Home

>

Developers

>

Topic

Linear electric motors, and high speed printing in general

Posted by buggy123

|

Linear electric motors, and high speed printing in general May 26, 2015 03:13AM |

Registered: 8 years ago Posts: 3 |

Warning: long, rambling post!

tl;dr: linear electric motors: [en.wikipedia.org]

Recently, I've been thinking a lot about how it might be possible to make 3d printers faster, and about just how fast a printer could possibly print. My goal is to figure out how a printer could print at a brisk 1000mm/s+. Normally, the speed a printer can print at is limited by the maximum acceleration of the printer, because while you might be able to get a normal printer to print faster by lowering acceleration it will spend more time getting up to that speed. And the way I see it, the maximum acceleration of a printer is limited by 2 factors: motor strength and structural rigidity. If the frame of a printer isn't rigid enough for a given acceleration, you get inaccurate or low quality prints. If the motor isn't strong enough to accelerate the moving mass of the printer, it skips steps and your printer produces a pile of plastic spaghetti. It's possible to make the frame more rigid, but this increases the mass the motor has to move. However, increasing the strength of the motor generally doesn't increase the moving mass of the printer. So theoretically, the maximum acceleration of a printer is limited mainly by the motor if you are willing to make the frame stronger as necessary.

However in reality the situation is slightly more complicated. The rotor of whatever motor is used adds to the moving mass of the motor. This means that even if you were to use ridiculously oversized and overpowered stepper motors, the maximum acceleration would still be close to the unburdened acceleration of the steppers. With a reasonable maximum acceleration of 500rps^2 for the stepper motor, and a standard GT2 8 tooth pulley, this comes out to about 7000mm/s^2. Given a max stepper RPM of 3000, this gives a maximum speed of 800mm/s. At 800mm/s, it would take the printer about 5 mm to get up to speed. Not terrible, but this is in a ideal scenario that completely ignores the mass of the printer, ignores friction, etc. This is all at the maximum RPM of the stepper, at lower speeds the torque, and therefore maximum acceleration, of the stepper is higher. But obviously, the maximum speed of the printer is lower at lower stepper speeds. It might be possible to reduce the acceleration required from the stepper by gearing it up or using a larger pulley, but this would reduce the (already fairly low) resolution of the stepper.

Overall, steppers are fairly limiting. They're simple, but just aren't able to handle higher speeds. Servos are nice in that they can usually accelerate much faster than a comparably sized stepper, and have higher torque as well. They are also much more precise than steppers, allowing for the use of larger pulleys, which in turn reduce the acceleration required from the motor. However, servos are expensive, ESPECIALLY powerful servo motors. And because servos aren't mechanically precise like steppers(I.e. its either in the correct position or its skipped steps and failed entirely), they might not be precise enough for a printer near their torque limit; the controlling electronics would fail to move it to exactly where it needs to go. Because of all this, a heavier printer designed to be rigid enough to handle 1000m/s and comparatively high acceleration would require servos (and electronics and powersource) that could easily cost more than a thousand dollars, each. Figuring out how much exactly would require designing a printer and calculating the moving mass, which is somewhat pointless when the motors it would require are without a doubt prohibitively expensive. So really, servos aren't the greatest option for these kinds of speeds, even if they are functionally ideal.

halfway tl;dr: I more or less reiterated what everyone here probably agrees are the factors that limit a printer's maximum speed, and why the current options for increasing a printer's maximum speed are impractical.

SO, on to the new stuff. Having established above that we primarily need a better drive system to make faster printers, I thought about how that might be done. We need something that doesn't add as much mass to the moving parts of the printer, and is sufficiently strong and precise enough. I had the idea of forgoing motors and belts entirely, and instead using electromagnets on the sides of the printer to attract magnets attached to the arms of the printer, which would let you put practically any sized electromagnets on the side of the printer and run as much current as you want through them, without increasing the moving mass of the printer. This would unfortunately require a closed loop system to function, like a servo. Keep in mind that i'm focusing on delta style printers, which can usually reach higher speeds anyway.

I've been mulling over this idea for a while, until I saw something on TV about maglev trains. At one point, they showed old footage of a scientist demonstrating a electric motor that not only levitates a metal object above it, but propels it as well. This made me realize that something like my idea probably already exists. About 5 seconds of googling later, and I found out that I essentially came up with a linear electric motor. This shouldn't be confused with (slow) linear actuators, which are essentially a stepper motor with a built in threaded rod.

After looking through the data sheets for a few industrial linear motors, I found that they seem to have moderate strength, not much better than a stepper, but have very little moving mass, more than enough precision, and very high maximum speeds, around 20 meters a second or more! As usual with any sort of industrial equipment, I wasn't able to find anything resembling a price even after searching 12 different sites, so I have no idea how much they would cost, but it's probably a lot given that those are precision made industrial grade motors. And generally, they place the electromagnets on the slider instead of the rail, meaning that the rail has to be lined with magnets and the slider has to have wires running to it. As far as I could find, no one is selling anything resembling a 'consumer' version of a linear motor, and DIY versions are almost nonexistent.

So while this looks promising I can find almost nothing about it. Theoretically, it might not be too hard to make or too expensive, it might even prove to be a practical replacement for steppers overall. Electromagnets aren't expensive and can be partially built using printed parts, and neodymium magnets aren't terribly expensive either. And there have been a variety of suggestions for DIY servo encoders that could be adapted to a linear setup. But with so little information about this I have no idea if this would really be practical or not, which is why I've come here. You guys are always looking for ways to improve printers and so far it seems that this concept has gone unnoticed. Do any of you see any potential in this?

tl;dr: linear electric motors: [en.wikipedia.org]

Recently, I've been thinking a lot about how it might be possible to make 3d printers faster, and about just how fast a printer could possibly print. My goal is to figure out how a printer could print at a brisk 1000mm/s+. Normally, the speed a printer can print at is limited by the maximum acceleration of the printer, because while you might be able to get a normal printer to print faster by lowering acceleration it will spend more time getting up to that speed. And the way I see it, the maximum acceleration of a printer is limited by 2 factors: motor strength and structural rigidity. If the frame of a printer isn't rigid enough for a given acceleration, you get inaccurate or low quality prints. If the motor isn't strong enough to accelerate the moving mass of the printer, it skips steps and your printer produces a pile of plastic spaghetti. It's possible to make the frame more rigid, but this increases the mass the motor has to move. However, increasing the strength of the motor generally doesn't increase the moving mass of the printer. So theoretically, the maximum acceleration of a printer is limited mainly by the motor if you are willing to make the frame stronger as necessary.

However in reality the situation is slightly more complicated. The rotor of whatever motor is used adds to the moving mass of the motor. This means that even if you were to use ridiculously oversized and overpowered stepper motors, the maximum acceleration would still be close to the unburdened acceleration of the steppers. With a reasonable maximum acceleration of 500rps^2 for the stepper motor, and a standard GT2 8 tooth pulley, this comes out to about 7000mm/s^2. Given a max stepper RPM of 3000, this gives a maximum speed of 800mm/s. At 800mm/s, it would take the printer about 5 mm to get up to speed. Not terrible, but this is in a ideal scenario that completely ignores the mass of the printer, ignores friction, etc. This is all at the maximum RPM of the stepper, at lower speeds the torque, and therefore maximum acceleration, of the stepper is higher. But obviously, the maximum speed of the printer is lower at lower stepper speeds. It might be possible to reduce the acceleration required from the stepper by gearing it up or using a larger pulley, but this would reduce the (already fairly low) resolution of the stepper.

Overall, steppers are fairly limiting. They're simple, but just aren't able to handle higher speeds. Servos are nice in that they can usually accelerate much faster than a comparably sized stepper, and have higher torque as well. They are also much more precise than steppers, allowing for the use of larger pulleys, which in turn reduce the acceleration required from the motor. However, servos are expensive, ESPECIALLY powerful servo motors. And because servos aren't mechanically precise like steppers(I.e. its either in the correct position or its skipped steps and failed entirely), they might not be precise enough for a printer near their torque limit; the controlling electronics would fail to move it to exactly where it needs to go. Because of all this, a heavier printer designed to be rigid enough to handle 1000m/s and comparatively high acceleration would require servos (and electronics and powersource) that could easily cost more than a thousand dollars, each. Figuring out how much exactly would require designing a printer and calculating the moving mass, which is somewhat pointless when the motors it would require are without a doubt prohibitively expensive. So really, servos aren't the greatest option for these kinds of speeds, even if they are functionally ideal.

halfway tl;dr: I more or less reiterated what everyone here probably agrees are the factors that limit a printer's maximum speed, and why the current options for increasing a printer's maximum speed are impractical.

SO, on to the new stuff. Having established above that we primarily need a better drive system to make faster printers, I thought about how that might be done. We need something that doesn't add as much mass to the moving parts of the printer, and is sufficiently strong and precise enough. I had the idea of forgoing motors and belts entirely, and instead using electromagnets on the sides of the printer to attract magnets attached to the arms of the printer, which would let you put practically any sized electromagnets on the side of the printer and run as much current as you want through them, without increasing the moving mass of the printer. This would unfortunately require a closed loop system to function, like a servo. Keep in mind that i'm focusing on delta style printers, which can usually reach higher speeds anyway.

I've been mulling over this idea for a while, until I saw something on TV about maglev trains. At one point, they showed old footage of a scientist demonstrating a electric motor that not only levitates a metal object above it, but propels it as well. This made me realize that something like my idea probably already exists. About 5 seconds of googling later, and I found out that I essentially came up with a linear electric motor. This shouldn't be confused with (slow) linear actuators, which are essentially a stepper motor with a built in threaded rod.

After looking through the data sheets for a few industrial linear motors, I found that they seem to have moderate strength, not much better than a stepper, but have very little moving mass, more than enough precision, and very high maximum speeds, around 20 meters a second or more! As usual with any sort of industrial equipment, I wasn't able to find anything resembling a price even after searching 12 different sites, so I have no idea how much they would cost, but it's probably a lot given that those are precision made industrial grade motors. And generally, they place the electromagnets on the slider instead of the rail, meaning that the rail has to be lined with magnets and the slider has to have wires running to it. As far as I could find, no one is selling anything resembling a 'consumer' version of a linear motor, and DIY versions are almost nonexistent.

So while this looks promising I can find almost nothing about it. Theoretically, it might not be too hard to make or too expensive, it might even prove to be a practical replacement for steppers overall. Electromagnets aren't expensive and can be partially built using printed parts, and neodymium magnets aren't terribly expensive either. And there have been a variety of suggestions for DIY servo encoders that could be adapted to a linear setup. But with so little information about this I have no idea if this would really be practical or not, which is why I've come here. You guys are always looking for ways to improve printers and so far it seems that this concept has gone unnoticed. Do any of you see any potential in this?

|

Re: Linear electric motors, and high speed printing in general May 26, 2015 06:48AM |

Registered: 10 years ago Posts: 14,672 |

I experimented with linear motors and maglev many years ago, when they were popularised by Eric Laithwaite. You could make the slider very light by using a linear induction motor, then the slider is just a sheet of aluminium. No magnets needed. You would need coils all the way along the frame. It's cheaper and generally more efficient to put the coils on the slider, then you have a much shorter length of coils working against a long strip of aluminium on the frame; but the slider then carries the mass of the coils and associated iron or ferrite core.

You would also need a linear encoder to track the position of the slider - the sort of thing used in digital calipers.

Be aware that for standard FDM printer technology, the limiting factor isn't how fast you can move or accelerate the head, it's how fast you can extrude plastic and have it solidify where you want it. I can move the head of my delta printer at 500mm/sec, but I can't print at that speed.

Edited 1 time(s). Last edit at 05/26/2015 06:49AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

You would also need a linear encoder to track the position of the slider - the sort of thing used in digital calipers.

Be aware that for standard FDM printer technology, the limiting factor isn't how fast you can move or accelerate the head, it's how fast you can extrude plastic and have it solidify where you want it. I can move the head of my delta printer at 500mm/sec, but I can't print at that speed.

Edited 1 time(s). Last edit at 05/26/2015 06:49AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Linear electric motors, and high speed printing in general May 26, 2015 11:39AM |

Registered: 11 years ago Posts: 335 |

Linear motors are not well suited to DIY or to delta printers for several reasons.

Linear motors require pneumatics in vertical applications since they provide no resistance to motion when unpowered and fighting gravity is an enormous waste of power.

DIY is not an option. Getting accurate positioning from a motor is difficult - you need to use a lot of tricks to avoid cogging (ironless motors are not well suited to this application). Linear motors also create extremely strong attractive forces since you have a stack of magnets next to a block of iron. A linear motor suitable for 3d printer use would likely create >50lb of attractive force. This makes assembly dangerous and requires expensive linear bearings to manage.

Even if you get the thing built, you still need to figure out the encoder/drive.

There are actually plenty of ways to get sufficient acceleration for 3d printing without resorting to linear motors. Servos, hybrid servos and closed-loop steppers should all be sufficient and much more cost effective.

I am actually building a 3d printer with linear servos, but it will probably take another 3-6 months to finish.

I have a sneaking suspicion that accelerating a hotend at 5G will either snap the heatbreak or shear the bowden tube.

Linear motors require pneumatics in vertical applications since they provide no resistance to motion when unpowered and fighting gravity is an enormous waste of power.

DIY is not an option. Getting accurate positioning from a motor is difficult - you need to use a lot of tricks to avoid cogging (ironless motors are not well suited to this application). Linear motors also create extremely strong attractive forces since you have a stack of magnets next to a block of iron. A linear motor suitable for 3d printer use would likely create >50lb of attractive force. This makes assembly dangerous and requires expensive linear bearings to manage.

Even if you get the thing built, you still need to figure out the encoder/drive.

There are actually plenty of ways to get sufficient acceleration for 3d printing without resorting to linear motors. Servos, hybrid servos and closed-loop steppers should all be sufficient and much more cost effective.

I am actually building a 3d printer with linear servos, but it will probably take another 3-6 months to finish.

I have a sneaking suspicion that accelerating a hotend at 5G will either snap the heatbreak or shear the bowden tube.

|

Re: Linear electric motors, and high speed printing in general May 26, 2015 12:38PM |

Registered: 10 years ago Posts: 14,672 |

Quote

691175002

Linear motors are not well suited to DIY or to delta printers for several reasons.

Let's see...

Quote

691175002

Linear motors require pneumatics in vertical applications since they provide no resistance to motion when unpowered and fighting gravity is an enormous waste of power.

In a delta printer, you could use solenoid-activated brakes instead of pneumatics - but it adds to the complexity. Countering gravity would certainly use some power, but so do stepper motors when stationary. You can reduce the stepper motor current when the motor is stationary, but only by so much if it is countering gravity.

Quote

691175002

DIY is not an option. Getting accurate positioning from a motor is difficult - you need to use a lot of tricks to avoid cogging (ironless motors are not well suited to this application).

Linear induction motors do not suffer from cogging.

Quote

691175002

Linear motors also create extremely strong attractive forces since you have a stack of magnets next to a block of iron. A linear motor suitable for 3d printer use would likely create >50lb of attractive force. This makes assembly dangerous and requires expensive linear bearings to manage.

Linear induction motors do not have attractive forces between the moving and non-moving parts.

Quote

691175002

Even if you get the thing built, you still need to figure out the encoder/drive.

Yes, that would require quite a lot of work up front. Perhaps the same sort of encoder used in digital calipers, feeding a small microcontroller, which in turn generates a variable frequency and/or variable current drive feeding a 2-phase linear induction motor via a dual H-bridge chip. The encoder/feedback part has been done before to drive DC motors instead of stepper motors in a DIY 3D printer. I think the poster said he used less than $10 of electronic parts to drive 3 motors. In this application, a higher power H-bridge would probably be needed, because a linear induction motor would be less efficient than the geared DC motor he was using.

Quote

691175002

There are actually plenty of ways to get sufficient acceleration for 3d printing without resorting to linear motors. Servos, hybrid servos and closed-loop steppers should all be sufficient and much more cost effective.

I think that is probably true.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Linear electric motors, and high speed printing in general May 26, 2015 02:38PM |

Registered: 11 years ago Posts: 335 |

The high accelerations of a servo are only viable because their average power draw is so low (allowing high peak currents). If you are constantly at 50%+ duty cycle to fight gravity your maximum acceleration will be very poor, especially if you want to go up. This isn't as much of a problem for regular servos since the rotor inertia is pre-reduction.

Do you have examples of linear induction motors being used in this kind of application? I was under the impression they are not viable for positioning. I haven't even seen a linear induction motor sold in a linear stage or coupled with a high resolution encoder. In high stiffness positioning applications you generally see only iron core motors.

The control problems for linear motors are much more difficult to overcome because your control bandwidth needs to be higher. An electrical degree in a linear motor is a huge distance, so you need dramatically higher encoder resolution and accurate field control. An electrical degree in a servo or stepper motor only corresponds to a tiny distance after screw/belt reduction.

Do you have examples of linear induction motors being used in this kind of application? I was under the impression they are not viable for positioning. I haven't even seen a linear induction motor sold in a linear stage or coupled with a high resolution encoder. In high stiffness positioning applications you generally see only iron core motors.

The control problems for linear motors are much more difficult to overcome because your control bandwidth needs to be higher. An electrical degree in a linear motor is a huge distance, so you need dramatically higher encoder resolution and accurate field control. An electrical degree in a servo or stepper motor only corresponds to a tiny distance after screw/belt reduction.

|

Re: Linear electric motors, and high speed printing in general May 26, 2015 03:43PM |

Registered: 9 years ago Posts: 978 |

|

Re: Linear electric motors, and high speed printing in general May 26, 2015 04:35PM |

Registered: 11 years ago Posts: 335 |

Quote

frankvdh

AliExpress is your friend when it comes to supplies and prices... 12V linear motors start about $21 for 200mm/1000N.

There's no reason you couldn't have a hybrid... a stepper for the vertical axis (which doesn't move much or fast), and linears for X,Y.

A motor glued to a screw is a linear actuator, not a linear motor. Aliexpress does not have any true linear motors for sale.

I am using a hybrid (ballscrew Z) for my build but obviously with a delta that is not possible.

|

Re: Linear electric motors, and high speed printing in general May 26, 2015 05:14PM |

Admin Registered: 16 years ago Posts: 13,884 |

... here I've posted some images of an old type-wheel printer, where the head is positioned by a linear motor:

[forums.reprap.org]

Go to the first post of the thread, where I've sketched a basic principle of a DIY-able linear motor and through the discussion ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

[forums.reprap.org]

Go to the first post of the thread, where I've sketched a basic principle of a DIY-able linear motor and through the discussion ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Linear electric motors, and high speed printing in general May 26, 2015 05:59PM |

Registered: 9 years ago Posts: 977 |

Indeed, 3 to 6 months... and what will you be using to drive your PLA filament, a Greg's Wade's geared extruder?Quote

691175002

...

I am actually building a 3d printer with linear servos, but it will probably take another 3-6 months to finish.

...

LOL!

Sorry, but as far as I can see, every successful RepRap 3D printer design has required a good dose of humility on the part of its creator(s). And adherence to the KISS principle. And reasonable, actually modest performance/size/build cost/quality expectations.

Whereas there are tons of overengineered "mega" (in one way or another) 3D printer designs that never even reach completion, and the very few that actually manage to print their first test 10mm cube do not get past the single one-of-a-kind prototype stage.

Edit: the thread Viktor refers to above dates back to 2008, any person with a grain of critical thinking would conclude there would be good reasons why not a single working RepRap 3D printer using linear motors has been built in the last 7 years.

Edited 1 time(s). Last edit at 05/26/2015 06:08PM by AndrewBCN.

|

Re: Linear electric motors, and high speed printing in general May 26, 2015 06:37PM |

Registered: 11 years ago Posts: 335 |

Quote

AndrewBCN

Indeed, 3 to 6 months... and what will you be using to drive your PLA filament, a Greg's Wade's geared extruder?

LOL!

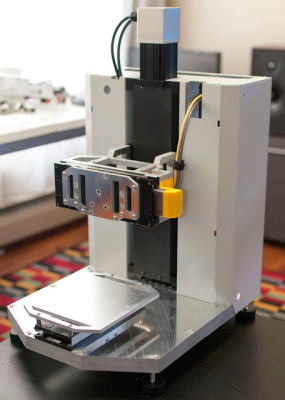

Linear servos are actually great for 3d printing if you ignore their astronomical cost and complexity.

I'll admit its a pretty silly idea. I found the linear stages on ebay and the auction was so cheap I couldn't help myself. After they arrived I had to come up with a project to justify their purchase. Extruder will be an E3D Chimera.

It should actually be a pretty straightforward build since the linear stages are complete and self contained. I pretty much just need to bolt them together at right angles.

|

Re: Linear electric motors, and high speed printing in general May 26, 2015 07:16PM |

Registered: 9 years ago Posts: 977 |

Check the thread Elements of 3D printer design in this forum (just a few threads down). There is much more to designing a 3D printer than simply solving the problem of linear/polar 3D motion.

Also there are may ways to get linear motion in a machine, stepper motors + belts or stepper motors + threaded screws have been traditionally used in RepRap 3D printers because they are inexpensive, simple to understand, easy to maintain and do the job.

Using linear motors is another possible solution of course, but the way I see it, it's much like a "Rube Goldberg machine" solution.

Also there are may ways to get linear motion in a machine, stepper motors + belts or stepper motors + threaded screws have been traditionally used in RepRap 3D printers because they are inexpensive, simple to understand, easy to maintain and do the job.

Using linear motors is another possible solution of course, but the way I see it, it's much like a "Rube Goldberg machine" solution.

|

Re: Linear electric motors, and high speed printing in general May 26, 2015 07:29PM |

Registered: 11 years ago Posts: 5,780 |

Quote

691175002

Linear servos are actually great for 3d printing if you ignore their astronomical cost and complexity.

I'll admit its a pretty silly idea. I found the linear stages on ebay and the auction was so cheap I couldn't help myself. After they arrived I had to come up with a project to justify their purchase. Extruder will be an E3D Chimera.

It should actually be a pretty straightforward build since the linear stages are complete and self contained. I pretty much just need to bolt them together at right angles.

Anything worth doing is worth overdoing!

I'm pretty sure the positioning accuracy/precision of those stages exceeds the positioning accuracy/precision of the molten plastic after it leaves the extruder nozzle, so you'll have insight into the absolute limitations of FDM printing resolution. If I had a couple of those stages I'd probably use them to make a printer, too.

Nothing exceeds like excess!

|

Re: Linear electric motors, and high speed printing in general May 26, 2015 08:17PM |

Registered: 8 years ago Posts: 3 |

Wow, this gathered a lot of attention!

After searching for a little while, I have found some articles about controlling them, but otherwise I haven't been able to find any actual examples of linear induction motors being used for positioning.

Yes, but if you can print at higher speeds you can at the very least increase print quality, assuming you don't run into resonance issues or other mechanical problems that would reduce print quality. Faster printing speed would let you print a object with smaller layers without increasing print times, or it would let you use a smaller nozzle to achieve finer details without increasing print times.

Wow, that looks really good! I hope it works well.

It might not be viable, yes, but its always a good idea to at least explore new concepts, even if they don't seem immediately viable. Linear motors might turn out to be almost useless, cheap/diy versions might have any variety of issues that would render them worthless for use in a 3d printer, but they also might not.

I mean, look at the Morgan. It won the Gada Prize by experimenting with a completely new motion system and design that could have proved to be impractical or useless.

Quote

691175002

Do you have examples of linear induction motors being used in this kind of application? I was under the impression they are not viable for positioning. I haven't even seen a linear induction motor sold in a linear stage or coupled with a high resolution encoder. In high stiffness positioning applications you generally see only iron core motors.

After searching for a little while, I have found some articles about controlling them, but otherwise I haven't been able to find any actual examples of linear induction motors being used for positioning.

Quote

dc42

Be aware that for standard FDM printer technology, the limiting factor isn't how fast you can move or accelerate the head, it's how fast you can extrude plastic and have it solidify where you want it. I can move the head of my delta printer at 500mm/sec, but I can't print at that speed.

Yes, but if you can print at higher speeds you can at the very least increase print quality, assuming you don't run into resonance issues or other mechanical problems that would reduce print quality. Faster printing speed would let you print a object with smaller layers without increasing print times, or it would let you use a smaller nozzle to achieve finer details without increasing print times.

Quote

691175002

(words, linear motor printer)

Wow, that looks really good! I hope it works well.

Quote

AndrewBCN

Check the thread Elements of 3D printer design in this forum (just a few threads down). There is much more to designing a 3D printer than simply solving the problem of linear/polar 3D motion.

Also there are may ways to get linear motion in a machine, stepper motors + belts or stepper motors + threaded screws have been traditionally used in RepRap 3D printers because they are inexpensive, simple to understand, easy to maintain and do the job.

Using linear motors is another possible solution of course, but the way I see it, it's much like a "Rube Goldberg machine" solution.

It might not be viable, yes, but its always a good idea to at least explore new concepts, even if they don't seem immediately viable. Linear motors might turn out to be almost useless, cheap/diy versions might have any variety of issues that would render them worthless for use in a 3d printer, but they also might not.

I mean, look at the Morgan. It won the Gada Prize by experimenting with a completely new motion system and design that could have proved to be impractical or useless.

|

Re: Linear electric motors, and high speed printing in general May 26, 2015 09:18PM |

Registered: 9 years ago Posts: 977 |

The Morgan is an exceedingly simple and elegant design, which I personally feel fully deserved the Gada Prize that it won.

There are two more designs which have proved to be real workhorses which I admire for their simplicity: the Kossel Mini (which is an evolution of the Rostock).

And the Prusa i3. Actually, in terms of mechanical complexity, the Prusa i3 is probably the most complex of the three, but I feel it compensates for this little extra complexity with ease of build, ease of calibration and general availability of building materials.

None of them were designed with unobtainium parts and none of them was designed for mega anything performance. A little research into the history of their development reveals that all three creators of these designs shared a similar way of thinking when solving the problems of their respective designs: minimalism, adherence to sound and proven solutions, and as I wrote before, modest performance/size/build cost/quality expectations, as well as basically adhering to the KISS principle.

There are two more designs which have proved to be real workhorses which I admire for their simplicity: the Kossel Mini (which is an evolution of the Rostock).

And the Prusa i3. Actually, in terms of mechanical complexity, the Prusa i3 is probably the most complex of the three, but I feel it compensates for this little extra complexity with ease of build, ease of calibration and general availability of building materials.

None of them were designed with unobtainium parts and none of them was designed for mega anything performance. A little research into the history of their development reveals that all three creators of these designs shared a similar way of thinking when solving the problems of their respective designs: minimalism, adherence to sound and proven solutions, and as I wrote before, modest performance/size/build cost/quality expectations, as well as basically adhering to the KISS principle.

|

Re: Linear electric motors, and high speed printing in general May 27, 2015 03:10PM |

Admin Registered: 16 years ago Posts: 13,884 |

... over the last 8 years I've thrown many alternative ideas 'into the bowl' - some only to test their value, others to spread some ideas/concepts around special problems or solutions before the big companies grab and block them with IP's

The Tripod/Delta concept seems to be actually the most interesting one, but other basic concepts weren't too bad either -- they only didn't collect the needed interest to start an own meme in time ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The Tripod/Delta concept seems to be actually the most interesting one, but other basic concepts weren't too bad either -- they only didn't collect the needed interest to start an own meme in time ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Linear electric motors, and high speed printing in general June 15, 2015 07:58PM |

Registered: 9 years ago Posts: 26 |

If you balance the weight of the 3d printer head with some counter ballast, then the motors on a delta printer would not need to create force to hold up the weights. The only force they have to create is to accelerate and de-accelerate the mass.

Sadly the amount of it mass need to move doubles in this case. But because no power is wasted in lifiting weight, all power can do to move mass.

Sadly the amount of it mass need to move doubles in this case. But because no power is wasted in lifiting weight, all power can do to move mass.

|

Re: Linear electric motors, and high speed printing in general June 16, 2015 10:07AM |

Registered: 11 years ago Posts: 335 |

Quote

wingmaster

If you balance the weight of the 3d printer head with some counter ballast, then the motors on a delta printer would not need to create force to hold up the weights. The only force they have to create is to accelerate and de-accelerate the mass.

Sadly the amount of it mass need to move doubles in this case. But because no power is wasted in lifiting weight, all power can do to move mass.

Counterweights allow the use of smaller motors but generally don't increase speed because of the additional intertia.

If you are going to play that game might as well use a constant force spring.

|

Re: Linear electric motors, and high speed printing in general December 07, 2017 02:44AM |

Registered: 6 years ago Posts: 8 |

So, did you ever build this?

Edited 1 time(s). Last edit at 12/07/2017 02:44AM by janbbeck.

Quote

691175002

Linear motors are not well suited to DIY or to delta printers for several reasons.

Linear motors require pneumatics in vertical applications since they provide no resistance to motion when unpowered and fighting gravity is an enormous waste of power.

DIY is not an option. Getting accurate positioning from a motor is difficult - you need to use a lot of tricks to avoid cogging (ironless motors are not well suited to this application). Linear motors also create extremely strong attractive forces since you have a stack of magnets next to a block of iron. A linear motor suitable for 3d printer use would likely create >50lb of attractive force. This makes assembly dangerous and requires expensive linear bearings to manage.

Even if you get the thing built, you still need to figure out the encoder/drive.

There are actually plenty of ways to get sufficient acceleration for 3d printing without resorting to linear motors. Servos, hybrid servos and closed-loop steppers should all be sufficient and much more cost effective.

I am actually building a 3d printer with linear servos, but it will probably take another 3-6 months to finish.

I have a sneaking suspicion that accelerating a hotend at 5G will either snap the heatbreak or shear the bowden tube.

Edited 1 time(s). Last edit at 12/07/2017 02:44AM by janbbeck.

|

Re: Linear electric motors, and high speed printing in general December 07, 2017 10:31AM |

Registered: 11 years ago Posts: 335 |

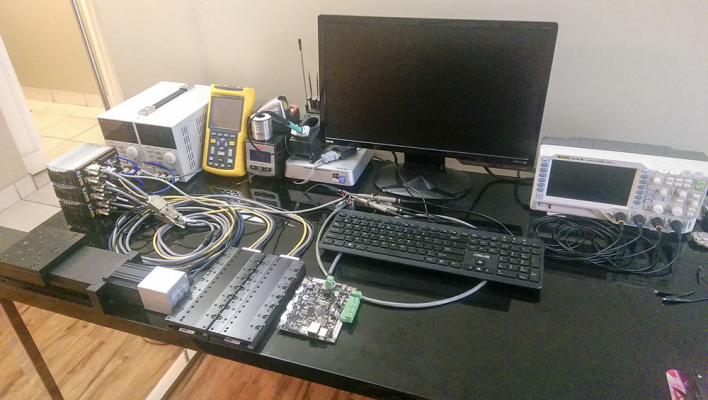

I've been making slow progress.

The current problem is that the Aliexpress extruders were producing waves in their output. Probably a bad batch of steppers or bad hobb geometry.

I decided to redesign the whole assembly with E3D titans because they have more resolution and are lighter as well. It will also need very good layer cooling, which is kind of a PITA to route to a Chimera since both blocks are so close together and there are wires everywhere.

Its an annoying task that I've been kicking down the road because it needs a mix of purchased, machined, and printed parts.

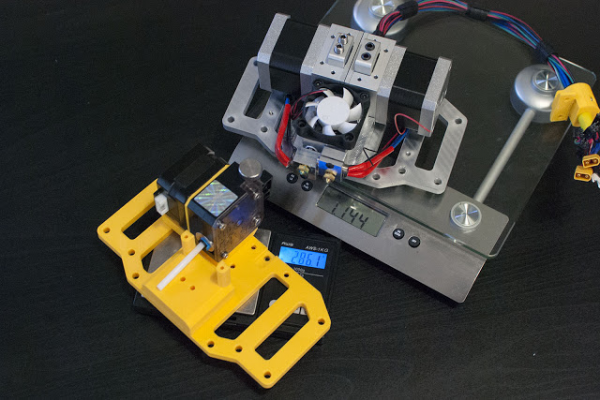

The motion is performing as expected even though the extruder used for this test weighs >1Kg.

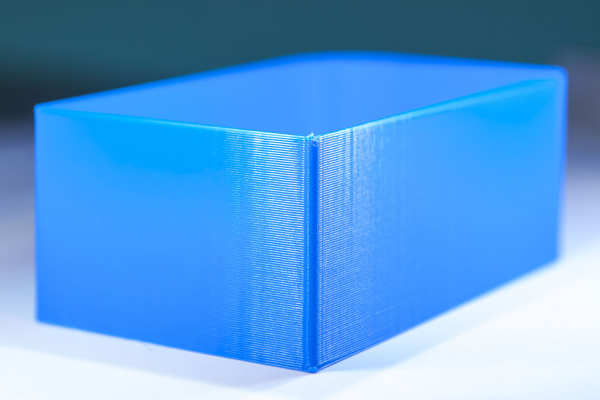

I am seeing evidence that the servo gains could use some tuning but there is no point spending a lot of time there until the extruder is finalized. The sample print is PLA at 0.2mm, 60mm/s 10,000mm/s2 with no cooling fan.

I haven't been able to test anything useful because without a layer fan the plastic just flops around if you try to print quickly.

The current problem is that the Aliexpress extruders were producing waves in their output. Probably a bad batch of steppers or bad hobb geometry.

I decided to redesign the whole assembly with E3D titans because they have more resolution and are lighter as well. It will also need very good layer cooling, which is kind of a PITA to route to a Chimera since both blocks are so close together and there are wires everywhere.

Its an annoying task that I've been kicking down the road because it needs a mix of purchased, machined, and printed parts.

The motion is performing as expected even though the extruder used for this test weighs >1Kg.

I am seeing evidence that the servo gains could use some tuning but there is no point spending a lot of time there until the extruder is finalized. The sample print is PLA at 0.2mm, 60mm/s 10,000mm/s2 with no cooling fan.

I haven't been able to test anything useful because without a layer fan the plastic just flops around if you try to print quickly.

|

Re: Linear electric motors, and high speed printing in general December 07, 2017 05:32PM |

Registered: 6 years ago Posts: 8 |

That is beautiful work!

I am working on a similar system:

[sites.google.com]

How did you do your sheet metal?

On cooling, have you looked into the Berd-Air? The guys on the Zesty Nimble group say very good things about it.

Thanks for the update!

I am working on a similar system:

[sites.google.com]

How did you do your sheet metal?

On cooling, have you looked into the Berd-Air? The guys on the Zesty Nimble group say very good things about it.

Thanks for the update!

|

Re: Linear electric motors, and high speed printing in general December 08, 2017 02:56AM |

Admin Registered: 16 years ago Posts: 13,884 |

... FYI - here's an old thread about linear drives and some related ideas: [forums.reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Linear electric motors, and high speed printing in general December 08, 2017 03:33AM |

Registered: 8 years ago Posts: 5,232 |

About the ironless inductive motor:

wouldn't it create a lot of heat in the aluminum? What about expansion then?

What about a pneumatic system? The slider would glide on an air cussion and the movement is controlled the way steering assist work in cars. A simple dual way valve controlled by a small servo.

wouldn't it create a lot of heat in the aluminum? What about expansion then?

What about a pneumatic system? The slider would glide on an air cussion and the movement is controlled the way steering assist work in cars. A simple dual way valve controlled by a small servo.

|

Re: Linear electric motors, and high speed printing in general December 08, 2017 08:58AM |

Registered: 10 years ago Posts: 150 |

IMHO, linear motors are fascinating, but would be interesting for 3D printing only if they could radically simplify mechanical architecture, or electronics, which is not the case.

Their qualities do not, by themselves, anything determinant, compared to a belt transmission.

My Zatsit delta printer has very low moving masses, and can reach accelerations up to 5G and a speed of more than 600 mm / s in XY, but it is impossible to actually print at these speeds: what limits the speed it is the ability to melt the filament with a sufficient volumetric rate, to control its viscous behavior, and especially to cool it quickly enough once it is deposited.

Linear motors do not change anything about this fundamental criterion ...

Edited 1 time(s). Last edit at 12/08/2017 09:06AM by M_Xeno.

Their qualities do not, by themselves, anything determinant, compared to a belt transmission.

My Zatsit delta printer has very low moving masses, and can reach accelerations up to 5G and a speed of more than 600 mm / s in XY, but it is impossible to actually print at these speeds: what limits the speed it is the ability to melt the filament with a sufficient volumetric rate, to control its viscous behavior, and especially to cool it quickly enough once it is deposited.

Linear motors do not change anything about this fundamental criterion ...

Edited 1 time(s). Last edit at 12/08/2017 09:06AM by M_Xeno.

|

Re: Linear electric motors, and high speed printing in general December 08, 2017 11:16AM |

Registered: 11 years ago Posts: 335 |

Quote

janbbeck

That is beautiful work!

I am working on a similar system:

[sites.google.com]

How did you do your sheet metal?

On cooling, have you looked into the Berd-Air? The guys on the Zesty Nimble group say very good things about it.

Nice project, the Granite Devices drives are a neat touch. I'm using VIX-IH drives, but those things must be twenty years old and there is no way to monitor the position/error of the servos for tuning which will probably be an issue.

I designed the entire printer in solidworks and had local shops do all the fabrication. I've done all my previous personal projects myself, but I wanted to try this instead to see how the quality/cost/convenience compares. Overall it was a very good experience and I learned a lot.

I'll look into using a pump and tubing to bring air, but unfortunately I don't have a good place to mount the pump.

Quote

M_Xeno

IMHO, linear motors are fascinating, but would be interesting for 3D printing only if they could radically simplify mechanical architecture, or electronics, which is not the case.

I don't think anyone can pretend linear motors make sense in a 3d printer, but they are certainly fun. My primary goal was actually dimensional accuracy, with speed being more of a side bonus. My frame weighs 80lb and every alignment is roughly +-0.001" against a granite square.

A lot of hobby printers have problems printing square which is inconvenient for some functional prints (gears in particular).

|

Re: Linear electric motors, and high speed printing in general December 08, 2017 05:20PM |

Registered: 6 years ago Posts: 8 |

Quote

691175002

Quote

janbbeck

That is beautiful work!

I am working on a similar system:

[sites.google.com]

How did you do your sheet metal?

On cooling, have you looked into the Berd-Air? The guys on the Zesty Nimble group say very good things about it.

Nice project, the Granite Devices drives are a neat touch. I'm using VIX-IH drives, but those things must be twenty years old and there is no way to monitor the position/error of the servos for tuning which will probably be an issue.

I designed the entire printer in solidworks and had local shops do all the fabrication. I've done all my previous personal projects myself, but I wanted to try this instead to see how the quality/cost/convenience compares. Overall it was a very good experience and I learned a lot.

I'll look into using a pump and tubing to bring air, but unfortunately I don't have a good place to mount the pump.

Quote

M_Xeno

IMHO, linear motors are fascinating, but would be interesting for 3D printing only if they could radically simplify mechanical architecture, or electronics, which is not the case.

I don't think anyone can pretend linear motors make sense in a 3d printer, but they are certainly fun. My primary goal was actually dimensional accuracy, with speed being more of a side bonus. My frame weighs 80lb and every alignment is roughly +-0.001" against a granite square.

A lot of hobby printers have problems printing square which is inconvenient for some functional prints (gears in particular).

Thank you for the info!

I take some issue with that statement of linear motors not making sense for a 3D printer. With increasing speeds and acceleration the mechanical stiffness of the printer structure matters more and more. This is also true of the stiffness of the drive system (usually belts) and the 'electrical stiffness' of the drive motors (usually steppers). If one takes 1 Kg mass and ac/decelerates at 1G, then F=ma dictates that that results in 10N of force - equivalent to about 1Kg of weight. Hold any printer still (motors powered on), and manually push at the effector with that force, and check with a dial indicator you will see some deflection. That deflection is due to the static stiffness of the printer, and gives the best accuracy you will be able to hold in the ideal case. Dynamic stiffness is an different issue entirely and in reality one will see worse results.

You did exactly the right thing in beefing up the structure the way you did.

All those acceleration and speed settings in the open loop stepper printers have very little meaning, because you never know if you actually reach them and with what accuracy you reach your positioning goals. That does not mean that you can't get pretty prints, but unless you then put them on a coordinate measuring machine you will never know how well they match the model. That does not matter if you print Yoda, but it can matter in some other cases.

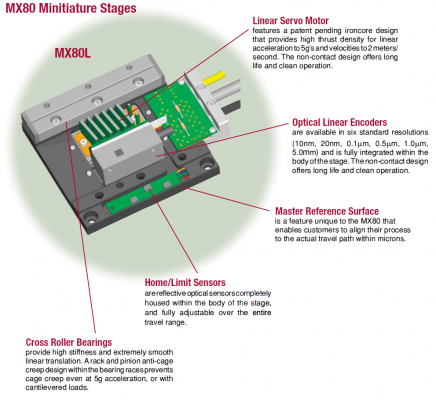

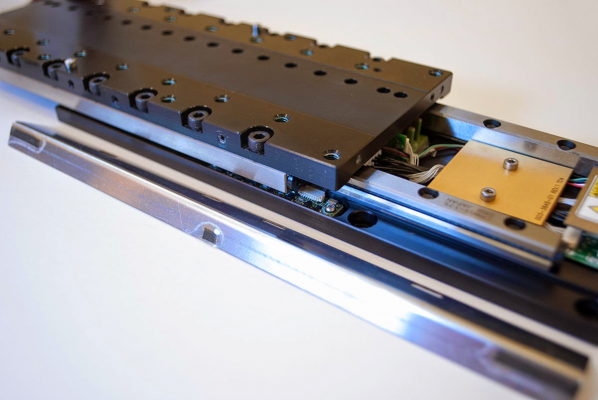

The MX80L units we both use are made to be very stiff in all those aspects and servo controlled on top of that for extreme accuracy and repeatability. And even with all that you can see how hard it is to hold the position in the servo loop at high speeds and acceleration. They measure position at the business end with a linear encoder instead of on a motor shaft (or not at all like steppers); and I checked those numbers with a laser interferometer. They do tell accurate positions.

There is a tradeoff between accuracy and speed/acceleration on 3D printers and you can improve on that with increased stiffness. I understand that maybe we are looking at this from different points of view, because I like to build CNC machines and accuracy for me may mean a different thing than it does for others.

Edited 1 time(s). Last edit at 12/08/2017 05:26PM by janbbeck.

|

Re: Linear electric motors, and high speed printing in general December 08, 2017 06:01PM |

Registered: 11 years ago Posts: 335 |

I also come from a CNC background so I agree with you completely. Sometimes I joke that I've spent more on metrology than machine tools.

Unfortunately the FDM process is probably too slow and sloppy to make use of the performance linear servos can achieve. I hope that I can print somewhat faster than average while also producing surface finishes that are slightly better than average, but I'm not expecting linear servos to ever be a cost effective or practical alternative to existing designs.

Unfortunately the FDM process is probably too slow and sloppy to make use of the performance linear servos can achieve. I hope that I can print somewhat faster than average while also producing surface finishes that are slightly better than average, but I'm not expecting linear servos to ever be a cost effective or practical alternative to existing designs.

|

Re: Linear electric motors, and high speed printing in general December 08, 2017 06:09PM |

Registered: 6 years ago Posts: 8 |

Quote

691175002

I also come from a CNC background so I agree with you completely. Sometimes I joke that I've spent more on metrology than machine tools.

Unfortunately the FDM process is probably too slow and sloppy to make use of the performance linear servos can achieve. I hope that I can print somewhat faster than average while also producing surface finishes that are slightly better than average, but I'm not expecting linear servos to ever be a cost effective or practical alternative to existing designs.

Could not agree more with everything you said there.

I would like to see more pictures of the making of your printer, if you have them.

|

Re: Linear electric motors, and high speed printing in general December 08, 2017 06:11PM |

Registered: 6 years ago Posts: 8 |

Oh, and since you like metrology as well, maybe you need a laser interferometer. This could be useful

[sites.google.com]

[sites.google.com]

|

Re: Linear electric motors, and high speed printing in general December 12, 2017 12:56PM |

Registered: 11 years ago Posts: 335 |

I've been working on a blog but the updates have been quite sporadic. Eventually I'll review all the posts and turn it into a proper build log.

[www.everythingbends.com]

I browsed your site and actually found the printed bellows to be very interesting, as in my experience custom bellows tend to be expensive and hard to source. Lasers are fun but I hope to never find myself in a situation where an interferometer is necessary.

[www.everythingbends.com]

I browsed your site and actually found the printed bellows to be very interesting, as in my experience custom bellows tend to be expensive and hard to source. Lasers are fun but I hope to never find myself in a situation where an interferometer is necessary.

|

Re: Linear electric motors, and high speed printing in general December 12, 2017 06:14PM |

Registered: 6 years ago Posts: 8 |

Quote

691175002

I've been working on a blog but the updates have been quite sporadic. Eventually I'll review all the posts and turn it into a proper build log.

[www.everythingbends.com]

I browsed your site and actually found the printed bellows to be very interesting, as in my experience custom bellows tend to be expensive and hard to source. Lasers are fun but I hope to never find myself in a situation where an interferometer is necessary.

The bellows work ok, and of course I did that because of the cost and source reasons you mention. But recently I found a source for bellows on aliexpress that turned out to be a far better option. Check out the picture I am attaching. 3 meters of bellows for my LRX45 rails. Total cost $100. I'm sure the flex filament alone would cost me more than that...

Also -> wow. There is a lot of really great information on your site. I am going to steal ideas shamelessly!

One thing I don't think is right at all, though, is this piece of information:

"I was quite surprised to learn that the stepper motors were the cause of this artifact since normally stepper motors perform quite linearly when micro-stepping."

They don't do that at all. Even with ideal sinusoidal driving - which you don't get - they suffer from issues.

I plan to servo drive my extruder.

Can't wait for the next update to your site....

Sorry, only registered users may post in this forum.