Dual wades like extruder

Posted by amigob

|

Re: Dual wades like extruder April 08, 2016 11:01AM |

Registered: 9 years ago Posts: 1,873 |

I started with clips because I wanted to be able to remove the glass and swap in a different one, but in practice I didn't do it very often. When I added the second extruder I had problems with the idle nozzle knocking the clips off, so for now I've just taped the glass to the heatbed with kapton tape. It's ugly but working ok so far. I like your solution a lot better.

|

Re: Dual wades like extruder April 09, 2016 04:19AM |

Registered: 8 years ago Posts: 260 |

tried to print these 2 small blocks on top of each other and that seems to be to difficult for me

slic3r has already problems with this the first layer is placed beside the object. if I switch the extruder assignment then it looks different again.

I tried loading separate objects ( 2 blocks ) where both need to be set to Z height 0

And loading 1 object , splitting them and again both objects have a Z level of 0

when I start slicing in all test I get the warning : At least one object is outside the printable area. Abort slicing,

If I press no, I get the strange results.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

slic3r has already problems with this the first layer is placed beside the object. if I switch the extruder assignment then it looks different again.

I tried loading separate objects ( 2 blocks ) where both need to be set to Z height 0

And loading 1 object , splitting them and again both objects have a Z level of 0

when I start slicing in all test I get the warning : At least one object is outside the printable area. Abort slicing,

If I press no, I get the strange results.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: Dual wades like extruder April 09, 2016 07:21AM |

Registered: 8 years ago Posts: 260 |

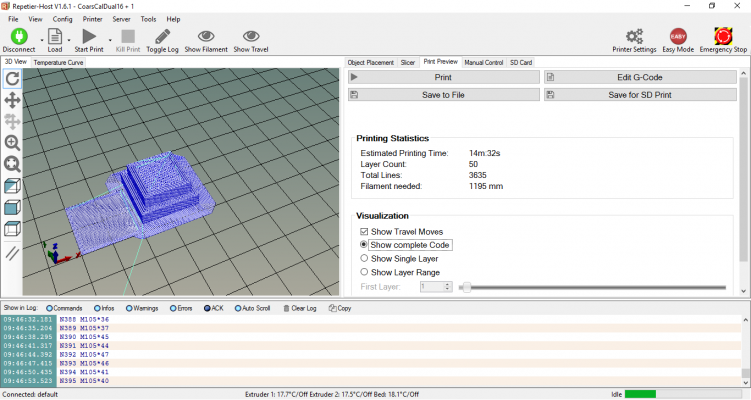

increasing the Z level of the top block with 0.1 um solved the problem?

Looking at the slices everything looks ok, no missing layer ?

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

Looking at the slices everything looks ok, no missing layer ?

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: Dual wades like extruder April 09, 2016 08:03AM |

Registered: 9 years ago Posts: 1,873 |

Yay - success!

Your experience sounds exactly like my first few prints. Everything seemed to be 10x more trouble and difficult to find simple instructions for how to do it.

If you are using repetier-host, the trick seems to be to load two stls separately and then use the "Object informations" dialog (click the cog icon in the list of parts) to assign both parts to the same object group. That should get rid of the "outside of printable area" messages. You can also set the extruder in the same dialog. If you are using Slic3r's stand alone plater it looks like you have to load one object, then open its settings dialog and use the "Load part..." button to load the second part as a sub-part of the same object.

Rendering preview is a pain - in Repetier host there are bugs so you can't rely on the colour coding to tell which plastic is going to be used at any point. Prints come out as expected but the preview is a mess, particularly in the bottom layers. In Slic3r's preview I can't find a way to colour code by extruder, so I can't tell what's supposed to be going on. Print and pray! I'm getting increasingly tempted by Simplify3D, but the $$$ is off-putting.

Edited 2 time(s). Last edit at 04/09/2016 08:11AM by JamesK.

Your experience sounds exactly like my first few prints. Everything seemed to be 10x more trouble and difficult to find simple instructions for how to do it.

If you are using repetier-host, the trick seems to be to load two stls separately and then use the "Object informations" dialog (click the cog icon in the list of parts) to assign both parts to the same object group. That should get rid of the "outside of printable area" messages. You can also set the extruder in the same dialog. If you are using Slic3r's stand alone plater it looks like you have to load one object, then open its settings dialog and use the "Load part..." button to load the second part as a sub-part of the same object.

Rendering preview is a pain - in Repetier host there are bugs so you can't rely on the colour coding to tell which plastic is going to be used at any point. Prints come out as expected but the preview is a mess, particularly in the bottom layers. In Slic3r's preview I can't find a way to colour code by extruder, so I can't tell what's supposed to be going on. Print and pray! I'm getting increasingly tempted by Simplify3D, but the $$$ is off-putting.

Edited 2 time(s). Last edit at 04/09/2016 08:11AM by JamesK.

|

Re: Dual wades like extruder April 09, 2016 09:23AM |

Registered: 8 years ago Posts: 260 |

> use the "Object informations" dialog (click the cog icon in the list of parts) to assign both parts to the same object group.

that helps :-)

> Repetier host there are bugs so you can't rely on the colour coding to tell which plastic is going to be used at any point

that helps, I start ignoring the preview because , the colors are also shifted by extruder offset.

Thanks,

Edited 1 time(s). Last edit at 04/09/2016 09:23AM by amigob.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

that helps :-)

> Repetier host there are bugs so you can't rely on the colour coding to tell which plastic is going to be used at any point

that helps, I start ignoring the preview because , the colors are also shifted by extruder offset.

Thanks,

Edited 1 time(s). Last edit at 04/09/2016 09:23AM by amigob.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: Dual wades like extruder April 09, 2016 09:38AM |

Registered: 9 years ago Posts: 1,873 |

Ah yes, that's another whole area of confusion. It seems to be best to put the extruder offsets in the firmware only, and keep the settings in repetier host and slic3r set to 0. Otherwise you can get double correction and endless confusion. I guess you could keep the firmware at 0 and do the compensation in the slic3r - haven't tried that.

|

Re: Dual wades like extruder April 09, 2016 10:18AM |

Registered: 8 years ago Posts: 260 |

|

Re: Dual wades like extruder April 09, 2016 10:22AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Dual wades like extruder April 09, 2016 10:27AM |

Registered: 8 years ago Posts: 260 |

|

Re: Dual wades like extruder April 09, 2016 10:30AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Dual wades like extruder April 09, 2016 12:50PM |

Registered: 8 years ago Posts: 260 |

went back to Repetier firmware setting ( not going to look back. maybe it was me :-) )

so in steps Repetier needs that

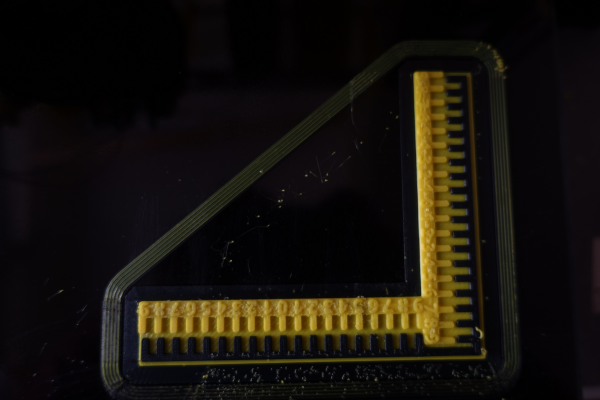

Y = 0.5 mm = 320 steps

X = 0.1 mm = 64 steps

and now thinking about the direction plus or minus

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

so in steps Repetier needs that

Y = 0.5 mm = 320 steps

X = 0.1 mm = 64 steps

and now thinking about the direction plus or minus

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: Dual wades like extruder April 09, 2016 01:11PM |

Registered: 9 years ago Posts: 1,873 |

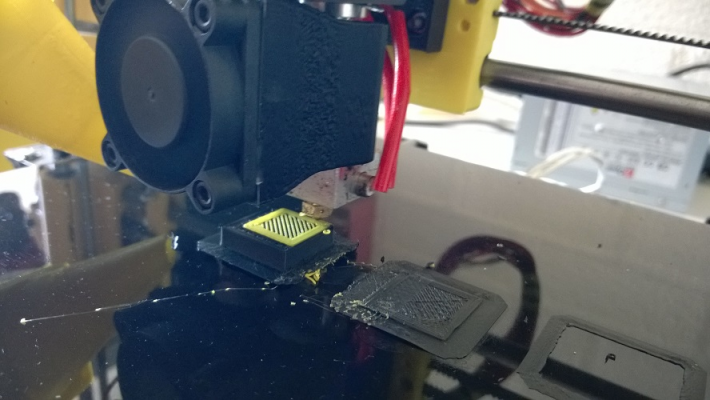

It's pretty cool to see someone else using that

It's a shame it takes a bit long to print now - I should probably try and find some way of reducing it a bit. I often stop it after a couple of layers of the pegs as the numbers are a bit unnecessary.

The signs depend on which extruder you assigned each part to, and which way it was sitting on the print bed. If you put the base on extruder 0 and the smaller part on extruder 1 (which has the offsets), then if the matching peg is on the axis increasing side of the 0 you need to add more to the offset value. So if your photo has X increasing left to right then you need to add the 64 steps to the existing value (you have 640 steps/mm? That seems high, I think mine is 160). Similarly, if Y is increase from front to back then I think you need to subtract the 320 from the existing offset. But I could be wrong - I have a history of getting my Y axis adjustment backwards !

Edited 1 time(s). Last edit at 04/09/2016 01:11PM by JamesK.

It's a shame it takes a bit long to print now - I should probably try and find some way of reducing it a bit. I often stop it after a couple of layers of the pegs as the numbers are a bit unnecessary.

The signs depend on which extruder you assigned each part to, and which way it was sitting on the print bed. If you put the base on extruder 0 and the smaller part on extruder 1 (which has the offsets), then if the matching peg is on the axis increasing side of the 0 you need to add more to the offset value. So if your photo has X increasing left to right then you need to add the 64 steps to the existing value (you have 640 steps/mm? That seems high, I think mine is 160). Similarly, if Y is increase from front to back then I think you need to subtract the 320 from the existing offset. But I could be wrong - I have a history of getting my Y axis adjustment backwards !

Edited 1 time(s). Last edit at 04/09/2016 01:11PM by JamesK.

|

Re: Dual wades like extruder April 09, 2016 02:31PM |

Registered: 8 years ago Posts: 260 |

I use 128 micro stepping for X and Y ( Raps128 )

I thought the same, subtract the 320, we where both wrong , I needed to add it :-)

There is one thing that I really have problems with and that is the skirt, both filaments are printed at the same place so that it sticks way to good to the bed

I need it to get the filament in the nozzle. but I will change that after the IR sensor is working. I will make it possible to extrude filament

in a basket en wipe the nozzle after that on a brush then I dot need skirt any more.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

I thought the same, subtract the 320, we where both wrong , I needed to add it :-)

There is one thing that I really have problems with and that is the skirt, both filaments are printed at the same place so that it sticks way to good to the bed

I need it to get the filament in the nozzle. but I will change that after the IR sensor is working. I will make it possible to extrude filament

in a basket en wipe the nozzle after that on a brush then I dot need skirt any more.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: Dual wades like extruder April 09, 2016 02:48PM |

Registered: 9 years ago Posts: 1,873 |

These offsets are very confusing! 128 microsteps - I bet that's smooth as silk. That's odd with the skirt, I think they are supposed to be side by side. I had one model where for some reason it didn't bother to do any skirt for the second nozzle, so it was touch and go if it would start extruding when it needed to. Plenty of strangeness in this dual extrusion stuff. Still, it's very neat when it works. I was messing around with putting an abs ball in a pla transparent cube. Silly stuff, but it made me smile.

|

Re: Dual wades like extruder April 09, 2016 05:14PM |

Registered: 8 years ago Posts: 260 |

with ooze prevention it doesn't do the overlapping skirt, strange,

the skirt was same height as the cat . but it was already breaking apart the last 25%

Edited 1 time(s). Last edit at 04/09/2016 05:18PM by amigob.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

the skirt was same height as the cat . but it was already breaking apart the last 25%

Edited 1 time(s). Last edit at 04/09/2016 05:18PM by amigob.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: Dual wades like extruder April 09, 2016 05:29PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Dual wades like extruder April 09, 2016 05:33PM |

Registered: 8 years ago Posts: 260 |

|

Re: Dual wades like extruder April 10, 2016 07:54AM |

Registered: 8 years ago Posts: 260 |

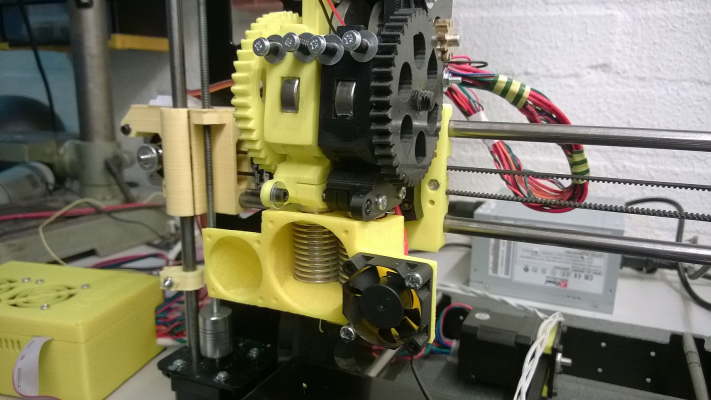

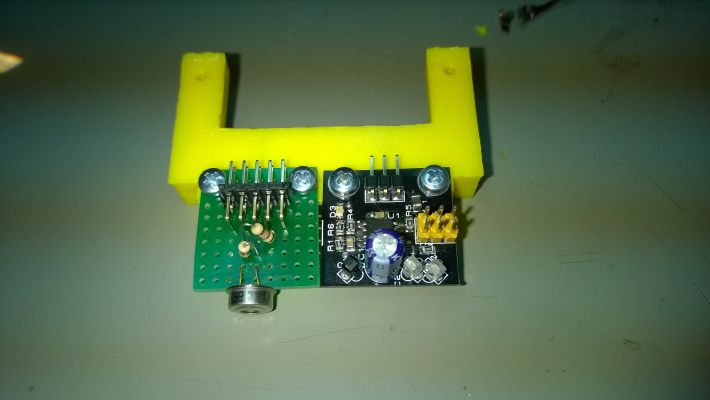

V2 cooler with separate filament cooler

dual coooler

it only meeds some small extensions to get the head under the nozzle

Edited 1 time(s). Last edit at 04/10/2016 07:56AM by amigob.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

dual coooler

it only meeds some small extensions to get the head under the nozzle

Edited 1 time(s). Last edit at 04/10/2016 07:56AM by amigob.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: Dual wades like extruder April 11, 2016 05:40PM |

Registered: 8 years ago Posts: 260 |

for this thin wall stuff you need the enclosure I will try one at 280c ( now 260 )

but the object is cooling down to quickly

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: Dual wades like extruder April 13, 2016 04:55PM |

Registered: 8 years ago Posts: 260 |

so sensor mount ready, mount everything to the X carrier tomorrow including cooler setup.

Edited 1 time(s). Last edit at 04/13/2016 04:55PM by amigob.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

Edited 1 time(s). Last edit at 04/13/2016 04:55PM by amigob.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: Dual wades like extruder April 13, 2016 05:04PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Dual wades like extruder April 13, 2016 05:29PM |

Registered: 8 years ago Posts: 260 |

|

Re: Dual wades like extruder April 13, 2016 06:02PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Dual wades like extruder April 14, 2016 03:40AM |

Registered: 8 years ago Posts: 260 |

> add a layer of insulation

Good idea and will do that.

I can only think of one high temperature isolation that I easily can get. That is exhaust isolation. If I remember correctly, they have, with and without adhesive.

Did someone already use that stuff to isolate the heater block ?

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

Good idea and will do that.

I can only think of one high temperature isolation that I easily can get. That is exhaust isolation. If I remember correctly, they have, with and without adhesive.

Did someone already use that stuff to isolate the heater block ?

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: Dual wades like extruder April 14, 2016 06:30AM |

Registered: 9 years ago Posts: 1,873 |

I have a sheet of insulation for wood stoves on order to try: [www.ebay.ca]

Haven't tried exhaust insulation.

Haven't tried exhaust insulation.

|

Re: Dual wades like extruder April 14, 2016 11:16AM |

Registered: 10 years ago Posts: 466 |

I use a ceramic sheet, used for kilns. I was able to find it at a local art store.

[www.scrapbooking-warehouse.com]

[www.scrapbooking-warehouse.com]

|

Re: Dual wades like extruder April 14, 2016 02:05PM |

Registered: 8 years ago Posts: 260 |

|

Re: Dual wades like extruder April 16, 2016 03:20AM |

Registered: 8 years ago Posts: 5,232 |

Sorry, only registered users may post in this forum.