Home

>

Developers

>

Topic

3D Printer Design (Thoughts)

Posted by TRoager

|

3D Printer Design (Thoughts) December 08, 2014 06:22PM |

Registered: 10 years ago Posts: 100 |

Hello Folks.

im in a bit of a crossroad here.

Im trying to decide how im gonna build my own 3D Printer.

Which design to choose on the XYZ movement.

I really like the z axis to move up and down or just fixed so no movement at all on the build plate.

so i got some design i like but im gonna choose 1 of em.

There is a Delta ( Fixed Build Plate)

Ultimaker (Z up and down) - Just dont like the 6mm Axis and hard to align.

Then theres something like dual bars for X and Y on a ultimaker design.

And then there is how to move it, im thinking of GT2 Belt for some HBot design or CoreXY, seems like a good design.

Else there is something like the solidoodle where it 1 motor is on the moving axis.

My future controller board is going to be something like smoothieboard because of the 32bit processor.

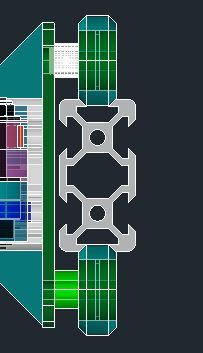

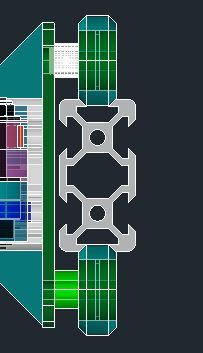

and im not sure about the frame, im thinking Openbeam or some lasercut acrylic or metalic sheets ( im tired of the wooden look on my current).

What do you guys prefer? Because i cant decide, what design has most stability and accuracy?

- Thanks in Advance

Edited 1 time(s). Last edit at 12/08/2014 06:23PM by TRoager.

im in a bit of a crossroad here.

Im trying to decide how im gonna build my own 3D Printer.

Which design to choose on the XYZ movement.

I really like the z axis to move up and down or just fixed so no movement at all on the build plate.

so i got some design i like but im gonna choose 1 of em.

There is a Delta ( Fixed Build Plate)

Ultimaker (Z up and down) - Just dont like the 6mm Axis and hard to align.

Then theres something like dual bars for X and Y on a ultimaker design.

And then there is how to move it, im thinking of GT2 Belt for some HBot design or CoreXY, seems like a good design.

Else there is something like the solidoodle where it 1 motor is on the moving axis.

My future controller board is going to be something like smoothieboard because of the 32bit processor.

and im not sure about the frame, im thinking Openbeam or some lasercut acrylic or metalic sheets ( im tired of the wooden look on my current).

What do you guys prefer? Because i cant decide, what design has most stability and accuracy?

- Thanks in Advance

Edited 1 time(s). Last edit at 12/08/2014 06:23PM by TRoager.

|

Re: 3D Printer Design (Thoughts) December 11, 2014 02:56AM |

Registered: 10 years ago Posts: 240 |

Certain designs lend themselves better depending on build area and footprint.

Quality can be achieved on most designs, it's a matter of how fast and what your needs are.

Deltas: Cheap, fast, reliable, easy to assemble... for a single nozzle setup. Not so good for duals, they work best with a light weight moving assembly. Can be more difficult to tune and have a lot of wasted upper space.

CoreXY/H-bot is better for dual nozzles and run faster than normal cartesians, but like traditional cartesians, they can have more wear an tear at high speeds and can require much more upper structure than a typical cartesian. Lots of parts and more complex to build, probably the most expensive design.

Traditional cartesian is cheaper and easier to build than a CoreXY/Hbot, but can't run as fast (in general) and has a high level of wear and tear. Has lots of support though.

8bit processors can handle a cartesian/CoreXY/H-bot

16bit can handle a cartesian/CoreXY/H-bot with an LCD or a delta without an lcd.

32bit can handle a delta and lcd.

More processing power alone won't make you go faster or give you better prints.

If you think an Ultimaker is hard to tune, you should probably skip on a delta.

I've been using V-slot for over a year, and I love it for frames and linear movement.

Quality can be achieved on most designs, it's a matter of how fast and what your needs are.

Deltas: Cheap, fast, reliable, easy to assemble... for a single nozzle setup. Not so good for duals, they work best with a light weight moving assembly. Can be more difficult to tune and have a lot of wasted upper space.

CoreXY/H-bot is better for dual nozzles and run faster than normal cartesians, but like traditional cartesians, they can have more wear an tear at high speeds and can require much more upper structure than a typical cartesian. Lots of parts and more complex to build, probably the most expensive design.

Traditional cartesian is cheaper and easier to build than a CoreXY/Hbot, but can't run as fast (in general) and has a high level of wear and tear. Has lots of support though.

8bit processors can handle a cartesian/CoreXY/H-bot

16bit can handle a cartesian/CoreXY/H-bot with an LCD or a delta without an lcd.

32bit can handle a delta and lcd.

More processing power alone won't make you go faster or give you better prints.

If you think an Ultimaker is hard to tune, you should probably skip on a delta.

I've been using V-slot for over a year, and I love it for frames and linear movement.

|

Re: 3D Printer Design (Thoughts) December 11, 2014 03:17PM |

Registered: 10 years ago Posts: 100 |

Thank you for your reply. Makes alot og sense.

But im getting used to slow speed around 30mm/s but the quality aint good enough for med yet. My ultimaker os made of MDF and i think its week and i really hate that the Rods have to rotate. But then again the usual Prusa i3 have some flaws in my opinion. Such as the build plate moving in 1 direction.

I was going to use the E3D Kraken as my hotend.

And then going for the reprap duet / Smoothie board.

But the frame is in my opionion a critical thing on the printer. And i was thinking something like using the frame as linear movement like you say. But im morr to the openbeam kind of alu extrusion, its cheap and i van maybe create a solid frame for less than i can get v slots for ?

?

But im getting used to slow speed around 30mm/s but the quality aint good enough for med yet. My ultimaker os made of MDF and i think its week and i really hate that the Rods have to rotate. But then again the usual Prusa i3 have some flaws in my opinion. Such as the build plate moving in 1 direction.

I was going to use the E3D Kraken as my hotend.

And then going for the reprap duet / Smoothie board.

But the frame is in my opionion a critical thing on the printer. And i was thinking something like using the frame as linear movement like you say. But im morr to the openbeam kind of alu extrusion, its cheap and i van maybe create a solid frame for less than i can get v slots for

?

?

|

Re: 3D Printer Design (Thoughts) December 11, 2014 06:48PM |

Registered: 10 years ago Posts: 240 |

As much as I dislike wood, the Ultimaker is actually one of the few printers I was impressed by.

It's actually stronger, and holds it's calibration better than many/most Reprap designs I've seen and worked with.

Add up the price of special rollers, bearings, shafts, spacers and shipping, then go compare it to the cost of V-slot, because you need the whole system in order to make it work. Also consider that there is no bearing surface on Openbeam. Your wheels ride on a sharp corner, and slowly destroys the wheels and accuracy over time.

Also, I strongly disagree with using M3 bolts to fasten a frame together unless you're making something very small. There is simply not enough surface contact to really get a good grip, and far too much leverage for such a small fastener. V-slot uses an M5 bolt with far more strength and clamping power.

It's actually stronger, and holds it's calibration better than many/most Reprap designs I've seen and worked with.

Add up the price of special rollers, bearings, shafts, spacers and shipping, then go compare it to the cost of V-slot, because you need the whole system in order to make it work. Also consider that there is no bearing surface on Openbeam. Your wheels ride on a sharp corner, and slowly destroys the wheels and accuracy over time.

Also, I strongly disagree with using M3 bolts to fasten a frame together unless you're making something very small. There is simply not enough surface contact to really get a good grip, and far too much leverage for such a small fastener. V-slot uses an M5 bolt with far more strength and clamping power.

|

Re: 3D Printer Design (Thoughts) December 12, 2014 02:36PM |

Registered: 10 years ago Posts: 100 |

|

Re: 3D Printer Design (Thoughts) December 13, 2014 06:52AM |

Registered: 11 years ago Posts: 296 |

|

Re: 3D Printer Design (Thoughts) December 13, 2014 01:20PM |

Registered: 10 years ago Posts: 100 |

|

Re: 3D Printer Design (Thoughts) December 14, 2014 02:57AM |

Registered: 10 years ago Posts: 240 |

Again, you have to look at the whole picture, cost of other parts, reliability, accuracy, maintenance, etc...

In the grand scheme of building a good, reliable printer, that's not a lot of money. More importantly, you are trying to save a few dollars on a multi-hundred dollar object in a place you can't just simply swap out later. This is an important part of a delta, are you sure you want to cut corners here?

In the grand scheme of building a good, reliable printer, that's not a lot of money. More importantly, you are trying to save a few dollars on a multi-hundred dollar object in a place you can't just simply swap out later. This is an important part of a delta, are you sure you want to cut corners here?

|

Re: 3D Printer Design (Thoughts) December 14, 2014 09:03AM |

Registered: 10 years ago Posts: 553 |

If ypure going to go the wheel and extrusion route, deltaprintr sells wheels for Misumi 1515 extrusion. Probably more reliable than v slot since it doesn't ride on a sharp edge.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: 3D Printer Design (Thoughts) December 15, 2014 09:18AM |

Registered: 10 years ago Posts: 100 |

|

Re: 3D Printer Design (Thoughts) December 21, 2014 04:50AM |

Registered: 9 years ago Posts: 158 |

My 2p worth.

V slot wheels don't run on a sharp edge*

The virtue of that 45º 'v'slot is that the wheel is self centering on the rail and the bearing surfaces are flat.

Putting a wheel in a square edged slot will mean either the wheel binds in the slot or the wheel has clearance to wobble around the slot.

-a

(* - Except dual V wheels running on openrail which is for attaching to a 3rd party extrusion.)

V slot wheels don't run on a sharp edge*

The virtue of that 45º 'v'slot is that the wheel is self centering on the rail and the bearing surfaces are flat.

Putting a wheel in a square edged slot will mean either the wheel binds in the slot or the wheel has clearance to wobble around the slot.

-a

(* - Except dual V wheels running on openrail which is for attaching to a 3rd party extrusion.)

|

Re: 3D Printer Design (Thoughts) February 03, 2015 10:16PM |

Registered: 11 years ago Posts: 471 |

|

Re: 3D Printer Design (Thoughts) February 04, 2015 11:08PM |

Registered: 9 years ago Posts: 977 |

Quote

epicepee

Just wanna throw out that an 8-bit MCU can run a delta just fine. Lots of people, including myself, use RAMPS to run deltas.

Thank you for your refreshingly honest post! There is a lot of FUD being spread here in this forum about using the ubiquitous Arduino Mega 2560 + RAMPS 1.4 combo to control linear delta printers. Something I always thought was quite odd was that when Johan Rocholl designed first the Rostock and then the Kossel lines of printers, he was using 8-bit MCUs so I couldn't understand why people insisted that a 32-bit controller was necessary.

I can quite understand that if you are running a linear delta printer at very high speeds, the 8-bit MCU can run out of cycles to perform the necessary calculations, but surely this is not the case when running a delta printer at normal printing speeds?

Edited 1 time(s). Last edit at 02/04/2015 11:08PM by AndrewBCN.

|

Re: 3D Printer Design (Thoughts) February 06, 2015 11:48AM |

Registered: 11 years ago Posts: 335 |

Quote

AndrewBCN

Thank you for your refreshingly honest post! There is a lot of FUD being spread here in this forum about using the ubiquitous Arduino Mega 2560 + RAMPS 1.4 combo to control linear delta printers. Something I always thought was quite odd was that when Johan Rocholl designed first the Rostock and then the Kossel lines of printers, he was using 8-bit MCUs so I couldn't understand why people insisted that a 32-bit controller was necessary.

I can quite understand that if you are running a linear delta printer at very high speeds, the 8-bit MCU can run out of cycles to perform the necessary calculations, but surely this is not the case when running a delta printer at normal printing speeds?

I think its just better to move away from 8-bit as quickly as possible.

For optimal printing, you need to smooth the g-code path into something that respects the limits of your printer while maintaining accuracy and speed. This is a very hard problem, some of the issues are discussed here: [dynomotion.com]

To get everything running on an 8-bit controller the motion planner takes a lot of shortcuts. There are situations that will cause non-ideal movement, and they only apply a trapezoidal acceleration profile (In higher end systems jerk and higher derivatives are generally smoothed as well).

Modern 32-bit microcontrollers are cheaper than the decade-old 8 bit stuff. Better software is free performance for everyone.

Sorry, only registered users may post in this forum.