first connection of my RAMPS V1.4

Posted by jepigepas

|

Re: first connection of my RAMPS V1.4 November 03, 2015 02:57AM |

Admin Registered: 13 years ago Posts: 7,000 |

poly fuses do get hot, when to much current goes threw them, this is how they cut off

Make sure your heated bed wires are nice and thick.

Make sure the wire from your 12v to the 11amp plugs is nice and thick

Make sure the 11amp screw terminals are nice and tight.

Check the resistance of your bed (this is quite low, and some meters just will not read that low, normally about 0.8 - 1.1 ohms, presuming 12v heated bed)

Hopefully your meter can read that low and check that the bed isn’t just a short

Edited 1 time(s). Last edit at 11/03/2015 02:59AM by Dust.

Make sure your heated bed wires are nice and thick.

Make sure the wire from your 12v to the 11amp plugs is nice and thick

Make sure the 11amp screw terminals are nice and tight.

Check the resistance of your bed (this is quite low, and some meters just will not read that low, normally about 0.8 - 1.1 ohms, presuming 12v heated bed)

Hopefully your meter can read that low and check that the bed isn’t just a short

Edited 1 time(s). Last edit at 11/03/2015 02:59AM by Dust.

|

Re: first connection of my RAMPS V1.4 November 03, 2015 08:15AM |

Registered: 11 years ago Posts: 469 |

|

Re: first connection of my RAMPS V1.4 November 03, 2015 08:53AM |

Registered: 8 years ago Posts: 53 |

|

Re: first connection of my RAMPS V1.4 November 03, 2015 10:20AM |

Registered: 11 years ago Posts: 469 |

Quote

jepigepas

I have measured 1.6 ohms on mine.

I have seen on the bed resistor from where came the slam. A bubble under the coating has exploded !

I think that my resistor has some short cut.

The problem is that I have no other resistor by me...

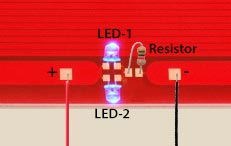

If that's the surface resistor then its only for the indicator LED !! you should be able to use the bed without the LED and resistor

Edited 1 time(s). Last edit at 11/03/2015 10:21AM by bigfilsing.

|

Re: first connection of my RAMPS V1.4 November 03, 2015 10:45AM |

Registered: 8 years ago Posts: 53 |

|

Re: first connection of my RAMPS V1.4 November 03, 2015 11:10AM |

Registered: 11 years ago Posts: 469 |

Quote

jepigepas

I have no LED on my bed resistance

I am manufacturing a resistance with pencil leads.

I'll put it in series with the bed restance in order to have an overall resistance of 2.5 Ohms.

I have no idea how that will work. If your heated bed is indeed defect then i think you may just have to buy a new one.

|

Re: first connection of my RAMPS V1.4 November 03, 2015 12:36PM |

Registered: 8 years ago Posts: 53 |

Yes but I have a lack of time.Quote

bigfilsing

Quote

jepigepas

I have no LED on my bed resistance

I am manufacturing a resistance with pencil leads.

I'll put it in series with the bed restance in order to have an overall resistance of 2.5 Ohms.

I have no idea how that will work. If your heated bed is indeed defect then i think you may just have to buy a new one.

|

Re: first connection of my RAMPS V1.4 November 03, 2015 08:39PM |

Registered: 8 years ago Posts: 53 |

Hello here are the last news of my experience.

I did a test with a resistance of 1.7 ohms in series with the bed resistance.

I made 5 degree increments up to a 60 ° C setpoint.

The bed temperature has increased more slowly as yesterday up to 55 ° C, but suddenly it began to climb faster.

The polyfuse began to warm more.

And the temperature has exceeded the setpoint of 60 ° C up to 68 ° C.

I stopped everything, but I have observed that a thyristor was blackened and he burned the insulation of a wire that touched it.

I send more details tomorrow with photos I hope.

good night,

Jack

I did a test with a resistance of 1.7 ohms in series with the bed resistance.

I made 5 degree increments up to a 60 ° C setpoint.

The bed temperature has increased more slowly as yesterday up to 55 ° C, but suddenly it began to climb faster.

The polyfuse began to warm more.

And the temperature has exceeded the setpoint of 60 ° C up to 68 ° C.

I stopped everything, but I have observed that a thyristor was blackened and he burned the insulation of a wire that touched it.

I send more details tomorrow with photos I hope.

good night,

Jack

|

Re: first connection of my RAMPS V1.4 November 04, 2015 01:13AM |

Registered: 11 years ago Posts: 469 |

I think you may just have to accept that your heated bed is defect and source a new one before you damage the ramps board.

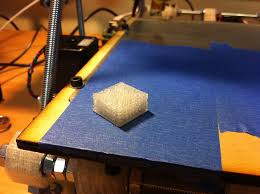

You can still print PLA without a heated bed ( using painters blue tape) so you could still experiment with your printer while you wait for a new heated bed!

Its normal for the thyristors to get warm/ hot, especially the one driving the heated bed but not hot enough to melt wire insulation.

I am concerned that you will do some irreparable damage to your ramps board.

Edited 1 time(s). Last edit at 11/04/2015 01:13AM by bigfilsing.

You can still print PLA without a heated bed ( using painters blue tape) so you could still experiment with your printer while you wait for a new heated bed!

Its normal for the thyristors to get warm/ hot, especially the one driving the heated bed but not hot enough to melt wire insulation.

I am concerned that you will do some irreparable damage to your ramps board.

Edited 1 time(s). Last edit at 11/04/2015 01:13AM by bigfilsing.

|

Re: first connection of my RAMPS V1.4 November 04, 2015 02:25AM |

Registered: 8 years ago Posts: 53 |

Quote

bigfilsing

I think you may just have to accept that your heated bed is defect and source a new one before you damage the ramps board.

You can still print PLA without a heated bed ( using painters blue tape) so you could still experiment with your printer while you wait for a new heated bed!

Its normal for the thyristors to get warm/ hot, especially the one driving the heated bed but not hot enough to melt wire insulation.

I am concerned that you will do some irreparable damage to your ramps board.

Could you please precise what you mean (using painters bleu tape)?

Do you advise me to paint the glass of the heated bed?

Or do you mean of an adhesive tape which has to be glued on the bed?

|

Re: first connection of my RAMPS V1.4 November 04, 2015 02:56AM |

Registered: 11 years ago Posts: 469 |

Quote

jepigepas

Quote

bigfilsing

I think you may just have to accept that your heated bed is defect and source a new one before you damage the ramps board.

You can still print PLA without a heated bed ( using painters blue tape) so you could still experiment with your printer while you wait for a new heated bed!

Its normal for the thyristors to get warm/ hot, especially the one driving the heated bed but not hot enough to melt wire insulation.

I am concerned that you will do some irreparable damage to your ramps board.

Could you please precise what you mean (using painters bleu tape)?

Do you advise me to paint the glass of the heated bed?

Or do you mean of an adhesive tape which has to be glued on the bed?

I think you may need to read up a bit more about 3D printing .

Before heated beds were readily available we printed PLA onto standard none heated beds. That of course had some issues with the printed part not sticking to the bed or in some cases sticking too well.

to make life easier many people started using blue painters tape to print on

|

Re: first connection of my RAMPS V1.4 November 04, 2015 05:59PM |

Registered: 11 years ago Posts: 1,049 |

Once again Marlin Configuration.h set up right?

[github.com]

shows Marlin Configuration.h

There are selections for :

Type of thermistor on extruder and bed.(100K)

Min / max temp for heaters

Heater control (bang bang- full ON full OFF) to Pulse Width Modulation (PWM) settings

Max power delivered to heater

I am surprised this is not set up in Mendalmax firmware

but your build is custom requiring custom settings

LED on heater bed is almost a must --- best reminder that bed is heating --- getting power!

Blue painters tape, or Kapton tape atop bed glass (or other substance) is common application to get first layer to stick

Glass bed is cheap, very flat, and thermally good for PLA, ABS

[github.com]

shows Marlin Configuration.h

There are selections for :

Type of thermistor on extruder and bed.(100K)

Min / max temp for heaters

Heater control (bang bang- full ON full OFF) to Pulse Width Modulation (PWM) settings

Max power delivered to heater

I am surprised this is not set up in Mendalmax firmware

but your build is custom requiring custom settings

LED on heater bed is almost a must --- best reminder that bed is heating --- getting power!

Blue painters tape, or Kapton tape atop bed glass (or other substance) is common application to get first layer to stick

Glass bed is cheap, very flat, and thermally good for PLA, ABS

|

Re: first connection of my RAMPS V1.4 November 07, 2015 09:32PM |

Registered: 8 years ago Posts: 53 |

Hello all of you,

I must thank you very much for your help !

Thank you Dust,

Thank you Bigfilsing,

Thank you Cozmicray,

Thanks to you I was finally able to print my first pieces using PLA.

My bed heating is out of order, so I have used blue painter's tape that I have put on a removable plastic sheet. So it is very easy to pick up the piece after printing.

I just wonder if it possible to print with ABS without bed heating ?

thanks again and best regards,

Jack

I must thank you very much for your help !

Thank you Dust,

Thank you Bigfilsing,

Thank you Cozmicray,

Thanks to you I was finally able to print my first pieces using PLA.

My bed heating is out of order, so I have used blue painter's tape that I have put on a removable plastic sheet. So it is very easy to pick up the piece after printing.

I just wonder if it possible to print with ABS without bed heating ?

thanks again and best regards,

Jack

|

Re: first connection of my RAMPS V1.4 November 08, 2015 01:20AM |

Registered: 11 years ago Posts: 469 |

Quote

jepigepas

Hello all of you,

I must thank you very much for your help !

Thank you Dust,

Thank you Bigfilsing,

Thank you Cozmicray,

Thanks to you I was finally able to print my first pieces using PLA.

My bed heating is out of order, so I have used blue painter's tape that I have put on a removable plastic sheet. So it is very easy to pick up the piece after printing.

I just wonder if it possible to print with ABS without bed heating ?

thanks again and best regards,

Jack

You are welcome. Thanks for taking time out to say thanks. Many dont and i always appreciate it when people do.

ABS can be very tricky to get to stick . Thats why most slicer software has options to use a brim and/or a raft.

ABS can warp when printing so i dont think you can print without a heated bed im afraid.

E3D sells some filament called Polymax that prints like PLA but has similar properties to ABS but even that needs a heated bed.

SO i guess the easiest and best way forward is to be patient and order a replacement heated bed and save yourself a lot of wasted filament and frustration.

6 dollars on ebay ebay heated bed

or

7 dollars on banggood banggood heated bed ( Faster shipping)

Good luck

Edited 1 time(s). Last edit at 11/08/2015 01:21AM by bigfilsing.

|

Re: first connection of my RAMPS V1.4 November 08, 2015 07:24AM |

Registered: 8 years ago Posts: 53 |

Quote

bigfilsing

Quote

jepigepas

Hello all of you,

I must thank you very much for your help !

Thank you Dust,

Thank you Bigfilsing,

Thank you Cozmicray,

Thanks to you I was finally able to print my first pieces using PLA.

My bed heating is out of order, so I have used blue painter's tape that I have put on a removable plastic sheet. So it is very easy to pick up the piece after printing.

I just wonder if it possible to print with ABS without bed heating ?

thanks again and best regards,

Jack

You are welcome. Thanks for taking time out to say thanks. Many dont and i always appreciate it when people do.

ABS can be very tricky to get to stick . Thats why most slicer software has options to use a brim and/or a raft.

ABS can warp when printing so i dont think you can print without a heated bed im afraid.

E3D sells some filament called Polymax that prints like PLA but has similar properties to ABS but even that needs a heated bed.

SO i guess the easiest and best way forward is to be patient and order a replacement heated bed and save yourself a lot of wasted filament and frustration.

6 dollars on ebay ebay heated bed

or

7 dollars on banggood banggood heated bed ( Faster shipping)

Good luck

Thank you very much,

I think I will have to replace also the thyristor of the bed heating, which has completely burn.

It has become completely black and has partially made melt the bleu screw connector in front of it. The consequence has been that it behaves now as a closed switch.

That helps me in some way, because I use now that connection to make run a little fan permanently.

I must tell you about an issue that I didn't tell you before:

When I ran my first piece, I saw suddenly that the PLA wire stopped to progress.

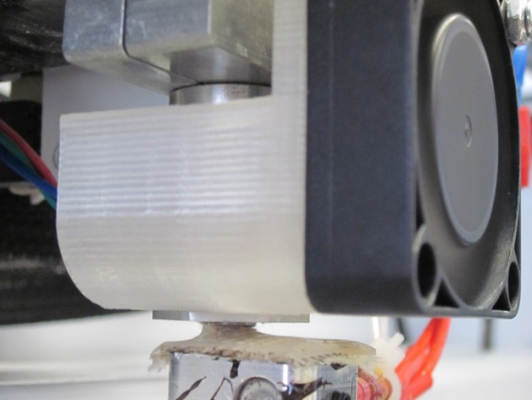

It seemed to get stuck in the extruder channel. After a lot of disassemblies/reassemblies, I noticed that the radiator of the channel was very hot.

The PLA was melting in the chanel, that is to say far away before to enter the nozzle of the extruder.

That is the raison of the little fan that I have placed very close to the extruder channel.

Now the channel remains cold and the PLA melt in the right place.

best regards,

Jack

|

Re: first connection of my RAMPS V1.4 November 08, 2015 07:38AM |

Registered: 11 years ago Posts: 469 |

|

Re: first connection of my RAMPS V1.4 November 08, 2015 10:52PM |

Registered: 8 years ago Posts: 53 |

hello,

I have made 3 pieces but at the 4th, in spite of the fan, the filament stops to flow. The temperature of the heater is 197 °C. The temperature of the chanel fins is cold (one can touch it easily with a finger).

I don't know how solve this new issue.

Have you had this kind of issue some times ?

I have made 3 pieces but at the 4th, in spite of the fan, the filament stops to flow. The temperature of the heater is 197 °C. The temperature of the chanel fins is cold (one can touch it easily with a finger).

I don't know how solve this new issue.

Have you had this kind of issue some times ?

|

Re: first connection of my RAMPS V1.4 November 09, 2015 01:52AM |

Registered: 11 years ago Posts: 469 |

You really don't make things easy friend

What kind of hot end do you have ??? What filament are you using ? What are your basic settings for temp/speed/ printing.

With so many different printers and set ups and parts how do you expect people to give advice to help you solve your issues

That's like ringing the AA and saying my car doesn't work ...help. They would at least need to know what make of car and type and the circumstances of the issue !!!!!!!!!

What kind of hot end do you have ??? What filament are you using ? What are your basic settings for temp/speed/ printing.

With so many different printers and set ups and parts how do you expect people to give advice to help you solve your issues

That's like ringing the AA and saying my car doesn't work ...help. They would at least need to know what make of car and type and the circumstances of the issue !!!!!!!!!

|

Re: first connection of my RAMPS V1.4 November 09, 2015 04:20AM |

Registered: 8 years ago Posts: 53 |

Dear Bigfilsing,

I understand what you mean.

the diameter of hotend's nozzle is 0.4 mm

and

the filament I use is PLA

On the Arduino, I have let the predefined settings.

I have just enter heat settings in Slic3 following the wizard of the "electronic guide".

These settings are :

layer height 0.3 mm

first layer height 0.35

Speed :

perimeters 50 mm/s

small perimeters 50 mm/s or %

external perimeters 60%

Infill 50 mm/s

solid infill: 60 mm/s or %

top solid infill 50 mm/s or %

support material 60 mm/s

bridges 30 mm/s

gap fill 20 mm/s

travel 130 mm/s

first layer speed 30 mm/s or %

max print speed 80 mm/s

Filament:

diameter: 1.75 mm

extrusion multiplier: 1

Temperature: first layer 200°C ; other layers 200 °C

Bed: 0

printer settings:

Z Offset 0 mm

custom G-code:

G28; home all axes

G1 Z5 F5000; lift nozzle

End G-code:

G28 X0; home X axis

extruder:

nozzle diameter 0.4 mm

extruder offset (x: 0 ; y: 0 )

retraction:

length 0.7 mm

lift z 0

speed 15 mm/S

extra length on restart: 0

minimum travel after retraction 1 mm

That is all I see in the Slic3r.

Do you think I have any thing to change in the configuration.h ?

I understand what you mean.

the diameter of hotend's nozzle is 0.4 mm

and

the filament I use is PLA

On the Arduino, I have let the predefined settings.

I have just enter heat settings in Slic3 following the wizard of the "electronic guide".

These settings are :

layer height 0.3 mm

first layer height 0.35

Speed :

perimeters 50 mm/s

small perimeters 50 mm/s or %

external perimeters 60%

Infill 50 mm/s

solid infill: 60 mm/s or %

top solid infill 50 mm/s or %

support material 60 mm/s

bridges 30 mm/s

gap fill 20 mm/s

travel 130 mm/s

first layer speed 30 mm/s or %

max print speed 80 mm/s

Filament:

diameter: 1.75 mm

extrusion multiplier: 1

Temperature: first layer 200°C ; other layers 200 °C

Bed: 0

printer settings:

Z Offset 0 mm

custom G-code:

G28; home all axes

G1 Z5 F5000; lift nozzle

End G-code:

G28 X0; home X axis

extruder:

nozzle diameter 0.4 mm

extruder offset (x: 0 ; y: 0 )

retraction:

length 0.7 mm

lift z 0

speed 15 mm/S

extra length on restart: 0

minimum travel after retraction 1 mm

That is all I see in the Slic3r.

Do you think I have any thing to change in the configuration.h ?

|

Re: first connection of my RAMPS V1.4 November 09, 2015 05:21AM |

Registered: 8 years ago Posts: 53 |

Quote

jepigepas

Dear Bigfilsing,

I understand what you mean.

the diameter of hotend's nozzle is 0.4 mm

and

the filament I use is PLA

On the Arduino, I have let the predefined settings.

I have just enter heat settings in Slic3 following the wizard of the "electronic guide".

These settings are :

layer height 0.3 mm

first layer height 0.35

Speed :

perimeters 50 mm/s

small perimeters 50 mm/s or %

external perimeters 60%

Infill 50 mm/s

solid infill: 60 mm/s or %

top solid infill 50 mm/s or %

support material 60 mm/s

bridges 30 mm/s

gap fill 20 mm/s

travel 130 mm/s

first layer speed 30 mm/s or %

max print speed 80 mm/s

Filament:

diameter: 1.75 mm

extrusion multiplier: 1

Temperature: first layer 200°C ; other layers 200 °C

Bed: 0

printer settings:

Z Offset 0 mm

custom G-code:

G28; home all axes

G1 Z5 F5000; lift nozzle

End G-code:

G28 X0; home X axis

extruder:

nozzle diameter 0.4 mm

extruder offset (x: 0 ; y: 0 )

retraction:

length 0.7 mm

lift z 0

speed 15 mm/S

extra length on restart: 0

minimum travel after retraction 1 mm

That is all I see in the Slic3r.

Do you think I have any thing to change in the configuration.h ?

For the diameter of the nozzle, I must add that the 0.4 mm is the diameter of the wire coming out of the nozzle.

|

Re: first connection of my RAMPS V1.4 November 09, 2015 05:33AM |

Registered: 8 years ago Posts: 53 |

Quote

jepigepas

Quote

jepigepas

Dear Bigfilsing,

I understand what you mean.

the diameter of hotend's nozzle is 0.4 mm

and

the filament I use is PLA

On the Arduino, I have let the predefined settings.

I have just enter heat settings in Slic3 following the wizard of the "electronic guide".

These settings are :

layer height 0.3 mm

first layer height 0.35

Speed :

perimeters 50 mm/s

small perimeters 50 mm/s or %

external perimeters 60%

Infill 50 mm/s

solid infill: 60 mm/s or %

top solid infill 50 mm/s or %

support material 60 mm/s

bridges 30 mm/s

gap fill 20 mm/s

travel 130 mm/s

first layer speed 30 mm/s or %

max print speed 80 mm/s

Filament:

diameter: 1.75 mm

extrusion multiplier: 1

Temperature: first layer 200°C ; other layers 200 °C

Bed: 0

printer settings:

Z Offset 0 mm

custom G-code:

G28; home all axes

G1 Z5 F5000; lift nozzle

End G-code:

G28 X0; home X axis

extruder:

nozzle diameter 0.4 mm

extruder offset (x: 0 ; y: 0 )

retraction:

length 0.7 mm

lift z 0

speed 15 mm/S

extra length on restart: 0

minimum travel after retraction 1 mm

That is all I see in the Slic3r.

Do you think I have any thing to change in the configuration.h ?

For the diameter of the nozzle, I must add that the 0.4 mm is the diameter of the wire coming out of the nozzle.

according to the "configuration.h, the number of steps by unit are defined as:

(160, 160, 3200, 939)

I precise that for E the 939 correspond to an extrusion of 94 mm of wire when I had imposed 100 mm.

the default max feedrate are (500, 500, 7.5, 25)

but I don't know what it means.

the max accelerations are (3000, 3000, 100, 10000)

Default XY jerk 20 mm/s

Z jerk 0.4

E jerk 5 mm/s

|

Re: first connection of my RAMPS V1.4 November 09, 2015 06:26AM |

Registered: 11 years ago Posts: 469 |

Ok i dont think the reason for your hotend jamming is the config .h

I know it can be very frustrating when it jams but be patient. Remember there are 1000's of home printers that work fine and yours will as well if you are patient !!!

You are under extruding 6% but i don't think that would make your filament jam in the hot end.

But while we are at it maybe you should adjust it. ( im assuming you know how to edit the config file and upload to your board )

So when you input 100 you get 96 mm. SO you divide 100 by 96 which = 1.04166

Your current e steps are 939 so you multiple 939 by 1.04166 which = 978.1

SO where it says 160,160,3200,939 you change the 939 to 978.1

Then save the file and upload it to your ramps board.

Then you test again to make sure when you input 100 mm it actually puts in 100 mm.

Watch this video calibrating extruder Then wait 10 mins..........then watch it again !!!

In fact you should watch all of the guys videos . He's made some very useful videos !!!

Please take a photo of you hot end so we can see what we are dealing with !!!

I know it can be very frustrating when it jams but be patient. Remember there are 1000's of home printers that work fine and yours will as well if you are patient !!!

You are under extruding 6% but i don't think that would make your filament jam in the hot end.

But while we are at it maybe you should adjust it. ( im assuming you know how to edit the config file and upload to your board )

So when you input 100 you get 96 mm. SO you divide 100 by 96 which = 1.04166

Your current e steps are 939 so you multiple 939 by 1.04166 which = 978.1

SO where it says 160,160,3200,939 you change the 939 to 978.1

Then save the file and upload it to your ramps board.

Then you test again to make sure when you input 100 mm it actually puts in 100 mm.

Watch this video calibrating extruder Then wait 10 mins..........then watch it again !!!

In fact you should watch all of the guys videos . He's made some very useful videos !!!

Please take a photo of you hot end so we can see what we are dealing with !!!

|

Re: first connection of my RAMPS V1.4 November 09, 2015 03:22PM |

Registered: 8 years ago Posts: 53 |

|

Re: first connection of my RAMPS V1.4 November 09, 2015 03:27PM |

Registered: 8 years ago Posts: 53 |

|

Re: first connection of my RAMPS V1.4 November 09, 2015 03:49PM |

Registered: 8 years ago Posts: 53 |

the fan on the right is the one that is driven by Printrun and was not running when the problem occurred.

The left is running permanently.

|

Re: first connection of my RAMPS V1.4 November 09, 2015 10:26PM |

Registered: 11 years ago Posts: 1,049 |

What brand of extruder / hotend?

Show us what is pushing filament into hotend

What is the Black hotend --- black anodized aluminum?

Fan positions are useless.

Fan for cooling above hot end should be tight

to finned cooler above hotend, keeping mechanical extruder cool

and filament stiff

Other fan should be ducted to cool PLA after extrusion.

Is the drive gear chewing up the filament?

Is there adjustment for idler pressing filament into drive gear?

Do you have away of measuring hot end temperature

Non contact themometer or a high temp thermometer to clamp on hotend?

See if Temperature is as commanded?

Show us what is pushing filament into hotend

What is the Black hotend --- black anodized aluminum?

Fan positions are useless.

Fan for cooling above hot end should be tight

to finned cooler above hotend, keeping mechanical extruder cool

and filament stiff

Other fan should be ducted to cool PLA after extrusion.

Is the drive gear chewing up the filament?

Is there adjustment for idler pressing filament into drive gear?

Do you have away of measuring hot end temperature

Non contact themometer or a high temp thermometer to clamp on hotend?

See if Temperature is as commanded?

|

Re: first connection of my RAMPS V1.4 November 09, 2015 11:14PM |

Registered: 11 years ago Posts: 469 |

Hi

Thats a bit of a weird set up but it should work but it wont be very good

.

It looks like there is some kind of cover shroud at the hot end to stop the air from the fan hitting the heater block . Not very efficient at all.

The fan arrangement isnt the best it could be thats for sure and i think this is where your problems is.

To be clear

You need a fan on the cool fins ( only the cool fins) to stop heat traveling up and making the filament soft before it reaches the hot end. Permanently on all the time

You can use a fan to keep the work piece cool. This fan is connected to the ramps and its speed can be controlled by the software.

It is much better if this fan has a duct so it only blows on the work piece and not the hotend at all. Otherwise the hotend and ramps are constantly heating to try and keep the hotend up to temprature while the fan is blowing it cold

Doesnt make sense right !!!

So the important one is the permanent one to cool the cool fins. It is better and more efficient if this has a duct so it blows only the cool fins

like this >>>>>

or like this Thingyverse hex fan shroud

You can make a temporary one with an alu coke can and duct tape ( it would work better than what you have now) while you print a new one

And try printing at 30mm/sec to start with. Printing too fast or too slow will give problems if everything else isnt calibrated correctly.

Edited 1 time(s). Last edit at 11/09/2015 11:24PM by bigfilsing.

Thats a bit of a weird set up but it should work but it wont be very good

.

It looks like there is some kind of cover shroud at the hot end to stop the air from the fan hitting the heater block . Not very efficient at all.

The fan arrangement isnt the best it could be thats for sure and i think this is where your problems is.

To be clear

You need a fan on the cool fins ( only the cool fins) to stop heat traveling up and making the filament soft before it reaches the hot end. Permanently on all the time

You can use a fan to keep the work piece cool. This fan is connected to the ramps and its speed can be controlled by the software.

It is much better if this fan has a duct so it only blows on the work piece and not the hotend at all. Otherwise the hotend and ramps are constantly heating to try and keep the hotend up to temprature while the fan is blowing it cold

Doesnt make sense right !!!

So the important one is the permanent one to cool the cool fins. It is better and more efficient if this has a duct so it blows only the cool fins

like this >>>>>

or like this Thingyverse hex fan shroud

You can make a temporary one with an alu coke can and duct tape ( it would work better than what you have now) while you print a new one

And try printing at 30mm/sec to start with. Printing too fast or too slow will give problems if everything else isnt calibrated correctly.

Edited 1 time(s). Last edit at 11/09/2015 11:24PM by bigfilsing.

|

Re: first connection of my RAMPS V1.4 November 10, 2015 06:24AM |

Registered: 8 years ago Posts: 53 |

Thank you very much Bigfilsing,

I have solved my problème yesterday by observing that the filament was not guided well.

The filament was skidding on the ball bearing during the extrusion.

So, I have added a second bearing and now since the filament stops skidding between the two bearings, which act as a real pulley.

The machine has just stopped after a work of 8 hours long.

Thank you again

I have solved my problème yesterday by observing that the filament was not guided well.

The filament was skidding on the ball bearing during the extrusion.

So, I have added a second bearing and now since the filament stops skidding between the two bearings, which act as a real pulley.

The machine has just stopped after a work of 8 hours long.

Thank you again

|

Re: first connection of my RAMPS V1.4 November 10, 2015 11:43AM |

Registered: 11 years ago Posts: 1,049 |

quote Bigfilsing "It looks like there is some kind of cover shroud at the hot end

to stop the air from the fan hitting the heater block . Not very efficient at all."

Confusing Statement

Cooling heater block (melting filament) is not helping

just requiring more power to keep it at temperature

Yes -- cool above heater to keep filament solid so it can feed

Yes -- cool after extrusion to solidify part.

Black shroud is probably silicone insulator

more for prevention of burning flesh.

quote Bigfilsing "It looks like there is some kind of cover shroud at the hot end

to stop the air from the fan hitting the heater block . Not very efficient at all."

to stop the air from the fan hitting the heater block . Not very efficient at all."

Confusing Statement

Cooling heater block (melting filament) is not helping

just requiring more power to keep it at temperature

Yes -- cool above heater to keep filament solid so it can feed

Yes -- cool after extrusion to solidify part.

Black shroud is probably silicone insulator

more for prevention of burning flesh.

quote Bigfilsing "It looks like there is some kind of cover shroud at the hot end

to stop the air from the fan hitting the heater block . Not very efficient at all."

|

Re: first connection of my RAMPS V1.4 November 11, 2015 12:11AM |

Registered: 11 years ago Posts: 469 |

Quote

cozmicray

quote Bigfilsing "It looks like there is some kind of cover shroud at the hot end

to stop the air from the fan hitting the heater block . Not very efficient at all."

Confusing Statement

Cooling heater block (melting filament) is not helping

just requiring more power to keep it at temperature

Yes -- cool above heater to keep filament solid so it can feed

Yes -- cool after extrusion to solidify part.

Black shroud is probably silicone insulator

more for prevention of burning flesh.

quote Bigfilsing "It looks like there is some kind of cover shroud at the hot end

to stop the air from the fan hitting the heater block . Not very efficient at all."

And your point is ??

Sorry, only registered users may post in this forum.