New RAMPS design

Posted by MrAlvin

|

New RAMPS design June 05, 2018 04:11PM |

Registered: 14 years ago Posts: 140 |

The RAMPS 1.4 board has been used very successfully for many years now, but it seems to me that it might be time for an upgrade to the design.

Will it be okay to ask in this forum location, about what people most want from a upgraded design of the RAMPS board?

Among my own wishes are:

- to make it much easier to use TMC2130 drivers. Like I would want it to be as simple as moving some jumpers.

- to have better connectors (and a better mosfet) for the heat-bed, so it would be possible to operate some of those 30x30cm heat-beds that are available these days.

- an easy path to run heat-bed and/or steppers at 24V volts.

- an easy way to chose between using the RAMPS board on an Arduino Mega or Arduino Due

What are some of your experiences (both good or bad) with the RAMPS board?

Edited 2 time(s). Last edit at 06/05/2018 06:08PM by MrAlvin.

Will it be okay to ask in this forum location, about what people most want from a upgraded design of the RAMPS board?

Among my own wishes are:

- to make it much easier to use TMC2130 drivers. Like I would want it to be as simple as moving some jumpers.

- to have better connectors (and a better mosfet) for the heat-bed, so it would be possible to operate some of those 30x30cm heat-beds that are available these days.

- an easy path to run heat-bed and/or steppers at 24V volts.

- an easy way to chose between using the RAMPS board on an Arduino Mega or Arduino Due

What are some of your experiences (both good or bad) with the RAMPS board?

Edited 2 time(s). Last edit at 06/05/2018 06:08PM by MrAlvin.

|

Re: New RAMPS design June 06, 2018 03:26AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: New RAMPS design June 06, 2018 04:38AM |

Admin Registered: 13 years ago Posts: 6,998 |

|

Re: New RAMPS design June 06, 2018 09:47AM |

Registered: 14 years ago Posts: 140 |

For some time I have been tinkering with designs for a board, and I have already gotten to iteration 3. But before I get serious about making a design ready for (open source) publication, I thought it might be a good idea to get some input about wishes and experiences, especially to see if there is anything I have overlooked.

So I really appreciate your comments and input.

In the process of trying out new designs, I have learned about many details of options and what is involved for each detail/issue. So I will try to address each detail that is brought up in this discussion.

About fuses

I have looked into options for blade fuses, little 1808 fuses, green little fuses, glass fuses, pcb fuses and even poly fuses.

And it turns out that polyfuses are (currently) the cheapest option on ebay. But this should not necessarily be the reason for a final decision.

I have wanted to have separate power connectors for the heat-bed, steppers and the rest of the board. So three fuses are needed.

I have tried to make a 'fuse PCB foot print' where it is a free choice for: blade fuses, little fuses 1808 or poly fuses.

And in the latest iteration 3 (new RAMPS design attempt) this fuse foot print is available for the heat bed and the main 12V power supply.

For the stepper drives I am thinking that a little green fuse (which is soldered in) will be okay, because power lines to the steppers are fully handled on the board, so the likely hood of a short circuit is rather limited.

What do you think about these choices?

Do you think would okay to simply let the supply chain (and the buyers) decide which type of fuses will end up being mounted?

And how often have you experienced shorting out the 12V for the stepper drivers?

About a stronger 5V regulator

It turns out that a 7805 in a SMD housing it rather costly (currently on both ebay and digikey), so I am reluctant to include it as a "must be installed" option for the basic board.

Further more, if powered from 24V, then it is likely to get very hot, even at low amperages. So I prefer some pins made ready, so one might later add a switch mode regulator. In my tests so far I have been using the MP1584 boards.

An other way to increase the amperage for on-board 5V availability, would be to lower the volts going to Vin, so the arduino regulator has power enough to handle the typical add-on (like LCD and SD card) , but so one can add a 5V 3A regulator at a later time, if it is needed.

So on my third iteration of a design suggestion, I have added a few diodes, so the voltage on Vin is lowered a bit.

But again I have also added an option to plug in another MP1584 regulator. I like the MP1584's as they do not produce excessive heat, like linear regulators do.

About Keep it open source.

To me that is a given :-) I am retired, and have no need to be making money on this design. I mainly do it because I like to design things - and because I like the flexibility and hackability that the current RAMPS board has provided.

I just feel like my board gets very cluttered with wires when I trying to install TMC2130 drivers. So I definitely want a different board, and I suppose a few others might feel the same way. So I will share :-)

About the Arduino Due

Why do you think it is buggy? Does it not work on the RADDS board, and the Duet boards?

Why not have a board that can start out on a Mega, and be upgraded to the DUE?

And possibly later upgraded to the ESP32? Or another 32-bit processor.

I happen to like this plugability and hackability, as I think it opens up for ideas and development. If I were to think profitability, then all-in-one boards might be cheaper, but thy also tend to limit people in their options and choices. And take away the idea and development and playing fases from the ordinary user, and puts it only in the hands of engineers. I like to mess with that separation concept.

Did I mention that I appreciate your ideas, thoughts and comments?

So I really appreciate your comments and input.

In the process of trying out new designs, I have learned about many details of options and what is involved for each detail/issue. So I will try to address each detail that is brought up in this discussion.

Quote

o_lampe

- Better fuses and

- stronger 5V regulator.

- Keep it open source. There are a few "new" Ramps boards but they are not OS.

- I'd keep my hands off of Arduino Due, since it is buggy to start with ( and RADDS already exists )

About fuses

I have looked into options for blade fuses, little 1808 fuses, green little fuses, glass fuses, pcb fuses and even poly fuses.

And it turns out that polyfuses are (currently) the cheapest option on ebay. But this should not necessarily be the reason for a final decision.

I have wanted to have separate power connectors for the heat-bed, steppers and the rest of the board. So three fuses are needed.

I have tried to make a 'fuse PCB foot print' where it is a free choice for: blade fuses, little fuses 1808 or poly fuses.

And in the latest iteration 3 (new RAMPS design attempt) this fuse foot print is available for the heat bed and the main 12V power supply.

For the stepper drives I am thinking that a little green fuse (which is soldered in) will be okay, because power lines to the steppers are fully handled on the board, so the likely hood of a short circuit is rather limited.

What do you think about these choices?

Do you think would okay to simply let the supply chain (and the buyers) decide which type of fuses will end up being mounted?

And how often have you experienced shorting out the 12V for the stepper drivers?

About a stronger 5V regulator

It turns out that a 7805 in a SMD housing it rather costly (currently on both ebay and digikey), so I am reluctant to include it as a "must be installed" option for the basic board.

Further more, if powered from 24V, then it is likely to get very hot, even at low amperages. So I prefer some pins made ready, so one might later add a switch mode regulator. In my tests so far I have been using the MP1584 boards.

An other way to increase the amperage for on-board 5V availability, would be to lower the volts going to Vin, so the arduino regulator has power enough to handle the typical add-on (like LCD and SD card) , but so one can add a 5V 3A regulator at a later time, if it is needed.

So on my third iteration of a design suggestion, I have added a few diodes, so the voltage on Vin is lowered a bit.

But again I have also added an option to plug in another MP1584 regulator. I like the MP1584's as they do not produce excessive heat, like linear regulators do.

About Keep it open source.

To me that is a given :-) I am retired, and have no need to be making money on this design. I mainly do it because I like to design things - and because I like the flexibility and hackability that the current RAMPS board has provided.

I just feel like my board gets very cluttered with wires when I trying to install TMC2130 drivers. So I definitely want a different board, and I suppose a few others might feel the same way. So I will share :-)

About the Arduino Due

Why do you think it is buggy? Does it not work on the RADDS board, and the Duet boards?

Why not have a board that can start out on a Mega, and be upgraded to the DUE?

And possibly later upgraded to the ESP32? Or another 32-bit processor.

I happen to like this plugability and hackability, as I think it opens up for ideas and development. If I were to think profitability, then all-in-one boards might be cheaper, but thy also tend to limit people in their options and choices. And take away the idea and development and playing fases from the ordinary user, and puts it only in the hands of engineers. I like to mess with that separation concept.

Did I mention that I appreciate your ideas, thoughts and comments?

|

Re: New RAMPS design June 06, 2018 09:52AM |

Registered: 14 years ago Posts: 140 |

|

Re: New RAMPS design June 06, 2018 11:35AM |

Registered: 14 years ago Posts: 140 |

|

Re: New RAMPS design June 06, 2018 12:09PM |

Registered: 14 years ago Posts: 140 |

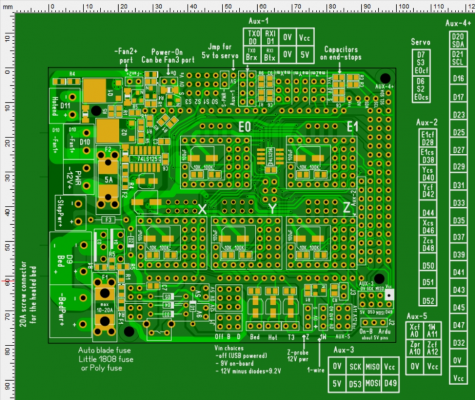

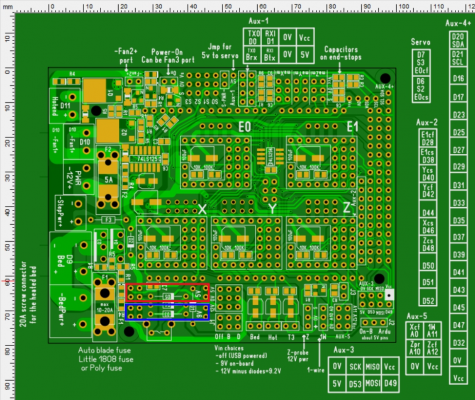

In the hopes of keeping a low entry price point, I have tried to limit additions to the board. And kept it as much as possible as add-on options. But I have tried to include connectors for typical add-on options.

My main design goal has been to be able to easily use TMC2130 drivers boards.

My second design goal has been to be able to easily switch between using an Arduino Mega or an Arduino Due as the controller board. Mind you, I have yet to manufacture a board to test if things actually work as they are intended to

But I have tried to learn as much as possible from previous designs for use with the Due.

In order to keep it easy to switch between the 5V Arduino Mega and the 3V Arduino Due, I use the term Vcc for plus for all logic chips, and for connector pins that also follow this automatic voltage shift, when moving from the Mega or Due board.

This Vcc rail is connected to the I/O pin on the Arduino power pins, so all logic plus is automatically following the board underneath.

There is also a 5V rail. This mainly connects to and additional 5V pin on Aux-3. By jumper J2 it is however possible to connect this 5V rail to the Due's 5V pin, so it might be possible to run some add-on, without needing to also add the auxiliary (add-on) 5V supply board.

The Aux-3 and Aux-4 connectors are kept identical to the RAMPS 1.4 board (with the addition of a 5V pin on Aux-3, that used to be nc (no connect)).

This 5V pin makes it relative simple to use all existing LCD and SDcard boards, as I have made a bi-directional logic level shifter board, that is supposed to go between Aux-3 and Aux-4, and any existing LCD and SDcard board, so the LCD/SDcard can still operate on 5V, just as they were designed to do, and the Due will only get 3V on all the data pins.

So what do you think?

Comments or questions are welcome :-)

My main design goal has been to be able to easily use TMC2130 drivers boards.

My second design goal has been to be able to easily switch between using an Arduino Mega or an Arduino Due as the controller board. Mind you, I have yet to manufacture a board to test if things actually work as they are intended to

But I have tried to learn as much as possible from previous designs for use with the Due.

In order to keep it easy to switch between the 5V Arduino Mega and the 3V Arduino Due, I use the term Vcc for plus for all logic chips, and for connector pins that also follow this automatic voltage shift, when moving from the Mega or Due board.

This Vcc rail is connected to the I/O pin on the Arduino power pins, so all logic plus is automatically following the board underneath.

There is also a 5V rail. This mainly connects to and additional 5V pin on Aux-3. By jumper J2 it is however possible to connect this 5V rail to the Due's 5V pin, so it might be possible to run some add-on, without needing to also add the auxiliary (add-on) 5V supply board.

The Aux-3 and Aux-4 connectors are kept identical to the RAMPS 1.4 board (with the addition of a 5V pin on Aux-3, that used to be nc (no connect)).

This 5V pin makes it relative simple to use all existing LCD and SDcard boards, as I have made a bi-directional logic level shifter board, that is supposed to go between Aux-3 and Aux-4, and any existing LCD and SDcard board, so the LCD/SDcard can still operate on 5V, just as they were designed to do, and the Due will only get 3V on all the data pins.

So what do you think?

Comments or questions are welcome :-)

|

Re: New RAMPS design June 07, 2018 06:20AM |

Registered: 8 years ago Posts: 5,232 |

I see you have two parallel headers for stepper motors on XYZ steppers, but with 24V ( or more ) it would be nicer to wire them in serial fashion.

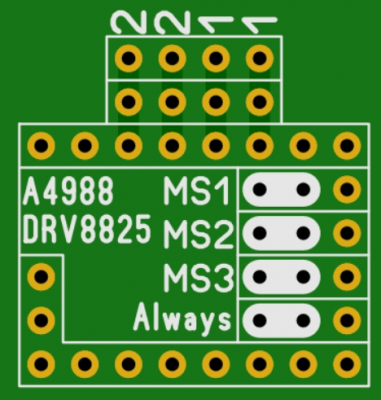

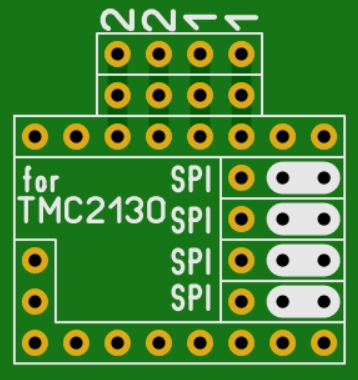

I couldn't identify microstepping jumpers, are there any or do you use FW configurable drivers?

The whole onboard fuse could be skipped, when using inline blade fuses from car-suppliers.

I couldn't identify microstepping jumpers, are there any or do you use FW configurable drivers?

The whole onboard fuse could be skipped, when using inline blade fuses from car-suppliers.

|

Re: New RAMPS design June 07, 2018 06:44AM |

Admin Registered: 13 years ago Posts: 6,998 |

|

Re: New RAMPS design June 07, 2018 08:31AM |

Registered: 7 years ago Posts: 23 |

I also built a new shield based on Arduino Due. Actually two shields, both based on Arduino Due. One shield has 5 steppers and the second 6 steppers. The second board allows the use of TMC2130 steppers that are configurable via the SPI bus. The second board I am about to start testing. I am a fan of Repetier firmware that I used from the beginning when I build my Delta printer.

When designing my boards I have looked over the following project Due3Dom.

I few ideas you might consider: the whole board can run at 12V, except the stepper motors. To power the board by 24V you need dc-dc boost converter to bring everything to 12V. In the same way, you need another dc-dc boost converter to get 5V for the board. Maybe 5V is not needed, but I wanted to be able to use the graphic LCD controller. You might consider using thermocouple or PT100 for temperature readings.

When designing my boards I have looked over the following project Due3Dom.

I few ideas you might consider: the whole board can run at 12V, except the stepper motors. To power the board by 24V you need dc-dc boost converter to bring everything to 12V. In the same way, you need another dc-dc boost converter to get 5V for the board. Maybe 5V is not needed, but I wanted to be able to use the graphic LCD controller. You might consider using thermocouple or PT100 for temperature readings.

|

Re: New RAMPS design June 07, 2018 01:38PM |

Registered: 14 years ago Posts: 140 |

Quote

o_lampe

I couldn't identify microstepping jumpers, are there any or do you use FW configurable drivers?

There are micro stepping jumpers, just like the RAMPS 1.4, only with some additions, so it becomes possible to select the SPI signals for the TMC2130 drivers.

Here are illustrations of how to use the jumpers:

Edited 1 time(s). Last edit at 06/07/2018 04:01PM by MrAlvin.

|

Re: New RAMPS design June 07, 2018 01:54PM |

Registered: 14 years ago Posts: 140 |

Quote

o_lampe

I see you have two parallel headers for stepper motors on XYZ steppers, but with 24V ( or more ) it would be nicer to wire them in serial fashion.

Quote

Dust

I agree about serial vs parallel steppers but as a 3rd stepper connector. This is wired in series. Making it easy to have dual stepper in series or parallel as needed.

Very interesting idea. To have the steppers in series. Thank you, I will have to look into that.

For now I am however out of space on this board (unless for some very minor additions), so for this design I think it needs to be considered as an add-on option.

But thank you for bringing the concept to my attention.

I mainly have the parallel option on X and Y, as this is something I started doing in one of the earlier design iterations. On earlier iterations the E0 and E1 also had the option, but on this board I ran out of space. But as this is meant to be with as few additions as possible, I think it is okay.

|

Re: New RAMPS design June 07, 2018 02:02PM |

Registered: 14 years ago Posts: 140 |

Quote

o_lampe

The whole onboard fuse could be skipped, when using inline blade fuses from car-suppliers.

Indeed it could, but as the RAMPS 1.4 has fuses, I have chosen to also include a fuse option on this board.

Way back in 2010 I made some boards without fuses, and because of tinkering, this turned the PCB wires into fuses in sted, so I like to have fuses :-) And including them on the board makes for a cleaner look - and hopefully also for an easier fuse replacement operation.

For future iterations I will however consider making a separate fuse board.

|

Re: New RAMPS design June 07, 2018 03:53PM |

Registered: 14 years ago Posts: 140 |

Quote

xebbmw

I also built a new shield based on Arduino Due. Actually two shields, both based on Arduino Due. One shield has 5 steppers and the second 6 steppers. The second board allows the use of TMC2130 steppers that are configurable via the SPI bus. The second board I am about to start testing.

Good to hear about it. Do you happen to have any online information or some photos you would like to share?

Quote

xebbmw

I am a fan of Repetier firmware that I used from the beginning when I build my Delta printer.

I have not really looked into firmware options yet, though I have tried to look into how to make a pins_my_board.h addition to Marlin firmware. But I really like the Repetier firmware as well, so I will eventually make sure it too will have a set of pins definitions that will work with this board.

Good to know about this project. I wonder why it does not appear to have a mention on the Reprap.og wiki. As I did try to find other shield-style boards, ment to be use with the Due, before I started on this project.

This is possible with this board, as the steppers have their own power connector. As does the heat bed. And then a power connector for the rest of the board. So it has three power connectors in all, making it possible to chose voltage for each section individually.Quote

xebbmw

I few ideas you might consider: the whole board can run at 12V, except the stepper motors.

Quote

xebbmw

I few ideas you might consider: the whole board can run at 12V, except the stepper motors. To power the board by 24V you need dc-dc boost converter to bring everything to 12V. In the same way, you need another dc-dc boost converter to get 5V for the board. Maybe 5V is not needed, but I wanted to be able to use the graphic LCD controller.

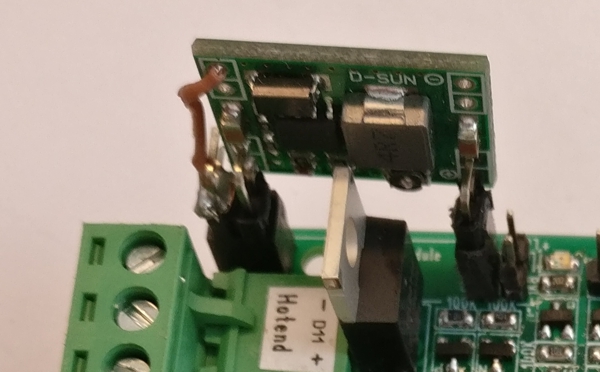

This board has an option to connect two DC-DC converters.

One is meant to convert 12V or 24V down to 5V, as the output pins are connected to the 5V rail.

This is the style of board that is meant to be used as the DC-DC down converter.

ebay link to mp1584 3A DC-DC down converter

And here is how I have placed it on one of the earlier design iterations.

And here is where there is room for two of them on this design (look at the red and blue frames at the bottom left).

Hmmm... what kind of temperature reading are you thnking about? There are already three ports to read temperature.Quote

xebbmw

You might consider using thermocouple or PT100 for temperature readings.

Are you thinking about a K-type thermocouple? These can be connected via the SPI port. For example a MAX6675. The MAX6675 can already be read by several firmwares.

In order to keep this as a very minimal board, I like to do this as an add-on option.

I had previous designs where it was included on the RAMPS board, but if it is an add-on, I could possibly add it to the next board as well.

It is always easy to have everything included on just one board, but then if something fries, it is often necessary to replace the entire board. This is one of the reasons that I like the concept of the RAMPS board. As it is essentially a bunch of wires, that connects other boards.

And I try to keep it that way in this design as well, though I have added a few resistors and small mosfets as well, as I think it makes it easier to connect some of the other boards.

I am however very much looking forward to hear a bit more about your experiences with your own board designs, and what and why you have chosen to include what is on them :-)

|

Re: New RAMPS design June 07, 2018 04:00PM |

Registered: 14 years ago Posts: 140 |

Quote

Dust

I think its time to drop as much through hole as possible

I agree. So I will replace what I can on this design, or make room for both options, as sometimes through hole components are cheaper or easier to source.

And I have yet to find a good surface mount mosfet, to be able to replace the IRLB3034PbF mosfet that I intend to use as the heat-bed mosfet. So if you have any suggestions, I would very much like a link or part number.

|

Re: New RAMPS design June 07, 2018 07:26PM |

Registered: 7 years ago Posts: 23 |

Quote

MrAlvin

Good to hear about it. Do you happen to have any online information or some photos you would like to share?

You may find some pictures of my Due6Step here

About mosfets, I use IRLR8743 in one board for the bed. It holds well, it is in SMD package and it is mounted on the board (some of the circuit used as heat sink). I tried to use IRLR2905 for the hot ends, but it did not work well as they were quite hot. Or maybe the ones I have are fakes, I bought them from China. Then I replaced them with IRLR8743 and it is just fine. For Due6Step I want to use also IRLB3034, as you see in the picture they are not soldered yet.

Regarding the SPI signals for TMC2130, I use the same jumpers as you do. Each jumper has two positions when TMC2130 or regular stepper drivers are installed. I mentioned more details here.

Edited 1 time(s). Last edit at 06/07/2018 10:20PM by xebbmw.

|

Re: New RAMPS design June 08, 2018 03:12PM |

Registered: 10 years ago Posts: 92 |

Regarding fuses:

I recently blew the fuse on a Duet 0.6 board, and was surprised to find that @dc42 has since then moved to a self-resetting fuse in his designs.

I made the modification to add it to my board, and find that to be a really nice feature, considering my likelihood of forgetting to turn off the board prior to working on the hotend.

I can't find the post about it at the moment, but in my notes I wrote down his suggested part numbers:

Multicomp MC36207 from Farnell

Bourns MF-MSMF014

Bel Fuse 0ZCJ0020FF2E

He also added a means of detecting the VSSA short with a 10k inline resistor to an I/O pin.

I recently blew the fuse on a Duet 0.6 board, and was surprised to find that @dc42 has since then moved to a self-resetting fuse in his designs.

I made the modification to add it to my board, and find that to be a really nice feature, considering my likelihood of forgetting to turn off the board prior to working on the hotend.

I can't find the post about it at the moment, but in my notes I wrote down his suggested part numbers:

Multicomp MC36207 from Farnell

Bourns MF-MSMF014

Bel Fuse 0ZCJ0020FF2E

He also added a means of detecting the VSSA short with a 10k inline resistor to an I/O pin.

|

Re: New RAMPS design June 08, 2018 03:40PM |

Registered: 14 years ago Posts: 140 |

Thank you, I will take a look at them. So far I have noticed the very interesting placing of the drivers, underneath the shield PCB. I will be interested in hearing about your experience, of how that affects the cooling/heating of the drivers.

Quote

xebbmw

About mosfets, I use IRLR8743 in one board for the bed. It holds well, it is in SMD package and it is mounted on the board (some of the circuit used as heat sink). I tried to use IRLR2905 for the hot ends, but it did not work well as they were quite hot. Or maybe the ones I have are fakes, I bought them from China. Then I replaced them with IRLR8743 and it is just fine. For Due6Step I want to use also IRLB3034, as you see in the picture they are not soldered yet.

Well it seems like the internal resistance of the IRLR2905 is about 30 milli Ohm (mO) at 5V on the gate (Vgs) - and 27 mO @10Vgs

The IRLR8743 is about 4 mO (4.5V Vgs)

and the IRLB3034 is about 2 mO (4.5V Vgs)

As the milli ohm value is part of the heat calculation on the house, it makes sense that the IRLR8743 runs cooler than the IRLR2905 .

The calculation for how hot the chip (the housing) gets, follows this formula: I x I x R = W

And then the datasheet will have a line about "Junction-to-Ambient".

Iin the case of a TO-220 house it is typically 62 degrees per watt ( C/W )

The TO-252 house on the IRLR2905 is smaller than the TO-220 house, so it has a 110 C/W rating, which is typical for the TO-252 housing, but with a large PCB layout of 1 square inch, it goes down to 50 C/W, but 1 square inch is actually a rather large PCB area.

So in practical terms the TO-252 housing has a temperature rise of between 50 *C and 110 *C, depending on how large an area of PCB will be dedicated to its cooling.

So the resulting heat calculation looks something like this: I x I x R x C = degree Celsius above ambient room temperature.

To get some rough but fairly comparable numbers at a 5A load:

IRLR2905: 5 x 5 x 0.027 x 110 = +74 *C

STP55NF06: 5 x 5 x 0.018? x 62.5 = +47 *C (used on the original RAMPS 1.4)

IRLR8743: 5 x 5 x 0.004 x 110 = +11 *C

IRLB8748 5 x 5 x 0.0068 x 62 = +11 *C

IRLB3034: 5 x 5 x 0.002 x 62 = +3 *C

*note:

- I brought in the STP55NF06 for comparison, but I have used an unrealistic low number for its on-resistance, as 18 mO is at Vgs = 10V. Who knows what the on-resistance is @5Vgs, because I can not find any reference in the datasheet.

- and the IRLB8748 is just another TO-220 housed option

And at a 10A load:

IRLR2905: 10 x 10 x 0.027 x 110 = +297 *C (but it has died way before it gets that hot. Around 175*C is the internal limit of all chips)

STP55NF06: 10 x 10 x 0.018? x 62.5 = +112.5 *C

IRLR8743: 10 x 10 x 0.004 x 110 = +44*C

IRLB8748 10 x 10 x 0.0068 x 62 = +43 *C

IRLB3034: 10 x 10 x 0.002 x 62 = +12*C

and for a 20A load:

IRLR8743: 20 x 20 x 0.004 x 110 = +176 *C

IRLB8748 20 x 20 x 0.0068 x 62 = +169 *C

IRLB3034: 20 x 20 x 0.002 x 62 = +50 *C

This is the reason I have included an option for two TO-220 houses in parallel at the heat bed. Even at a 20A load on the heat bed, each transistor only sees a 10A load. But even for a IRLB3034 this still means a difference of about +12 *C or +50 *C above ambient temperature. And I like my electronics to run cool :-)

hmmm.... now that I look at the numbers, it might even be possible to add some PCB cooling space for two IRLR8743 in parallel, and get to use SMD parts for the heat-bed as well, even if I aim for a 25A fuse for the heat-bed.

I will have to see if I can make space for that somehow :-)

It is possible to do mosfets in parallel, as their internal resistance increases with temperature. So as long as the temperature rise is not too fast, then the mosfets will equal each outher out, as they each get warmer. Another thing to note when doing mosfets in parallel: It is wise for each mosfet gate to have its own resistor connecting the gate to ground.

This is the opposite for diodes, where their resistance lowers with temperature, so the diode in parallel, with the lowest resistance takes a higher load, and increases in temperature, and takes a higher load.....and you get a run-away temperature rise, until it lets out the magic smoke. And then the next diode repeats that scenario.

But not so for mosfets.

Thank you for the link to that discussion.Quote

xebbmw

Regarding the SPI signals for TMC2130, I use the same jumpers as you do. Each jumper has two positions when TMC2130 or regular stepper drivers are installed. I mentioned more details here.

It also gave a good connection to a discussion about the RD3D/1.0 board. A board that I did notice on the Reprap wiki recently.

By the way, I would be interested to hear where you get those sockets for the blade fuses. I have so far not been able to find a good (and low cost) source.

|

Re: New RAMPS design June 08, 2018 06:21PM |

Registered: 7 years ago Posts: 23 |

The idea of placing the stepper drivers underneath the PCB is that I have a Delta printer. I am going to place the controller board at the bottom of the printer, below the heat bed where is not that much space. Thus I thought that placing the drivers underneath will reduce the vertical space occupied by the controller board. I will place everything in a printed box with some fans, I guess it should be fine.Quote

MrAlvin

So far I have noticed the very interesting placing of the drivers, underneath the shield PCB. I will be interested in hearing about your experience...

Thanks a lot for educating me. For me electronics is just a hobby, I am doing software programming as job in real life.Quote

MrAlvin

So the resulting heat calculation looks something like this: I x I x R x C = degree Celsius above ambient room temperature.

The fuse holders that I have are 3544-2 from Keystone. I bought them from Digikey but I see they are available also on AliexpressQuote

MrAlvin

By the way, I would be interested to hear where you get those sockets for the blade fuses. I have so far not been able to find a good (and low cost) source.

|

Re: New RAMPS design June 09, 2018 03:36AM |

Registered: 10 years ago Posts: 14,672 |

Quote

maso

Regarding fuses:

I recently blew the fuse on a Duet 0.6 board, and was surprised to find that @dc42 has since then moved to a self-resetting fuse in his designs.

I made the modification to add it to my board, and find that to be a really nice feature, considering my likelihood of forgetting to turn off the board prior to working on the hotend.

I can't find the post about it at the moment, but in my notes I wrote down his suggested part numbers:

Multicomp MC36207 from Farnell

Bourns MF-MSMF014

Bel Fuse 0ZCJ0020FF2E

He also added a means of detecting the VSSA short with a 10k inline resistor to an I/O pin.

See [duet3d.dozuki.com]. However, the Duet 0.6 doesn't have a fuse, it's the Duet WiFi/Ethernet/Maestro that do.

Just to be clear, this is a fuse to protect the analog ground connection from shorts, not a fuse in the power circuitry.

It's hard to fuse the bed heater circuit in a meaningful way, because ordinary fuses won't blow unless they receive a substantial overload for several seconds. Meanwhile it's likely that a PCB trace will fuse, or the PSU will detect the overload and go into hiccup mode.

Edited 3 time(s). Last edit at 06/09/2018 03:46AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New RAMPS design June 09, 2018 05:58AM |

Registered: 14 years ago Posts: 140 |

Quote

dc42

Just to be clear, this is a fuse to protect the analog ground connection from shorts, not a fuse in the power circuitry.

That makes sense, as the items maso listed, all were sub-1A fuses.

That is indeed the design challenge.Quote

dc42

It's hard to fuse the bed heater circuit in a meaningful way, because ordinary fuses won't blow unless they receive a substantial overload for several seconds. Meanwhile it's likely that a PCB trace will fuse, or the PSU will detect the overload and go into hiccup mode.

As I have however decided to try to limit myself in every way possible, with this particular design attempt, there may still be situations where the PCB traces simply will not manage.

Though, for those who plan on pushing the bord to it limits, I have left some parts of the traces on the underside exposed, so it would be easy to solder-attach some extra copper wire. The connectors associated with the bed still have a design limit of 20A, so for the adventures, they will need to be replaced as well.

But for heat beds above 15-20A, it probably makes more sense to simply use a separate mosfet board anyway.

|

Re: New RAMPS design June 09, 2018 12:47PM |

Registered: 14 years ago Posts: 140 |

Ah yes, that makes good sense.Quote

xebbmw

The idea of placing the stepper drivers underneath the PCB is that I have a Delta printer.

You are quite welcome. I used to work with computers and networks, so electronics is also a hobby for me.Quote

xebbmw

Thanks a lot for educating me. For me electronics is just a hobby, I am doing software programming as job in real life.

Thank you for the parts info, and the link. It has given me good clues of what to look for next.Quote

xebbmw

The fuse holders that I have are 3544-2 from Keystone. I bought them from Digikey but I see they are available also on Aliexpress

|

Re: New RAMPS design June 12, 2018 07:44PM |

Registered: 6 years ago Posts: 8 |

Couple of comments; as I am looking to replace the stm7f proprietary board in my MOOZ which is proprietary and doubtful due to various SPI backed hacks I can reverse engineer into something usable with Mainline Marlin 2.0 at this point.

So some considerations;

* ESP32 / $Whatever MCU boards should be well supported - I am over the arduino pinout configuration in general and think that the RAMPS series needs to seriously consider removing the Header pinout found on the older AVR duinos as a primary consideration for pinout. Just provide a row of headers for MCU attachment generally something like the 40PIN header found on the RPI's etc. the STM7 dev boards and the LPC chips which are the re-arm targets are not generally found in the Arduino baseboard layout so something generalized is IMNSHO a better bet. The upshot of this is better placement options for other components.

* As a corollary to the above - a lot of the boards now include Wifi AUX connectors ; whilst I appreciate there is nothing preventing someone from using any of the AUX ports for this purpose; some consideration to aerial and RF interference in terms of placement for this reason is probably worth considering.

* Most of the Unofficial RAMPs boards use surface mount mosfets with through PCB heat sink - the kicad you posted looks like this - so kudos!

* Am for keeping replaceable fuses, either barrel or Car style is good a bet; being able to actually replace fuses is a bonus - considering the point of them is to blow.

* I think a reference set of components would be a good idea - obviously the tmc2100 drivers are the dujour, but likewise with overrated mosfets; seems the target draw in many reviews seems to be in the 11-12A range; some maybe providing some higher end base tolerances for components would be a good idea.

Cheers.

So some considerations;

* ESP32 / $Whatever MCU boards should be well supported - I am over the arduino pinout configuration in general and think that the RAMPS series needs to seriously consider removing the Header pinout found on the older AVR duinos as a primary consideration for pinout. Just provide a row of headers for MCU attachment generally something like the 40PIN header found on the RPI's etc. the STM7 dev boards and the LPC chips which are the re-arm targets are not generally found in the Arduino baseboard layout so something generalized is IMNSHO a better bet. The upshot of this is better placement options for other components.

* As a corollary to the above - a lot of the boards now include Wifi AUX connectors ; whilst I appreciate there is nothing preventing someone from using any of the AUX ports for this purpose; some consideration to aerial and RF interference in terms of placement for this reason is probably worth considering.

* Most of the Unofficial RAMPs boards use surface mount mosfets with through PCB heat sink - the kicad you posted looks like this - so kudos!

* Am for keeping replaceable fuses, either barrel or Car style is good a bet; being able to actually replace fuses is a bonus - considering the point of them is to blow.

* I think a reference set of components would be a good idea - obviously the tmc2100 drivers are the dujour, but likewise with overrated mosfets; seems the target draw in many reviews seems to be in the 11-12A range; some maybe providing some higher end base tolerances for components would be a good idea.

Cheers.

|

Re: New RAMPS design June 13, 2018 03:04AM |

Registered: 14 years ago Posts: 140 |

Hi aenertia, and thank you for your comments

The RAMPS board is however specifically targeted towards the Arduino boards, so perhaps it would be better to design another board with the connector options as you mention. Once I have a tested and functioning design on this board, I will consider designing a more generic board.

In the mean time, it is possible to hack a ramps board, so it becomes easy to connect it to other MCU's for testing/development. One could for instance start out with a bear RAMPS board, and chose to solder the shield pins up, rather than down, and then it becomes 'easier' to wire signal pins to another MCU.

This concept follows the recommendation of how to connect a bluetooth board to the RAMPS 1.4 board.

I have tried to use mainly surface mounted components (SMD), and in sizes (0805) which I do not consider too hard to hand-solder, so anyone could basically make their own board. Or it will be easy (and cheap) to get all the SMD components machine placed, and be part of a kit where you just solder in all the through-hole connectors your self.

Would you like a list of well functioning components?

Like which are the best mosfets, capacitors etc. for the job?

And would you like the bed section to be able to (easily) handle at least 12A?

All components for the bed, in this design, has an official rating of to 20A.

Which MCU are you considering for use with your Marlin 2.0 hacking/testing?

Edited 1 time(s). Last edit at 06/13/2018 03:05AM by MrAlvin.

You have a good point for a more universal stepper-driver-holder-board.Quote

aenertia

* ESP32 / $Whatever MCU boards should be well supported - I am over the arduino pinout configuration in general and think that the RAMPS series needs to seriously consider removing the Header pinout found on the older AVR duinos as a primary consideration for pinout. Just provide a row of headers for MCU attachment generally something like the 40PIN header found on the RPI's etc. the STM7 dev boards and the LPC chips which are the re-arm targets are not generally found in the Arduino baseboard layout so something generalized is IMNSHO a better bet. The upshot of this is better placement options for other components.

The RAMPS board is however specifically targeted towards the Arduino boards, so perhaps it would be better to design another board with the connector options as you mention. Once I have a tested and functioning design on this board, I will consider designing a more generic board.

In the mean time, it is possible to hack a ramps board, so it becomes easy to connect it to other MCU's for testing/development. One could for instance start out with a bear RAMPS board, and chose to solder the shield pins up, rather than down, and then it becomes 'easier' to wire signal pins to another MCU.

As I try to keep the board as small as possible, this design also only has a AUX port option (Aux-1). For 5V operation of the board, and connecting to 3V devices for Bluetooth or WiFi, it does however have a duplicate of the AUX pins, where a voltage divider has been added to the TXO pin, so this pin only sends out 3V to the Bluetooth or WiFi device.Quote

aenertia

* As a corollary to the above - a lot of the boards now include Wifi AUX connectors ; whilst I appreciate there is nothing preventing someone from using any of the AUX ports for this purpose; some consideration to aerial and RF interference in terms of placement for this reason is probably worth considering.

This concept follows the recommendation of how to connect a bluetooth board to the RAMPS 1.4 board.

Thank you.Quote

aenertia

* Most of the Unofficial RAMPs boards use surface mount mosfets with through PCB heat sink - the kicad you posted looks like this - so kudos!

I have tried to use mainly surface mounted components (SMD), and in sizes (0805) which I do not consider too hard to hand-solder, so anyone could basically make their own board. Or it will be easy (and cheap) to get all the SMD components machine placed, and be part of a kit where you just solder in all the through-hole connectors your self.

Fuses that can blow (and then be replaced) are indeed part of their intended functionality :-)Quote

aenertia

* Am for keeping replaceable fuses, either barrel or Car style is good a bet; being able to actually replace fuses is a bonus - considering the point of them is to blow.

I am not quite sure what you are saying here?Quote

aenertia

* I think a reference set of components would be a good idea - obviously the tmc2100 drivers are the dujour, but likewise with overrated mosfets; seems the target draw in many reviews seems to be in the 11-12A range; some maybe providing some higher end base tolerances for components would be a good idea.

Would you like a list of well functioning components?

Like which are the best mosfets, capacitors etc. for the job?

And would you like the bed section to be able to (easily) handle at least 12A?

All components for the bed, in this design, has an official rating of to 20A.

Which MCU are you considering for use with your Marlin 2.0 hacking/testing?

Edited 1 time(s). Last edit at 06/13/2018 03:05AM by MrAlvin.

|

Re: New RAMPS design June 13, 2018 08:45AM |

Registered: 7 years ago Posts: 23 |

What micro controller is used on your MOOZ board?Quote

aenertia

Couple of comments; as I am looking to replace the stm7f proprietary board in my MOOZ which is proprietary and doubtful due to various SPI backed hacks I can reverse engineer into something usable with Mainline Marlin 2.0 at this point.

If you look at Github Marlin 2.0 thread, there are guys who build their boards based on STM32F7 and STM32F1 micro controllers. Look for posts made by Spawn32 and victorpv. Just for your info!

|

Re: New RAMPS design June 14, 2018 05:39PM |

Registered: 6 years ago Posts: 8 |

It's a decided hacked up STM32F4 -

Pictures of the board here : [photos.google.com]

I managed to get them to open source there hacked up marlin 1.0.1*mumble* version - on github.

Froked mooz3d repo

However they went and used some proprietary build chain that is windows only ; so far I haven't even been able to compile off there source drop - but at least in theory the pinouts etc can be divined from the source .h etc - although a lot of it is obfuscated by the use of their ARM SDK of choice black magic voodoo.

The PCB design is quite different from the Reference STM32 3d eval board they claimed to have based it off - and they have done some questionable things with the way they have attached the TFT - it's pretty much unusable in the stock firmware (no sd card reading from the tft, the seral usb connection is horribly broken to make most sprinter based comms to the unit unusable and even dangerous - octoprint seems to have a tendancy to drive the Z well past the Zero point - because the printer sorta reports marlin eeprom, but not really). I can get some relatively decent prints from it ; but it's got a lot of issues with bridging - especially after a couple of prints in a row; likely due to stress heating of components. Leveling is a nightmare and i've ruined several beds due to dodgy Z sensing, one of the key reasons I want to get off the mooz firmware is the issues with levelling.

Pictures of the board here : [photos.google.com]

I managed to get them to open source there hacked up marlin 1.0.1*mumble* version - on github.

Froked mooz3d repo

However they went and used some proprietary build chain that is windows only ; so far I haven't even been able to compile off there source drop - but at least in theory the pinouts etc can be divined from the source .h etc - although a lot of it is obfuscated by the use of their ARM SDK of choice black magic voodoo.

The PCB design is quite different from the Reference STM32 3d eval board they claimed to have based it off - and they have done some questionable things with the way they have attached the TFT - it's pretty much unusable in the stock firmware (no sd card reading from the tft, the seral usb connection is horribly broken to make most sprinter based comms to the unit unusable and even dangerous - octoprint seems to have a tendancy to drive the Z well past the Zero point - because the printer sorta reports marlin eeprom, but not really). I can get some relatively decent prints from it ; but it's got a lot of issues with bridging - especially after a couple of prints in a row; likely due to stress heating of components. Leveling is a nightmare and i've ruined several beds due to dodgy Z sensing, one of the key reasons I want to get off the mooz firmware is the issues with levelling.

|

Re: New RAMPS design June 14, 2018 06:47PM |

Registered: 6 years ago Posts: 8 |

wrt MCU Choice

- I have several ESP32's lying in front of me right now; however I am eyeing up the STM32F7 dev boards - in particular there is a Nucleo that looks like it will do the job and is reasonably priced at 60$ - this one [www.aliexpress.com]

Also considering the teensy 3.5 board (as it's 5v tolerant which the 3.6 isn't).

In all likelyhood my ideal board would have easy interfacing with an H3/5 Pi clone for Monitoring and/or potentially using klipper, definately more AUX Ports (I've got a need for 4 ; WIFI/BT, TFT, Offboard Controller(Pi Etc) and SD.

Definately keen to have SPI on the driver pinouts for the tcm2130's etc.

But the MCU would be one of the above.

Edited 1 time(s). Last edit at 06/14/2018 10:49PM by aenertia.

- I have several ESP32's lying in front of me right now; however I am eyeing up the STM32F7 dev boards - in particular there is a Nucleo that looks like it will do the job and is reasonably priced at 60$ - this one [www.aliexpress.com]

Also considering the teensy 3.5 board (as it's 5v tolerant which the 3.6 isn't).

In all likelyhood my ideal board would have easy interfacing with an H3/5 Pi clone for Monitoring and/or potentially using klipper, definately more AUX Ports (I've got a need for 4 ; WIFI/BT, TFT, Offboard Controller(Pi Etc) and SD.

Definately keen to have SPI on the driver pinouts for the tcm2130's etc.

But the MCU would be one of the above.

Edited 1 time(s). Last edit at 06/14/2018 10:49PM by aenertia.

|

Re: New RAMPS design June 17, 2018 05:47PM |

Registered: 9 years ago Posts: 93 |

I'm a bit late to the party, but have you have you considered other boards than the due?

the teensy 3.6 is also 32 bit but runs faster and have an FPU

and there is also TMC2208 that can handle a bit more current and runs cooler, the running cool part is something people newer talk about. 2208 also have stallguard 2, but i think that that they dont offer sensorless homing. you would need to check thou as i'm not sure

you might also get some good idea from Ramps FD V. 2.2 ( one of the safer versions)

EDIT: but yes a BOM for the design would be good so people know where to get them, links to mouser seems to be quite universal and they allow to buy 1 of most components

Edited 1 time(s). Last edit at 06/17/2018 05:55PM by boelle.

the teensy 3.6 is also 32 bit but runs faster and have an FPU

and there is also TMC2208 that can handle a bit more current and runs cooler, the running cool part is something people newer talk about. 2208 also have stallguard 2, but i think that that they dont offer sensorless homing. you would need to check thou as i'm not sure

you might also get some good idea from Ramps FD V. 2.2 ( one of the safer versions)

EDIT: but yes a BOM for the design would be good so people know where to get them, links to mouser seems to be quite universal and they allow to buy 1 of most components

Edited 1 time(s). Last edit at 06/17/2018 05:55PM by boelle.

|

Re: New RAMPS design June 17, 2018 06:17PM |

Registered: 6 years ago Posts: 8 |

Is Due event a consideration (it's not even produced anymore)

I think to sum it up generally these design goals are somewhat useful

3.3v safe board design.

Ability to interface $userschoice of MCU - assume no specific pinout

SPI controlled Motor controllers are likely going to be the norm

Plug-gable fuses

Assume interfacing with a General Purpose offboard for interface (Pi etc)

Support for more steppers than has been the case (to support multi-colour extruders) I think 7 drivers seems to be not crazy (zyz, rgbbw)

I think to sum it up generally these design goals are somewhat useful

3.3v safe board design.

Ability to interface $userschoice of MCU - assume no specific pinout

SPI controlled Motor controllers are likely going to be the norm

Plug-gable fuses

Assume interfacing with a General Purpose offboard for interface (Pi etc)

Support for more steppers than has been the case (to support multi-colour extruders) I think 7 drivers seems to be not crazy (zyz, rgbbw)

|

Re: New RAMPS design June 17, 2018 07:13PM |

Registered: 9 years ago Posts: 93 |

Quote

aenertia

Is Due event a consideration (it's not even produced anymore)

its just out of stock, it has not been marked as discontinued

Quote

aenertia

SPI controlled Motor controllers are likely going to be the norm

so is serial controlled onces like TMC2208 that can handle more current and run cooler than TM2130

Quote

aenertia

(to support multi-colour extruders) (zyz, rgbbw)

what is zyz and rgbbw??? if you mean CMYK then try to investigate it a bit more

CMYK assumes print on white paper, ask any in the graphic industrie and they will tell you the same.

on 3d printers we dont have white paper so we need 5 colors, not 4. black and white are easy to get. then try and find cyan filament in the right tone/shade that also conforms to the patone color system. Yellow is a bit more easy to get but you still have to look for the right shade/tone. Magneta is also very hard to find.

i did this investigation when the 5 way diamond hotend came out and i gave up... i had to buy a pallet of the cyan to get places like Devil design and form futura to make it correctly... so that would be 2 pallets... one in cyan and one in magneta.

Quote

aenertia

Ability to interface $userschoice of MCU - assume no specific pinout

then its no longer a shield, and you would be able to do this no matter what MCU the shield is made for, just solder wires and connect it to mcu

Sorry, only registered users may post in this forum.