Home

>

Developers

>

Topic

Z-Probe - new idea

Posted by RobertKuhlmann

|

Z-Probe - new idea August 22, 2014 11:50AM |

Registered: 10 years ago Posts: 78 |

(copied/moved from a discussion in the "Teacup"-thread)

I've got a new idea for a z-probe

Task:

We need to measure the distance between the nozzle and the bed-surface for several points (the more the better) and store the measurements in an array that will be used to auto-level the bed to keep a constant distance between nozzle and bed on every x/y-coordinate during print.

Problem:

The nozzle may and should be could during the measurement. Therefore it may be, and often is, dirty, partially covered with filament remnants. So the nozzle likely is electrically insulated and most of the printbeds are electrically insulated anyway. The filament remnants on the (cold) nozzle would affect the measurements too. The mechanic and other parts of a z-probe affect accuracy and/or speed of the print, even if not in use, because they add weight we have to move during print.

Solution:

We build a small plastic cap that has a defined height and covers the nozzle with some vertical clearance (with respect to filament remnants) and some clearance in diameter too. The outer height of the probe is constant of course. The probe may have a tip like a nozzle without the hole in it. The inner hole of the probe (where the nozzle will be situated) has some simple springs to keep the probe in place.

The body of the probe consists of two parts. The upper part is a ring and its inner diameter is big enough to contain the nozzle and the springs as fixture. The lower part is the round tip of the probe, being sharp on the bottom end and flat on the upper side. Between the flat end of the bottom part and the upper part we place a piezoelectric plate (e.g. from a very very cheap speaker or sth. similar - even new it costs a few cents). The upper part of the probe has a small hole where two thin wires can comes out from the piezo.

We connect these wires to a small PCB with the required electronics to convert the piezo signal to something we can send to an IO-port of our microcontroller. The firmware will take care of the offset between nozzle-tip and probe-tip.

With the probe attached to the nozzle we can start our automatic measurement. After we've finished the measurement, we can take of the probe and print as usual with no extra weight on the toolhead and not additional wires. Sounds promising to me. grinning smiley

Best: You can print the parts of the probe. The electronics should be very simple and somewhat independent from the hardware.

Comments, ideas, critics welcome.

Edited 1 time(s). Last edit at 08/22/2014 11:51AM by RobertKuhlmann.

I've got a new idea for a z-probe

Task:

We need to measure the distance between the nozzle and the bed-surface for several points (the more the better) and store the measurements in an array that will be used to auto-level the bed to keep a constant distance between nozzle and bed on every x/y-coordinate during print.

Problem:

The nozzle may and should be could during the measurement. Therefore it may be, and often is, dirty, partially covered with filament remnants. So the nozzle likely is electrically insulated and most of the printbeds are electrically insulated anyway. The filament remnants on the (cold) nozzle would affect the measurements too. The mechanic and other parts of a z-probe affect accuracy and/or speed of the print, even if not in use, because they add weight we have to move during print.

Solution:

We build a small plastic cap that has a defined height and covers the nozzle with some vertical clearance (with respect to filament remnants) and some clearance in diameter too. The outer height of the probe is constant of course. The probe may have a tip like a nozzle without the hole in it. The inner hole of the probe (where the nozzle will be situated) has some simple springs to keep the probe in place.

The body of the probe consists of two parts. The upper part is a ring and its inner diameter is big enough to contain the nozzle and the springs as fixture. The lower part is the round tip of the probe, being sharp on the bottom end and flat on the upper side. Between the flat end of the bottom part and the upper part we place a piezoelectric plate (e.g. from a very very cheap speaker or sth. similar - even new it costs a few cents). The upper part of the probe has a small hole where two thin wires can comes out from the piezo.

We connect these wires to a small PCB with the required electronics to convert the piezo signal to something we can send to an IO-port of our microcontroller. The firmware will take care of the offset between nozzle-tip and probe-tip.

With the probe attached to the nozzle we can start our automatic measurement. After we've finished the measurement, we can take of the probe and print as usual with no extra weight on the toolhead and not additional wires. Sounds promising to me. grinning smiley

Best: You can print the parts of the probe. The electronics should be very simple and somewhat independent from the hardware.

Comments, ideas, critics welcome.

Edited 1 time(s). Last edit at 08/22/2014 11:51AM by RobertKuhlmann.

|

Re: Z-Probe - new idea August 22, 2014 03:22PM |

Registered: 9 years ago Posts: 6 |

|

Re: Z-Probe - new idea August 22, 2014 03:29PM |

Registered: 10 years ago Posts: 78 |

Simple:Quote

reprapraps

Why not use a laserpointer (1-5€ in price) and a pi-cam for calibration? Then u have a server too, and its touchless. depending on where u mount the laser you could as well have a 3d scanner with it.

Think about mounting a laserpointer onto the toolhead of a RepRap Morgan. Guess how accurate the measurement of the distance between nozzle and bed would be? It's too big and too heavy to leave it mounted while printing but removing it after calibration would devalue the measurements.

While a plastic cap with a piezo and some very thin cables weights almost nothing.

|

Re: Z-Probe - new idea August 22, 2014 03:43PM |

Registered: 9 years ago Posts: 6 |

|

Re: Z-Probe - new idea August 22, 2014 03:54PM |

Registered: 10 years ago Posts: 78 |

How about the pi-cam (> 20€, 9g)? I think the laser-pointer alone won't do it (not to mention we need a Raspberry-Pi for that). Or do you mean a solution with the cam mounted to the printer-frame?

Maybe I didn't get your idea right. Please let me know.

|

Re: Z-Probe - new idea August 22, 2014 04:13PM |

Registered: 9 years ago Posts: 6 |

|

Re: Z-Probe - new idea August 22, 2014 04:54PM |

Registered: 10 years ago Posts: 78 |

A frame-mounted cam with only 5MP (giving app. 1.25MP in effective resolution) looking at the printbed sounds like a very difficult equipment for good z-axis-measurements.

The optic of the cam (assuming it is able to be focused for any point of the whole printbed) is not very accurate. You'd have to measure and correct (in the software) the failures of the lens. Then you only have a very few pixel to measure a concrete height and, last but not least, the laser doesn't give a small sharp point for this cam, but a point with a halo around it (that will not be circular-shaped, as the camera has to "look" from an angle).

Sounds very complicated to me, with quite an uncertainty for success of such a project. Especially the software would be far too complex for the simple task to detect some z-axis-values.

I love to keep it simple and working. Don't get me wrong. Your approach sounds very challenging. But that's not what is attractive for me. I like a minimalistic, but working and accurate solution.

When I'm looking at my own idea and think about what could be done better, I would think about replacing the piezo by a switch or even a diy-micro-contact (getting rid of the additional electronics that way). Or something like that.

And most important: Handling should be as simple as possible. Pulling a plastic cap over the nozzle, starting the z-calibration by a custom M-command and removing the cap afterwards sounds simple enough to me.

Edited 1 time(s). Last edit at 08/22/2014 05:50PM by RobertKuhlmann.

The optic of the cam (assuming it is able to be focused for any point of the whole printbed) is not very accurate. You'd have to measure and correct (in the software) the failures of the lens. Then you only have a very few pixel to measure a concrete height and, last but not least, the laser doesn't give a small sharp point for this cam, but a point with a halo around it (that will not be circular-shaped, as the camera has to "look" from an angle).

Sounds very complicated to me, with quite an uncertainty for success of such a project. Especially the software would be far too complex for the simple task to detect some z-axis-values.

I love to keep it simple and working. Don't get me wrong. Your approach sounds very challenging. But that's not what is attractive for me. I like a minimalistic, but working and accurate solution.

When I'm looking at my own idea and think about what could be done better, I would think about replacing the piezo by a switch or even a diy-micro-contact (getting rid of the additional electronics that way). Or something like that.

And most important: Handling should be as simple as possible. Pulling a plastic cap over the nozzle, starting the z-calibration by a custom M-command and removing the cap afterwards sounds simple enough to me.

Edited 1 time(s). Last edit at 08/22/2014 05:50PM by RobertKuhlmann.

|

Re: Z-Probe - new idea August 24, 2014 11:46AM |

Registered: 13 years ago Posts: 7,616 |

A camera for finding the location of a light point? One can always add complexity. The more complexity, the better?

There's stuff like this, reflective light barriers: [www.mouser.de]

Pretty much the same optical sensor RepRap uses for opto endstops since years, just a different housing. What I've found out so far: the angle between light source and -sensor is important; when parallel (most reflective light barriers are parallel) the detected distance heavily relies on the surface quality (which can change due to dust or similar). When at an angle, the photosensor's maximum signal and distance from the measured part is pretty independent from the surface. Problem left open: detecting a maximum is more difficult than detecting a threshold.

Coming back to this laser pointer ... there's a laser diode inside and such a thing could be used to extend sensor range and/or to sharpen the signal.

There's stuff like this, reflective light barriers: [www.mouser.de]

Pretty much the same optical sensor RepRap uses for opto endstops since years, just a different housing. What I've found out so far: the angle between light source and -sensor is important; when parallel (most reflective light barriers are parallel) the detected distance heavily relies on the surface quality (which can change due to dust or similar). When at an angle, the photosensor's maximum signal and distance from the measured part is pretty independent from the surface. Problem left open: detecting a maximum is more difficult than detecting a threshold.

Coming back to this laser pointer ... there's a laser diode inside and such a thing could be used to extend sensor range and/or to sharpen the signal.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Z-Probe - new idea August 29, 2014 06:08PM |

Registered: 10 years ago Posts: 14,672 |

For print head height sensing I use two narrow beam infrared LEDs pointing towards the bed at a 45 degree angle, and a phototransistor also looking at the bed at a 45 degree angle to pick up the reflections. The LEDs are offset from each other a little so that the bed reflects the light from them into the phototransistor maximally at slightly different heights. So the height at which they reflect equally is quite well-defined and varies only slightly between different bed surfaces.

I mount the LEDs and phototransistor, along with a microcontroller and the rest of the electronics, on a small board that fits on the side of the print head.

Such was the interest among owners of Ormerod printers that a made up a batch of 50. They sold out within a couple of weeks, and I have just commissioned another batch. More details and a link to github are at [miscsolutions.wordpress.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I mount the LEDs and phototransistor, along with a microcontroller and the rest of the electronics, on a small board that fits on the side of the print head.

Such was the interest among owners of Ormerod printers that a made up a batch of 50. They sold out within a couple of weeks, and I have just commissioned another batch. More details and a link to github are at [miscsolutions.wordpress.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Z-Probe - new idea September 19, 2014 10:15AM |

Registered: 12 years ago Posts: 93 |

Fotek inductove proximity sensors have a 5mm range and cost $3.25 they have 3 wires and work with marlin and ramps 1.4 without firmware changes for end stop use. I'm pretty happy with them as my end stops. No more pesky micro switches.

Capacitive sensor data sheet here [www.servo.com.hk]

Edited 1 time(s). Last edit at 09/19/2014 10:19AM by metzindustries.

Capacitive sensor data sheet here [www.servo.com.hk]

Edited 1 time(s). Last edit at 09/19/2014 10:19AM by metzindustries.

|

Re: Z-Probe - new idea September 19, 2014 02:14PM |

Registered: 10 years ago Posts: 14,672 |

I tried capacitive and inductive height sensing, but I prefer to measure the nozzle height above the bed itself, rather than the height above a metal plate under the bed, and I use a glass bed. That's why I find differential IR works best. It means I can swap glass bed plates between prints for fast turnaround. I also tried ultrasonic, but it is rather sensitive to temperature. I guess that if you are printing direct on an aluminium bed, then capacitive or inductive should work well.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Z-Probe - new idea September 25, 2014 08:12PM |

Registered: 9 years ago Posts: 119 |

Quote

reprapraps

Why not use a laserpointer (1-5€ in price) and a pi-cam for calibration? Then u have a server too, and its touchless. depending on where u mount the laser you could as well have a 3d scanner with it.

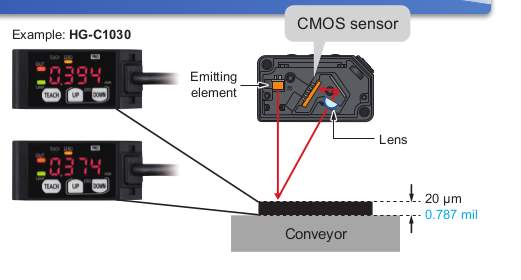

What you are talking about doing, is reverse engineering one of these Panasonic HG-C series.

Panasonic use a laser and a strip light sensor similar to a camera, then they use trigonometry similar to the 3D scanners, made my Makerbot for example, to work out where the laser spot is resting when it hits a surface.

By keeping all the angles known and looking for the brightest pixel on the camera strip they can predict how far the surface is from the laser. They are very costly because of the hight tollerance of the components in the region of £400.

So it can be done, the accuracy depends on your quality of laser, the resolution of your camera, and how good your software is in converting a picture into a linear plot of the laser position.

Lloyd

Edited 2 time(s). Last edit at 09/25/2014 08:13PM by ezwul.

Sorry, only registered users may post in this forum.