Home

>

Developers

>

Topic

X Y axis accuracy doubled.

Posted by Madkite

|

X Y axis accuracy doubled. May 27, 2011 03:26PM |

Registered: 13 years ago Posts: 177 |

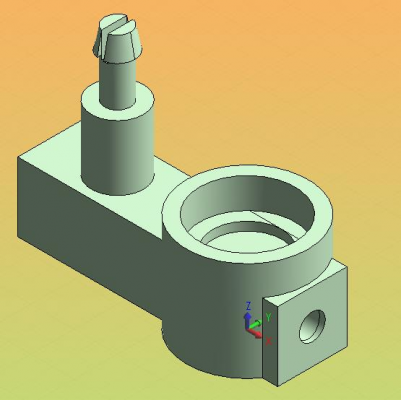

Here is my long touted mod to double the X Y accuracy of Mendel.

[www.thingiverse.com]

I have found this eliminates a lot of lash I had on the X axis and evrything seems t move more sharply. Though the movement thing might be me having a placebo effect. Anyway it allows your Mendel to run at exactly the same speed as before with twice the positioning accuracy. The motors have to turn twice as fast though but this seems to be no problem. After all the motors now require half the torque to move the carriages so its not surprising. Also the only parts moving at double the speed are the motor armature and the belt. These are very light and so have little mass to stop and start. All in all I think this works really well but let me know what you think.

After installing set the X Y steps per mm to exactly double.

[www.thingiverse.com]

I have found this eliminates a lot of lash I had on the X axis and evrything seems t move more sharply. Though the movement thing might be me having a placebo effect. Anyway it allows your Mendel to run at exactly the same speed as before with twice the positioning accuracy. The motors have to turn twice as fast though but this seems to be no problem. After all the motors now require half the torque to move the carriages so its not surprising. Also the only parts moving at double the speed are the motor armature and the belt. These are very light and so have little mass to stop and start. All in all I think this works really well but let me know what you think.

After installing set the X Y steps per mm to exactly double.

|

Re: X Y axis accuracy doubled. May 27, 2011 03:59PM |

Registered: 13 years ago Posts: 7,616 |

Ah, a little genius! Congratulations to this excellent idea!

The more exact movement is not too surprising, as not only the motor tourque is cut in half, but also the forces on the motor and belt end mounts.

The more exact movement is not too surprising, as not only the motor tourque is cut in half, but also the forces on the motor and belt end mounts.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: X Y axis accuracy doubled. May 27, 2011 04:21PM |

Registered: 13 years ago Posts: 177 |

Thank you Traumflug.

I did think of all that when I was designing it but its all getting a bit blurry this late at night. I have spent the week revising some bits as they collided with things. So the physics have not been on my mind.

The next step would be to design it all directly in to the Mendel parts. I designed this to be added with minimal disassembly but if you were building from scratch it would be stronger.

In careful observation I have noticed the weak X axis can flex and I think this causes a lot of backlash errors for people. The lower forces really make a noticeable difference when printing. The almost complete elimination of lash makes the edges all meet and match up very nicely where before you would get gaps.

I need to go to bed I can't type properly now.

I did think of all that when I was designing it but its all getting a bit blurry this late at night. I have spent the week revising some bits as they collided with things. So the physics have not been on my mind.

The next step would be to design it all directly in to the Mendel parts. I designed this to be added with minimal disassembly but if you were building from scratch it would be stronger.

In careful observation I have noticed the weak X axis can flex and I think this causes a lot of backlash errors for people. The lower forces really make a noticeable difference when printing. The almost complete elimination of lash makes the edges all meet and match up very nicely where before you would get gaps.

I need to go to bed I can't type properly now.

|

Re: X Y axis accuracy doubled. May 31, 2011 12:15AM |

Registered: 13 years ago Posts: 384 |

This looks great, I can't wait to see some prints coming out

reprapworld.com

PLA, ABS, PETG multiple colors (3 and 1.75 mm) €16,49 / kg

Megatronics 3.0 €79.99 / Minitronics €37,19

reprapworld.com

PLA, ABS, PETG multiple colors (3 and 1.75 mm) €16,49 / kg

Megatronics 3.0 €79.99 / Minitronics €37,19

|

Re: X Y axis accuracy doubled. May 31, 2011 01:08PM |

Registered: 13 years ago Posts: 177 |

Had it printing all afternoon.

As requested, hears it printing and as a bonus some horrendous unshaven monster at the beginning!

Make your Mendel twice as accurate.

[www.thingiverse.com]

As requested, hears it printing and as a bonus some horrendous unshaven monster at the beginning!

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: X Y axis accuracy doubled. May 31, 2011 04:16PM |

Registered: 13 years ago Posts: 177 |

On another development note I have been trying a new way to fix my aluminium bed to the Y axis.

I didn't like the bolts with springs under and did away with that as the main support, it is too wobbly.

Instead I use the screw now without springs to adjust he leveling. The bed is attached to the Y axis by a 4mm by 50mm long stud. I drilled and tapped the bed right in the middle. Then I did the same with the aluminium sheet of the y axis but drilled it through 4mm instead of tapping.

I then screwed the stud in to the bed and locked a knut against it so it would not turn and it did not protrude through the top. I then had a knut wither side of the Y axis and used them to set the height. I fixed 3 off the old bots back locking one tight to the bed with a knut. I have a knut either side of the plastic piece it goes through so that one it can move the bed up and down. I then left the other two loose and used them to pull it in the other direction. The locked one also prevents the bed from having the slightest rotation.

The 4mm stud has enough flexibility to level the bed but is totally rigid moving back and forth so the bed cant jiggle. You have to think a little more when leveling but it not any harder when you have done it.

Make your Mendel twice as accurate.

[www.thingiverse.com]

I didn't like the bolts with springs under and did away with that as the main support, it is too wobbly.

Instead I use the screw now without springs to adjust he leveling. The bed is attached to the Y axis by a 4mm by 50mm long stud. I drilled and tapped the bed right in the middle. Then I did the same with the aluminium sheet of the y axis but drilled it through 4mm instead of tapping.

I then screwed the stud in to the bed and locked a knut against it so it would not turn and it did not protrude through the top. I then had a knut wither side of the Y axis and used them to set the height. I fixed 3 off the old bots back locking one tight to the bed with a knut. I have a knut either side of the plastic piece it goes through so that one it can move the bed up and down. I then left the other two loose and used them to pull it in the other direction. The locked one also prevents the bed from having the slightest rotation.

The 4mm stud has enough flexibility to level the bed but is totally rigid moving back and forth so the bed cant jiggle. You have to think a little more when leveling but it not any harder when you have done it.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: X Y axis accuracy doubled. May 31, 2011 08:21PM |

Registered: 13 years ago Posts: 1,780 |

|

Re: X Y axis accuracy doubled. June 01, 2011 01:00AM |

Registered: 13 years ago Posts: 128 |

MadKite: Very interesting indeed.

The only cogs necessary are on the motors. The double accuracy is achieved by using (what we call in sailing) as double purchase - means you only require half the power but have to move twice as much belt. Also, by using the belt to pull in both directions you minimise any slop.

Really neat

Here is an idea that may save some nuts/bolts by capturing the ball bearing. I cannot recall where I saw this idea (it is not mine).

The only cogs necessary are on the motors. The double accuracy is achieved by using (what we call in sailing) as double purchase - means you only require half the power but have to move twice as much belt. Also, by using the belt to pull in both directions you minimise any slop.

Really neat

Here is an idea that may save some nuts/bolts by capturing the ball bearing. I cannot recall where I saw this idea (it is not mine).

|

Re: X Y axis accuracy doubled. June 01, 2011 06:50AM |

Registered: 13 years ago Posts: 177 |

Thanks cluso99. I got my inspiration from cranes and rigging.

I'm hoping some other people try it out in the next few weeks. I'm sure it wouldn't be hard to design one for the other Mendel's but I only have the standard one to work from.

As for accuracy, I just made a 100mm round part and its circular to within .1mm. Allowing for the achievable accuracy of squirting hot plastic that really good.

Make your Mendel twice as accurate.

[www.thingiverse.com]

I'm hoping some other people try it out in the next few weeks. I'm sure it wouldn't be hard to design one for the other Mendel's but I only have the standard one to work from.

As for accuracy, I just made a 100mm round part and its circular to within .1mm. Allowing for the achievable accuracy of squirting hot plastic that really good.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: X Y axis accuracy doubled. June 16, 2011 03:27AM |

Registered: 12 years ago Posts: 20 |

|

Re: X Y axis accuracy doubled. June 16, 2011 05:31PM |

Registered: 13 years ago Posts: 177 |

The mechanism will work for any machine that uses belts like a Mendel. You just need to find somewhere to clamp the belt on the outside and design a pulley like mine for the carriage. As long as there is space to fit it in it will work.

I don't think mine will fit a Pursa. The Y axis clamp parts for the belt might as they just clamp to the 8mm studding but the rest would need new parts I'm sure. I don't have one (Yet.) so I have little to design from.

Make your Mendel twice as accurate.

[www.thingiverse.com]

I don't think mine will fit a Pursa. The Y axis clamp parts for the belt might as they just clamp to the 8mm studding but the rest would need new parts I'm sure. I don't have one (Yet.) so I have little to design from.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: X Y axis accuracy doubled. June 30, 2011 02:05PM |

Registered: 12 years ago Posts: 7 |

Soon to be new reprapper, and I'm already hunting down useful mods and such to make when I pull a Ship of Theseus on my Clonedel parts. This is now on my list of absolutely brilliant mods to make.

You've done even better than just reducing backlash and increasing accuracy with this mod. By adding a 2:1 gear ratio between the motor and the load, you've actually reduced the reflected inertia of the load at the motor shaft by 4:1. That means the stepper needs 1/4th the torque to accelerate the carriage. So you should be able to at least double your acceleration without losing steps. Quadrupling the acceleration might not work, since you still have rotor inertia in there, but you should definitely be able to greatly increase your acceleration. Or increase your max speed if your firmware doesn't have acceleration. This almost certainly explains the movements being snappier.

Ideally, the reflected load inertia should equal the motor rotor inertia so you're operating at as low a torque as possible without putting excessive energy into accelerating your motor rotor. Just based off a large NEMA 17 rotor inertia and the 8 tooth T5 pulley, an ideal load for the X or Y axis is about 110g. (!) Your simple modification moves that up to 440g, which sounds a lot closer to the actual load on the Y axis. I predict your steppers are running cooler and happier as a result of all this. The only real downside I see is that you're using twice as much belt and flexing and reverse flexing significant segments of the belt. You've probably halved or quartered the life of the belt, but I gather the life of the belts is pretty significant anyways, so it's clearly worth it.

So I think you should definitely work up the parts to implement this on a Mendel from scratch since it's a significant upgrade over the standard mechanics.. As soon as I get my printer up and my toolchain together I'm going to look at porting this to the Prusa as well.

You've done even better than just reducing backlash and increasing accuracy with this mod. By adding a 2:1 gear ratio between the motor and the load, you've actually reduced the reflected inertia of the load at the motor shaft by 4:1. That means the stepper needs 1/4th the torque to accelerate the carriage. So you should be able to at least double your acceleration without losing steps. Quadrupling the acceleration might not work, since you still have rotor inertia in there, but you should definitely be able to greatly increase your acceleration. Or increase your max speed if your firmware doesn't have acceleration. This almost certainly explains the movements being snappier.

Ideally, the reflected load inertia should equal the motor rotor inertia so you're operating at as low a torque as possible without putting excessive energy into accelerating your motor rotor. Just based off a large NEMA 17 rotor inertia and the 8 tooth T5 pulley, an ideal load for the X or Y axis is about 110g. (!) Your simple modification moves that up to 440g, which sounds a lot closer to the actual load on the Y axis. I predict your steppers are running cooler and happier as a result of all this. The only real downside I see is that you're using twice as much belt and flexing and reverse flexing significant segments of the belt. You've probably halved or quartered the life of the belt, but I gather the life of the belts is pretty significant anyways, so it's clearly worth it.

So I think you should definitely work up the parts to implement this on a Mendel from scratch since it's a significant upgrade over the standard mechanics.. As soon as I get my printer up and my toolchain together I'm going to look at porting this to the Prusa as well.

|

Re: X Y axis accuracy doubled. June 30, 2011 07:37PM |

Registered: 13 years ago Posts: 486 |

|

Re: X Y axis accuracy doubled. June 30, 2011 08:15PM |

Registered: 13 years ago Posts: 1,780 |

|

Re: X Y axis accuracy doubled. July 01, 2011 01:28AM |

Registered: 14 years ago Posts: 3,742 |

Quote

brnrd

I also thought that the having the belt turn with the teeth facing outside leads to belt failure according to Nophead.

Having the teeth face outside is an advantage of the Mendel X-axis design!

The problem that nophead was referring to is the 90° angles used on the Mendel motor bracket.

This causes fatigue on the belts and after enough hours of use the belt breaks (this took 6 months to happen to me, I am sure with nophead and his 24/7 machine use this occurred monthly). The modified Mendel motor bracket only has 45° bends reducing the fatigue on the belt.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: X Y axis accuracy doubled. July 01, 2011 03:18AM |

Admin Registered: 17 years ago Posts: 7,879 |

The belt specification has a minimum pulley diameter, which is IIRC10 teeth if it flexes only forwards, so we are slightly out of spec. When it flexes both ways the minimum pulley size is a lot bigger so we are way out of spec. My belts snapped after printing about 4 Mendels, which is about 200 hours. I could stretch it to 10 by turning the belt round half way through. Since I went to only bending one way it has lasted more than a year of continuous printing.

I don't think the angle at each bend matters much, it is the total angle the belt flexes through when it goes through all the pulleys. With the original design that was +/-180 with the new design it is just 180. I don't know if my hack here will have a problem [hydraraptor.blogspot.com] as one half of the belt flexes through 180 and the other -180 but over a bigger diameter. It depends if the limitation is due to the total angle it bends through, or if bending backwards is worse than forwards.

This new scheme does look like it would break belts as it does bend the end sections both ways.

[www.hydraraptor.blogspot.com]

I don't think the angle at each bend matters much, it is the total angle the belt flexes through when it goes through all the pulleys. With the original design that was +/-180 with the new design it is just 180. I don't know if my hack here will have a problem [hydraraptor.blogspot.com] as one half of the belt flexes through 180 and the other -180 but over a bigger diameter. It depends if the limitation is due to the total angle it bends through, or if bending backwards is worse than forwards.

This new scheme does look like it would break belts as it does bend the end sections both ways.

[www.hydraraptor.blogspot.com]

|

Re: X Y axis accuracy doubled. July 01, 2011 12:47PM |

Registered: 13 years ago Posts: 177 |

Well I can report on belt breaking problem now.

So far I have had the Y axis not break but the steel banding inside snapped and so it stretched out causing massive inaccuracy. I'm thinking of getting some belting with Kevlar banding instead for it. Curiously though the X axis shows no sign of deterioration. And the breaks happen to the sections that pass over the drive gear most frequently. A small section of the belt was affected causing 3 breaks as I have my settings so if I print one part its in the middle. This section when printing in the middle would not get bent the other way when printing most object as the movements were normally too short.

Basically the steel snaps and then the plastic of the belt stretches out until it would break if you ran it enough. It gets really inaccurate though when this is happening. And it appears to be the bending round the drive cog not the added barrings that does it. I think the X axis is not as affected as the angel is less then the Y over the cog.

I might have to redesign the Y brackets to make the angle less so its more like the X axis angle if its possible.

But the Kevlar might solve it.

Make your Mendel twice as accurate.

[www.thingiverse.com]

So far I have had the Y axis not break but the steel banding inside snapped and so it stretched out causing massive inaccuracy. I'm thinking of getting some belting with Kevlar banding instead for it. Curiously though the X axis shows no sign of deterioration. And the breaks happen to the sections that pass over the drive gear most frequently. A small section of the belt was affected causing 3 breaks as I have my settings so if I print one part its in the middle. This section when printing in the middle would not get bent the other way when printing most object as the movements were normally too short.

Basically the steel snaps and then the plastic of the belt stretches out until it would break if you ran it enough. It gets really inaccurate though when this is happening. And it appears to be the bending round the drive cog not the added barrings that does it. I think the X axis is not as affected as the angel is less then the Y over the cog.

I might have to redesign the Y brackets to make the angle less so its more like the X axis angle if its possible.

But the Kevlar might solve it.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: X Y axis accuracy doubled. July 01, 2011 01:05PM |

Registered: 13 years ago Posts: 177 |

Greg Frost

The reduced backlash is because of the reduced strain on the components that pulls the carriages back and forth.

I had a big problem with X axis backlash which this completely solved.

Edited 1 time(s). Last edit at 07/01/2011 01:06PM by Madkite.

Make your Mendel twice as accurate.

[www.thingiverse.com]

The reduced backlash is because of the reduced strain on the components that pulls the carriages back and forth.

I had a big problem with X axis backlash which this completely solved.

Edited 1 time(s). Last edit at 07/01/2011 01:06PM by Madkite.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: X Y axis accuracy doubled. July 01, 2011 01:26PM |

Registered: 13 years ago Posts: 177 |

KSevcik

Thanks for the comment.

I hadn't worked out the torque calculations but the acceleration and to speed way exceed what I can make the extruder do anyway. That's why I was thinking about the accuracy more. The reduced torque is just a side benefit really.

The X belt lasts just the same it appears. The Y is my problem right now as it only got through one reel of plastic and failed. A couple of months printing something every day. Probably 6 to 8 hours a day and that's it. I think if I put a sleave on the lower idler baring on the Y axis brackets and run the belt round the other side under the studding across the middle instead of over the top and hopefully that might do the trick.

Make your Mendel twice as accurate.

[www.thingiverse.com]

Thanks for the comment.

I hadn't worked out the torque calculations but the acceleration and to speed way exceed what I can make the extruder do anyway. That's why I was thinking about the accuracy more. The reduced torque is just a side benefit really.

The X belt lasts just the same it appears. The Y is my problem right now as it only got through one reel of plastic and failed. A couple of months printing something every day. Probably 6 to 8 hours a day and that's it. I think if I put a sleave on the lower idler baring on the Y axis brackets and run the belt round the other side under the studding across the middle instead of over the top and hopefully that might do the trick.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: X Y axis accuracy doubled. July 04, 2011 03:34PM |

Registered: 13 years ago Posts: 177 |

I replaced and reconfigured the belt on the Y axis this weekend. Turns out you can run the belt under the studying without modification. I just had to take out one of the motor screws or the belt hits it.

So now the angle around the Y cog is reduced I will see how long it lasts. Got some Kevlar belt to try next time too.

Make your Mendel twice as accurate.

[www.thingiverse.com]

So now the angle around the Y cog is reduced I will see how long it lasts. Got some Kevlar belt to try next time too.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: X Y axis accuracy doubled. August 09, 2011 07:31PM |

Registered: 16 years ago Posts: 438 |

It should also be fairly trivial to reroute the belt so it goes the other direction around the pulleys on the X carriage. It would be more difficult to anchor the ends of the belt, as the ends would be on the inside. Since the belts would bend only one direction (inward) it should eliminate the breaking issue.

--

I'm building it with Baling Wire

____________ / ___ ___ \ | \ / | \____/ \____/

--

I'm building it with Baling Wire

|

Re: X Y axis accuracy doubled. August 10, 2011 05:00PM |

Registered: 13 years ago Posts: 177 |

I ended up putting the Kevlar belt on the Y axis. But the X axis is still running the same old steel cored belt and bending it both ways with no problem! The Kevlar is better though being more flexible so going round smaller pulleys is possible. But I don't know why it is fine on the X but not on the Y.

While that configuration would stop it bending both ways it would require extensive modification to the machine to do. A Kevlar belt is much easier.

Make your Mendel twice as accurate.

[www.thingiverse.com]

While that configuration would stop it bending both ways it would require extensive modification to the machine to do. A Kevlar belt is much easier.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: X Y axis accuracy doubled. August 11, 2011 01:12AM |

Registered: 14 years ago Posts: 3,742 |

And WHERE can you by Kevlar T5 timing belts from?

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: X Y axis accuracy doubled. August 11, 2011 04:23AM |

Registered: 12 years ago Posts: 1,611 |

jgilmore Wrote:

-------------------------------------------------------

> It should also be fairly trivial to reroute the

> belt so it goes the other direction around the

> pulleys on the X carriage.

I think that's what a respondent to Madkite on the thingiverse page has done in this video: [www.youtube.com]

-------------------------------------------------------

> It should also be fairly trivial to reroute the

> belt so it goes the other direction around the

> pulleys on the X carriage.

I think that's what a respondent to Madkite on the thingiverse page has done in this video: [www.youtube.com]

|

Re: X Y axis accuracy doubled. August 11, 2011 10:47AM |

Registered: 13 years ago Posts: 177 |

You can buy it here. I'm sure other belting shops carry it too.

[www.beltingonline.com]

I would run the belt like that if I built a printer from scratch but it was an impractical solution when modifying Mendel. I rather like the way the belt runs on that printer though.

Make your Mendel twice as accurate.

[www.thingiverse.com]

[www.beltingonline.com]

I would run the belt like that if I built a printer from scratch but it was an impractical solution when modifying Mendel. I rather like the way the belt runs on that printer though.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: X Y axis accuracy doubled. August 12, 2011 12:47AM |

Registered: 14 years ago Posts: 3,742 |

Those belts are also steel reinforced.

The above indicates that his Kevlar belts do not have steel reinforcement - or have I read something into his text that isn't there?

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Quote

MadKite

I ended up putting the Kevlar belt on the Y axis. But the X axis is still running the same old steel cored belt and bending it both ways with no problem! The Kevlar is better though being more flexible so going round smaller pulleys is possible. But I don't know why it is fine on the X but not on the Y.

The above indicates that his Kevlar belts do not have steel reinforcement - or have I read something into his text that isn't there?

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: X Y axis accuracy doubled. August 12, 2011 03:08AM |

Registered: 13 years ago Posts: 177 |

The Kevlar replaces the steel and it is stronger and more flexible so does not crack and snap like the steel banding does. It is more expensive however. But not by any considerable about regarding the length required for a reprap.

Make your Mendel twice as accurate.

[www.thingiverse.com]

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: X Y axis accuracy doubled. August 12, 2011 03:24AM |

Registered: 14 years ago Posts: 3,742 |

Looks much cheaper to me:

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

You selected: Width: 5 Length: 6 Type: Not Required Tension: Kevlar Material: Standard 590 White PU Total: £18.42 ex VAT

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: X Y axis accuracy doubled. August 13, 2011 07:51AM |

Registered: 12 years ago Posts: 139 |

On the orginal claim that this is more accurate... I'm running a 19mm dia pulley on my stepper. On the straight thru design for every revolution on the pulley the extruder moves Pi*D. In this design the motion is cut in half, so the stepper reduced (like going with a 8.5mm pulley but that would result in belt life issues). Most steppers are running at 200 steps per rev meaning for each step in the std design the extruder travels 0.3mm. But most of us are running with microstep drives that run at 1/16 steps. So the distance moved is actully 0.018 (18 microns) per step.

So when you see code like this:

G1 X44.19 Y25.19 E2.375

G1 X41.09 Y24.7 E2.482

G1 X35.49 Y25.34 E2.674

G1 X31.34 Y27.35 E2.831

it does its best to achieve the hundredth values to say +/- 10 microns... meaning that .19 could be .20 or .18.

Doubling the accurcy would result in +/- 5 microns... you can do the math.

The claim is true but I don't think meaningful in the real world when you consider compliance in the extruder extention tube, belt flex, pulley mounding flex, ect. In other words when comparing the results of machines built with two different designs, you won't see any difference.

So when you see code like this:

G1 X44.19 Y25.19 E2.375

G1 X41.09 Y24.7 E2.482

G1 X35.49 Y25.34 E2.674

G1 X31.34 Y27.35 E2.831

it does its best to achieve the hundredth values to say +/- 10 microns... meaning that .19 could be .20 or .18.

Doubling the accurcy would result in +/- 5 microns... you can do the math.

The claim is true but I don't think meaningful in the real world when you consider compliance in the extruder extention tube, belt flex, pulley mounding flex, ect. In other words when comparing the results of machines built with two different designs, you won't see any difference.

|

Re: X Y axis accuracy doubled. September 09, 2011 07:29PM |

Registered: 12 years ago Posts: 91 |

Sorry, only registered users may post in this forum.