Home

>

Developers

>

Topic

Multi-material/multi-colour Active Mixing printhead (three materials)

Posted by anchelyn

|

Multi-material/multi-colour Active Mixing printhead (three materials) September 05, 2016 04:17AM |

Registered: 7 years ago Posts: 4 |

Hello guys!

Long-time lurker and fellow developer here. Over the last three years, through my undergraduate studies, I managed to build a working prototype of an active mixing print-head based on James Corbett and Pia Taubert’s work from 2012. I completed work on this prototype about three months ago (at the end of my Bachelor’s Thesis (see submission date), and the release of the RoVa4D and other factors finally compelled me to release my work, open source to you guys.

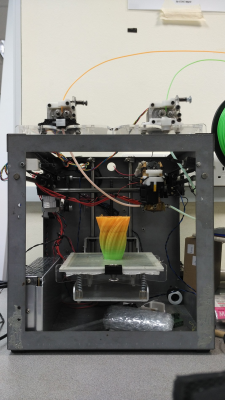

Picture of two-extruder version of prototype, later prototype had three

NOTE: This is a WORKING PROTOTYPE, so simply manufacturing the parts + electronic controls should get you a print-head that works. If people are interested, I’ll release more info so that someone who would want to assemble one and continue developing it could do so.

I made it with three design considerations in mind: low-cost, modular, user-friendly. Therefore, a good number of parts are basically 3D printed, while the only custom parts would be the mixing chamber itself and the Bowden tube adaptors. Being modular also means that this prototype can theoretically be mounted on any 3D printer (with some modifications to the X-carriage mount). I also tried to simplify as much as possible the number of parts and steps to assemble/disassemble the prototype for maintenance.

A brief summary of what the prototype is and what can do:

Active Mixing multi-material 3D print-head that takes up to 3 different materials into a single nozzle and blends them into a homogenous mix before printing.

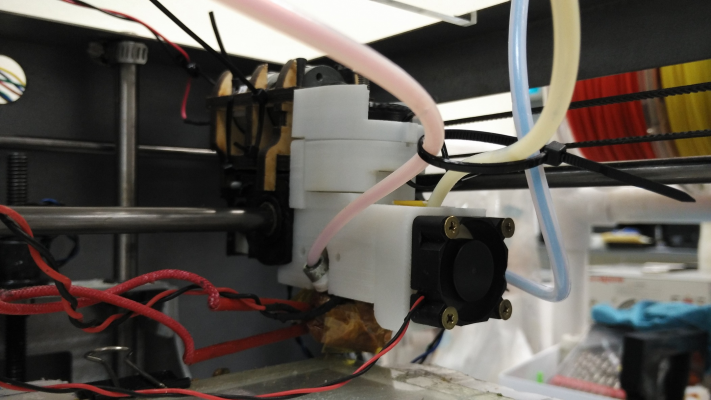

Close-up of three-material input and print-head

Platform used: Solidoodle 3D printer, with control board replaced with Arduino MEGA2560 with RAMPS 1.4

Advantages:

* Printing of different blends of materials/colours consistently and homogeneously

* Current prototype is stable and does not leak/jam often

* Low cost (80% 3D printed parts)

* Modular (print head can be installed on various printers)

* Easy to maintain

* Almost entirely based on open-source work

* Cheap compared to nearest competitor, Diamond hot-end (final prototype $447 SGD vs $377 for comparable no. of parts)

* Does not exist anywhere else in the market

* Only two other printers Cube C Pro and RoVa4D has potentially similar capability, but in the range of $7000 SGD or above, and is entirely proprietary (printer & material)

What it can do:

* Create different/unique blends of materials that do not exist with manufacturers

* Allow both Visual and Functional accuracy of parts/prototypes

* Print in discrete colours/materials

* Print in varying ratios of all three materials or two materials

* Print different materials/ratios of materials between layers

* Print different materials/ratios of materials within layers

* Automatically switch between different materials/ratio of materials in a print

* Automatically purge out previous material/ratio of materials to form distinct borders

* Support up to 16 discrete ratios

* Automatic fan-based cooling systems for extruders and nozzle

Target audience:

* In current form: Hobbyists/developers with printers

* Further development: Low cost market for SMEs for part prototyping

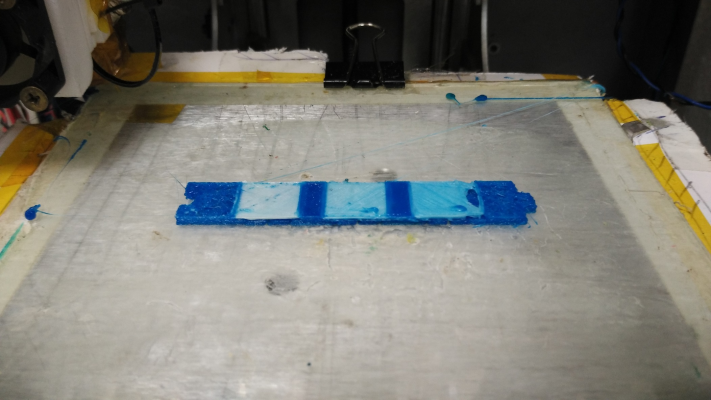

Pictures of some prints, all filaments used were from ESun:

Jointed print example with both flexible and rigid PLA in a single print

Jointed print (as above) but with varying percentage of Flex PLA/PLA

Prints made using only RYB PLA

Prints of various blends of pairs of materials. From top: ABS/ABS, ABS/Flex PLA, ABS/PLA, PLA/Flex PLA

Model of Sacrum bone (bone at end of spine) with tumor (tumor in pink, enclosed by bone simulated by white PLA)

Specifications:

Hardware | Solidoodle printer

Electronics | Arduino MEGA 2560 with RAMPS 1.4 shield

| Fan extension board

| SD card extension board

| CNC shield V3 extension (for additional extruders)

Power supply | 12 V power supply

Firmware | Repetier Firmware V0.92

Software | Repetier Host V1.6.1

| Slic3r V1.2.9

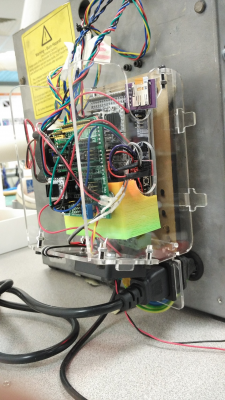

Picture of electronics:

Link to Thesis (for those of you who might be interested in more details):

Active Mixing prototype thesis

If anyone has any questions or are interested in more, please feel free to PM or reply.

Cheers!

Long-time lurker and fellow developer here. Over the last three years, through my undergraduate studies, I managed to build a working prototype of an active mixing print-head based on James Corbett and Pia Taubert’s work from 2012. I completed work on this prototype about three months ago (at the end of my Bachelor’s Thesis (see submission date), and the release of the RoVa4D and other factors finally compelled me to release my work, open source to you guys.

Picture of two-extruder version of prototype, later prototype had three

NOTE: This is a WORKING PROTOTYPE, so simply manufacturing the parts + electronic controls should get you a print-head that works. If people are interested, I’ll release more info so that someone who would want to assemble one and continue developing it could do so.

I made it with three design considerations in mind: low-cost, modular, user-friendly. Therefore, a good number of parts are basically 3D printed, while the only custom parts would be the mixing chamber itself and the Bowden tube adaptors. Being modular also means that this prototype can theoretically be mounted on any 3D printer (with some modifications to the X-carriage mount). I also tried to simplify as much as possible the number of parts and steps to assemble/disassemble the prototype for maintenance.

A brief summary of what the prototype is and what can do:

Active Mixing multi-material 3D print-head that takes up to 3 different materials into a single nozzle and blends them into a homogenous mix before printing.

Close-up of three-material input and print-head

Platform used: Solidoodle 3D printer, with control board replaced with Arduino MEGA2560 with RAMPS 1.4

Advantages:

* Printing of different blends of materials/colours consistently and homogeneously

* Current prototype is stable and does not leak/jam often

* Low cost (80% 3D printed parts)

* Modular (print head can be installed on various printers)

* Easy to maintain

* Almost entirely based on open-source work

* Cheap compared to nearest competitor, Diamond hot-end (final prototype $447 SGD vs $377 for comparable no. of parts)

* Does not exist anywhere else in the market

* Only two other printers Cube C Pro and RoVa4D has potentially similar capability, but in the range of $7000 SGD or above, and is entirely proprietary (printer & material)

What it can do:

* Create different/unique blends of materials that do not exist with manufacturers

* Allow both Visual and Functional accuracy of parts/prototypes

* Print in discrete colours/materials

* Print in varying ratios of all three materials or two materials

* Print different materials/ratios of materials between layers

* Print different materials/ratios of materials within layers

* Automatically switch between different materials/ratio of materials in a print

* Automatically purge out previous material/ratio of materials to form distinct borders

* Support up to 16 discrete ratios

* Automatic fan-based cooling systems for extruders and nozzle

Target audience:

* In current form: Hobbyists/developers with printers

* Further development: Low cost market for SMEs for part prototyping

Pictures of some prints, all filaments used were from ESun:

Jointed print example with both flexible and rigid PLA in a single print

Jointed print (as above) but with varying percentage of Flex PLA/PLA

Prints made using only RYB PLA

Prints of various blends of pairs of materials. From top: ABS/ABS, ABS/Flex PLA, ABS/PLA, PLA/Flex PLA

Model of Sacrum bone (bone at end of spine) with tumor (tumor in pink, enclosed by bone simulated by white PLA)

Specifications:

Hardware | Solidoodle printer

Electronics | Arduino MEGA 2560 with RAMPS 1.4 shield

| Fan extension board

| SD card extension board

| CNC shield V3 extension (for additional extruders)

Power supply | 12 V power supply

Firmware | Repetier Firmware V0.92

Software | Repetier Host V1.6.1

| Slic3r V1.2.9

Picture of electronics:

Link to Thesis (for those of you who might be interested in more details):

Active Mixing prototype thesis

If anyone has any questions or are interested in more, please feel free to PM or reply.

Cheers!

|

Re: Multi-material/multi-colour Active Mixing printhead (three materials) October 05, 2016 05:14PM |

Registered: 9 years ago Posts: 1,873 |

Hi Nicholas,

welcome to the forum.

Many thanks for sharing, that was a very interesting read. I maybe missing something (had to skim fast for a first pass), but I couldn't see much detail about how you sealed the top of the mixing chamber to prevent leakage back up the mixing shaft. Could you expand on that?

Regards,

James.

welcome to the forum.

Many thanks for sharing, that was a very interesting read. I maybe missing something (had to skim fast for a first pass), but I couldn't see much detail about how you sealed the top of the mixing chamber to prevent leakage back up the mixing shaft. Could you expand on that?

Regards,

James.

|

Re: Multi-material/multi-colour Active Mixing printhead (three materials) October 09, 2016 12:39AM |

Registered: 7 years ago Posts: 4 |

Hi James!

Thanks for the welcome! Yup, I agree. ABS and PLA have a nasty habit of leaking out of any gaps available. That was the major problem plaguing this concept at the start, actually.

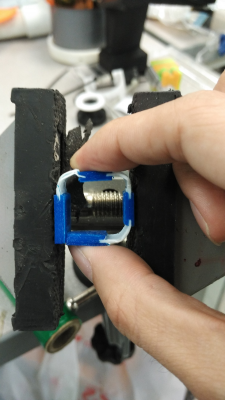

Sealing of the mixing chamber is achieved by using a precision machined mixing chamber and mixing rod (tolerance ~100um or less). That amount of tolerance is enough to keep the viscous ABS and PLA from flowing back upwards and clogging up the heat sink. I also used PTFE sealing tape on all of the threaded joints (between the heat-sink and heater block/mixing chamber, between mixing chamber and nozzle, etc) to keep the ABS from leaking. The last point of leaking is actually at the PTFE Bowden tubes leading directly into the heated chamber, which tended to soften and rupture at elevated temperatures for long periods of time. I avoided that by threading a few M5 nuts onto the outside of the PTFE tube to disperse heat and reduce bending stresses directly where the tube enters the mixing chamber (you can see the nuts on the PTFE tubes in some of the images above).

I did try other methods to seal the chamber previously (including silicon O-rings directly within the chamber), but all of those methods failed as the high RPM of the rod basically wore down anything that was not metal, leading to leaks.

Thanks for the question! If you have any others, feel free to ask.

Nicholas

Thanks for the welcome! Yup, I agree. ABS and PLA have a nasty habit of leaking out of any gaps available. That was the major problem plaguing this concept at the start, actually.

Sealing of the mixing chamber is achieved by using a precision machined mixing chamber and mixing rod (tolerance ~100um or less). That amount of tolerance is enough to keep the viscous ABS and PLA from flowing back upwards and clogging up the heat sink. I also used PTFE sealing tape on all of the threaded joints (between the heat-sink and heater block/mixing chamber, between mixing chamber and nozzle, etc) to keep the ABS from leaking. The last point of leaking is actually at the PTFE Bowden tubes leading directly into the heated chamber, which tended to soften and rupture at elevated temperatures for long periods of time. I avoided that by threading a few M5 nuts onto the outside of the PTFE tube to disperse heat and reduce bending stresses directly where the tube enters the mixing chamber (you can see the nuts on the PTFE tubes in some of the images above).

I did try other methods to seal the chamber previously (including silicon O-rings directly within the chamber), but all of those methods failed as the high RPM of the rod basically wore down anything that was not metal, leading to leaks.

Thanks for the question! If you have any others, feel free to ask.

Nicholas

|

Re: Multi-material/multi-colour Active Mixing printhead (three materials) October 09, 2016 08:02PM |

Registered: 9 years ago Posts: 978 |

|

Re: Multi-material/multi-colour Active Mixing printhead (three materials) October 10, 2016 04:51AM |

Registered: 10 years ago Posts: 14,672 |

Thanks for your work in this area! Your thesis is an interesting read.

My primary interest is delta printers, in which height above the print head is not an issue but sideways protrusion is. So direct motor drive would be preferred to using the bevel gears. Perhaps the heatsink could then be eliminated, especially if a thermally-insulating coupling is used to couple the motor shaft to the mixer shaft.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

My primary interest is delta printers, in which height above the print head is not an issue but sideways protrusion is. So direct motor drive would be preferred to using the bevel gears. Perhaps the heatsink could then be eliminated, especially if a thermally-insulating coupling is used to couple the motor shaft to the mixer shaft.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Multi-material/multi-colour Active Mixing printhead (three materials) October 13, 2016 02:21AM |

Registered: 7 years ago Posts: 4 |

Quote

frankvdh

Thanks for sharing.

I wonder whether a "rifled" nozzle, with helical grooves would get useful mixing without the complexity of moving parts? In your project research, did you find anyone who had done any experimentation in that area?

Thanks for the question! Yes, this work is based of James Myles Corbett and Pia Taubert's work in 2012 on Active Mixing; both featured on this forums before! Corbett did do some preliminary work on determining whether mixing can be done in a static manner (i.e. without any active components like you described) or must it be done in an active manner as I have done. He determined that static mixing was ineffective for PLA after a range of experiments, so he decided to work on active mixing instead. Taubert and myself followed Corbett's preliminary work on that end.

Here is some information on both his and Taubert's work, and a few other peopel who were interested in it: [forums.reprap.org]

And here is the link to their reports: [reprap.org]

Quote

dc42

Thanks for your work in this area! Your thesis is an interesting read.

My primary interest is delta printers, in which height above the print head is not an issue but sideways protrusion is. So direct motor drive would be preferred to using the bevel gears. Perhaps the heatsink could then be eliminated, especially if a thermally-insulating coupling is used to couple the motor shaft to the mixer shaft.

Yes, that would be possible! My original design actually incorporated a vertically mounted motor, but still with a heat sink. I changed to a bevel geared system because I was using a closed-off cartesian system (Solidoodle) and I wanted to preserve Z build volume. You could do experiments to find a method to introduce some thermally-insulating method, but my previous experiments found that method ineffective. Perhaps a water-cooled jacket might be a good alternative if you want to keep the vertical footprint of the extruder small.

Nicholas

|

Re: Multi-material/multi-colour Active Mixing printhead (three materials) October 13, 2016 06:38AM |

Registered: 9 years ago Posts: 1,873 |

The idea that keeps going around in my head is an electro-magnetically coupled mixing element. I have wondered if a low frequency drive signal for mixing could be used along with a high frequency for heating, so the active part does double duty as both a stirrer and an inductively coupled heater.

|

Re: Multi-material/multi-colour Active Mixing printhead (three materials) October 13, 2016 02:50PM |

Registered: 10 years ago Posts: 14,672 |

Quote

JamesK

The idea that keeps going around in my head is an electro-magnetically coupled mixing element. I have wondered if a low frequency drive signal for mixing could be used along with a high frequency for heating, so the active part does double duty as both a stirrer and an inductively coupled heater.

I thought about this for some time before I posted my previous reply. There were two problems that I didn't work out how to overcome:

1. The mixing device is a narrow round or hexagonal tube. Something with such a small diameter would be hard to rotate by electromagnetic induction, because of the difficulty of inducing enough current in it.

2. At least part of the mixing chamber would have to be made of an electrically non-conductive material so as to let the electromagnetic field through. In order to handle higher temperature filaments, that probably means fabricating the mixing chamber from glass, alumina or another ceramic, which isn't easy.

Edited 1 time(s). Last edit at 10/13/2016 02:52PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Multi-material/multi-colour Active Mixing printhead (three materials) October 13, 2016 02:59PM |

Registered: 9 years ago Posts: 1,873 |

Interesting points David. Possibly rotation isn't necessary, I was considering an iron billet that could be moved up and down, or perhaps side to side, in the mixing chamber. That should be easier to achieve than rotation, much like pulling the centre of a solenoid up. While rotation seems optimal, it may be enough to just get something rattling around inside the melt chamber.

The materials question is interesting. I'd rather assumed that enough magnetic field would penetrate a non-ferrous material like aluminium to still be effective, but I may be way off the mark there. It sounds ripe for some experimentation! Wish I was still young enough to be doing a post-grad course, or old enough to have the time to spend on my own projects. It does all sound a bit over complicated, but it's not obvious that active mixing is ever going to be simple.

The materials question is interesting. I'd rather assumed that enough magnetic field would penetrate a non-ferrous material like aluminium to still be effective, but I may be way off the mark there. It sounds ripe for some experimentation! Wish I was still young enough to be doing a post-grad course, or old enough to have the time to spend on my own projects. It does all sound a bit over complicated, but it's not obvious that active mixing is ever going to be simple.

|

Re: Multi-material/multi-colour Active Mixing printhead (three materials) October 14, 2016 04:59AM |

Registered: 10 years ago Posts: 14,672 |

Quote

JamesK

Interesting points David. Possibly rotation isn't necessary, I was considering an iron billet that could be moved up and down, or perhaps side to side, in the mixing chamber. That should be easier to achieve than rotation, much like pulling the centre of a solenoid up. While rotation seems optimal, it may be enough to just get something rattling around inside the melt chamber.

The design presented in the thesis has a mixing chamber with a very low volume - it's basically just the gap between the mixing rod and the hole it sits in. I was trying to keep this low mixing chamber volume, to minimise the amount of material that has to be purged on a colour change. I suspect an up and down motion would not mix very well, because the three (or preferably five) materials are coming in from different directions around the mixing chamber.

Quote

JamesK

The materials question is interesting. I'd rather assumed that enough magnetic field would penetrate a non-ferrous material like aluminium to still be effective, but I may be way off the mark there.

It depends on the frequency. I was assuming that quite a high frequency would be needed to get enough induced current in such a small rod, maybe 10kHz. The skin depth in aluminium is 0.8mm @ 10Khz according to the Wikipedia image at [upload.wikimedia.org].

It might be possible to put a large cap on top of the mixing rod to make it easier to induce current in it. Then the aluminium chamber block could have a disc cut out of the top to accommodate the cap, and a piece of ceramic or thin aluminium fitted on top of the block to seal it. Molten filament would surround the cap so the melt volume would increase considerably, but with any luck the filament in that area wouldn't tend to mix with the filament lower down because there would be no upwards/downwards movement of filament in that area in that area. If it is sealed well enough, there may also be a permanent air bubble there.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Multi-material/multi-colour Active Mixing printhead (three materials) October 14, 2016 12:43PM |

Registered: 7 years ago Posts: 4 |

Quote

dc42

It depends on the frequency. I was assuming that quite a high frequency would be needed to get enough induced current in such a small rod, maybe 10kHz. The skin depth in aluminium is 0.8mm @ 10Khz according to the Wikipedia image at [upload.wikimedia.org].

It might be possible to put a large cap on top of the mixing rod to make it easier to induce current in it. Then the aluminium chamber block could have a disc cut out of the top to accommodate the cap, and a piece of ceramic or thin aluminium fitted on top of the block to seal it. Molten filament would surround the cap so the melt volume would increase considerably, but with any luck the filament in that area wouldn't tend to mix with the filament lower down because there would be no upwards/downwards movement of filament in that area in that area. If it is sealed well enough, there may also be a permanent air bubble there.

A sharp 90 degree constriction where the rod would flatten out to the cap might further help in restricting material flow backwards too. Another way you could ensure material would be forced downwards (which I did not manage to implement successfully) would be by means of a screw extrusion system, similar in principle to screws used injection molding machines. I attempted the same idea by using some store-bought hardened tool steel drill bits (3mm diameter) but the drill bit actually caused "pulsing" of the filament as it was forced out of the nozzle. The result is a wavy pattern as the width of the filament periodically increased and decreased.

Example of rather obvious pulsing. Usually the culmulative effect of many pulsed layers isn't so obvious, but the reduction in overall visual quality of the part is evident.

I suspected it was because of the uneven profile of the drill bit, causing greater or lesser amounts of material to enter the mixing chamber periodically. However, I cannot be sure because the drill bit at that time was spinning much faster than what the frequency/periods of the pulses would suggest, and neither did I do any further studies on relating RPM/DC drive voltage to pulse length/width. I avoided the problem entirely by just using a smooth rod instead and simply relying on shear forces for mixing, but obviously the smooth rod would not help with pushing the filament down.

Maybe someone else might have other ideas.

|

Re: Multi-material/multi-colour Active Mixing printhead (three materials) October 14, 2016 05:05PM |

Registered: 9 years ago Posts: 978 |

Taking a step back...

It seems to me that this approach is using different pressures in small reservoirs to control the proportions of each colour in the mix. At each cycle of the pump, more or less material will flow into the mixing chamber depending on the pressure in the reservoir, which in turn depends on the speed of the extruder motor. I think that there will inevitably be a "capacitance" and "resistance" in the reservoir which means that the mix will differ from what is commanded.

I'm wondering whether a rotating cutter could slice off the appropriate length of solid filament, to be subsequently melted and mixed. That would take the capacitance and resistance out of the mixing equation. Sharpness (and therefore metallurgy) of the cutter would be an issue. Perhaps laser cutters? Time to melt the filament could be a problem however.

So perhaps maintain relatively large reservoirs of molten plastic for each colour at constant pressure and have a "metering pump" to collect the right quantity of each colour, mix them together in a chamber, and extrude the result. Perhaps a variable diameter opening into the mixing chamber? Or how about varying the rotation speed of the "pump" to vary the time that each reservoir outlet is open?

It seems to me that this approach is using different pressures in small reservoirs to control the proportions of each colour in the mix. At each cycle of the pump, more or less material will flow into the mixing chamber depending on the pressure in the reservoir, which in turn depends on the speed of the extruder motor. I think that there will inevitably be a "capacitance" and "resistance" in the reservoir which means that the mix will differ from what is commanded.

I'm wondering whether a rotating cutter could slice off the appropriate length of solid filament, to be subsequently melted and mixed. That would take the capacitance and resistance out of the mixing equation. Sharpness (and therefore metallurgy) of the cutter would be an issue. Perhaps laser cutters? Time to melt the filament could be a problem however.

So perhaps maintain relatively large reservoirs of molten plastic for each colour at constant pressure and have a "metering pump" to collect the right quantity of each colour, mix them together in a chamber, and extrude the result. Perhaps a variable diameter opening into the mixing chamber? Or how about varying the rotation speed of the "pump" to vary the time that each reservoir outlet is open?

|

Re: Multi-material/multi-colour Active Mixing printhead (three materials) October 15, 2016 03:28AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Multi-material/multi-colour Active Mixing printhead (three materials) November 07, 2016 10:22PM |

Registered: 8 years ago Posts: 24 |

Sorry, I couldn't resist... Arcus3D M2 - Six material, active mixing linear delta 3d printer.

Edited 3 time(s). Last edit at 11/07/2016 11:11PM by darenschwenke.

Edited 3 time(s). Last edit at 11/07/2016 11:11PM by darenschwenke.

Sorry, only registered users may post in this forum.