Home

>

Developers

>

Topic

Bot using commercial motorised linear stages?

Posted by PZC

|

Bot using commercial motorised linear stages? August 21, 2013 03:24PM |

Registered: 10 years ago Posts: 1 |

Hi Gang,

I'm wondering if it's possible to make a bot out of commercial (Parker Daedal) motorised linear stages together with RAMBo or RAMPS electronics.

In a nutshell, I already have the stages but will need to add the driver electronics and extruder.

These stages have a very coarse thread pitch - roughly 0.2" per revolution - so even with x16 micro stepping I'm looking at a movement of roughly 0.0016mm per micro step.

My question is: is that step size compatible with RAMBo / RAMPS? Or is my project doomed from the start?

Thanks.

I'm wondering if it's possible to make a bot out of commercial (Parker Daedal) motorised linear stages together with RAMBo or RAMPS electronics.

In a nutshell, I already have the stages but will need to add the driver electronics and extruder.

These stages have a very coarse thread pitch - roughly 0.2" per revolution - so even with x16 micro stepping I'm looking at a movement of roughly 0.0016mm per micro step.

My question is: is that step size compatible with RAMBo / RAMPS? Or is my project doomed from the start?

Thanks.

|

Re: Bot using commercial motorised linear stages? August 21, 2013 03:53PM |

Registered: 12 years ago Posts: 1,236 |

|

Re: Bot using commercial motorised linear stages? August 24, 2013 05:58PM |

Registered: 10 years ago Posts: 474 |

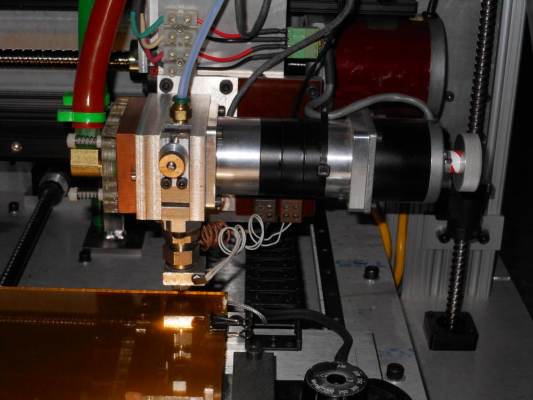

Sounds like you have the basis of a good 3-D printer problem is I would not suggest trying to use standard reprap electronics instead think of it as a CNC machine use Mach 3 or EMC 2 to control it if you need info go to CNC zone control hot end temperature and heat bed temperature with standalone controllers here is a picture of mine if you Google large scale repstrap you should find more on my machine and a couple videos URL=http://s1333.photobucket.com/user/richard_nelson1/media/3d%20printer/DSCN0055_zps5b7442c7.jpg.html]

[/URL]

|

Re: Bot using commercial motorised linear stages? August 28, 2013 06:05AM |

Registered: 15 years ago Posts: 242 |

|

Re: Bot using commercial motorised linear stages? August 28, 2013 07:58AM |

Registered: 10 years ago Posts: 474 |

Sorry, only registered users may post in this forum.