Home

>

Developers

>

Topic

one stepper +5 filaments = dog box shifting!

Posted by o_lampe

one stepper +5 filaments = dog box shifting!  May 21, 2015 06:24AM |

Registered: 8 years ago Posts: 5,232 |

Today, if you want to use several colors on your printer, you have to deal with one stepper per color.

For more than 2 colors the only option until now is to use bowden-style remote steppers for each color.

But in car racing we use "dog box" gears. ( see example-picture )

Why don´t we put several gears on an extended stepper shaft and shift through the colors on_the_fly ?

I have a picture of an MK8 direct drive extruder on my mind, with an extended body to fit 5 driver/idler gear combos next to each other.

This way only one color at a time would be extruded.

Another difficulty is to put that many hotends in a row. But tests would tell, if they could be made in one block.

Another point is the firmware adaption. A servo driven shifter would be cool, but for now we can live with the "pause at z" option to change color while the print pauses.

OK guys, fire up your lathe and build a dog box extruder for me

-Olaf

For more than 2 colors the only option until now is to use bowden-style remote steppers for each color.

But in car racing we use "dog box" gears. ( see example-picture )

Why don´t we put several gears on an extended stepper shaft and shift through the colors on_the_fly ?

I have a picture of an MK8 direct drive extruder on my mind, with an extended body to fit 5 driver/idler gear combos next to each other.

This way only one color at a time would be extruded.

Another difficulty is to put that many hotends in a row. But tests would tell, if they could be made in one block.

Another point is the firmware adaption. A servo driven shifter would be cool, but for now we can live with the "pause at z" option to change color while the print pauses.

OK guys, fire up your lathe and build a dog box extruder for me

-Olaf

Re: one stepper +5 filaments = dog box shifting!  May 21, 2015 10:36AM |

Registered: 11 years ago Posts: 335 |

I think it makes more sense to work around the limitations of bowden. It is more flexible and scales in number of extruders very well. I think an encoder on the hot end to compensate for hysteresis could overcome most of the drawbacks. Adding an encoder is also a fairly straightforward project compared to building a linkage that is reliable under high acceleration and temperatures.

Any mechanical solution adds complexity and weight even if you can cut down on the number of steppers used.

Any mechanical solution adds complexity and weight even if you can cut down on the number of steppers used.

Re: one stepper +5 filaments = dog box shifting!  May 22, 2015 02:58AM |

Registered: 8 years ago Posts: 5,232 |

To drive 5 extruders with a bowden concept, you couldn´t use RAMPS/Mega combos anymore.

Last night I made some sketches for a compact, simple design with only one lever.

I used to work with SolidWorks, but I don´t have access to it anymore. I´m just starting with OpenSCAD,

It will take a while, before I can present anything.

-Olaf

Last night I made some sketches for a compact, simple design with only one lever.

I used to work with SolidWorks, but I don´t have access to it anymore. I´m just starting with OpenSCAD,

It will take a while, before I can present anything.

-Olaf

Re: one stepper +5 filaments = dog box shifting!  May 29, 2015 02:10PM |

Registered: 10 years ago Posts: 466 |

Re: one stepper +5 filaments = dog box shifting!  May 30, 2015 03:14AM |

Registered: 8 years ago Posts: 5,232 |

Good News!

Does the motherbord send the color information from the g-code? With a preview/countdown, when the next extruder should start heating up

It would be great, if the daughterboard could also tell the motherboard to take a break until the next extruder is hot.

-Olaf

Edited 1 time(s). Last edit at 05/30/2015 03:16AM by o_lampe.

Does the motherbord send the color information from the g-code? With a preview/countdown, when the next extruder should start heating up

It would be great, if the daughterboard could also tell the motherboard to take a break until the next extruder is hot.

-Olaf

Edited 1 time(s). Last edit at 05/30/2015 03:16AM by o_lampe.

Re: one stepper +5 filaments = dog box shifting!  June 03, 2015 01:35PM |

Registered: 8 years ago Posts: 69 |

Ciao,

new here and working a multi material printer.

I am interested in knowing more abut your ideas as I want to use one extruder motor (or the least as possible).

Right now I am planning to have 4 materials printer and was looking at the Kimbra marlin firmware variation.

Any feedback or suggestions based on what you are working on?

Thanks

Alessandro

new here and working a multi material printer.

I am interested in knowing more abut your ideas as I want to use one extruder motor (or the least as possible).

Right now I am planning to have 4 materials printer and was looking at the Kimbra marlin firmware variation.

Any feedback or suggestions based on what you are working on?

Thanks

Alessandro

Re: one stepper +5 filaments = dog box shifting!  June 03, 2015 10:28PM |

Registered: 9 years ago Posts: 978 |

@Olaf... G-code doesn't include colour. The slicer would have to generate G-code commands to change extruders at the right time. I guess in your scenario that would involve stopping the head, heating the new extruder, switching to it, then starting the head again and extruder.

A couple of thoughts on this...

Why not keep all extruders hot all the time?

If you always change extruders when the motor is in a particular position, then you always know that all the extruders are waiting at that position... then you probably could have fairly small tolerances on the dog teeth. And/or you could change from one extruder to another while the motor continued to run.

Changing your idea a bit... imagine that the motor shaft is vertical, with a 45 degree bevel gear. The extruders are in a circle around it, with 45 degree bevel gears on horizontal shafts. To drive filament, use a servo or solenoid to move an extruder (or just a gear on its shaft) inward so that the gear meshes with the motor gear. Conversely, move outward to disengage. If you have a mixing nozzle like a Diamond, you could engage several extruders at the same time to mix colours. If the motor gear was larger than the extruder gears, you could have as many extruders around the motor as you wanted.

For a proof of concept, I think you could probably print the components, rather than needing to machine them from metal.

Frank

A couple of thoughts on this...

Why not keep all extruders hot all the time?

If you always change extruders when the motor is in a particular position, then you always know that all the extruders are waiting at that position... then you probably could have fairly small tolerances on the dog teeth. And/or you could change from one extruder to another while the motor continued to run.

Changing your idea a bit... imagine that the motor shaft is vertical, with a 45 degree bevel gear. The extruders are in a circle around it, with 45 degree bevel gears on horizontal shafts. To drive filament, use a servo or solenoid to move an extruder (or just a gear on its shaft) inward so that the gear meshes with the motor gear. Conversely, move outward to disengage. If you have a mixing nozzle like a Diamond, you could engage several extruders at the same time to mix colours. If the motor gear was larger than the extruder gears, you could have as many extruders around the motor as you wanted.

For a proof of concept, I think you could probably print the components, rather than needing to machine them from metal.

Frank

Re: one stepper +5 filaments = dog box shifting!  June 04, 2015 12:46PM |

Registered: 10 years ago Posts: 1,401 |

I think I have the solution for "one extruder one nozzle multiple filaments". I will post a design either later today or tomorrow, it uses one long hobbed rod, the filament its guided In a housing pressed against the idle bearings, the housing is engaged with the hobbed bolt via solenoid actuators push-pull type (cheap on eBay). In theory the solenoid should have enough power to create a good grip between idler and hobbed bolt. Some mixing percentages might be achievable by adjusting voltage to the solenoids so the pressure rate on the filaments can vary, it won't be a perfect color mixer system but at least it will be quite cheap.

The trick will be then sequencing the solenoids with the extrusion timing. The mega board alone might be able to handle it or a cheap nano could process the signal coming from the mega.

Edited 1 time(s). Last edit at 06/04/2015 12:55PM by ggherbaz.

The trick will be then sequencing the solenoids with the extrusion timing. The mega board alone might be able to handle it or a cheap nano could process the signal coming from the mega.

Edited 1 time(s). Last edit at 06/04/2015 12:55PM by ggherbaz.

Re: one stepper +5 filaments = dog box shifting!  June 04, 2015 02:58PM |

Registered: 8 years ago Posts: 5,232 |

Re: one stepper +5 filaments = dog box shifting!  June 04, 2015 03:03PM |

Registered: 8 years ago Posts: 5,232 |

Where is my reply to Franks proposal? Do we have censorship in this forum?

All I wanted to say, is: with a big gear on the stepper and smaller gears on each extruder, the torque hungry bowden setup won´t have an easy time.

And I have started a "commercial collaboration" and can not tell more about my progress.

-Olaf

Edited 1 time(s). Last edit at 06/04/2015 03:04PM by o_lampe.

All I wanted to say, is: with a big gear on the stepper and smaller gears on each extruder, the torque hungry bowden setup won´t have an easy time.

And I have started a "commercial collaboration" and can not tell more about my progress.

-Olaf

Edited 1 time(s). Last edit at 06/04/2015 03:04PM by o_lampe.

Re: one stepper +5 filaments = dog box shifting!  June 05, 2015 01:41AM |

Registered: 9 years ago Posts: 1 |

Would something like the 'palette' do the trick? [www.3ders.org] (and no I am not affiliated with these guys).

Re: one stepper +5 filaments = dog box shifting!  June 05, 2015 05:01AM |

Registered: 8 years ago Posts: 5,232 |

The Palette would waste a lot of filament between color changes. The hole string between the Palette box and the hotend would have to be dumped.

I wonder, if they can retract at all?

But I´d use it as standalone device to make my own colors at home...

-Olaf

Edited 1 time(s). Last edit at 06/05/2015 05:05AM by o_lampe.

I wonder, if they can retract at all?

But I´d use it as standalone device to make my own colors at home...

-Olaf

Edited 1 time(s). Last edit at 06/05/2015 05:05AM by o_lampe.

Re: one stepper +5 filaments = dog box shifting!  June 05, 2015 10:43AM |

Registered: 10 years ago Posts: 1,401 |

This is the idea I was referring to, still lot to do and test.

Olaf, yes I understand your point so it will have to be only on and off option.

for control I will have to develop this idea:

[www.youtube.com]

Solenoid:

[www.ebay.com]

or

[www.ebay.com]

I will do some test before I get crazy with this idea.

Re: one stepper +5 filaments = dog box shifting!  June 05, 2015 10:52AM |

Registered: 8 years ago Posts: 5,232 |

Re: one stepper +5 filaments = dog box shifting!  June 05, 2015 11:03AM |

Registered: 8 years ago Posts: 69 |

Re: one stepper +5 filaments = dog box shifting!  June 05, 2015 12:05PM |

Registered: 10 years ago Posts: 1,401 |

Quite similar, the only thing is that servos capable of holding the torque needed will cost a lot more than the solenoid and correct angles will have to be set compare to only on-off switching needed for solenoid. Also servo glitches are common with Arduino controllers so shielding is important.

Both Alessandro and mine share the same principle, so we might be hopefully in the right direction.

It's going to take me some time before I can start working on my design since I'm finishing another project with higher priority, but I will report back when I get something functional. My main problem will be firmware development, I'm good with mechanics and electronics but an ignorant when it comes to software development.

Both Alessandro and mine share the same principle, so we might be hopefully in the right direction.

It's going to take me some time before I can start working on my design since I'm finishing another project with higher priority, but I will report back when I get something functional. My main problem will be firmware development, I'm good with mechanics and electronics but an ignorant when it comes to software development.

Re: one stepper +5 filaments = dog box shifting!  June 05, 2015 12:13PM |

Registered: 8 years ago Posts: 69 |

Ciao,

very good points.

Yes cost needs to be considered for sure.

Also about the torque, another thing to be considered carefully, would help some levers/mechanism.

I lean towards servos since, as you mention, software is already in the firmware to manage the servos. Usually are used for the bed leveling.

I am looking both at Marlin and its variation called Kimbra, contacted the developer.

I will continue my original post since I am on development stage for a project and I am on a schedule to finish it !!!

In any case will check this post so that ideas can be exchanged.

Alessandro

very good points.

Yes cost needs to be considered for sure.

Also about the torque, another thing to be considered carefully, would help some levers/mechanism.

I lean towards servos since, as you mention, software is already in the firmware to manage the servos. Usually are used for the bed leveling.

I am looking both at Marlin and its variation called Kimbra, contacted the developer.

I will continue my original post since I am on development stage for a project and I am on a schedule to finish it !!!

In any case will check this post so that ideas can be exchanged.

Alessandro

Re: one stepper +5 filaments = dog box shifting!  June 05, 2015 04:45PM |

Registered: 9 years ago Posts: 135 |

From a cursory look at their videos of the machine in action, I can tell you that's not how it works at all.Quote

o_lampe

The Palette would waste a lot of filament between color changes. The hole string between the Palette box and the hotend would have to be dumped.

It appears that the Pallette takes in the g-code, starts queuing up the filament bits and sending them in one constant fused strand to the printer, and then it passes along the g-code to the printer once the string is 'full'.

If that's the case, then it almost certainly wouldn't handle retraction very well, but it also doesn't waste much filament either.

Re: one stepper +5 filaments = dog box shifting!  June 05, 2015 07:04PM |

Registered: 9 years ago Posts: 978 |

Quote

Feign

It appears that the Pallette takes in the g-code, starts queuing up the filament bits and sending them in one constant fused strand to the printer, and then it passes along the g-code to the printer once the string is 'full'.

Yeah, that's how I read it too. I think that colour change precision would be limited by the precision in allowing for the lag between Palette and printer.

Re: one stepper +5 filaments = dog box shifting!  June 06, 2015 03:51AM |

Registered: 8 years ago Posts: 5,232 |

Re: one stepper +5 filaments = dog box shifting!  June 14, 2015 03:37PM |

Registered: 12 years ago Posts: 1,450 |

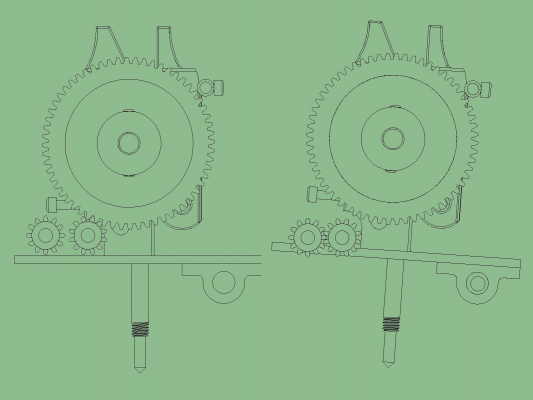

I have been working on and off for the last year or so on an idea similar to Olaf's. In my case I use the meshing of gears directly with a solenoid doing the disengaging and the same stepper that feeds the filament driving a leadscrew to select the extruder which will be used next. The gears are pre-aligned by software so that the teeth are always ready to mesh correctly when they are selected. In the diagram below the left hand part shows the stepper motor gear engaged with the large drive gear on the extruder. The right hand part shows the extruder and its gear lifted out of contact but the left hand small gear driving the leadscrew is now meshed.

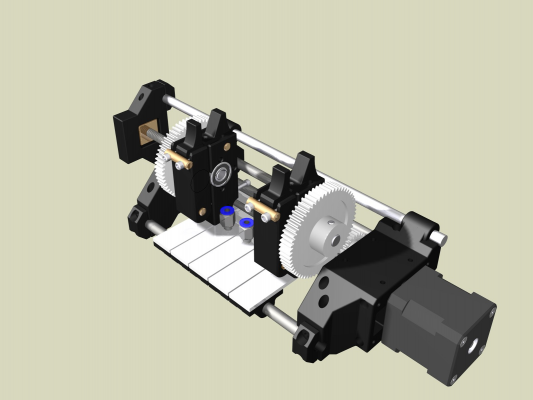

The CAD impression below shows a possible layout with two close-coupled extruders and three bowden extruders.

Although I hope to return to this method, the present development is based on having separate steppers on all extruders - 5 at present

Mike

The CAD impression below shows a possible layout with two close-coupled extruders and three bowden extruders.

Although I hope to return to this method, the present development is based on having separate steppers on all extruders - 5 at present

Mike

Sorry, only registered users may post in this forum.