|

Ramps 1.6 and VCC issues March 17, 2021 11:06PM |

Registered: 3 years ago Posts: 2 |

This is a bizarre issue.

Everything was working fine until a month ago. I upgraded to ramps 1.6 after my 1.4 board decided it wanted to go to the big chip in the sky. I ordered a kit to replace the 1.4 and the 2560. Everything was working fine. I notice my prints are quite a bit better. I then do a complete overhaul of the printer. New rods, bearings, belts, and a new Y axis motor. Another test print and it honestly is the best print I have ever done.

What the heck, I'll add auto bed leveling. I install the BLTouch. Plug it in and no power (in my defense, I forgot about the vcc to 5v jumper). So I find the new location of the jumper location and per every diagram I found, it is the two pins closest to the E0 motor connection. No problem. I power down, put the jumper on and....

I released the magic smoke from the 2560.

So I order another 2560. I check all the connections, connectors, pinouts, crimps, and do a full assessment. Everything looks good, everything is crimped correctly, the wires are in the right positions, so I turn it on and nothing happens. Good, I unplug it and put the jumper across vcc to 5v and....

The magic smoke monster appears again.

Fine, I order another 2 boards. While I am at it, I order another ramps 1.6. New boards arrive and I swap out the 2560. This time I use another new 1.6 board and 2560. The only wires I connect are the power wires on the ramps board.

I turn the power on without the jumper. I measure voltage on vcc as 4.95v. I confirm the 5v pin has 0v. I plug a jumper on vcc to 5v again and....

Another magic smoke monster...

So I am thinking that it is a manufacturing issue. The only constant through the whole thing is that the 2560 boards have been from the same manufacturer. I know that this can be done as there are posts about it. I am seeking the forums opinion however. I do have 2 different 2560 boards coming.

I should also add that I dug out a spare 1.4 board, and that is working fine with the BLTouch and a new 2560 board installed albeit very slowly though.

Everything was working fine until a month ago. I upgraded to ramps 1.6 after my 1.4 board decided it wanted to go to the big chip in the sky. I ordered a kit to replace the 1.4 and the 2560. Everything was working fine. I notice my prints are quite a bit better. I then do a complete overhaul of the printer. New rods, bearings, belts, and a new Y axis motor. Another test print and it honestly is the best print I have ever done.

What the heck, I'll add auto bed leveling. I install the BLTouch. Plug it in and no power (in my defense, I forgot about the vcc to 5v jumper). So I find the new location of the jumper location and per every diagram I found, it is the two pins closest to the E0 motor connection. No problem. I power down, put the jumper on and....

I released the magic smoke from the 2560.

So I order another 2560. I check all the connections, connectors, pinouts, crimps, and do a full assessment. Everything looks good, everything is crimped correctly, the wires are in the right positions, so I turn it on and nothing happens. Good, I unplug it and put the jumper across vcc to 5v and....

The magic smoke monster appears again.

Fine, I order another 2 boards. While I am at it, I order another ramps 1.6. New boards arrive and I swap out the 2560. This time I use another new 1.6 board and 2560. The only wires I connect are the power wires on the ramps board.

I turn the power on without the jumper. I measure voltage on vcc as 4.95v. I confirm the 5v pin has 0v. I plug a jumper on vcc to 5v again and....

Another magic smoke monster...

So I am thinking that it is a manufacturing issue. The only constant through the whole thing is that the 2560 boards have been from the same manufacturer. I know that this can be done as there are posts about it. I am seeking the forums opinion however. I do have 2 different 2560 boards coming.

I should also add that I dug out a spare 1.4 board, and that is working fine with the BLTouch and a new 2560 board installed albeit very slowly though.

|

Re: Ramps 1.6 and VCC issues March 17, 2021 11:34PM |

Admin Registered: 13 years ago Posts: 6,998 |

where did the smoke come from?

The vcc to 5v jumper should just connect the servo 5v lines to vcc.

If you don't have anything plugged into servo plugs, it shouldn't do anything.

but, one issue is the mega 2560 power supply has always been low current.

If you have GLCD and a BLTOUCH its to much for the supply. Just the GLCD can be to much for it...

I would make your own 5v from a 7805 on 12v and plug that into the 5v pin. ie power the servos separately

The vcc to 5v jumper should just connect the servo 5v lines to vcc.

If you don't have anything plugged into servo plugs, it shouldn't do anything.

but, one issue is the mega 2560 power supply has always been low current.

If you have GLCD and a BLTOUCH its to much for the supply. Just the GLCD can be to much for it...

I would make your own 5v from a 7805 on 12v and plug that into the 5v pin. ie power the servos separately

|

Re: Ramps 1.6 and VCC issues May 10, 2021 11:34PM |

Registered: 3 years ago Posts: 2 |

After some more digging into this, I can confirm that it is a manufacturing issue. Somewhere in the process, + and - on servo's is getting some type of debris across them. I have ordered roughly 50 boards from various sellers and all have been the same, a direct short across + and -. I have communicated this to all sellers that I ordered from. I have noticed the most have pulled the products but some are still selling them.

I would like to keep this printer on a RAMPS 1.x setup as it is the easiest to work on.

I would like to keep this printer on a RAMPS 1.x setup as it is the easiest to work on.

|

Re: Ramps 1.6 and VCC issues May 11, 2021 02:26AM |

Admin Registered: 13 years ago Posts: 6,998 |

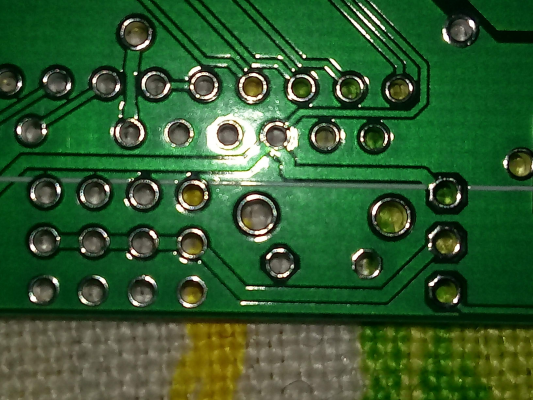

Can you take a high resolution photo of the bottom of the pcb?

The 5v track is on the bottom and should have nice isolation from the gnds

eg here is an unpopulated ramps 1.4 I have

you can clearly see the 5v rail in the middle of the servo plugs on the left of image, nicely isolated from the surrounding traces.

Edited 1 time(s). Last edit at 05/11/2021 02:27AM by Dust.

The 5v track is on the bottom and should have nice isolation from the gnds

eg here is an unpopulated ramps 1.4 I have

you can clearly see the 5v rail in the middle of the servo plugs on the left of image, nicely isolated from the surrounding traces.

Edited 1 time(s). Last edit at 05/11/2021 02:27AM by Dust.

|

Re: Ramps 1.6 and VCC issues February 06, 2022 08:29AM |

Registered: 2 years ago Posts: 15 |

|

Re: Ramps 1.6 and VCC issues March 07, 2022 09:37AM |

Registered: 14 years ago Posts: 140 |

Quote

Chipa

I burned my board 3 times ... and now I bought bunch of AMS1117 5v regulators- and keep replacing them ..

The linear regulators (such as the AMS1117), are essentially smart resistors. Meaning, that what ever energy is not needed, in order to deliver 5V on the output, is simply being burned-up as heat in the linear regulator chip.

So, if you lower the voltage on the Vin pin, then there will be less energy for the AMS1117 to burn, while it still delivers 5V output.

Some heat examples:

- 12V input at 5V output, and the use of 200mA at 5V.

The voltage difference 12V - 5V = 7V (at 200mA) must be burned in the regulator chip. 7V x 200mA = 1.4W

Same setup but now 300mA is used at 5V. What must be burned, as heat in the regulator chip is: 7V x 300mA = 2.1W

Same setup, but now500mA is used at 5V, this burns 7V x 500mA = 3.5W in the regulator chip.

- now lets supply the Vin pin with only 7.5V, and let us see how much heat needs to be burnt up in the regulator chip

The voltage difference is 7.5V - 5V = 2.5V - that needs to be dissipated as heat.

At 200mA use at 5V this leads to 2.5V x 200mA = 0.5W

So at 7.5V on Vin, then only 0.5W needs to be dissipated as heat in the regulator.

At 300mA use at 5V the left over energy is: 2.5V x 300mA = 0,75W

At 500 mA use at 5V, still only leaves 2.5V x 500mA = 1.25W that needs to be dissipated by the regulator chip.

Now lets look at how much heat the housing of a typical AMS1117 is designed/meant to be able to burn.

The housing is typically SOT-223 or TO-252

A SOT-223 housing will rise 90°C/W that is being burnt by the chip.

A TO-252 housing will rise 80°C/W

But copper heatsinking in the PCB design can lower how many degrees raise there is per watt burned by the chip. So a good PCB design, where about 4-6x the size of the chip, is being dedicated to heatsinking, can cut this heat rise in about half.

The junction temperature (the temperature on the wafer, inside the chip) must not exceed 165*C

The heat travel resistance, from the junction to the outside housing is 15*C/W.

So at 1W the housing temperature must no exceed 150*C

At 3.5W the housing temperature must not exceed 112*C

But let us play it 'safe' and lets say that the housing temperature must not exceed 90-100*C - or more specifically 90*C

This all leads us to conclude:

When 12V is on Vin, then an AMS1117 ( SOT-223 housing)

- must not supply more than 140mA (at the 5V output) - if there is NOT a lot of PCB dedicated to heatsinking,

- and could supply as much as 285mA (at the 5V output) - if there is a lot of PCB being dedicated to act as a heat sink.

When 7.5V is on Vin, then an AMS1117 ( SOT-223 housing)

- can deliver as much as 400mA (at the 5V output) - if there is NOT a lot of PCB dedicated to heatsinking

- and can deliver as much as 800mA (at the 5V output) - if there is a lot of PCB being dedicated to act as a heat sink.

So, in order to prevent the AMS1117 chips on the Arduino Mega board on burning up, and letting the magic smoke out, then I highly recommend, that you change the power supply system for Vin, to something closer to 7.5V, rather then the close to 12V that is being supplied right now.

The smart method to get closer to 7.5V for Vin, is to use a DC-DC switching mode power supply converter module. These can be bought for less than US$1

The simple way to lower the 12V to something closer to 7.5V is to place some diodes in series.

Each diode will cause a voltage drop of about 0.6V.

So placing 4-6 diodes in series, in the path of the plus line, between 12V and Vin, will cause the voltage at Vin, to drop about 2.4V (4 diodes) and a 3.6V drop (6 diodes).

12V - 3.6V = 8.4V - which is very likely to be close enough to the ideal 7.5V

At 8.4V at Vin, and only burning 1W in the regulator chip, still leaves 300mA available at 5V.

I hope all of these number examples makes some sense to you.

And I especially hope, that it is clear, that the best way to avoid burning the AMS1117 chips, is to lower the voltage at Vin. Okay?

FYI, I have used this datasheet, to get the specs of a AMS1117 chip: [www.advanced-monolithic.com]

Edited 3 time(s). Last edit at 03/07/2022 09:59AM by MrAlvin.

|

Re: Ramps 1.6 and VCC issues March 07, 2022 04:38PM |

Admin Registered: 13 years ago Posts: 6,998 |

|

Re: Ramps 1.6 and VCC issues March 07, 2022 08:44PM |

Registered: 14 years ago Posts: 140 |

Sorry, only registered users may post in this forum.