Home

>

Developers

>

Topic

My own 3D printer design: comments and criticism

Posted by mman1506

|

My own 3D printer design: comments and criticism June 21, 2014 12:07AM |

Registered: 9 years ago Posts: 1 |

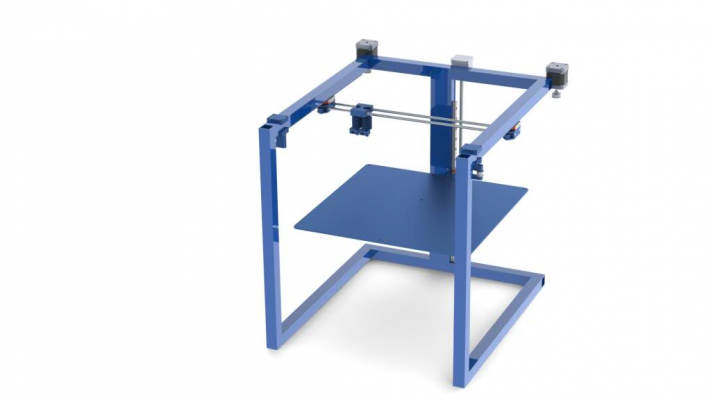

I wasn't really happy with the 3D printers currently on the market (low speed, weak construction, high moving axis mass) so I designed my own. I have some limited experience with my own Makibox 3D printer already and I've built a few CNC routers.

I haven't finished CADing most obvius being the stepper mounts and the hole patterns for the gussets but I want to figure out whether this is the direction i want to go in before putting more time into this design.

It's a H bot XY design using HiWIN linear rails to hopefully avoid the racking issue associated with the H bot style. The focus of the design is high speed printing so keeping the mass of the moving axis as low as possible and reducing backlash with easily tensionable belts was a high priority. The fixed idlers are on clamp so they can be quickly tensioned. I've decided to build it with welded/gusseted 1X1 box tube as it is cheaper and stiffer than t slot extrusion.

I have a few questions.

1) Is the E3D v6 hotend the way to go? Is there a cheaper hot end that is equivalent?

2)What's the best bowden extruder currently?

3)Should I go up to a 8mm rods over the current 6mm rods?

4)I'm interested in designing a heated enclosure over a hotbed similar to the stratasy printers. Has anyone built a working printer using this technique?

I haven't finished CADing most obvius being the stepper mounts and the hole patterns for the gussets but I want to figure out whether this is the direction i want to go in before putting more time into this design.

It's a H bot XY design using HiWIN linear rails to hopefully avoid the racking issue associated with the H bot style. The focus of the design is high speed printing so keeping the mass of the moving axis as low as possible and reducing backlash with easily tensionable belts was a high priority. The fixed idlers are on clamp so they can be quickly tensioned. I've decided to build it with welded/gusseted 1X1 box tube as it is cheaper and stiffer than t slot extrusion.

I have a few questions.

1) Is the E3D v6 hotend the way to go? Is there a cheaper hot end that is equivalent?

2)What's the best bowden extruder currently?

3)Should I go up to a 8mm rods over the current 6mm rods?

4)I'm interested in designing a heated enclosure over a hotbed similar to the stratasy printers. Has anyone built a working printer using this technique?

|

Re: My own 3D printer design: comments and criticism June 22, 2014 04:26PM |

Registered: 10 years ago Posts: 790 |

1) Yes, unless you want to pay the big bucks for something I've heard [not experienced, but from reliable people whose opinions I trust] is most excellent indeed, then pay the big bucks.

2) Same manufacture, Micron, creates a bowden version. But since I don't have much knowledge in the way of bowden, my suggestion here could easily be moot through my ignorance.

3) Rods can bend easily over distances, and as far as I've been told they're actually one of the worst things, because they do bend a lot. I'm using OpenBuild's V-Slot for my linear motions. I have both 1000mmX12mm rails and 20X60X1500mm V-Slot. There is no comparison with stiffness. Bending the rails is the same in all directions, but bending the V-Slot along the thinner side seems to bend just less than the rails. Bending along the long side gives no visible bending in my hand pressure. Seated the right way and you will eliminate bending as far as cost effectiveness goes. But if you're sticking to rails, it depends on how large your length of railing is going to be. 12mm rails obviously doesn't seem to be enough for 1000mm lengths, and my solidoodle has about 350mm lengths with 8mm and even that has bouncing in corners and is easily hand bent with a single finger, so there's a good start.

4) No experience or even vague memory to help there, sorry.

Suggestions: go CoreXY over H-Bot. I can't think of any advantage H-Bot has over CoreXY besides simplicity in building. Why no spend a bit of extra time and a bit more on material for something that works better? Here's a good modification of the original CoreXY that I plan on using.

Hope this helps! Again, I'm not the most experienced. I simply have a heavily modified Solidoodle that may well no longer be able to be called a Solidoodle, and lots of time spent crawling these forums gaining as much knowledge as possible for building my own printer from my own designs. Take my advice with a grain of salt.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

2) Same manufacture, Micron, creates a bowden version. But since I don't have much knowledge in the way of bowden, my suggestion here could easily be moot through my ignorance.

3) Rods can bend easily over distances, and as far as I've been told they're actually one of the worst things, because they do bend a lot. I'm using OpenBuild's V-Slot for my linear motions. I have both 1000mmX12mm rails and 20X60X1500mm V-Slot. There is no comparison with stiffness. Bending the rails is the same in all directions, but bending the V-Slot along the thinner side seems to bend just less than the rails. Bending along the long side gives no visible bending in my hand pressure. Seated the right way and you will eliminate bending as far as cost effectiveness goes. But if you're sticking to rails, it depends on how large your length of railing is going to be. 12mm rails obviously doesn't seem to be enough for 1000mm lengths, and my solidoodle has about 350mm lengths with 8mm and even that has bouncing in corners and is easily hand bent with a single finger, so there's a good start.

4) No experience or even vague memory to help there, sorry.

Suggestions: go CoreXY over H-Bot. I can't think of any advantage H-Bot has over CoreXY besides simplicity in building. Why no spend a bit of extra time and a bit more on material for something that works better? Here's a good modification of the original CoreXY that I plan on using.

Hope this helps! Again, I'm not the most experienced. I simply have a heavily modified Solidoodle that may well no longer be able to be called a Solidoodle, and lots of time spent crawling these forums gaining as much knowledge as possible for building my own printer from my own designs. Take my advice with a grain of salt.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: My own 3D printer design: comments and criticism June 28, 2014 02:35AM |

Registered: 12 years ago Posts: 799 |

Hmm, i don`t think this design will work very well, at least you need a closed square frame at the top, otherwhise the belt will pull the frame together at the front side.

Then you would need a cross stabilisation at the frame at the Y direction (left/right) to eliminate vibrations when the printer is running fast small movements to the Y direction (even with H-belt)

As the printer is looking pretty large (50x50cm? i would stay with 8mm rods.

For a bowden its more important to have a hotend with as less force needed as possible, the extruder is not so important as most of them now should be strong and good enough.

when printing fast in a closed environment beware of possible cooling down issuse of the filament when extruded, you may need a air circulisation and/or cooling at the hotend.

What the 289 $ for a Extruder/Hotend, thats way to expensive, at least its still only a extruder, thats half of the cost what a vitamins-kit of a printer normally cost.

289 $ for a Extruder/Hotend, thats way to expensive, at least its still only a extruder, thats half of the cost what a vitamins-kit of a printer normally cost.

And it even doesn`t seem very lightweight, whats neccessary for fast printing, how heavy is this kit ?

Chri

Edited 3 time(s). Last edit at 06/28/2014 02:37AM by Chri.

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

Then you would need a cross stabilisation at the frame at the Y direction (left/right) to eliminate vibrations when the printer is running fast small movements to the Y direction (even with H-belt)

As the printer is looking pretty large (50x50cm? i would stay with 8mm rods.

For a bowden its more important to have a hotend with as less force needed as possible, the extruder is not so important as most of them now should be strong and good enough.

when printing fast in a closed environment beware of possible cooling down issuse of the filament when extruded, you may need a air circulisation and/or cooling at the hotend.

Quote

MrDoctorDIV

1) Yes, unless you want to pay the big bucks for something I've heard [not experienced, but from reliable people whose opinions I trust] is most excellent indeed, then pay the big bucks.

What the

289 $ for a Extruder/Hotend, thats way to expensive, at least its still only a extruder, thats half of the cost what a vitamins-kit of a printer normally cost.

289 $ for a Extruder/Hotend, thats way to expensive, at least its still only a extruder, thats half of the cost what a vitamins-kit of a printer normally cost.And it even doesn`t seem very lightweight, whats neccessary for fast printing, how heavy is this kit ?

Chri

Edited 3 time(s). Last edit at 06/28/2014 02:37AM by Chri.

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

Sorry, only registered users may post in this forum.