Home

>

Developers

>

Topic

heatmap of the heatbed

Posted by amigob

|

heatmap of the heatbed April 19, 2016 04:35PM |

Registered: 8 years ago Posts: 260 |

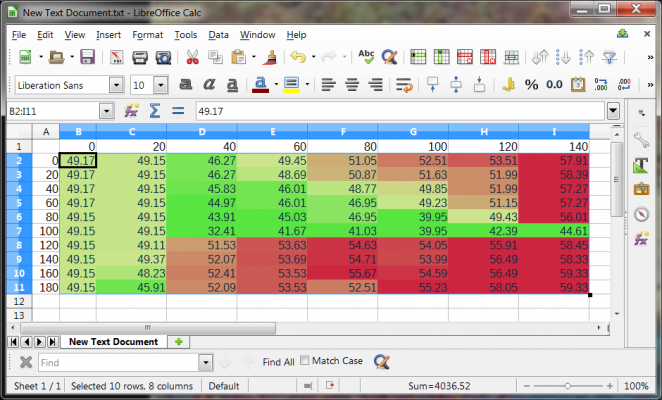

The first scan of the head bed of my Prusa.

the heater was heating up, bit I have no explanation for the right bottom corner.

here movie

it seems that sampling the temperature is so fast that you don't see it in the move.

So I can decrease the pitch for a finer grid.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

the heater was heating up, bit I have no explanation for the right bottom corner.

here movie

it seems that sampling the temperature is so fast that you don't see it in the move.

So I can decrease the pitch for a finer grid.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: heatmap of the heatbed April 19, 2016 05:18PM |

Registered: 8 years ago Posts: 260 |

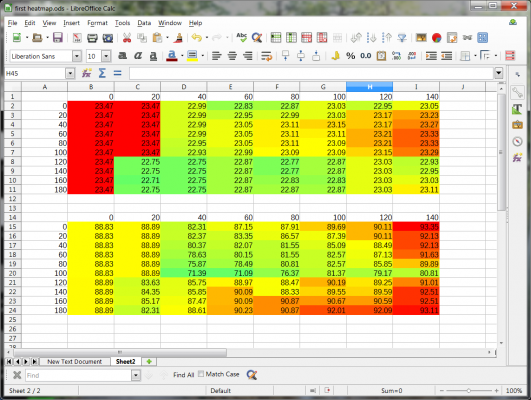

I definitely need to check the adhesion of the heater in the middle of the bed

Edited 1 time(s). Last edit at 04/19/2016 05:20PM by amigob.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

Edited 1 time(s). Last edit at 04/19/2016 05:20PM by amigob.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: heatmap of the heatbed April 19, 2016 07:18PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: heatmap of the heatbed April 20, 2016 03:27AM |

Registered: 8 years ago Posts: 260 |

That is why I made the low temperature map, I thought that something influences the measurement from outside ( light )

But in principle the low temperature measurement shows that is not the case.

I checked the heater but I couldn't real find that it was loss.

I couldn't scan the complete heat bed yet. Because of the dual extruder setup . I couldn't get to all the locations. But that is just software and configuration.

I setup my dual extruder so that the right extruder has the X offset , because of that I had 2 move my X zeroing sensor to be able to get 0.0 on the print surface.

But if I give the left extruder a minus X offset I think that will solve the problem, because then Repetier will correct for it. ( mhh difficult to explain :-) )

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

But in principle the low temperature measurement shows that is not the case.

I checked the heater but I couldn't real find that it was loss.

I couldn't scan the complete heat bed yet. Because of the dual extruder setup . I couldn't get to all the locations. But that is just software and configuration.

I setup my dual extruder so that the right extruder has the X offset , because of that I had 2 move my X zeroing sensor to be able to get 0.0 on the print surface.

But if I give the left extruder a minus X offset I think that will solve the problem, because then Repetier will correct for it. ( mhh difficult to explain :-) )

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: heatmap of the heatbed April 20, 2016 06:46AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: heatmap of the heatbed April 20, 2016 07:40AM |

Registered: 11 years ago Posts: 5,780 |

We had something similar going on in a Taz printer at the Milwaukee Makerspace. A FLIR camera indicated at least 20C temperature variation across the bed surface with a cool spot right in the center. That printer had a heater glued directly to a glass bed. I'll never understand the use of glass for a print bed.

Anyway, someone applied glue directly to the glass and printed something and the glass broke either due to print shrinkage or excessive force trying to remove it from the bed, so now I'm replacing the glass with a cast aluminum tooling plate. I'm also converting from a dumb 4-point leveling scheme to a 3-point scheme. I'll probably replace the plastic bushings on the Y axis with ball bushings, too.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Anyway, someone applied glue directly to the glass and printed something and the glass broke either due to print shrinkage or excessive force trying to remove it from the bed, so now I'm replacing the glass with a cast aluminum tooling plate. I'm also converting from a dumb 4-point leveling scheme to a 3-point scheme. I'll probably replace the plastic bushings on the Y axis with ball bushings, too.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: heatmap of the heatbed April 20, 2016 07:54AM |

Registered: 8 years ago Posts: 260 |

|

Re: heatmap of the heatbed April 20, 2016 09:41AM |

Registered: 8 years ago Posts: 260 |

Mhh found the settling times. by default it would be 0.1 seconds. So I already measure to fast for that.

But the sensors I got are not setup with default values ( one critical one was already different my sensors went to PWM mode automatically, by default it should be I2C ),

so I need to first check the setting tonight.

[cdn-shop.adafruit.com]

The setteling time depends on the IIR and the FIR filters. I have read a little bit about it but I have no clue on what the best is for this.

I expect that I want to have a descent filter that removes spikes, but that gives a big settling time.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

But the sensors I got are not setup with default values ( one critical one was already different my sensors went to PWM mode automatically, by default it should be I2C ),

so I need to first check the setting tonight.

[cdn-shop.adafruit.com]

The setteling time depends on the IIR and the FIR filters. I have read a little bit about it but I have no clue on what the best is for this.

I expect that I want to have a descent filter that removes spikes, but that gives a big settling time.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: heatmap of the heatbed April 20, 2016 10:23AM |

Registered: 12 years ago Posts: 1,450 |

The biggest single thing that influences the temperature of various points on the bed is how well insulated it is on the top - by what is being printed. A large object covering the center of the panel (and presumably the temperature sensor) will hold the heat in there so that the temperature towards the edge of the piece will be much lower. What would be nice is a multi-zone heater so that each area is independent - I am not sure how that could be done at a reasonable price though.

Mike

Mike

|

Re: heatmap of the heatbed April 20, 2016 10:41AM |

Registered: 8 years ago Posts: 260 |

This temperature sensor is ~1cm above the glass plate, it is a contact less sensor, and I agree with the statement that where the object is printed it can easily hold the temperature. I just want to have the starting

temperature reproducible. That is now because of the position of the bed temperature sensor not possible. The temperature matrix is just a nice to have feature. But t show also how good the measurement is.

Let me say this, I don't trust the measurements that it is doing now :-)

It has to big jumps and high temperatures at the edge. I think I need to check what the settling time is ( directly connected to the IIR and FIR filters ).

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

temperature reproducible. That is now because of the position of the bed temperature sensor not possible. The temperature matrix is just a nice to have feature. But t show also how good the measurement is.

Let me say this, I don't trust the measurements that it is doing now :-)

It has to big jumps and high temperatures at the edge. I think I need to check what the settling time is ( directly connected to the IIR and FIR filters ).

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: heatmap of the heatbed April 20, 2016 02:39PM |

Registered: 8 years ago Posts: 260 |

|

Re: heatmap of the heatbed April 20, 2016 02:41PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: heatmap of the heatbed April 20, 2016 03:37PM |

Registered: 8 years ago Posts: 260 |

it had full IIR and FIR digital filter, I switched of the IIR now, readings still good, settling time is now 0.1 sec

when I reduced the FIR filter, readings where completely wrong -91c

I have now the problem that repetier ignores the delay that I added???

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

when I reduced the FIR filter, readings where completely wrong -91c

I have now the problem that repetier ignores the delay that I added???

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: heatmap of the heatbed April 20, 2016 03:42PM |

Registered: 8 years ago Posts: 260 |

|

Re: heatmap of the heatbed April 21, 2016 02:55AM |

Registered: 8 years ago Posts: 260 |

What a good night sleep can do

I know what is going on. I created a double loop with the moves and the delay and the measurement

The problem is that the moves are queued and the delay and measurements not.. I would expect that a function that queues something would have that made clear in the name of the function.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

I know what is going on. I created a double loop with the moves and the delay and the measurement

The problem is that the moves are queued and the delay and measurements not.. I would expect that a function that queues something would have that made clear in the name of the function.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: heatmap of the heatbed April 21, 2016 06:44AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: heatmap of the heatbed April 21, 2016 02:59PM |

Registered: 8 years ago Posts: 260 |

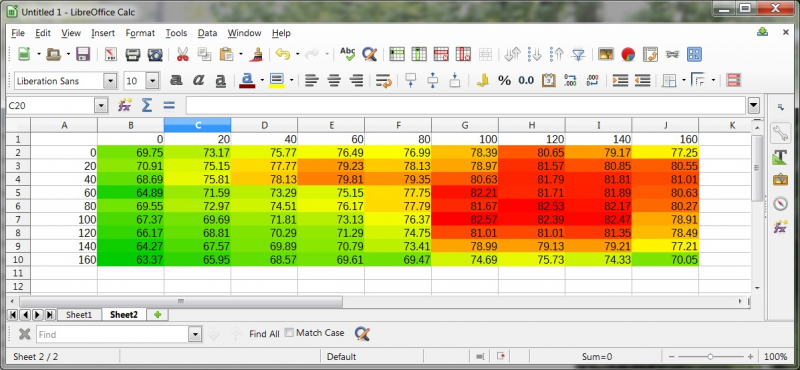

and now a good one :-)

complete measurement takes 1 minute, so bed was still heating up

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

complete measurement takes 1 minute, so bed was still heating up

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: heatmap of the heatbed April 21, 2016 03:10PM |

Registered: 8 years ago Posts: 260 |

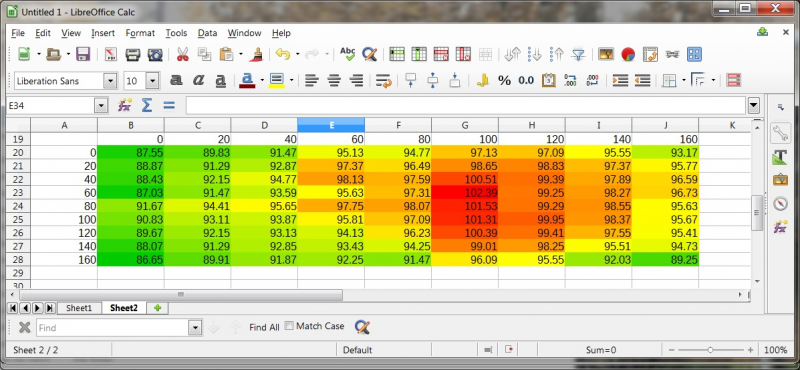

and now after 6 minutes

not bad about ~ 10 degrees difference

Now making a gcode implementation for heating bed to what for IR sensor to reach desired temperature

with overruling the set temperature

Edited 1 time(s). Last edit at 04/21/2016 03:13PM by amigob.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

not bad about ~ 10 degrees difference

Now making a gcode implementation for heating bed to what for IR sensor to reach desired temperature

with overruling the set temperature

Edited 1 time(s). Last edit at 04/21/2016 03:13PM by amigob.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: heatmap of the heatbed April 21, 2016 03:17PM |

Registered: 9 years ago Posts: 1,873 |

That looks much more believable  The 10 degrees centre to corner difference is about what I remember seeing with my heatbed. Very nice capability you've implemented there. How big is the offset from the sensor to the nozzle? You could imagine using the sensor to monitor the print surface temperature and adjust cooling and speed based on actual temperatures instead of guesswork based on layer time (temperature build-up can be very different depending on the tool path for the same layer time). That would be hugely useful.

The 10 degrees centre to corner difference is about what I remember seeing with my heatbed. Very nice capability you've implemented there. How big is the offset from the sensor to the nozzle? You could imagine using the sensor to monitor the print surface temperature and adjust cooling and speed based on actual temperatures instead of guesswork based on layer time (temperature build-up can be very different depending on the tool path for the same layer time). That would be hugely useful.

The 10 degrees centre to corner difference is about what I remember seeing with my heatbed. Very nice capability you've implemented there. How big is the offset from the sensor to the nozzle? You could imagine using the sensor to monitor the print surface temperature and adjust cooling and speed based on actual temperatures instead of guesswork based on layer time (temperature build-up can be very different depending on the tool path for the same layer time). That would be hugely useful.

The 10 degrees centre to corner difference is about what I remember seeing with my heatbed. Very nice capability you've implemented there. How big is the offset from the sensor to the nozzle? You could imagine using the sensor to monitor the print surface temperature and adjust cooling and speed based on actual temperatures instead of guesswork based on layer time (temperature build-up can be very different depending on the tool path for the same layer time). That would be hugely useful.

|

Re: heatmap of the heatbed April 21, 2016 04:31PM |

Registered: 8 years ago Posts: 260 |

using it to check temperature of the object while printing is an option.

Until now I only needed that when I printed thin walls and then I don't think it will work.

Just implemented , M703 , call it with a temperature and it will switch the heater to max temperature ( config )

and waits until the bed sensor reaches the requested temperature.

And then sets the temperature to requested bed temperature

video here

Edited 1 time(s). Last edit at 04/21/2016 04:31PM by amigob.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

Until now I only needed that when I printed thin walls and then I don't think it will work.

Just implemented , M703 , call it with a temperature and it will switch the heater to max temperature ( config )

and waits until the bed sensor reaches the requested temperature.

And then sets the temperature to requested bed temperature

video here

Edited 1 time(s). Last edit at 04/21/2016 04:31PM by amigob.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: heatmap of the heatbed April 25, 2016 08:16AM |

Registered: 8 years ago Posts: 260 |

so made the first prints with the M703, had some small problems finding the correct way of injecting M703

Add it to the repertier start code, didn't always work ( still don't know why ), it is also not really the correct location because

I need to change printer settings when I change filament type.

Then I moved it to the start code of slic3r, that didn't work because I ended up with 2 blobs of filament on the middle of the build plate.

Because the extruders where starting to heat before the M703 command.

They would probable be pushed of when printing, but I didn't like it.

For now it looks like I will integrate a post processing script that adds the command, but I need to check if I can handle different scrips for different filaments.

Like to have it automated.

BTW, I manually now add the M703 S100 and the bed heating is done within 7 minutes ( top of the bed is then 100c ).

the filament sticks so well that I am going to reduce the temperature for the first layer, and increase it for non first layer layers in the hope that it will stick less :-)

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

Add it to the repertier start code, didn't always work ( still don't know why ), it is also not really the correct location because

I need to change printer settings when I change filament type.

Then I moved it to the start code of slic3r, that didn't work because I ended up with 2 blobs of filament on the middle of the build plate.

Because the extruders where starting to heat before the M703 command.

They would probable be pushed of when printing, but I didn't like it.

For now it looks like I will integrate a post processing script that adds the command, but I need to check if I can handle different scrips for different filaments.

Like to have it automated.

BTW, I manually now add the M703 S100 and the bed heating is done within 7 minutes ( top of the bed is then 100c ).

the filament sticks so well that I am going to reduce the temperature for the first layer, and increase it for non first layer layers in the hope that it will stick less :-)

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

Sorry, only registered users may post in this forum.