How to modify a standard RAMPS 1.4 to work with Arduino Due?

Posted by AndrewBCN

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 06, 2015 06:28AM |

Registered: 10 years ago Posts: 501 |

Quote

dc42

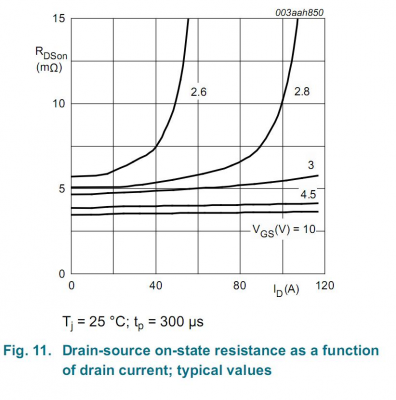

Now suppose we have a device with the maximum 2.5V gate threshold voltage. To a first approximation, we have lost 0.5V gate drive. So to account for the worst case, we should use the 2.5V curve. That shows that the device would drop about 15V @ 10A! I stress that this only gives a rough idea of the worst case, it is not precise.

What I can see is, with VGS=2.5V & VDS=15V the FET will eat 10A, nothing more.

But I cannot see the RDSon, power lost or whatever, of a FET with 2.5V threshold, 2.8V VGS and 24V VDS.

I may assume it'll be not fine but I can't read it out.

One year ago I switched the FETs on two RAMPS to IRLB3034, with MEGA2560 they are working pretty fine.

Now I'm thinking on a RAMPS combined with a DUE, 2 IRLBs still lying around.

My transistor tester says: FET1 2.9V, FET2 3.0V.

(

(Yesterday I took a look at RADDS's, it uses a BUK954R8.

Unfortunately Conrad doesn't sell those....

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 06, 2015 07:55AM |

Registered: 10 years ago Posts: 14,672 |

Quote

bianchifan

Yesterday I took a look at RADDS's, it uses a BUK954R8.

Unfortunately Conrad doesn't sell those....

That mosfet doesn't give any Rds(on) data for Vgs=3V either. As far as I am aware, it is not possible to get a mosfet with a specified Rds(on) @ Vgs=3.0V and Ids greater than about 5A. I spent a while looking for such a mosfet recently, to use on my budget 32-bit controller board.

Any sound, reproducible design for a heated bed driver suitable for use with 3.3v electronics should use one of the following techniques:

1. Amplify the gate drive signal from 3.3V nominal to about 5V.

2. Use 3 or more mosfets in parallel, where each has a specified Rds(on) @ Vgs=3.0V and Ids = 1/3 of the rated maximum heater current.

3. For every board manufactured, measure the voltage drop of the mosfet with a 10A load (or whatever the max rated load is supposed to be) and with the 3.3V drive set to the minimum level that may be found on a Due. Reject all boards that have too high a voltage drop (or replace the mosfet and re-test).

4. Use a mosfet that has eluded me, for which Rds(on) @ Vgs=3V is specified for Ids=10A or more. I expect such mosfets will become available within a year or two.

There is another very good reason to use technique (1), with inverting drivers, which is that the Arduino Due outputs have pullups enabled by default after a processor reset. Using inverting drivers means the heater will be off by default instead of on.

Edited 1 time(s). Last edit at 05/06/2015 08:00AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 06, 2015 11:27AM |

Registered: 10 years ago Posts: 203 |

Hope is useful, Ramps-FD v1a by Geeetech, use IRLB8743PBF mosfets.

Motedis_kossel delta printer

Ramps1.4 for Due

Motedis_kossel delta printer

Ramps1.4 for Due

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 06, 2015 01:06PM |

Registered: 10 years ago Posts: 501 |

Quote

dc42

That mosfet doesn't give any Rds(on) data for Vgs=3V either.

1st page' quick reference table, RDSon, points to fig. 11

Figure 11 is showin' all we need, RDSon for VGS: 3V, 2.8V, 2.6 V.

Figure 8 shows VGS going down to 2V, with VGS=2.5V ID will be 40A.

2.6 V is the turning point with RDS dramatically rising, at 2.5 V RDS reaches 15 mOhm.

RADDS is prooved for working well without any cooling, the developer speaks of 15A (~0.7W)

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 06, 2015 01:23PM |

Registered: 9 years ago Posts: 977 |

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 06, 2015 01:34PM |

Admin Registered: 17 years ago Posts: 7,879 |

Typically it does (note the graph says "typical values"), but there is no guaranteed maximum value for RDSon at 3V stated.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 06, 2015 04:47PM |

Registered: 10 years ago Posts: 14,672 |

I am sick and tired of saying the same thing over and over again. For (I hope) the last time:

1. Mosfets have manufacturing tolerances. To get an idea of these tolerances, take a look at the difference between minimum and maximum gate threshold voltage on the data sheets of any of the mosfets that have been referred to in recent posts.

2. THE 'TYPICAL' VALUES SHOWN ON THE GRAPHS IN THE DATASHEET ARE NOT GUARANTEED. Some devices will perform better than typical. Some will be worse.

3. No professional electronics engineer would rely on anything other than worst-case values shown on the datasheet for a mass-produced design.

If the designer of RADDS is not taking the worst-case specifications into account, then he is clearly an amateur. If he tested a small number of RADDS boards and found that they don't overheat at 15A without cooling, all that proves is that he has been lucky in that the batch of mosfets used in the boards he tested were not close to the worst-case specifications. Perhaps he will continue to be lucky, and none of the batches of mosfets used in producing future boards will overheat at a typical 10A heated bed current. Or perhaps he won't, and some users of RADDS boards will find that the heated bed mosfet experiences thermal runaway.

To me (and any electronics engineer worth his salt), relying on a device performing well away from its published worst-case specifications is totally unacceptable in mass-produced electronics. That is why my budget 32-bit controller board includes a driver to raise the gate voltage to 5V nominal - and invert it to ensure that the default state when the firmware fails to start up or the device is being programmed is for the heaters to be off, without relying on a pulldown resistor being strong enough to overcome the internal pullup resistor in the microcontroller on the Due. The RADDS uses 33K pulldown resistors, which appears a bit weak considering that the internal pullup resistors in the Due may be as low as 50K.

You don't find the mosfets being driven out of worst-case spec on professionally designed boards such as the Duet and the Smoothieboard.

Edited 4 time(s). Last edit at 05/06/2015 05:11PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. Mosfets have manufacturing tolerances. To get an idea of these tolerances, take a look at the difference between minimum and maximum gate threshold voltage on the data sheets of any of the mosfets that have been referred to in recent posts.

2. THE 'TYPICAL' VALUES SHOWN ON THE GRAPHS IN THE DATASHEET ARE NOT GUARANTEED. Some devices will perform better than typical. Some will be worse.

3. No professional electronics engineer would rely on anything other than worst-case values shown on the datasheet for a mass-produced design.

If the designer of RADDS is not taking the worst-case specifications into account, then he is clearly an amateur. If he tested a small number of RADDS boards and found that they don't overheat at 15A without cooling, all that proves is that he has been lucky in that the batch of mosfets used in the boards he tested were not close to the worst-case specifications. Perhaps he will continue to be lucky, and none of the batches of mosfets used in producing future boards will overheat at a typical 10A heated bed current. Or perhaps he won't, and some users of RADDS boards will find that the heated bed mosfet experiences thermal runaway.

To me (and any electronics engineer worth his salt), relying on a device performing well away from its published worst-case specifications is totally unacceptable in mass-produced electronics. That is why my budget 32-bit controller board includes a driver to raise the gate voltage to 5V nominal - and invert it to ensure that the default state when the firmware fails to start up or the device is being programmed is for the heaters to be off, without relying on a pulldown resistor being strong enough to overcome the internal pullup resistor in the microcontroller on the Due. The RADDS uses 33K pulldown resistors, which appears a bit weak considering that the internal pullup resistors in the Due may be as low as 50K.

You don't find the mosfets being driven out of worst-case spec on professionally designed boards such as the Duet and the Smoothieboard.

Edited 4 time(s). Last edit at 05/06/2015 05:11PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 06, 2015 05:29PM |

Registered: 8 years ago Posts: 1 |

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 06, 2015 05:53PM |

Registered: 9 years ago Posts: 977 |

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 06, 2015 07:09PM |

Registered: 10 years ago Posts: 14,672 |

Quote

pgScorpio

The IRLZ44N Does the job too (maybe even better).

55V / 25A @Vgs = 3.3v

VGS(th) Gate Threshold Voltage 1.0 – 2.0 V !

The datasheet I found (at [www.irf.com]) only quotes Rds(on) down to 4.0V. Perhaps you have found a different datasheet? It's not unknown for different manufacturers of the same part number to quote different specifications, although it is unusual. But as Andrew says, the Rds(on) of the IRLZ44 is too high to make it a good choice for the heated bed mosfet (0.035 ohms @ Vgs=4V Ids=21A according to the datasheet I just linked to).

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 25, 2015 12:57PM |

Registered: 11 years ago Posts: 88 |

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 25, 2015 01:48PM |

Registered: 9 years ago Posts: 977 |

Quote

f3rDz

will there be any other modifications to do if i will be supplying 24v on the hacked ramps?

i'm not that knowledgeable in electronics

Hi,

There are a few threads in this forum about using 24V with a RAMPS 1.4, but basically the RAMPS was designed for 12V operation, 24V operation is considered experimental and unsupported. IMO it also has practically zero benefits for RepRap use and adds considerable reliability and safety concerns.

If you are already modifying a RAMPS for use with a Due I strongly advise AGAINST using 24V.

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 25, 2015 01:52PM |

Registered: 9 years ago Posts: 977 |

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 25, 2015 07:34PM |

Registered: 10 years ago Posts: 814 |

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 25, 2015 08:29PM |

Registered: 11 years ago Posts: 88 |

Quote

AndrewBCN

Quote

f3rDz

will there be any other modifications to do if i will be supplying 24v on the hacked ramps?

i'm not that knowledgeable in electronics

Hi,

There are a few threads in this forum about using 24V with a RAMPS 1.4, but basically the RAMPS was designed for 12V operation, 24V operation is considered experimental and unsupported. IMO it also has practically zero benefits for RepRap use and adds considerable reliability and safety concerns.

If you are already modifying a RAMPS for use with a Due I strongly advise AGAINST using 24V.

well i guess i have to throw away those 24v heated bed and heater cartridges.

thanks andy

Edited 1 time(s). Last edit at 05/25/2015 08:30PM by f3rDz.

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 26, 2015 02:54AM |

Registered: 10 years ago Posts: 14,672 |

Quote

f3rDz

well i guess i have to throw away those 24v heated bed and heater cartridges.

There are plenty of 24V capable boards around, such as the Duet and the Smoothieboard.

Edited 1 time(s). Last edit at 05/26/2015 09:48AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 26, 2015 07:50AM |

Registered: 9 years ago Posts: 977 |

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 26, 2015 11:09AM |

Registered: 9 years ago Posts: 4,977 |

Quote

f3rDz

Quote

AndrewBCN

Quote

f3rDz

will there be any other modifications to do if i will be supplying 24v on the hacked ramps?

i'm not that knowledgeable in electronics

Hi,

There are a few threads in this forum about using 24V with a RAMPS 1.4, but basically the RAMPS was designed for 12V operation, 24V operation is considered experimental and unsupported. IMO it also has practically zero benefits for RepRap use and adds considerable reliability and safety concerns.

If you are already modifying a RAMPS for use with a Due I strongly advise AGAINST using 24V.

well i guess i have to throw away those 24v heated bed and heater cartridges.

thanks andy

You must not. I used long time a solid state relay for my heatbed. This should also work great for a hotend.

| Triffid Hunter's Calibration Guide | --> X <-- Drill for new Monitor | Most important Gcode. |

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 26, 2015 01:03PM |

Registered: 9 years ago Posts: 977 |

Quote

Wurstnase

...

You must not. I used long time a solid state relay for my heatbed. This should also work great for a hotend.

A reasonable quality 15A DC SSR will cost you 3x or 4x the price of a new, $9 (including shipping) 12V MK2B PCB heatbed, and it adds yet another component/failure point for your 3D printer. The 12V hotend cartridges cost $1 each.

So you figure out if the added cost and complexity are worth the zero added convenience of using a 24V PSU with a RAMPS 1.4.

BTW the SSR will work fine with the bang-bang heatbed temperature control, but won't work at all with the PID switching frequencies used for the hotend cartridges.

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 26, 2015 02:44PM |

Registered: 9 years ago Posts: 4,977 |

Well. My SSR worked well with PID on my heatbed. Also you can have much more power on your heatbed with 24V. I just started to order a 24V 200x200 with 350W.

BTW, the normal frequency is realy slow. Less tehn 130Hz, doesn't remember the right number, but it's in that range. No SSR should have problems with that.

Sure a 12V heatbed is cheap, but you can have much more power with 24V.

Edit: there are some cheap fake-ssr in the market. They are good enough for our repraps. I think that this is some kind of triac. Don't know, but it works.

Edited 1 time(s). Last edit at 05/26/2015 02:46PM by Wurstnase.

BTW, the normal frequency is realy slow. Less tehn 130Hz, doesn't remember the right number, but it's in that range. No SSR should have problems with that.

Sure a 12V heatbed is cheap, but you can have much more power with 24V.

Edit: there are some cheap fake-ssr in the market. They are good enough for our repraps. I think that this is some kind of triac. Don't know, but it works.

Edited 1 time(s). Last edit at 05/26/2015 02:46PM by Wurstnase.

| Triffid Hunter's Calibration Guide | --> X <-- Drill for new Monitor | Most important Gcode. |

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 26, 2015 06:27PM |

Registered: 9 years ago Posts: 977 |

Actually triac based SSR's are AC only. DC SSR's are based on MOSFETs with - for the good quality ones - various protections that make them expen$ive. They also usually require a heatsink. And their max. operating switching frequency is usually restricted.

In the end, one would spend a lot more money and add various components to get a resulting circuitry that performs the same or worse than the cheap MOSFET on the RAMPS. This is why personally I don't recommend them. Note that I am strongly in favor of the KISS principle for RepRap 3D printers.

You also have to understand that using a separate 300W 24V DC PSU just for the heatbed is a huge waste of money and electricity. You only use the 360W during the warmup phase of the print, to actually maintain temperature the duty cycle goes down to 10~20% i.e. you are only using around 30W and wasting the rest.

In the end, one would spend a lot more money and add various components to get a resulting circuitry that performs the same or worse than the cheap MOSFET on the RAMPS. This is why personally I don't recommend them. Note that I am strongly in favor of the KISS principle for RepRap 3D printers.

You also have to understand that using a separate 300W 24V DC PSU just for the heatbed is a huge waste of money and electricity. You only use the 360W during the warmup phase of the print, to actually maintain temperature the duty cycle goes down to 10~20% i.e. you are only using around 30W and wasting the rest.

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 27, 2015 07:14AM |

Registered: 10 years ago Posts: 501 |

If you are not familiar with electronics maybe it's not the best idea..Quote

f3rDz

will there be any other modifications to do if i will be supplying 24v on the hacked ramps?

i'm not that knowledgeable in electronics

First you have to look at the capacitors for the stepsticks, 35V should be ok, 25V isn't enough, 16V...

In case of exchange 50V is better than 35V.

Next point are the fuses, have a look at the wiki (24V RAMPS) please.

For supply voltage the diode has to be cut, I prefer buck circuits with retail output (no LDO).

BTW... DC-SSR are nonsense in our context, for our discussed FETs work better.

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 27, 2015 07:42AM |

Registered: 9 years ago Posts: 977 |

Well, we had two digressions in this thread:

1) Choice of 3.3V logic compatible MOSFET: conclusion, the IRLB8743 ($0.80) should work fine and the IRLB3034 ($1) should work fine too, perhaps even better.

2) Using 24V on a RAMPS modified for Due operation: just don't (and if you want to continue discussing this, please create a separate thread).

Hopefully we can go back to the main topic.

1) Choice of 3.3V logic compatible MOSFET: conclusion, the IRLB8743 ($0.80) should work fine and the IRLB3034 ($1) should work fine too, perhaps even better.

2) Using 24V on a RAMPS modified for Due operation: just don't (and if you want to continue discussing this, please create a separate thread).

Hopefully we can go back to the main topic.

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 27, 2015 08:20AM |

Registered: 11 years ago Posts: 469 |

Quote

AndrewBCN

Well, we had two digressions in this thread:

1) Choice of 3.3V logic compatible MOSFET: conclusion, the IRLB8743 ($0.80) should work fine and the IRLB3034 ($1) should work fine too, perhaps even better.

2) Using 24V on a RAMPS modified for Due operation: just don't (and if you want to continue discussing this, please create a separate thread).

Hopefully we can go back to the main topic.

So what about 18 volts ??? Just kidding

My Due just arrived but i have to travel for the next 2 weeks.....damn. cant wait to get back. Really looking forward to the continuation of this thread . Some great work and dev being done ...thanks guys.

Just a thought, well...a question really. What are the real life benefits that can be reasonably expected.

On a selfish note im looking to getting the modded ramps/Due working on a delta where i ( and many others) have experienced problems with the standard 8 bit Mega.

IS there a way to easily benchmark the performance improvements ???

Anybody have any tips on Mosfet removal ? I have replaced a blown one in the past and remember it being quite tricky as the original ones seemed to be soldered thru the PCB( i.e. soldered on both sides) EVen my trusty solder sucker didn't seem to

get all of the solder out. It was a while ago and i seem to remember having to carefully drill out the remaining solder/ mosfet legs

Cheers

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 27, 2015 08:37AM |

Admin Registered: 17 years ago Posts: 7,879 |

Assuming the MOSFETs are rated for 24V all that you need to do to use 24V heaters is to connect the positive leads direct to +24V instead of the 12V terminal on the RAMPS. That avoids problems with cap and poly fuse voltage limits. The only issue you will have is that the LEDs will get reverse biased when off. That can be fixed by putting reversed diodes across them.

To clear solder from plated through holes that go into ground planes you need a high power temperature controlled soldering iron and crank up the temperature a bit. If it is only one that is blocked it is sometimes easier to push the leg in while heating it with a soldering iron instead of clearing it out.

[www.hydraraptor.blogspot.com]

To clear solder from plated through holes that go into ground planes you need a high power temperature controlled soldering iron and crank up the temperature a bit. If it is only one that is blocked it is sometimes easier to push the leg in while heating it with a soldering iron instead of clearing it out.

[www.hydraraptor.blogspot.com]

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 27, 2015 08:38AM |

Registered: 9 years ago Posts: 4,977 |

My fast and easy way for my personal performance is a cylinder(d=50, h=10, $fn=360); or something like that. I removed any E-command and print that as fast as possible. Modify the speed with your jog or with the host.

| Triffid Hunter's Calibration Guide | --> X <-- Drill for new Monitor | Most important Gcode. |

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 27, 2015 09:04AM |

Registered: 9 years ago Posts: 977 |

Quote

bigfilsing

...

Anybody have any tips on Mosfet removal ?

...

Basically, removing the MOSFETs on the RAMPS is a PITA

, as in it takes me a good 15 minutes to remove one and properly clean the through holes, but just 1 minute to solder the new one in.

, as in it takes me a good 15 minutes to remove one and properly clean the through holes, but just 1 minute to solder the new one in.

Tools used: Hakko solder station with a flat blade-style solder tip, inexpensive spring-loaded solder sucker, and solder wick.

Note that I remove the MOSFET without cutting its leads. Cutting the leads and then unsoldering these would probably save a good few minutes, so I admit my method is far from optimal.

Also you may want to test Q1 and Q2 (the hotend heater cartridge and fan MOSFETs) before replacing them, as they may or may not work correctly with 3.3V logic levels. Q3 is more critical and personally I suggest replacing it regardless.

Edited 2 time(s). Last edit at 05/27/2015 09:36AM by AndrewBCN.

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 27, 2015 10:36AM |

Registered: 10 years ago Posts: 814 |

Patience, Soldering Iron, Sucker, and Wick is required to replace the mosfet. I usually cut the leads of the old mosfet to get the body out of the way. Add a touch of fresh solder or flux to both the component side and solder side of each lead. The fresh flux will help with solder removal. Remove legs one at a time by grabbing with needle nose pliers and apply heat on solder side. Clear hole by applying heat and quickly use sucker. Sometime wicking wire will help with stubborn holes. Try not to over heat any hole. Be ready to walk away and let the board cool rather than causing damage by overheating a pad.

I used to work in an electronics assembly plant, and have a lot of experience in electronic repair. I have replaced a few heatbed mosfets upgrading the RAMPS boards I have, but for this I chose to order a bare board kit. I can solder in the fresh parts faster then I can replace three mosfets in tight quarters.

I used to work in an electronics assembly plant, and have a lot of experience in electronic repair. I have replaced a few heatbed mosfets upgrading the RAMPS boards I have, but for this I chose to order a bare board kit. I can solder in the fresh parts faster then I can replace three mosfets in tight quarters.

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 27, 2015 11:23AM |

Registered: 9 years ago Posts: 590 |

Cutting the leads of the MOSFET to be removed definitely makes things easier.

To clean the holes from the old solder, I found that using a hollow steel needle of the corresponding size is much easier for me compared to using solder wick and/or my (simple spring loaded) suction pump. Check for "hollow needles desoldering tool" on eBay to see the type of tool that I use.

To clean the holes from the old solder, I found that using a hollow steel needle of the corresponding size is much easier for me compared to using solder wick and/or my (simple spring loaded) suction pump. Check for "hollow needles desoldering tool" on eBay to see the type of tool that I use.

Re: How to modify a standard RAMPS 1.4 to work with Arduino Due? May 27, 2015 12:04PM |

Registered: 9 years ago Posts: 131 |

Sorry, only registered users may post in this forum.