Home

>

Developers

>

Topic

Wobblenaught

Posted by Anonymous User

|

Anonymous User

Wobblenaught July 24, 2014 06:36PM |

I have an idea for a 3d printer. It's basically a prusa mendel, but instead of using the 4 thread rods that go diagonally between the top of the printer and the bottom that form the triangle shape, I'm gonna use suspension cable. It's kind of a cross between a printrbot and a mendel. If you use the z-axis smooth rod as vertical support and use the tension from the cables to stabilize the top of the printer, you can eliminate the wobble and the thread rods for a fraction of the price. What do you think?

|

Re: Wobblenaught July 25, 2014 04:30PM |

Registered: 10 years ago Posts: 581 |

Threaded rods are a pretty small fraction of the total cost of the printer.

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

|

Re: Wobblenaught July 25, 2014 05:10PM |

Registered: 10 years ago Posts: 979 |

@3dkarma: I would agree that it is not a large portion of the total costs. However, your meta message seems to be that you shouldn't remove them just because they are cheap. If you can remove them and make the printer simpler, easier to assemble, better looking, etc then I would say go for it.

@napalmvictory: You won't be able to do a direct string for rod replacement. First of all, the Mendel has horrible stability in the Y direction. You would need to at least flare the bottom and put a string between the top of the two rods. I would suggest a $1.50 guitar tuner to keep everything well tensioned. Additionally, this will require a more rigid base that will be able to hold up under all the tension.

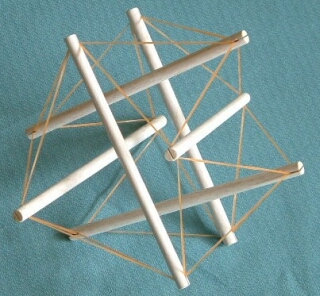

Joking:

You could just go all the way and use a tensegrity structure. This one has pairs of rods that are orthogonal to the others. You could make a tripteron with this.

Edited 2 time(s). Last edit at 07/25/2014 05:14PM by nicholas.seward.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

@napalmvictory: You won't be able to do a direct string for rod replacement. First of all, the Mendel has horrible stability in the Y direction. You would need to at least flare the bottom and put a string between the top of the two rods. I would suggest a $1.50 guitar tuner to keep everything well tensioned. Additionally, this will require a more rigid base that will be able to hold up under all the tension.

Joking:

You could just go all the way and use a tensegrity structure. This one has pairs of rods that are orthogonal to the others. You could make a tripteron with this.

Edited 2 time(s). Last edit at 07/25/2014 05:14PM by nicholas.seward.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

|

Anonymous User

Re: Wobblenaught July 25, 2014 06:06PM |

It's not a major leap forward, but if you can save $10 on a build without hurting performance, I think it's worth it. Aesthetically, it could be an improvement. Is cable better looking than thread rod? I guess it depends, but it would be more reminiscent of say, the golden gate bridge than the terminator. I see what you're saying about outright replacing thread rod for cable. I'll need to look into beefing up some other components to compensate, especially adding feet to the z axis smooth rod.

|

Re: Wobblenaught July 26, 2014 05:08AM |

Registered: 10 years ago Posts: 439 |

|

Re: Wobblenaught July 26, 2014 09:44AM |

Registered: 10 years ago Posts: 979 |

Quote

Ralph.Hilton

I suspect that to gain the same stability as given by 8mm rods, you would need 8mm cable and that the cost would be higher than the rods.

This is not true. Bridges are a good example.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

|

Re: Wobblenaught July 26, 2014 09:52AM |

Admin Registered: 16 years ago Posts: 13,884 |

... my 'gut-feeling' from my own steelwire-experiments/developments around 1990 says: -- with 0.3mm thick steel-wires you'll get some peceptible elasticity along the structure, 0.75mm would be sufficient, 1.5mm already slightly 'overkill'

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Anonymous User

Re: Wobblenaught July 26, 2014 10:27PM |

Thanks for the input. I'm going to try and max out the height to demonstrate effectiveness. My smooth rods are 1 yard (.9m) long, so that's how tall it will be. I just bought 10 yards of 1/32" stainless steal wire rope. Cost me all of $3.50. I won't know for sure how effective it is until I start building, but the theory's sound at least.

|

Re: Wobblenaught July 26, 2014 10:30PM |

Registered: 10 years ago Posts: 979 |

What is the diameter of your smooth rods? 8mm will buckle at that length.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

|

Anonymous User

Re: Wobblenaught July 26, 2014 10:39PM |

|

Re: Wobblenaught July 26, 2014 11:14PM |

Registered: 10 years ago Posts: 979 |

Stainless is not as strong. What angle will the wire make with the rod? The smaller this is... the more buckling you will get. Additionally, even small X accelerations (0.1g) will start some gnarly big oscillations (quickly estimated to be 2mm) no matter how you support the ends of the rods. It is even possible to hit the natural frequency and get 1cm+ oscillations.

If you specify your target acceleration, wire angle, acceptable error, and effector mass then I could crunch the numbers and suggest a rod diameter. (A ballpark guess is 16-24mm.)

I will make the assumption that you will halve the tension when compared to the tension that will cause the rod to buckle. For your setup, the buckling force is 50lbf. Halve that and spread it over 4 wires and that leaves you with 8lbf of tension in the Z direction. That seems low to me but maybe it would be okay.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

If you specify your target acceleration, wire angle, acceptable error, and effector mass then I could crunch the numbers and suggest a rod diameter. (A ballpark guess is 16-24mm.)

I will make the assumption that you will halve the tension when compared to the tension that will cause the rod to buckle. For your setup, the buckling force is 50lbf. Halve that and spread it over 4 wires and that leaves you with 8lbf of tension in the Z direction. That seems low to me but maybe it would be okay.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

|

Anonymous User

Re: Wobblenaught July 26, 2014 11:46PM |

16-24? Ouch. Maybe not such a good idea to go big. I'm stuck on 8mm because that's what I have. I was going for 45 degrees on the y axis, or whatever the standard is for the mendel. On the x axis 1 @ 0 degrees, which connects the top of the 2 rods together, then probrably 2 more at, say 15 degrees on both sides. I'm leaning towards putting the motors on the bottom and extending the rods out some to attach the cables. Since the cost is negligable, might as well use more.

BTW: I just saw the CoreXZ. Very cool. I guess that's why you know so much about using cable.

Edited 1 time(s). Last edit at 07/27/2014 12:45AM by napalmvictory.

BTW: I just saw the CoreXZ. Very cool. I guess that's why you know so much about using cable.

Edited 1 time(s). Last edit at 07/27/2014 12:45AM by napalmvictory.

|

Re: Wobblenaught July 27, 2014 01:23AM |

Registered: 10 years ago Posts: 979 |

For 8mm I would limit your length to 300mm. Scaling up is tricky but for a rough idea scale everything the same. If you want to go from 300mm to 900mm long then the diameter needs to go from 8mm to 24mm. (It is tricky because the loads will probably increase too from weight from the other axes. If everything is directly scaled then so will the error. This means you have to increase the diameter of the rod over the naive scaling. As you can imagine, this gets a little unsustainable.)

Industry usually abandons unsupported rails once you get much bigger than a RepRap because of this scaling issue. It is a lot less about the material and quantity than it is about the outside dimensions of the supporting members. A 1.25 OD x 1.125 ID steel tube is just as stiff as a 1" solid steel rod with less than a third of the weight so you don't get the scaling issues mentioned above. (That just blows my mind.) So the solution is usually to attach a supported rail system to larger structural members. For you, you could have large structural pylons but you would have to buy/build some supported rails.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

Industry usually abandons unsupported rails once you get much bigger than a RepRap because of this scaling issue. It is a lot less about the material and quantity than it is about the outside dimensions of the supporting members. A 1.25 OD x 1.125 ID steel tube is just as stiff as a 1" solid steel rod with less than a third of the weight so you don't get the scaling issues mentioned above. (That just blows my mind.) So the solution is usually to attach a supported rail system to larger structural members. For you, you could have large structural pylons but you would have to buy/build some supported rails.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

|

Re: Wobblenaught July 27, 2014 01:52AM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Wobblenaught July 29, 2014 09:56AM |

Admin Registered: 11 years ago Posts: 3,096 |

For me 8mm rods cost 77 eurocents at the local hardware store.

It's 1.39 euros for a stainles steel variant.

Both for one meter, and I think that kind of says that using rope and connectors for those ropes will make it way more complicated, and more expensive.. I like the idea though. Cost just isn't a good reason, thats all I'm saying. But why not still do it?

I've seen nice steel cable at my local hardware store, if you manage to get some kind that doesn't stretch over time (which is inevitable), you can try it out? Maybe designing some cable tensioners too would help?

http://www.marinusdebeer.nl/

It's 1.39 euros for a stainles steel variant.

Both for one meter, and I think that kind of says that using rope and connectors for those ropes will make it way more complicated, and more expensive.. I like the idea though. Cost just isn't a good reason, thats all I'm saying. But why not still do it?

I've seen nice steel cable at my local hardware store, if you manage to get some kind that doesn't stretch over time (which is inevitable), you can try it out? Maybe designing some cable tensioners too would help?

http://www.marinusdebeer.nl/

|

Re: Wobblenaught July 29, 2014 10:35AM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Wobblenaught July 29, 2014 11:06AM |

Registered: 10 years ago Posts: 790 |

I've got 8mm X 1000mm rods. I ordered them before doing all my research and I regret it every time I look at them. Pieces of crap for 3D printing applications and I will never put them in a printer. Not stable in the slightest, I don't think I could print even at 10mm/s if I did use them. Just the weight of themselves would bow them. Even the 12mm X 1000mm rods seem undersized. The 12mm X 500mm seem to be the closest to properly sized, but in the end, for those distances, I don't think using regular round rods is going to be reasonable.

Rant done, pound of salt to be given.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Rant done, pound of salt to be given.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Wobblenaught July 29, 2014 01:38PM |

Admin Registered: 16 years ago Posts: 13,884 |

... in most CNC-applications with thin rods they are used 'supported', so the won't bend

I'm using double-rod-profiles with paired 4mm-rods for a delta - here an image of the frame:

Edited 1 time(s). Last edit at 07/29/2014 01:39PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

I'm using double-rod-profiles with paired 4mm-rods for a delta - here an image of the frame:

Edited 1 time(s). Last edit at 07/29/2014 01:39PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Wobblenaught July 29, 2014 02:15PM |

Registered: 10 years ago Posts: 439 |

I would say that stabilizing a 1 meter vertical rod sufficiently to avoid wobble with cable is a totally lost cause.

Using 8mm rod makes it totally impossible. I am using 12m rod for a 600mm Z height and there is a slight flexing with dibond sheet for stabilization.

You need 20mm rod minimum and far more than cable to hold it still. If you want a cheap solution then maybe try concrete.

Using 8mm rod makes it totally impossible. I am using 12m rod for a 600mm Z height and there is a slight flexing with dibond sheet for stabilization.

You need 20mm rod minimum and far more than cable to hold it still. If you want a cheap solution then maybe try concrete.

|

Anonymous User

Re: Wobblenaught July 29, 2014 08:30PM |

I don't really need a tensioner, since I can use a couple m8 nuts on the thread rod to give it tension. Maybe not as precise as a guitar tuner, but it should be sufficient. I don't think I need to apply a ton of tension to it. Just enough to keep it steady. I think the printrbot uses m8 rod with no support. This is just going to be a variant on that with more stability.

|

Anonymous User

Re: Wobblenaught August 01, 2014 10:35PM |

Here's a sneak peek. Bending on the smooth rod is not an issue. The thread rod did bend a lot so I added a third rod and some end caps to support the structure. I'm fairly optimistic that it will perform well. It seems to steady the z axis quite a bit. I'll post the source on thingiverse when I'm done.

|

Re: Wobblenaught August 01, 2014 11:58PM |

Registered: 10 years ago Posts: 979 |

Sorry, only registered users may post in this forum.