Aluminum Sheet Between Heater and Glass

Posted by Shachar85

|

Re: Aluminum Sheet Between Heater and Glass January 29, 2016 07:09PM |

Registered: 8 years ago Posts: 26 |

I am still waiting for a delta printer I ordered so I have been reading up on problems, possibilities, and upgrades that I'm likely to encounter. I'm not in a rush and intend on pushing my kit to its limits but can't imagine I won't eventually want to maximize my build volume and minimize printing issues. I have found your arguments for a cast Al bed compelling . The listed prices and choices seem resonable for such a critical part. Since you have experience working with cast plate beds I was wondering if cutting the plate into a hexagon or circle using a band saw would disrupt the grain or expansion characteristics of the plate. I'd appreciate any observations you may have. Thanks.

Quote

the_digital_dentist

Places like Speedy Metals and any of a dozen other on-line metals dealers will cut any size you want. My 12.5 x 12 x 1/4" plate ran about $40. Try:

[www.onlinemetals.com]

[alcobrametals.com]

[www.speedymetals.com]

Speedy Metals has a 12" x 18" x 1/4" plate for $57. If you don't want to cut it, they'll cut it to the exact size you need for a few $ more.

Search google for "cast aluminum tooling plate", "cast jig plate", etc.

Alcoa's MIC-6 spec says flatness is within 0.015" on 1/4" plate, but that's over a 36.5" x 96.5" sheet. Smaller pieces are much flatter.

Here are videos that demonstrate the level/flatness of my printer's bed along with sag/misalignment in linear guides and supporting structures, etc.:

unheated flatness test

heated bed flatness test

note: the gauge is reading in 1/100th of a mm (10 um in the rightmost digit). The heated (105C) bed flatness test may be off a bit- the longer the probe stays in contact with the heated bed plate, the more negative the readings become. I don't entirely trust the readings toward the end and think the bed is flatter than it reads. I should rerun the test going in the opposite direction to check it. Regardless of what the gauge reads, the bed is flat enough to print almost edge to edge.

I would love to see similar measurements done on the typical thin aluminum/glass/4 point leveling scheme bed.

'

|

Re: Aluminum Sheet Between Heater and Glass January 29, 2016 08:40PM |

Registered: 11 years ago Posts: 5,780 |

It shouldn't be a problem- that's what it is for. The reason the stuff is used for jigs is that the randomly oriented grain structure makes it very easy to machine, as well as having very predictable and uniform thermal expansion.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Aluminum Sheet Between Heater and Glass February 01, 2016 04:05AM |

Registered: 8 years ago Posts: 601 |

Quote

dc42

Quote

MechaBits

I'm sold on the cast alu plate, but it is tricky here in the UK, ebay are skewing results for sure, maybe they dont want us to have the manufacturing good stuff here in the UK, for fear of what we'll make with it.

See EcoCast here: [www.aluminiumwarehouse.co.uk].

Ahhh great link!! Searched for something like this for ages the other day! I'm now turned to using one of these, seems like a great idea. I was originally going to use a mk2b heater and glass set up, Will this be fine for heating up the alu plate?

also, what thickness will I want? a 10mm thick plate is only around £10-15, but will a nema 17 and belt be fine with that amount of weight?

|

Re: Aluminum Sheet Between Heater and Glass February 01, 2016 04:45AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Origamib

Quote

dc42

Quote

MechaBits

I'm sold on the cast alu plate, but it is tricky here in the UK, ebay are skewing results for sure, maybe they dont want us to have the manufacturing good stuff here in the UK, for fear of what we'll make with it.

See EcoCast here: [www.aluminiumwarehouse.co.uk].

Ahhh great link!! Searched for something like this for ages the other day! I'm now turned to using one of these, seems like a great idea. I was originally going to use a mk2b heater and glass set up, Will this be fine for heating up the alu plate?

also, what thickness will I want? a 10mm thick plate is only around £10-15, but will a nema 17 and belt be fine with that amount of weight?

PCB bed heaters are frequently underpowered, and with a thick aluminium bed you will need more heating power to heat it to operating temperature in a reasonable amount of time. I suggest a silicone heater, a little smaller than the bed plate so that you have room for fixings around the edge. These people [www.aliexpress.com] will make a bed heater to your own size, voltage and power specifications, with or without thermistor (but a separate thermistor in contact with the aluminium will be more accurate). Choose either 24V or AC mains voltage, depending on the size of the bed.

I can't advise you on thickness without knowing how large your bed will be, and it isn't really my area of expertise anyway.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Aluminum Sheet Between Heater and Glass February 01, 2016 07:27AM |

Registered: 8 years ago Posts: 601 |

Thanks for the reply  Currently looking at a 200x200mm bed (Standard mk2b heater size), mainly because its cheap! I managed to pick up a good quality one for about £4. I wasn't really that fussed to have a heated bed at the start, I figured it would be my upgrade later on once everything else was fine-tuned. But of course, reprap has given me ideas....

Currently looking at a 200x200mm bed (Standard mk2b heater size), mainly because its cheap! I managed to pick up a good quality one for about £4. I wasn't really that fussed to have a heated bed at the start, I figured it would be my upgrade later on once everything else was fine-tuned. But of course, reprap has given me ideas....

I only worry for the thickness as I don't want it to warp, and on the other hand I don't want a bed too heavy to be moved! I may have to experiment later on with this, perhaps converting to a leadscrew on that axis.

P.S. - sorry to OP for going off-topic!

Currently looking at a 200x200mm bed (Standard mk2b heater size), mainly because its cheap! I managed to pick up a good quality one for about £4. I wasn't really that fussed to have a heated bed at the start, I figured it would be my upgrade later on once everything else was fine-tuned. But of course, reprap has given me ideas....

Currently looking at a 200x200mm bed (Standard mk2b heater size), mainly because its cheap! I managed to pick up a good quality one for about £4. I wasn't really that fussed to have a heated bed at the start, I figured it would be my upgrade later on once everything else was fine-tuned. But of course, reprap has given me ideas....I only worry for the thickness as I don't want it to warp, and on the other hand I don't want a bed too heavy to be moved! I may have to experiment later on with this, perhaps converting to a leadscrew on that axis.

P.S. - sorry to OP for going off-topic!

|

Re: Aluminum Sheet Between Heater and Glass February 01, 2016 07:50AM |

Registered: 10 years ago Posts: 14,672 |

IMO for a bed that small, you might as well use 4mm glass, a thin sheet of aluminium as a heat spreader, and a PCB bed heater. I expect digital dentist would disagree. I also think a mk2b heater will be woefully underpowered for a thick aluminium bed.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Aluminum Sheet Between Heater and Glass February 01, 2016 10:11AM |

Registered: 11 years ago Posts: 5,780 |

For that size bed 6mm should be adequate. I use 1/4" (6.35mm) plate for my 305 x 317 mm bed and I can print edge to edge. 6mm plate won't weigh much more than thin aluminum plus glass, so the mass unlikely to be a problem. If you start getting layer shifting in the Y axis, reduce acceleration and jerk a little.

I don't know the power rating of that heater, but mine delivers about 1/2 Watt per cm^2 and the bed gets up to 105C in about 5 minutes, without any insulation on the underside of the bed. Similar power density should do the same for you.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I don't know the power rating of that heater, but mine delivers about 1/2 Watt per cm^2 and the bed gets up to 105C in about 5 minutes, without any insulation on the underside of the bed. Similar power density should do the same for you.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Aluminum Sheet Between Heater and Glass March 21, 2016 05:02PM |

Registered: 11 years ago Posts: 1,277 |

When I used just glass and a MK2B I could get to 136c then I added the thin heat sink (heat spreader) and I couldn't make it past 105c at 24v. I had to go to 28V and increase the range in Marlin from 255 to 511 to make it to 110c.Quote

dc42

IMO for a bed that small, you might as well use 4mm glass, a thin sheet of aluminium as a heat spreader, and a PCB bed heater. I expect digital dentist would disagree. I also think a mk2b heater will be woefully underpowered for a thick aluminium bed.

All of the above is with the board being 3.6ohm for 2+3 so 160W and the MK3 is basically what I already have minus air gaps but from what I have read to get it to 110c I would need to run 18-24v on the 12v side and at 1.4 ohms that is ~411 watts so I would need one heck of a power supply. I almost bought the MK3 since my MK2B shorted onto the heat spreader and took out my ramps board and everything down the line (I replaced it all and as soon as the heat spreader is clamped down dead short). So, on a standard 220x220 I3 style configuration I think tool plate is overkill but on a larger printer? Get the tool plate.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Aluminum Sheet Between Heater and Glass April 23, 2016 11:46AM |

Registered: 11 years ago Posts: 5,780 |

Quote

toxuin

Anyone knows a decent place to obtain a 14.5 x 14.5 inches tooling plate in Canada?.. Those mentioned above stores quote me from $180 to $350 for that! That's... not even close to $40 mentioned by digital_dentist.

And does precise thickness really matter in case I wish to use 0.8 mm nozzle? Will a plain 1/4" piece of sheet aluminum do?.. I can get it in my town for ~$30.

I just bought another 12" square piece of cast tooling plate from Speedy metals for $40. It's labeled Alca 5 which I looked up and found is made in Canada.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Aluminum Sheet Between Heater and Glass April 23, 2016 12:19PM |

Registered: 8 years ago Posts: 260 |

Dark A. if you did the measurements with the integrated sensor in the heater, then what you are seeing is pretty normal.

Adding a head spreader will increase the heat transfer to the glass and that means that the heater can't get to the old temperature.

So the question is: did you measure the glass temperature, because that is way more important then the temperature measured in side your heater ( you are not printing on the heater ).

I am really measuring the glass temperature from above, and that looks nothing like the temperature that sensor in the heater is telling.

The advantage of aluminum bed is very clear, it is a lot easier to get a good temperature of your build surface. And I think you need less energy

for it then to get the top of a glass plate at a correct temperature. Why because glass is a insulator that means that you will loose more energy at the bottom

Because there the air is moving and moving air is not a good insulator.

look at this, this show why glass is a lot more difficult. it is not glass but it is a very good thermal isolator.

[www.youtube.com]

But still I have chosen glass because the printed object sticks like hell when the bed is warm, and loosens of the bed when it gets below 25c.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

Adding a head spreader will increase the heat transfer to the glass and that means that the heater can't get to the old temperature.

So the question is: did you measure the glass temperature, because that is way more important then the temperature measured in side your heater ( you are not printing on the heater ).

I am really measuring the glass temperature from above, and that looks nothing like the temperature that sensor in the heater is telling.

The advantage of aluminum bed is very clear, it is a lot easier to get a good temperature of your build surface. And I think you need less energy

for it then to get the top of a glass plate at a correct temperature. Why because glass is a insulator that means that you will loose more energy at the bottom

Because there the air is moving and moving air is not a good insulator.

look at this, this show why glass is a lot more difficult. it is not glass but it is a very good thermal isolator.

[www.youtube.com]

But still I have chosen glass because the printed object sticks like hell when the bed is warm, and loosens of the bed when it gets below 25c.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: Aluminum Sheet Between Heater and Glass April 23, 2016 01:21PM |

Registered: 11 years ago Posts: 1,277 |

Tell you what I had some of these shops quote me a price as they are one off shops and screw them at 250-300 dollars to have 5 countersunk holes done. No, I can't do that here but going from regular aluminium to Mic6 was a 200 dollar increase in one shop, which is outrageous.Quote

the_digital_dentist

Quote

toxuin

Anyone knows a decent place to obtain a 14.5 x 14.5 inches tooling plate in Canada?.. Those mentioned above stores quote me from $180 to $350 for that! That's... not even close to $40 mentioned by digital_dentist.

And does precise thickness really matter in case I wish to use 0.8 mm nozzle? Will a plain 1/4" piece of sheet aluminum do?.. I can get it in my town for ~$30.

I just bought another 12" square piece of cast tooling plate from Speedy metals for $40. It's labeled Alca 5 which I looked up and found is made in Canada.

If I knew 100% that the issues I am having with this printer was the bed I might do it but when I see 250-300 dollars and I see something like $499 plus 130 shipping ($629 in total) for a 3-5 day delivery from China on a Qidi (Flashforge Creator Pro clone) I can't justify the expense. So, SEARS is closing down 10 more stores and 65, or it was 69, Kmart stores and if they close the one down here I will hope I can get a Drill Press from them as Sears is the better of the crappy Chinese sub 500 dollar drill presses. I need a DP for a few things so then I can get [www.midweststeelsupply.com] for about $14.41 + $11.22 shipping and hope it slips through the cracks and UPS doesn't bend it too as they have bent (or USPS or FedEx) every thing I have purchased since I moved here.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Aluminum Sheet Between Heater and Glass April 23, 2016 09:22PM |

Registered: 9 years ago Posts: 245 |

Seriously, right now I have a 4mm alubed (nothing fancy) and I have drilled the holes and countersunk them myself with normal electrical handdrill.. I then have 4mm boroplat on top with PrintBite on one side and PEI on the other... I do not belive it would matter if I used MIC6 or not. I have a 500w AC heater under it.

Do you Guys print directly on the Alubed, or?

Edit: forgot to ask the question my post was all about

Edited 2 time(s). Last edit at 04/23/2016 09:24PM by dintid.

My Instructables - both total newbie instructables and some for intermediate users.

My Designs on Thingiverse

YouTube channel containing a few 3D printing videos - they are videos for my Instructables, and mostly not standalone.

Ultius / Tantillus Thingiverse Group

Do you Guys print directly on the Alubed, or?

Edit: forgot to ask the question my post was all about

Edited 2 time(s). Last edit at 04/23/2016 09:24PM by dintid.

My Instructables - both total newbie instructables and some for intermediate users.

My Designs on Thingiverse

YouTube channel containing a few 3D printing videos - they are videos for my Instructables, and mostly not standalone.

Ultius / Tantillus Thingiverse Group

|

Re: Aluminum Sheet Between Heater and Glass April 23, 2016 09:29PM |

Registered: 11 years ago Posts: 1,277 |

Trust me I know my limitations and I can't cut straight nor can I drill straight so I see that Sears has lowered the price on their 12in Drill Press by ~53 dollars and with tax I will get it for about 193 dollars. From everything I have seen on that model it is a nice DP with little runout. I wish I could find out more but as we all know a DP is really made for wood but this one goes from 300rpm to almost 3100rpm. Most of the stuff I drill is under half inch (so about 12mm) and I suspect this would handle it. To counter sink a 3.5mm hole what do I buy?Quote

dintid

Seriously, right now I have a 4mm alubed (nothing fancy) and I have drilled the holes and countersunk them myself with normal electrical handdrill.. I then have 4mm boroplat on top with PrintBite on one side and PEI on the other... I do not belive it would matter if I used MIC6 or not. I have a 500w AC heater under it.

Do you Guys print directly on the Alubed, or?

Edit: forgot to ask the question my post was all about

edit: I love glass and will never use anything else though I am going to buy 4mm (3/16) Boro as the 3mm I have was a bit too thin. I have read that the 1/4in Boro actually retains heat better but I have no idea.

Edited 1 time(s). Last edit at 04/23/2016 09:31PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Aluminum Sheet Between Heater and Glass April 23, 2016 09:46PM |

Registered: 11 years ago Posts: 5,780 |

This is what a countersink bit looks like:

[www.amazon.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

[www.amazon.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Aluminum Sheet Between Heater and Glass April 23, 2016 09:51PM |

Registered: 11 years ago Posts: 1,277 |

I know what it looks like but I have seen different sizes and for a 3.5mm hole which size of countersink do I get? Just anything? I do know I need the metric one since metric uses 90 degree and we use 82 degrees.

Edited 2 time(s). Last edit at 04/23/2016 09:53PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Aluminum Sheet Between Heater and Glass April 23, 2016 10:07PM |

Registered: 11 years ago Posts: 5,780 |

The size doesn't matter as along as it is big enough. You just drill into the metal until the diameter is large enough for your screw head. You can do it with a hand drill.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Aluminum Sheet Between Heater and Glass April 23, 2016 10:11PM |

Registered: 11 years ago Posts: 1,277 |

Alright, good to know as my screws are all countersunk 3mm so I need a 90 degree countersink which leaves me having to find a metric. Too bad they don't make this to fit my Dremel as I can do it with it with two stead hands but with a regular hand drill I suck at it and I have never gotten better do it either. Using a hack saw I cannot cut a strait line, or any hand saw, no matter how hard I try. I can cut straight with scissors though, lol.Quote

the_digital_dentist

The size doesn't matter as along as it is big enough. You just drill into the metal until the diameter is large enough for your screw head. You can do it with a hand drill.

edit: I went looking and look what I found - [www.mytoolstore.com.au] Now to see if I can't find that in the USA.

Edited 3 time(s). Last edit at 04/23/2016 10:39PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Aluminum Sheet Between Heater and Glass April 24, 2016 05:36AM |

Registered: 9 years ago Posts: 245 |

I'm Danish and only use metric stuff... and I have done it using regular drills, and it Works. Problem is how the "cone" MIGHT not be smooth-sided and the screw might sit a bit ascew untill you tighten it way Down.. which it should be anyway (even with springs on it..Quote

Dark Alchemist

Alright, good to know as my screws are all countersunk 3mm so I need a 90 degree countersink which leaves me having to find a metric. Too bad they don't make this to fit my Dremel as I can do it with it with two stead hands but with a regular hand drill I suck at it and I have never gotten better do it either. Using a hack saw I cannot cut a strait line, or any hand saw, no matter how hard I try. I can cut straight with scissors though, lol.Quote

the_digital_dentist

The size doesn't matter as along as it is big enough. You just drill into the metal until the diameter is large enough for your screw head. You can do it with a hand drill.

edit: I went looking and look what I found - [www.mytoolstore.com.au] Now to see if I can't find that in the USA.

When using a regular drill to countersink you most often have to make the hole somewhat deeper due to the angle of the drills... not an issue if the plate is >2mm though.

I bought some "countersink drill bits for metal" Here is a just an image I browsed

Edited 1 time(s). Last edit at 04/24/2016 05:37AM by dintid.

My Instructables - both total newbie instructables and some for intermediate users.

My Designs on Thingiverse

YouTube channel containing a few 3D printing videos - they are videos for my Instructables, and mostly not standalone.

Ultius / Tantillus Thingiverse Group

|

Re: Aluminum Sheet Between Heater and Glass April 24, 2016 07:07AM |

Registered: 11 years ago Posts: 5,780 |

You're overthinking this. You don't have to use metric screws, and you don't have to worry about the angle at the tip of the countersink bit even if you do. It isn't even necessary to countersink- it's a nice thing to do that removes the screw heads from the path of the nozzle (and prevents crashing into them), but not necessary for the leveling system to function.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Aluminum Sheet Between Heater and Glass April 24, 2016 06:25PM |

Registered: 9 years ago Posts: 67 |

Quote

Dark Alchemist

Alright, good to know as my screws are all countersunk 3mm so I need a 90 degree countersink which leaves me having to find a metric. Too bad they don't make this to fit my Dremel as I can do it with it with two stead hands but with a regular hand drill I suck at it and I have never gotten better do it either. Using a hack saw I cannot cut a strait line, or any hand saw, no matter how hard I try. I can cut straight with scissors though, lol.Quote

the_digital_dentist

The size doesn't matter as along as it is big enough. You just drill into the metal until the diameter is large enough for your screw head. You can do it with a hand drill.

edit: I went looking and look what I found - [www.mytoolstore.com.au] Now to see if I can't find that in the USA.

Do you have a Harbor Freight nearby?

Countersink search

This one is a 90deg: 90deg countersink

Rick

|

Re: Aluminum Sheet Between Heater and Glass April 24, 2016 07:04PM |

Registered: 11 years ago Posts: 1,277 |

Yep, I found that last night and may just grab that. I can use my hand or a drill.Quote

llamatrails

Quote

Dark Alchemist

Alright, good to know as my screws are all countersunk 3mm so I need a 90 degree countersink which leaves me having to find a metric. Too bad they don't make this to fit my Dremel as I can do it with it with two stead hands but with a regular hand drill I suck at it and I have never gotten better do it either. Using a hack saw I cannot cut a strait line, or any hand saw, no matter how hard I try. I can cut straight with scissors though, lol.Quote

the_digital_dentist

The size doesn't matter as along as it is big enough. You just drill into the metal until the diameter is large enough for your screw head. You can do it with a hand drill.

edit: I went looking and look what I found - [www.mytoolstore.com.au] Now to see if I can't find that in the USA.

Do you have a Harbor Freight nearby?

Countersink search

This one is a 90deg: 90deg countersink

Rick

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Aluminum Sheet Between Heater and Glass April 26, 2016 07:42PM |

Registered: 11 years ago Posts: 1,277 |

I have now purchased a new printer to be here next week so I will treat this printer as a learning experience AND as a clunker to see if I can ever get it working right in my spare time (like people do with old cars in the garage).

I am going to print up a new extruder to hold an e3d v6 style hotend as I tested for another hour two days ago and my findings are weird. What I did was clamp a glass plate to the front of the hotend which made the glass flat and I tested this with the bed hot (took about 10c more to get to the real temp due to the now air gap) and all over was the same distance apart after 20 mins of fiddling. GOOD, this was a perfect scenario to test the last piece I have not changed out.

So, I go to print and the same results as if I had done nothing differently so I gave out a large WTH? I go to change the filament to another brand and this time (nothing has changed from the previous test) instead of it lifting and peeling it acts as if I am printing with sandpaper. Since this is a real J-Head and not a clone I can't change the nozzle so I am left with changing out the entire hotend.

My I3 rework needs a new extruder that can properly hold this v6 clone right so I will use the new printer (a Flashforge Creator Pro clone) to print the extruder and see what gives. If this doesn't work then I have no ideas left. Seriously if a piece of paper has the same drag all over the plate yet I am getting the results I am then it must be a funky nozzle. I don't have a magnifier of say 50-300x that it would take to look at any damage on the nozzle but I do know there is some.

How can I go from lifting off while printing (even with hair spray) to changing the filament and it looked like I was dragging sandpaper over it behind the nozzle unless the nozzle has some issues?

Thanks for all of the help.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

I am going to print up a new extruder to hold an e3d v6 style hotend as I tested for another hour two days ago and my findings are weird. What I did was clamp a glass plate to the front of the hotend which made the glass flat and I tested this with the bed hot (took about 10c more to get to the real temp due to the now air gap) and all over was the same distance apart after 20 mins of fiddling. GOOD, this was a perfect scenario to test the last piece I have not changed out.

So, I go to print and the same results as if I had done nothing differently so I gave out a large WTH? I go to change the filament to another brand and this time (nothing has changed from the previous test) instead of it lifting and peeling it acts as if I am printing with sandpaper. Since this is a real J-Head and not a clone I can't change the nozzle so I am left with changing out the entire hotend.

My I3 rework needs a new extruder that can properly hold this v6 clone right so I will use the new printer (a Flashforge Creator Pro clone) to print the extruder and see what gives. If this doesn't work then I have no ideas left. Seriously if a piece of paper has the same drag all over the plate yet I am getting the results I am then it must be a funky nozzle. I don't have a magnifier of say 50-300x that it would take to look at any damage on the nozzle but I do know there is some.

How can I go from lifting off while printing (even with hair spray) to changing the filament and it looked like I was dragging sandpaper over it behind the nozzle unless the nozzle has some issues?

Thanks for all of the help.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Aluminum Sheet Between Heater and Glass April 27, 2016 12:09PM |

Registered: 11 years ago Posts: 5,780 |

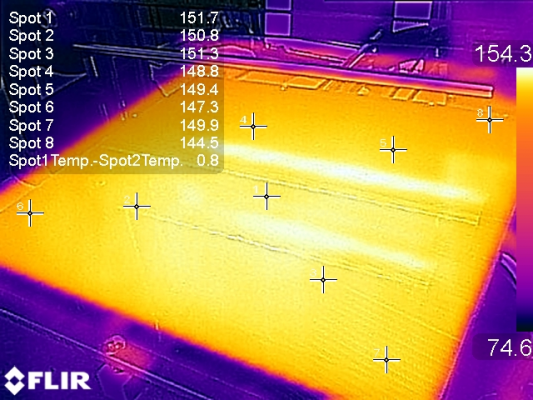

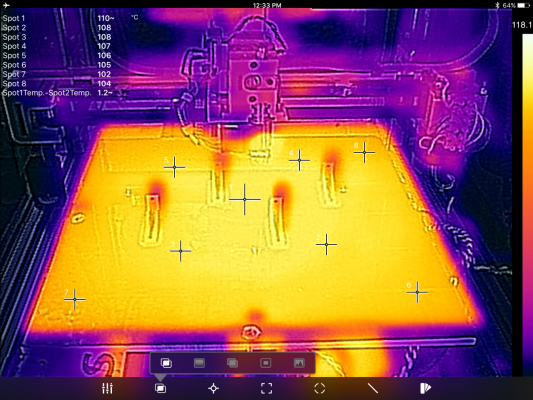

The new cast tooling plate I purchased was used to replace a broken glass bed on a Taz 3 printer at the Milwaukee Makerspace. I was preparing to run a test print last night and ran into the guy with the FLIR camera. We took a picture of the new aluminum bed plate heated to 70C (the camera was set to read out degrees F). This is the sort of even heating you get with a 1/4" cast tooling plate bed:

The two bright horizontal lines are IR reflections of the X axis guide rails, not hot spots. This is just the bed with the original 240W silicone heater glued on using high temperature silicone, and no insulation on the underside. There is a 0.002 in. layer of PET tape in the top surface. No glass.

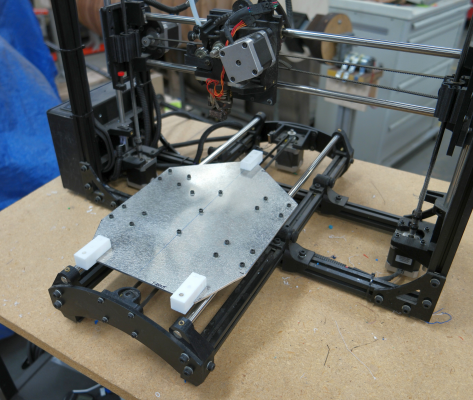

Here's the modified undercarriage mounted on the printer- I was able to cut away about 1/2 of the mass of the undercarriage plate. The three white blocks are teflon supports for the leveling screws.

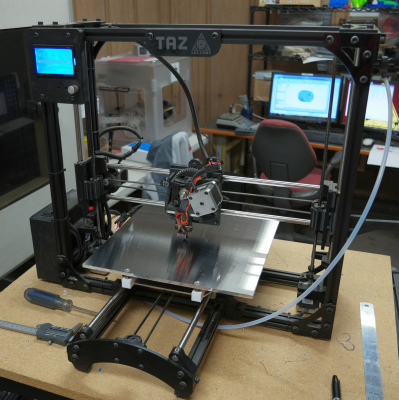

Here's the new bed on the printer before the PET tape was applied:

Son of MegaMax has been at the makerspace for a few weeks and we took a picture of it running an ABS print at 105C. He hasn't sent me the image yet but when he does I'll post it. It looks about the same as the above image- very even heating with some fall-off at the corners and edges, as expected.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The two bright horizontal lines are IR reflections of the X axis guide rails, not hot spots. This is just the bed with the original 240W silicone heater glued on using high temperature silicone, and no insulation on the underside. There is a 0.002 in. layer of PET tape in the top surface. No glass.

Here's the modified undercarriage mounted on the printer- I was able to cut away about 1/2 of the mass of the undercarriage plate. The three white blocks are teflon supports for the leveling screws.

Here's the new bed on the printer before the PET tape was applied:

Son of MegaMax has been at the makerspace for a few weeks and we took a picture of it running an ABS print at 105C. He hasn't sent me the image yet but when he does I'll post it. It looks about the same as the above image- very even heating with some fall-off at the corners and edges, as expected.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Aluminum Sheet Between Heater and Glass April 27, 2016 02:43PM |

Registered: 11 years ago Posts: 5,780 |

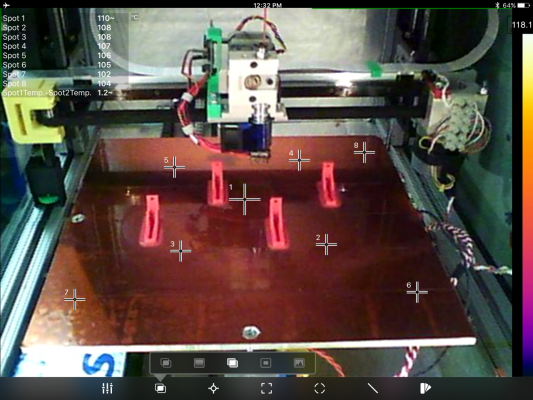

Here's SoM at 105C with a few small prints in progress:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Aluminum Sheet Between Heater and Glass April 27, 2016 03:24PM |

Registered: 11 years ago Posts: 1,277 |

|

Re: Aluminum Sheet Between Heater and Glass June 16, 2016 07:48AM |

Registered: 9 years ago Posts: 125 |

Anyone found any shops in Europe that also ship to mainland Europe (Aluminiumwarehouse only ships in the UK)?

The price looks quite ok from the Aluwarehouse, but its lack of shipping seems to be a showstopper. Should maybe ask them for a quote and see if they're willing to ship overseas.

Edit: I'm more specifically interested in shipping to Estonia.

Edited 2 time(s). Last edit at 06/16/2016 09:42AM by Mikk36.

The price looks quite ok from the Aluwarehouse, but its lack of shipping seems to be a showstopper. Should maybe ask them for a quote and see if they're willing to ship overseas.

Edit: I'm more specifically interested in shipping to Estonia.

Edited 2 time(s). Last edit at 06/16/2016 09:42AM by Mikk36.

|

Re: Aluminum Sheet Between Heater and Glass June 16, 2016 09:25AM |

Registered: 8 years ago Posts: 260 |

I think you need to look in Germany, and the name I found for these plates are

Gussplatten or

Alu Gussplatten feingefräst

[www.aluminium-online-shop.de]

Edited 1 time(s). Last edit at 06/16/2016 09:26AM by amigob.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

Gussplatten or

Alu Gussplatten feingefräst

[www.aluminium-online-shop.de]

Edited 1 time(s). Last edit at 06/16/2016 09:26AM by amigob.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: Aluminum Sheet Between Heater and Glass June 16, 2016 04:23PM |

Registered: 8 years ago Posts: 622 |

So what thickness would you guys recommend for a 400mm x 400mm bed? If it makes any difference, it will have insulation underneath, the heater will be AC mains about 800W, and it will have a removable glass print surface. It'll be lifted by 3 lead screws so weight isn't really an issue but I wouldn't want to wait more than about 5 minutes max for the print surface to heat up to about 60 degC. I can get EcoCast precision machined both faces from 5 to 50 mm from aluminium warehouse that has been linked to earlier in this thread (thanks again DC42).

|

Re: Aluminum Sheet Between Heater and Glass June 16, 2016 04:44PM |

Registered: 11 years ago Posts: 5,780 |

I wouldn't use less than 1/4" (6.35 mm). Maybe 8-10 mm???

My 1/4" bed heats to 105C in about 5 minutes with about 0.46 W/cm^2, about the same power density as you have available. Putting glass on it will slow things down a bit, but since your target is 60C, probably not enough to matter.

Edited 1 time(s). Last edit at 06/16/2016 04:44PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

My 1/4" bed heats to 105C in about 5 minutes with about 0.46 W/cm^2, about the same power density as you have available. Putting glass on it will slow things down a bit, but since your target is 60C, probably not enough to matter.

Edited 1 time(s). Last edit at 06/16/2016 04:44PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Aluminum Sheet Between Heater and Glass June 17, 2016 03:55AM |

Registered: 8 years ago Posts: 622 |

Quote

the_digital_dentist

I wouldn't use less than 1/4" (6.35 mm). Maybe 8-10 mm???

My 1/4" bed heats to 105C in about 5 minutes with about 0.46 W/cm^2, about the same power density as you have available. Putting glass on it will slow things down a bit, but since your target is 60C, probably not enough to matter.

Thanks. Do you have heat insulation under your bed? Any idea what 8mm or 10 would do to the warm up time? If it's say 25% thicker would the warm up time be 25% longer or is that too simple? Price wise, 6 mm would cost me £31.57, 8 mm £36.03, 10 mm £37.96 so there is hardly any difference and on that basis I'd be tempted to go for 10 mm. Just a bit concerned about warm up time though.

Also, I haven't bought the heater yet but I've seen a 400 x 400mm 1.5kW which seems insanely high unless it was a miss print. Assuming it isn't a miss print, should I be tempted? As control is going to be "bang bang" via a SSR, would a heater that powerful lead to overshoot probs? I'm guessing not if the warm up time is in the order of 5 minutes but correct me if I'm wrong.

P.S. 60 deg C on it's own isn't a target. 60 deg C in 5 minutes (or less) is a target but at some point in the future, I may want to use higher temperatures so I'd like to spec things to allow for that possibility.

Thanks in advance.

Sorry, only registered users may post in this forum.