Home

>

Developers

>

Topic

Z axis not working properly

Posted by Shachar85

|

Z axis not working properly February 20, 2016 02:53AM |

Registered: 8 years ago Posts: 63 |

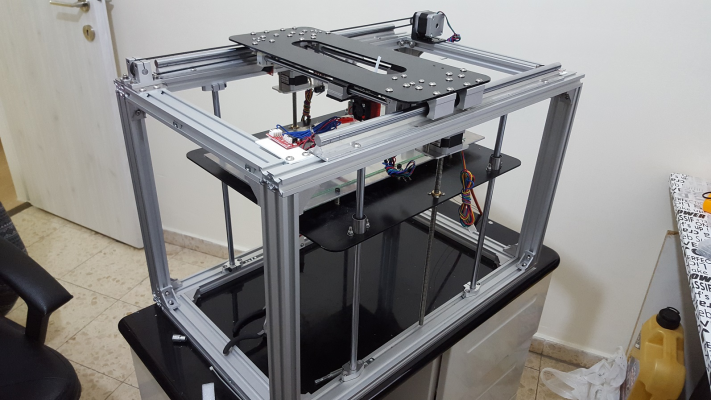

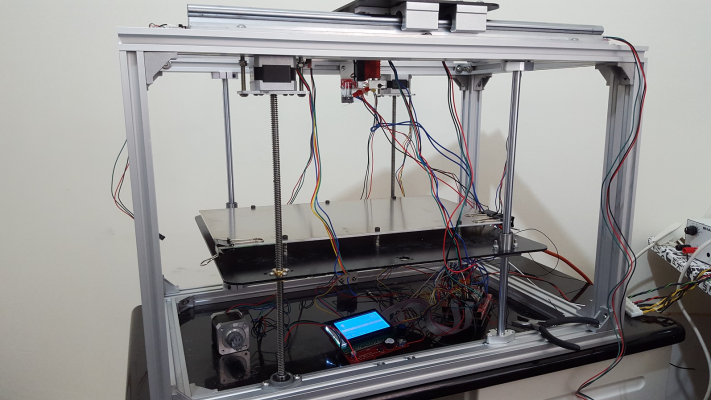

While designing, I had a feeling that I'm doing something wrong with the z axis. I continued anyway and paying the price now.

The original design included 4 linear rods and 2 stepper motor.

As some of you probably guessed - it got stuck. It is not possible for the 4 rods to be completely 100% parallel. That was what I feared and it happened.

As can seen in the other picture, I tried to move the motors to the sides, instead of 2 shafts (diagonal).

Now when Z axis moves, it kind of vibrate - the sides of the rods don't move at the same velocity. Like they are racing and each time one passes the other.

Can't print that way.

So now I'm looking for a solution. I have some ideas that might cost a lot or/and take a lot of time to accomplish.

I was hoping someone knew an easier and faster way to make it work?

Will really appreciate any ideas

The original design included 4 linear rods and 2 stepper motor.

As some of you probably guessed - it got stuck. It is not possible for the 4 rods to be completely 100% parallel. That was what I feared and it happened.

As can seen in the other picture, I tried to move the motors to the sides, instead of 2 shafts (diagonal).

Now when Z axis moves, it kind of vibrate - the sides of the rods don't move at the same velocity. Like they are racing and each time one passes the other.

Can't print that way.

So now I'm looking for a solution. I have some ideas that might cost a lot or/and take a lot of time to accomplish.

I was hoping someone knew an easier and faster way to make it work?

Will really appreciate any ideas

|

Re: Z axis not working properly February 20, 2016 07:23AM |

Registered: 11 years ago Posts: 5,780 |

The reason you have to support the opposite side of the undercarriage plate is because of flex in the guide rails. You can almost completely eliminate that flex by using fully supported guide rails or linear guides. It is very easy to add a mounting plate to the frame of the printer. Your thin undercarriage will also flex because it is just a sheet of whatever it's made of. The bed plate is only supported at hopefully 3 (or less optimal 4) points. Why do you need a big, floppy sheet in the undercarriage? I would make a triangular frame from the t-slot extrusions that will probably be lighter and will definitely be more rigid than that thin sheet.

I would use a standard cantilever configuration (rail - screw- rail) on one side of the bed and then add a second screw on the opposite side. I would definitely drive both screws with a single motor by adding pulleys and a belt.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I would use a standard cantilever configuration (rail - screw- rail) on one side of the bed and then add a second screw on the opposite side. I would definitely drive both screws with a single motor by adding pulleys and a belt.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Z axis not working properly February 20, 2016 07:04PM |

Registered: 9 years ago Posts: 1,873 |

Quote

I would use a standard cantilever configuration (rail - screw- rail) on one side of the bed and then add a second screw on the opposite side.

The nice thing about a cantilevered bed is that you don't have to worry about thermal expansion soaking up all the tolerance in the bearings and locking things up, but you might lose that advantage if you put another screw on the opposite side, depending on how much play was in the screw. On the other hand, a cantilevered system has to be heavily built to keep the flex in spec. I really like the idea of core XY with the bed moving in Z, but I still can't decide on the best way to support the bed.

|

Re: Z axis not working properly February 22, 2016 03:20AM |

Registered: 8 years ago Posts: 63 |

so if I understand correctly - what you suggest is actually removing 2 rods (from the first picture)

making it

OXO

...X

instead of

OXO

OXO

(O=rod, X= screw. don't mind the dots)

and you suggest using supported rails instead of the rods. Is this what you meant?

Well for starter I can check the option of removing 2 rods.

using supported rails instead of rods will require bigger modifications (including waiting time for shipping) and less printing size at Z axis.

I really hope I can avoid that

btw, the undercarriage is indeed heavier than should be. I might change it in the future.

making it

OXO

...X

instead of

OXO

OXO

(O=rod, X= screw. don't mind the dots)

and you suggest using supported rails instead of the rods. Is this what you meant?

Well for starter I can check the option of removing 2 rods.

using supported rails instead of rods will require bigger modifications (including waiting time for shipping) and less printing size at Z axis.

I really hope I can avoid that

btw, the undercarriage is indeed heavier than should be. I might change it in the future.

|

Re: Z axis not working properly February 22, 2016 07:25AM |

Registered: 9 years ago Posts: 1,873 |

I think it would be nice to understand where the problems are in your original layout. In your original post you mentioned

While at some level that's true, I don't see any reason that you can't get the 4 smooth rods sufficiently parallel given the amount of play in the bearings, at least for a given temperature. Then the question hinges around what happens during thermal expansion across the temperature range. Did you try removing the threaded rods, loosening the fittings for three of the four smooth rods and moving the bed to the top before tightening the top fittings, then moving the bed to the bottom and tightening the bottom fittings. This way you use the bed itself to determine the parallel nature of the rods. Getting the rods square to the XY axes is a bit more tricky, but you only need to do it for the first rod. A temporary spacer would work for the close axis, you might need a jig for the other one,or you could wing it and see if there's a visible problem before worrying about it...

Once the four rods are tightened in place with the bed close to each end, the bed should move freely up and down if you support it with your hand in the middle (lead screws still not fitted at this point). If it doesn't you need to figure out why - a bent rod being the only reasonable explanation if the bed is free at the ends but not in the middle of the travel.

Assuming the bed runs freely when supported in the middle, the next test is if it runs freely if you only hold it at one edge. This is where I suspect you may have a problem as you don't have a lot of Z depth on the mountings to resist twisting forces, and with the screws in the middle of the long axis you have the potential for some twisting. If this is the case then you have a couple of options for counteracting it. First is to create a bearing block with about twice the Z height you currently have which can hold two bearings. The block has to transmit and resist twisting forces between the smooth rod and the bed carrier, so it will need a decent size flange or T shape to mount to the carrier. A cantilevered bed is the extreme case of the tall Z and a big flange bearing mount - enough to leave the opposite side unsupported.

The other way to tackle twisting is to move the lead screws out to the corners - you could imagine four lead screws on a belt drive with two linear guides in the middle positions. The linear guides would need to be sufficiently large to overcome the combined lateral forces of the four screws. Three lead screws would probably work well too, two in the corners and one in the middle of the opposing side, perhaps with three linears in the symmetric configuration.

And to come back to one of DD's points, the bed carrier has to be stiff, otherwise all bets are off. A skeleton construction made out of box or U-section or even 90 degree angle extrusion might be a good idea.

Edited 1 time(s). Last edit at 02/22/2016 07:27AM by JamesK.

Quote

it got stuck. It is not possible for the 4 rods to be completely 100% parallel

While at some level that's true, I don't see any reason that you can't get the 4 smooth rods sufficiently parallel given the amount of play in the bearings, at least for a given temperature. Then the question hinges around what happens during thermal expansion across the temperature range. Did you try removing the threaded rods, loosening the fittings for three of the four smooth rods and moving the bed to the top before tightening the top fittings, then moving the bed to the bottom and tightening the bottom fittings. This way you use the bed itself to determine the parallel nature of the rods. Getting the rods square to the XY axes is a bit more tricky, but you only need to do it for the first rod. A temporary spacer would work for the close axis, you might need a jig for the other one,or you could wing it and see if there's a visible problem before worrying about it...

Once the four rods are tightened in place with the bed close to each end, the bed should move freely up and down if you support it with your hand in the middle (lead screws still not fitted at this point). If it doesn't you need to figure out why - a bent rod being the only reasonable explanation if the bed is free at the ends but not in the middle of the travel.

Assuming the bed runs freely when supported in the middle, the next test is if it runs freely if you only hold it at one edge. This is where I suspect you may have a problem as you don't have a lot of Z depth on the mountings to resist twisting forces, and with the screws in the middle of the long axis you have the potential for some twisting. If this is the case then you have a couple of options for counteracting it. First is to create a bearing block with about twice the Z height you currently have which can hold two bearings. The block has to transmit and resist twisting forces between the smooth rod and the bed carrier, so it will need a decent size flange or T shape to mount to the carrier. A cantilevered bed is the extreme case of the tall Z and a big flange bearing mount - enough to leave the opposite side unsupported.

The other way to tackle twisting is to move the lead screws out to the corners - you could imagine four lead screws on a belt drive with two linear guides in the middle positions. The linear guides would need to be sufficiently large to overcome the combined lateral forces of the four screws. Three lead screws would probably work well too, two in the corners and one in the middle of the opposing side, perhaps with three linears in the symmetric configuration.

And to come back to one of DD's points, the bed carrier has to be stiff, otherwise all bets are off. A skeleton construction made out of box or U-section or even 90 degree angle extrusion might be a good idea.

Edited 1 time(s). Last edit at 02/22/2016 07:27AM by JamesK.

|

Re: Z axis not working properly February 22, 2016 07:34AM |

Registered: 11 years ago Posts: 5,780 |

Fully supported rails like those in your Y axis, or linear guides, like these:

or these:

Bolt an aluminum or steel plate to the side of the printer and screw these things down.

Since there are no side loads on the Z axis (at least, there shouldn't be), you might be able to get away with a single, wide linear guide like this:

And yes, the OXO

X is what I meant. It's just a standard cantilevered design but adds a second screw to support the far end of the undercarriage.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

or these:

Bolt an aluminum or steel plate to the side of the printer and screw these things down.

Since there are no side loads on the Z axis (at least, there shouldn't be), you might be able to get away with a single, wide linear guide like this:

And yes, the OXO

X is what I meant. It's just a standard cantilevered design but adds a second screw to support the far end of the undercarriage.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Z axis not working properly February 23, 2016 04:23AM |

Registered: 8 years ago Posts: 63 |

Update:

I tried to loose the rods and tighten again, as James advised. (not for the first time, but I realllyyy tried to be precise this time).

For the upper half of Z axis - it now runs very smooth!

At the middle of the movement downward, the bed construction started vibrating a bit.

At the last quarter it got stuck for a bit (I freed it and it continued fine).

I tightened all screws while the bed was up. I'll try again and tight the lower screws when the bed is down.

I know the rods didn't came 100% straight. The were bent a bit, but I was hoping not too much. Might be the reason.

I'll keep trying.

I'm hoping I can get it to work smoothly even for half the way, so I can print some parts that will help me improve the printer.

I tried to loose the rods and tighten again, as James advised. (not for the first time, but I realllyyy tried to be precise this time).

For the upper half of Z axis - it now runs very smooth!

At the middle of the movement downward, the bed construction started vibrating a bit.

At the last quarter it got stuck for a bit (I freed it and it continued fine).

I tightened all screws while the bed was up. I'll try again and tight the lower screws when the bed is down.

I know the rods didn't came 100% straight. The were bent a bit, but I was hoping not too much. Might be the reason.

I'll keep trying.

I'm hoping I can get it to work smoothly even for half the way, so I can print some parts that will help me improve the printer.

|

Re: Z axis not working properly February 23, 2016 04:28AM |

Registered: 8 years ago Posts: 63 |

|

Re: Z axis not working properly February 23, 2016 08:06AM |

Registered: 11 years ago Posts: 5,780 |

I don't know why my last post got screwed up- there were links. Oh well.

Your problem is keeping the thing flat and level. When it gets out of skew, the mechanism binds and your print fails. How does using two motors to drive 4 screws prevent that? I've seen a lot of reports from people with i3 type printers complaining that the Z axis motors/screws get out of sync. What will/can you do differently to guarantee that the motors/screws all remain synchronized? There is only one way of guaranteeing that multiple screws stay synchronized - use a single motor and belt to dive them. You may have to use a bigger motor and maybe even an external driver module for it. That's life in the world of machine design.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Your problem is keeping the thing flat and level. When it gets out of skew, the mechanism binds and your print fails. How does using two motors to drive 4 screws prevent that? I've seen a lot of reports from people with i3 type printers complaining that the Z axis motors/screws get out of sync. What will/can you do differently to guarantee that the motors/screws all remain synchronized? There is only one way of guaranteeing that multiple screws stay synchronized - use a single motor and belt to dive them. You may have to use a bigger motor and maybe even an external driver module for it. That's life in the world of machine design.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Z axis not working properly February 23, 2016 10:21AM |

Registered: 8 years ago Posts: 63 |

No doubt 2 motors have the disadvantage of chance of getting out of sync, but they have a hell of advantage of twice the power of a single motor.

Now, while I agree with you about 1 motor with a big belt - this motor has to drive 4 screws. That's a lot.

So when you say a big motor - are you saying NEMA23 big? or a big NEMA17 big?

and here's an idea - I don't know if it's a good one....but an idea -

if I use 2 motors on a single belt - will I get twice the force on the belt? or maybe at least 150%?

or maybe it will cause more problems?

Logically, it seems to me like a not-too-bad idea. Did you ever try it?

Now, while I agree with you about 1 motor with a big belt - this motor has to drive 4 screws. That's a lot.

So when you say a big motor - are you saying NEMA23 big? or a big NEMA17 big?

and here's an idea - I don't know if it's a good one....but an idea -

if I use 2 motors on a single belt - will I get twice the force on the belt? or maybe at least 150%?

or maybe it will cause more problems?

Logically, it seems to me like a not-too-bad idea. Did you ever try it?

|

Re: Z axis not working properly February 23, 2016 10:58AM |

Registered: 9 years ago Posts: 1,873 |

The Z axis places relatively low requirements on the motors, even with 8mm lead. Your design looks a lot bigger than mine, but my first instinct would be to try a single nema17 of fairly ordinary spec and see how it goes. A single motor design has sufficient beneifts that I would look at mechanical advantage through larger sized pulleys on the shafts before I considered multiple motors. If you go with four screws you may need extra idler pulleys to increase the contact angle of the belt around the pulley. 180 is ideal, 90 is getting marginal, although possible with sufficient belt tension (and mounts and bearings to cope with the side load). It's easier to get required contact with two screws than four.

|

Re: Z axis not working properly February 23, 2016 02:47PM |

Registered: 11 years ago Posts: 5,780 |

No, I've never tried using two motors on a single belt. Motors do not step perfectly- there is typically a 5% spec on step to step position. What happens when the motors don't step exactly the same, say one is +5% and the other is -5%? Combine that with microstepping and I think that you're asking for a lot of easily avoidable trouble.

How much are you going to save by trying to use two undersized motors instead of one adequately sized motor? I look at your printer and it is obvious you've got a pretty good investment in time and money in it. Why cheap-out now, with the finish line so close?

Required motor torque is calculated based on the load. If you can do your own taxes using Turbotax, you can calculate the torque required on the Oriental Motor web site. Then you shop for the motor that delivers the calculated torque (and maybe the power supply and driver, too, if necessary). You'll have to make some guesses at some of the entries, but if you guess on the conservative side, you'll end up with a torque value that will work. If that value is <100 oz-in, you can use a NEMA-17 motor. If it isn't, you have to go larger, maybe to NEMA-23. You can always buy a used motor on ebay- motors are extremely reliable- it's unlikely you'll ever get stuck with a bad one.

Does your Y axis motion work the way it is supposed to? Driving it from one side may cause racking (the undriven side may lag behind the driven side, and if it is bad enough, it could bind, just like you print bed). You're using fully supported rails, so they will be very rigid, so it may work OK...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

How much are you going to save by trying to use two undersized motors instead of one adequately sized motor? I look at your printer and it is obvious you've got a pretty good investment in time and money in it. Why cheap-out now, with the finish line so close?

Required motor torque is calculated based on the load. If you can do your own taxes using Turbotax, you can calculate the torque required on the Oriental Motor web site. Then you shop for the motor that delivers the calculated torque (and maybe the power supply and driver, too, if necessary). You'll have to make some guesses at some of the entries, but if you guess on the conservative side, you'll end up with a torque value that will work. If that value is <100 oz-in, you can use a NEMA-17 motor. If it isn't, you have to go larger, maybe to NEMA-23. You can always buy a used motor on ebay- motors are extremely reliable- it's unlikely you'll ever get stuck with a bad one.

Does your Y axis motion work the way it is supposed to? Driving it from one side may cause racking (the undriven side may lag behind the driven side, and if it is bad enough, it could bind, just like you print bed). You're using fully supported rails, so they will be very rigid, so it may work OK...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Z axis not working properly February 24, 2016 07:35AM |

Registered: 8 years ago Posts: 63 |

James, thanks for the tips. I have 2 designs in the end of this post. Hope you can have a look.

Mark, be sure there is no cheaping out. I'm pot committed a long time ago. The problem is that any mistake I make will take me another month or two to get the new parts.

Most of the parts are from AliExpress. Otherwise, I would pay 3 times what I paid...and you're right... I paid pretty much. (no complaints. just saying).

Now, the reason I want 4 screws is it feels more rigid and unambiguous. Unlike bearings that do whatever they want, a nut will be where you tell him to be.

Of course the downside is that 4 screws will be much less tolerant than bearings.

My point is that I want the next update to be the last update for Version 1.0. So I'm trying to be on the safe side, which means stronger motor that will even straighten a bit bent screw.

Problem with NEMA23 is that I never used one and it requires a different kind of driver. One I never used - a door to more unknown mistakes.

Of course I'm gonna use the calculator you post here. Seems to be a great tool. I'll be smarter then.

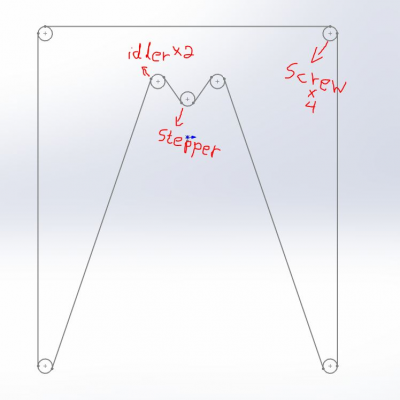

Ok, so for the designs:

Simple. I can stretch the belt moving the motor on the printer's frame.

Cons - I couldn't find a closed loop GT2 belt long enough (about 2000mm). Is there a way to close on open GT2? of course in a away that will not miss a tooth

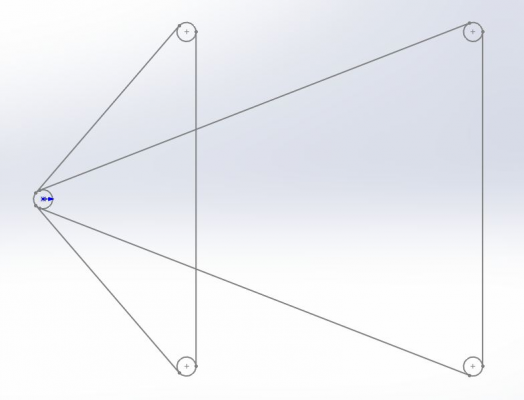

More complicated. I have to use a double pulley, which I don't know if I trust:

Probably will have to use an idler to stretch at least one of the belts, but that's not a problem.

Will it work? Any better ideas?

Mark, be sure there is no cheaping out. I'm pot committed a long time ago. The problem is that any mistake I make will take me another month or two to get the new parts.

Most of the parts are from AliExpress. Otherwise, I would pay 3 times what I paid...and you're right... I paid pretty much. (no complaints. just saying).

Now, the reason I want 4 screws is it feels more rigid and unambiguous. Unlike bearings that do whatever they want, a nut will be where you tell him to be.

Of course the downside is that 4 screws will be much less tolerant than bearings.

My point is that I want the next update to be the last update for Version 1.0. So I'm trying to be on the safe side, which means stronger motor that will even straighten a bit bent screw.

Problem with NEMA23 is that I never used one and it requires a different kind of driver. One I never used - a door to more unknown mistakes.

Of course I'm gonna use the calculator you post here. Seems to be a great tool. I'll be smarter then.

Ok, so for the designs:

Simple. I can stretch the belt moving the motor on the printer's frame.

Cons - I couldn't find a closed loop GT2 belt long enough (about 2000mm). Is there a way to close on open GT2? of course in a away that will not miss a tooth

More complicated. I have to use a double pulley, which I don't know if I trust:

Probably will have to use an idler to stretch at least one of the belts, but that's not a problem.

Will it work? Any better ideas?

|

Re: Z axis not working properly February 24, 2016 07:54AM |

Registered: 9 years ago Posts: 1,873 |

The double pulley/double belt idea is interesting, I hadn't thought of that before, but it feels overly complicated. I probably should mention that the single biggest problem I had with my build was getting the lead screws well enough aligned to run smoothly. It was a beast of a job with two screws, I would hate to have to do it for four. Also, while we need the screws to move the bed, they are also the primary source of error in the bed position. Any lateral force that the lead screws generate has to be resisted by the smooth rods, so from that point of view fewer screws is better. Two screws should be fine if we can make the carrier sufficiently stiff and get the bearings running smoothly. Which reminds me, the (admittedly cheap) bearings I got took some time to bed in, so if they aren't running particularly smoothly yet (even when run on a spare rod without any load) it may improve with time.

I'd recommend that you keep it as simple as possible and only go to more extreme solutions if you're forced to. Two screws, and a single nema 17 will probably do it. You might want to order in some 40 and 60 tooth pulleys for the rods so that you can add 2:1 or 3:1 torque advantage that way if you need it. You don't need a lot of speed or acceleration on the Z axis, and it's far better to have a smoothly moving bed with the minimum drive chain needed than to try and brute force a binding mechanism with lots of power - that way lies backlash and much unhappiness.

James

I'd recommend that you keep it as simple as possible and only go to more extreme solutions if you're forced to. Two screws, and a single nema 17 will probably do it. You might want to order in some 40 and 60 tooth pulleys for the rods so that you can add 2:1 or 3:1 torque advantage that way if you need it. You don't need a lot of speed or acceleration on the Z axis, and it's far better to have a smoothly moving bed with the minimum drive chain needed than to try and brute force a binding mechanism with lots of power - that way lies backlash and much unhappiness.

James

|

Re: Z axis not working properly February 24, 2016 10:46AM |

Registered: 8 years ago Posts: 63 |

Then we're back to square one...

4 shafts (well...or 2) and 2 screws.

I'm not sure that the flexibility of the plate is what causing the vibrations\rotations.

Maybe it has to do with it, but I think the main reason is that gap between the screw and the nut. The same one causing backlash.

While it is very small, when it is in the middle and bearings in both sides, it is enough to free the bearings to move few mm each side.

I'm not 100% sure about it, but if it is indeed correct, then a more rigid structure will not give the best solution.

Maybe I should change my LMH10UU to LMH10LUU for longer support on the shaft

BTW, I checked the motor sizing of Oriental Motor. I had a problem determining the breakaway torque of the screw, but I played with the values a little bit and I think a strong nema17 will do. specially if I play with the ratio with the pulley's tooth number

4 shafts (well...or 2) and 2 screws.

I'm not sure that the flexibility of the plate is what causing the vibrations\rotations.

Maybe it has to do with it, but I think the main reason is that gap between the screw and the nut. The same one causing backlash.

While it is very small, when it is in the middle and bearings in both sides, it is enough to free the bearings to move few mm each side.

I'm not 100% sure about it, but if it is indeed correct, then a more rigid structure will not give the best solution.

Maybe I should change my LMH10UU to LMH10LUU for longer support on the shaft

BTW, I checked the motor sizing of Oriental Motor. I had a problem determining the breakaway torque of the screw, but I played with the values a little bit and I think a strong nema17 will do. specially if I play with the ratio with the pulley's tooth number

|

Re: Z axis not working properly February 24, 2016 10:57AM |

Registered: 11 years ago Posts: 5,780 |

I like the double pulley- I didn't know those were available. The alternative is to just stack two pulleys if your motor's shaft is long enough. The only problem I see with the second arrangement is that the belt loop to the left doesn't engage much of the drive pulley- I'd add an idler or two to get more wrap around that pulley. I read somewhere that the minimum engagement should be 6 teeth or 90 degrees, which ever is greater. If you can move the motor to the center of the frame you can use two shorter, equal length belts, and the forces produced by the belt tension will almost cancel at the motor.

I'm not sure I like the idea of 4 screws- it seems over constrained and likely to cause problems.

Using NEMA-23 motors is no different than using NEMA-17 motors. They vibrate a little more, but in the Z axis you'll never hear it except when jogging. I used NEMA-23 motors with an Arduino/RAMPS combo for almost two years without any problems. I probably didn't get the full torque out of the motors, but it worked OK. Right now my Z axis uses a NEMA-23 motor driven directly by the driver on the smoothieboard. Using external drivers is very easy- you just bring the step, direction, and enable lines (and gnd or +5V) to the external driver board. The nice thing about external drivers is you have a lot of options- you can go cheap and just get a chopper driver ( a beefier version of the A4988 used in the tiny modules on the RAMPS board) for $15 or you can get a little fancier and get a DSP driver for $35. They all have big heatsinks so you're unlikely to cook them. Current is set using jumpers so it is easy and accurate- no guessing and no tiny pots to break. The other big advantage to external drivers is the ability to use higher voltage power supplies. A high voltage supply (8-10X motor rated voltage) will really take control of the motor and deliver all the torque it's capable of producing. Motor power supplies consist of a transformer, rectifier, and filter cap- no regulation is needed.

Edited 1 time(s). Last edit at 02/24/2016 10:58AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I'm not sure I like the idea of 4 screws- it seems over constrained and likely to cause problems.

Using NEMA-23 motors is no different than using NEMA-17 motors. They vibrate a little more, but in the Z axis you'll never hear it except when jogging. I used NEMA-23 motors with an Arduino/RAMPS combo for almost two years without any problems. I probably didn't get the full torque out of the motors, but it worked OK. Right now my Z axis uses a NEMA-23 motor driven directly by the driver on the smoothieboard. Using external drivers is very easy- you just bring the step, direction, and enable lines (and gnd or +5V) to the external driver board. The nice thing about external drivers is you have a lot of options- you can go cheap and just get a chopper driver ( a beefier version of the A4988 used in the tiny modules on the RAMPS board) for $15 or you can get a little fancier and get a DSP driver for $35. They all have big heatsinks so you're unlikely to cook them. Current is set using jumpers so it is easy and accurate- no guessing and no tiny pots to break. The other big advantage to external drivers is the ability to use higher voltage power supplies. A high voltage supply (8-10X motor rated voltage) will really take control of the motor and deliver all the torque it's capable of producing. Motor power supplies consist of a transformer, rectifier, and filter cap- no regulation is needed.

Edited 1 time(s). Last edit at 02/24/2016 10:58AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Z axis not working properly February 24, 2016 11:02AM |

Registered: 9 years ago Posts: 1,873 |

Interesting. Generally you don't need to worry about backlash with the bed - as long as the bearings run smoothly gravity will always hold the bed down against the screws. Hence my suggestion to focus on getting the carrier to run smoothly with the lead screws removed as a first step. You want to get to the point where you can lift the bed up and down the full travel with one finger under any edge of the carrier before you start worrying about getting the lead screws attached.

The fairly generous lateral play in the nuts is intentional - you need that to have any chance of getting the things to run well and to reduce the amount of lateral force transmitted to the carrier. Yes, I would expect long bearings, or doubled up bearings in a rigid carrier would be a good idea. I used LMH8LUU flanged bearings with a normal lm8uu on top with both in an aluminum block for the Z axis of my Prusa-like build to try and ensure resistance to twisting forces.

The fairly generous lateral play in the nuts is intentional - you need that to have any chance of getting the things to run well and to reduce the amount of lateral force transmitted to the carrier. Yes, I would expect long bearings, or doubled up bearings in a rigid carrier would be a good idea. I used LMH8LUU flanged bearings with a normal lm8uu on top with both in an aluminum block for the Z axis of my Prusa-like build to try and ensure resistance to twisting forces.

|

Re: Z axis not working properly February 24, 2016 11:04AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Z axis not working properly February 24, 2016 07:07PM |

Registered: 10 years ago Posts: 550 |

isn't that 5% for microstepping? Using a geared nema17 maybe an option?Quote

the_digital_dentist

Motors do not step perfectly- there is typically a 5% spec on step to step position. What happens when the motors don't step exactly the same, say one is +5% and the other is -5%? Combine that with microstepping and I think that you're asking for a lot of easily avoidable trouble.

|

Re: Z axis not working properly February 24, 2016 08:42PM |

Registered: 11 years ago Posts: 5,780 |

Nope. The basic spec on the full step accuracy is usually 5%. That's why going to >16:1 microstepping doesn't result in increased resolution (it will reduce noise and vibration, but you won't get finer positioning precision). A geared motor will increase torque but reduce speed. If you can live with the reduced speed (usually OK on the Z axis), it should be OK, but a geared NEMA-17 motor often costs more than a NEMA-23 motor depending on the torque/size of the motor. The Z axis in my printer has a 20 tooth pulley on the motor and 42 tooth pulleys on the two Z axis screws.

Here's a NEMA-23 motor that provides about 2.5X more torque than you can get in an ungeared NEMA-17 motor for $27 shipped. It even has an antivibration mount: [www.ebay.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Here's a NEMA-23 motor that provides about 2.5X more torque than you can get in an ungeared NEMA-17 motor for $27 shipped. It even has an antivibration mount: [www.ebay.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Z axis not working properly February 25, 2016 02:46AM |

Registered: 8 years ago Posts: 63 |

ok then 4 screw idea is off.

Like I said before - as least risks as possible.

This evening I'll try the idea of 2 shafts instead of 4 ans see how it goes.

I'll also give another shot in getting everything as parallel as possible.

From the results, I'll decide about going to a more rigid undercarriage (probably) and/or a longer bearing (not sure about it. will result in less Z axis range).

I'll most defiantly change the steppers to a big nema17 or maybe 23. Haven't decided yet.

2 screws with belts. I'm thinking 1 belt.

The idea of a motor in the middle for canceling side forces is great (!), but it has the price of Z axis range, so I'll probably pass.

Like I said before - as least risks as possible.

This evening I'll try the idea of 2 shafts instead of 4 ans see how it goes.

I'll also give another shot in getting everything as parallel as possible.

From the results, I'll decide about going to a more rigid undercarriage (probably) and/or a longer bearing (not sure about it. will result in less Z axis range).

I'll most defiantly change the steppers to a big nema17 or maybe 23. Haven't decided yet.

2 screws with belts. I'm thinking 1 belt.

The idea of a motor in the middle for canceling side forces is great (!), but it has the price of Z axis range, so I'll probably pass.

|

Re: Z axis not working properly February 25, 2016 04:44AM |

Registered: 10 years ago Posts: 550 |

You're right, I should have search for it [www.geckodrive.com]Quote

the_digital_dentist

Nope. The basic spec on the full step accuracy is usually 5%. That's why going to >16:1 microstepping doesn't result in increased resolution (it will reduce noise and vibration, but you won't get finer positioning precision).

geared (27:1) Nema-17 3NM, will give you 0.067° per step. At 12V I get a max of ~50RPM out of it. USD28 [www.omc-stepperonline.com]Quote

the_digital_dentist

A geared motor will increase torque but reduce speed. If you can live with the reduced speed (usually OK on the Z axis), it should be OK, but a geared NEMA-17 motor often costs more than a NEMA-23 motor depending on the torque/size of the motor. The Z axis in my printer has a 20 tooth pulley on the motor and 42 tooth pulleys on the two Z axis screws.

Here's a NEMA-23 motor that provides about 2.5X more torque than you can get in an ungeared NEMA-17 motor for $27 shipped. It even has an antivibration mount: [www.ebay.com]

Edited 1 time(s). Last edit at 02/25/2016 04:44AM by Frans@France.

|

Re: Z axis not working properly February 25, 2016 08:40AM |

Registered: 11 years ago Posts: 5,780 |

Well, there you go. I wonder about backlash in the gear mechanism - will it cause any artifacts in prints? If you lift the nozzle during retraction, does the bed return to the same Z level when the extrusion restarts? Hmmmm.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Z axis not working properly February 25, 2016 09:57AM |

Registered: 10 years ago Posts: 550 |

|

Re: Z axis not working properly March 27, 2016 02:30AM |

Registered: 8 years ago Posts: 63 |

Guys I'm about to order some parts for the new assembly (took me some time....)

Need your advice about the lead screw for the Z axis.

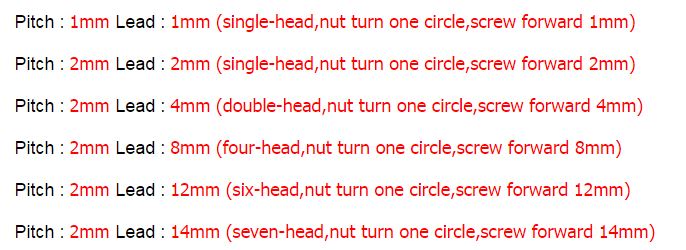

The seller have several options of screws:

I think the smaller lead is better for Z axis, isn't it so?

Need your advice about the lead screw for the Z axis.

The seller have several options of screws:

I think the smaller lead is better for Z axis, isn't it so?

|

Re: Z axis not working properly March 27, 2016 03:40AM |

Registered: 11 years ago Posts: 5,780 |

The Z Axis screws on my printer are 1/2" (yes, inches!) lead. The belt drive uses 42 tooth pulleys on the screws and a 20 tooth pulley on the motor and I get as perfect Z axis behavior as I have ever seen. I don't think the pitch matters much in terms of print quality, but the longer the pitch the more likely the bed will fall if power is cut. This also means the load on the motor is higher. In my case the detent torque in the motor and the torque multiplication by the pulleys prevents the X axis from dropping. I used a NEMA-23 motor because I had it but I've never calculated the required torque - I got lucky and it worked.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Z axis not working properly March 27, 2016 06:32AM |

Registered: 8 years ago Posts: 63 |

|

Re: Z axis not working properly March 27, 2016 07:08AM |

Registered: 9 years ago Posts: 1,873 |

Sorry, only registered users may post in this forum.