2013 06:19PM |

Registered: 10 years ago Posts: 37 |

|

Re: Annoucing our dual extruder design release July 15, 2013 09:21PM |

Registered: 11 years ago Posts: 250 |

I'm still trying to wrap my head around how it works...

As one feeds, the other retracts...

Got a video of this in operation?

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

As one feeds, the other retracts...

Got a video of this in operation?

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Annoucing our dual extruder design release July 15, 2013 09:27PM |

Registered: 11 years ago Posts: 979 |

|

Re: Annoucing our dual extruder design release July 15, 2013 09:49PM |

Registered: 10 years ago Posts: 37 |

The top part with the gears toggles left or right to engage or disengage the filament and motor....don't see the toggle mechanism though.

similar principle to the way stratasys does it, but different. Still might be covered by one of their patents. Dglass3D should be sure to check into that before selling them.

similar principle to the way stratasys does it, but different. Still might be covered by one of their patents. Dglass3D should be sure to check into that before selling them.

|

Re: Annoucing our dual extruder design release July 15, 2013 10:21PM |

Registered: 11 years ago Posts: 979 |

|

Re: Annoucing our dual extruder design release July 15, 2013 10:33PM |

Registered: 10 years ago Posts: 5 |

|

Re: Annoucing our dual extruder design release July 15, 2013 11:08PM |

Registered: 10 years ago Posts: 2 |

1013 Wrote:

-------------------------------------------------------

> The top part with the gears toggles left or right

> to engage or disengage the filament and

> motor....don't see the toggle mechanism though.

>

> similar principle to the way stratasys does it,

> but different. Still might be covered by one of

> their patents. Dglass3D should be sure to check

> into that before selling them.

Thanks for bringing this up, we didn't know about the patent but check it out and as Brian "Dglass3D" mentioned we seem to be in the clear. Along with some video footage we will be sharing our design and prototype journey later this week to show the evolution of our development. this has been a fun journey and we have many more fun details to share about our extruder head, filament feedstock and upcoming printer design.

Thanks for all your feedback and input!

-------------------------------------------------------

> The top part with the gears toggles left or right

> to engage or disengage the filament and

> motor....don't see the toggle mechanism though.

>

> similar principle to the way stratasys does it,

> but different. Still might be covered by one of

> their patents. Dglass3D should be sure to check

> into that before selling them.

Thanks for bringing this up, we didn't know about the patent but check it out and as Brian "Dglass3D" mentioned we seem to be in the clear. Along with some video footage we will be sharing our design and prototype journey later this week to show the evolution of our development. this has been a fun journey and we have many more fun details to share about our extruder head, filament feedstock and upcoming printer design.

Thanks for all your feedback and input!

|

Re: Annoucing our dual extruder design release July 15, 2013 11:38PM |

Registered: 11 years ago Posts: 979 |

|

Re: Annoucing our dual extruder design release July 16, 2013 03:26AM |

Registered: 13 years ago Posts: 202 |

When I worked on dual extrusion (unfortunately did not finish) I palnned on actuating a lever to switch the mechanism from one to another buy moving the cradle beyond the axis soft limits, where an actuator bar would be placed.

Manufacturer of low tolerance Filaments PLA, ABS, ASA, PETG, TPU, PA, PVA,

[www.miafilament.com]

[github.com]

Manufacturer of low tolerance Filaments PLA, ABS, ASA, PETG, TPU, PA, PVA,

[www.miafilament.com]

[github.com]

|

Re: Annoucing our dual extruder design release July 16, 2013 09:47AM |

Registered: 10 years ago Posts: 5 |

It is a passive system that allows for small retracts, the down side is that large retracts are not possible with the current setup. This allows the filament to be backed out enough to not bleed from the tip. We will be building a finger hold that will allow the user to manually release the tension and change the filament at the head. We have a solution for full retract but it would be difficult on a head that is adaptable for many printers.

|

Re: Annoucing our dual extruder design release July 16, 2013 09:59PM |

Registered: 10 years ago Posts: 37 |

carld@dglass3d Wrote:

-------------------------------------------------------

>

>

> Thanks for bringing this up, we didn't know about

> the patent but check it out and as Brian

> "Dglass3D" mentioned we seem to be in the clear.

> Along with some video footage we will be sharing

> our design and prototype journey later this week

> to show the evolution of our development. this

> has been a fun journey and we have many more fun

> details to share about our extruder head, filament

> feedstock and upcoming printer design.

>

> Thanks for all your feedback and input!

glad you looked into it.

BTW, one thing that jumped out at me from your pictures is a potential gear meshing issue when you swap between filaments. I could see those large pitch gears jamming when the toggle rotates. May need to try some finer pitch gears.

And don't forget the safety glasses when working with power tools

Edited 1 time(s). Last edit at 07/16/2013 10:01PM by 1013.

-------------------------------------------------------

>

>

> Thanks for bringing this up, we didn't know about

> the patent but check it out and as Brian

> "Dglass3D" mentioned we seem to be in the clear.

> Along with some video footage we will be sharing

> our design and prototype journey later this week

> to show the evolution of our development. this

> has been a fun journey and we have many more fun

> details to share about our extruder head, filament

> feedstock and upcoming printer design.

>

> Thanks for all your feedback and input!

glad you looked into it.

BTW, one thing that jumped out at me from your pictures is a potential gear meshing issue when you swap between filaments. I could see those large pitch gears jamming when the toggle rotates. May need to try some finer pitch gears.

And don't forget the safety glasses when working with power tools

Edited 1 time(s). Last edit at 07/16/2013 10:01PM by 1013.

|

Re: Annoucing our dual extruder design release July 28, 2013 11:18AM |

Registered: 10 years ago Posts: 2 |

We finally uploaded video footage of our print head in operation. We have some additional design refinements to make but we are nearly there.

You can check out the video here: Extruder Head Video

And see more updates here: More Information Here

Thanks for your feedback!

Carl

You can check out the video here: Extruder Head Video

And see more updates here: More Information Here

Thanks for your feedback!

Carl

|

Re: Annoucing our dual extruder design release July 28, 2013 12:34PM |

Registered: 11 years ago Posts: 979 |

Sorry, only registered users may post in this forum.