CraftWare

geschrieben von BombieTHeZombie

|

Re: CraftWare 16. July 2014 07:27 |

Registrierungsdatum: 10 Jahre zuvor Beiträge: 99 |

bei mir kam der Fehler, nachdem mein Antivirus-Programm den Download mit der Meldung "Win32: Evo-gen [susp]" quittierte. Es wurde aber dennoch ein Teil des Programms runtergeladen, also nicht das komplette Programm.

Als ich den runtergeladenen Teil startete (ich hatte erst nicht bemerkt, dass es unvollständig runtergeladen war), kam bei mir die Meldung keine Win32 Anwendung. Mit einem anderen Rechner und anderem AV-Programm ließ sich das Programm problemlos runterladen. Eine Prüfung mit "virustotal" ergab, dass das keine schädliche Datei ist.

Also habe ich in meinem AV eingetragen, dass die Datei zu den Guten gehört. Danach wurde das Programm komplett runtergeladen und funktioniert auch.

Gruß Thomas

Als ich den runtergeladenen Teil startete (ich hatte erst nicht bemerkt, dass es unvollständig runtergeladen war), kam bei mir die Meldung keine Win32 Anwendung. Mit einem anderen Rechner und anderem AV-Programm ließ sich das Programm problemlos runterladen. Eine Prüfung mit "virustotal" ergab, dass das keine schädliche Datei ist.

Also habe ich in meinem AV eingetragen, dass die Datei zu den Guten gehört. Danach wurde das Programm komplett runtergeladen und funktioniert auch.

Gruß Thomas

|

Re: CraftWare 16. July 2014 12:49 |

Registrierungsdatum: 10 Jahre zuvor Beiträge: 501 |

|

Re: CraftWare 16. July 2014 14:49 |

Registrierungsdatum: 12 Jahre zuvor Beiträge: 1.916 |

|

Re: CraftWare 16. July 2014 17:14 |

Registrierungsdatum: 9 Jahre zuvor Beiträge: 6 |

Ja, falsch-positive.

[community.norton.com]

Ich habe einen Streit mit Symantec eröffnet.

In Bezug auf CraftWare: Ich weiß nicht versprechen, aber wir planen, in dieser Woche frei 1,02.

Danke Jungs!

[community.norton.com]

Ich habe einen Streit mit Symantec eröffnet.

In Bezug auf CraftWare: Ich weiß nicht versprechen, aber wir planen, in dieser Woche frei 1,02.

Danke Jungs!

|

Re: CraftWare 17. July 2014 13:42 |

Registrierungsdatum: 9 Jahre zuvor Beiträge: 102 |

|

Re: CraftWare 18. July 2014 04:34 |

Registrierungsdatum: 9 Jahre zuvor Beiträge: 1 |

|

Re: CraftWare 19. July 2014 03:18 |

Registrierungsdatum: 12 Jahre zuvor Beiträge: 799 |

Nö bisher keine Dualhead unterstützung.

___

I just tried out Beta 1.02, a little bit better, but before i give feedback again i would like to have an answer on my most important question.

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

___

I just tried out Beta 1.02, a little bit better, but before i give feedback again i would like to have an answer on my most important question.

Quote

Chri

....

And before i forget it, the most important question, whats the target of the software when it is finished, will it be free or will there be an base(free) and/or a pro version ? what will the cost be?, just what licence typ do you plan ?

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

|

Re: CraftWare 19. July 2014 04:45 |

Registrierungsdatum: 10 Jahre zuvor Beiträge: 249 |

I´m missing a adjustment for extruder-/heatbed-temperature after the first layer.

There is no bridge detection..... please make an option for bridging-speed and extrusion-width.

Isn´t ist better to change the "extrusion width" under ->Basic settings -> Resolution into "Nozzle Diameter" ?

There is no bridge detection..... please make an option for bridging-speed and extrusion-width.

Isn´t ist better to change the "extrusion width" under ->Basic settings -> Resolution into "Nozzle Diameter" ?

|

Re: CraftWare 19. July 2014 07:55 |

Registrierungsdatum: 10 Jahre zuvor Beiträge: 1.103 |

No, because you can extrude at different widths using the same nozzle diameter.Quote

Plastikschmelzer

Isn´t ist better to change the "extrusion width" under ->Basic settings -> Resolution into "Nozzle Diameter" ?

@hjani1970:

Why does vertical shell depend on layer height, while horizontal shell depends on extrusion width?

I think you mixed something up in calculation

1-mal bearbeitet. Zuletzt am 19.07.14 07:56.

Grüße

Marco

Thingiverse

|

Re: CraftWare 19. July 2014 08:46 |

Registrierungsdatum: 10 Jahre zuvor Beiträge: 249 |

|

Re: CraftWare 21. July 2014 08:59 |

Registrierungsdatum: 9 Jahre zuvor Beiträge: 6 |

Quote

Chri

Nö bisher keine Dualhead unterstützung.

___

Quote

Chri

I just tried out Beta 1.02, a little bit better, but before i give feedback again i would like to have an answer on my most important question.

And before i forget it, the most important question, whats the target of the software when it is finished, will it be free or will there be an base(free) and/or a pro version ? what will the cost be?, just what licence typ do you plan ?

Chri

Ok, it will be free all time, but we may display CraftBot advertisement in a non-annoying manner once after software launch.

|

Re: CraftWare 21. July 2014 14:08 |

Registrierungsdatum: 12 Jahre zuvor Beiträge: 799 |

Quote

hjani1970

Quote

Chri

Nö bisher keine Dualhead unterstützung.

___

Quote

Chri

I just tried out Beta 1.02, a little bit better, but before i give feedback again i would like to have an answer on my most important question.

And before i forget it, the most important question, whats the target of the software when it is finished, will it be free or will there be an base(free) and/or a pro version ? what will the cost be?, just what licence typ do you plan ?

Chri

Ok, it will be free all time, but we may display CraftBot advertisement in a non-annoying manner once after software launch.

Thats great to hear

so lets move on

feature request

* Preset (and/or save function) for different printers at the "options" function, or combined with the slicing save function ?

* "Low quality" mode for displaying complex STL`s/Gcode on slow machines (no reflections ect.)

cosmetic thing

at the Build-volume selection, when you are at the (X) selection and you press TAB its not jumping to (Y) and further not jumping to (Z), but this would be nice to enter the values faster

brim around an object should always be in a cirle around it to ensure that it sticks good and not lines like infill

when there are lines then there is alway a "short" side where the layer is not sticking very well

* Autodrop feature does not work/show at the STL view (you maybe know that already

)

)Support:

* Feature: a mask feature to select a bunch of support structures for deleting them

* the support function doesn`t have a collision detection if it is coming in touch with an other support structure, it does make structure inside the other structure.

* when you make a part with support generate a gcode and afterwards you go back to the STL view, move the part to a different position and click on slie again the support structure is on the old position, so maybe the "Autogenerate Support" function should be run again by itself or at least the old support code should be removed

it would be good to make a version-history and/or a bugfix list where we know which bugs are already known and/or which features are on your todo list as there is already alot of stuff we "found"

mfg Chri

2-mal bearbeitet. Zuletzt am 21.07.14 14:13.

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

|

Re: CraftWare 26. July 2014 06:35 |

Registrierungsdatum: 9 Jahre zuvor Beiträge: 6 |

Hello,

Sorry for not answering until now.

Thanks for suggestions!

A new version (1.03) is now available to download.

I have added the changelog to our site [www.craftunique.com]

Sorry for not answering until now.

Thanks for suggestions!

A new version (1.03) is now available to download.

I have added the changelog to our site [www.craftunique.com]

|

Re: CraftWare 26. July 2014 06:52 |

Registrierungsdatum: 10 Jahre zuvor Beiträge: 249 |

|

Re: CraftWare 30. July 2014 02:53 |

Registrierungsdatum: 12 Jahre zuvor Beiträge: 799 |

*at the options dialog the "build volume" is crap now on my machines

*Corners at the inner loops of a square hole are still round.

Feature request:

* Could you maybe make an option to also deactivate all "reflection" (Lightspot) on the parts to get even more speed on low machines (my i5 Laptop with Intel Onboard vga is still not running smooth in gcode view )

)

* Multitouch Support would be cool, i own a Lenovo Miix 2 8" now, the software is running relativly smooth but the movements have to be controlled with an bluetooth mouse.

i attached my testpart STL, so you can maybe check the problems on this part compared to how skeinforge is doing the toolpath.

Chri

3-mal bearbeitet. Zuletzt am 30.07.14 03:07.

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

*Corners at the inner loops of a square hole are still round.

Feature request:

* Could you maybe make an option to also deactivate all "reflection" (Lightspot) on the parts to get even more speed on low machines (my i5 Laptop with Intel Onboard vga is still not running smooth in gcode view

)

)* Multitouch Support would be cool, i own a Lenovo Miix 2 8" now, the software is running relativly smooth but the movements have to be controlled with an bluetooth mouse.

i attached my testpart STL, so you can maybe check the problems on this part compared to how skeinforge is doing the toolpath.

Chri

3-mal bearbeitet. Zuletzt am 30.07.14 03:07.

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

|

Re: CraftWare 30. July 2014 16:09 |

Registrierungsdatum: 9 Jahre zuvor Beiträge: 6 |

Hello,

* build volume settings is crap now.

Yes, I've noticed this. The other error report I got is also from a win8 system, so someone of us must upgrade in order to catch this bug. Until that I'll manually set the size of the forms, not with Qt's adtjustSize() thing.

* Corners at the inner loops of a square hole are still round.

I think it's time for some technical explanation: CraftWare uses an experimental method for polygon offsetting: it works in raster space instead of the traditional vector space. Every slice is represented as a 8bit black/white image. The offsetting operation is performed with a blur image effect followed by a threshold operation at a specific intensity level. Then a contour detection algorithm follows that produces an outline (basically an iso-contour) which is composed of ExtrusionWidth/3 length vector-segments. And finally here comes an area based path optimizer algorithm which builds longer segments of those small segments based on the PathSmoothing parameter.

Because of blur, as processing loops:

- 90deg corners on the outside will collapse into somewhat round corners but the rounding will not exceed ExtrusionWidth. (RepairCornes can heal those)

- 90deg corners on the inside (holes) will grow to even rounder shapes, in the end they will become circles. (RepairCornes cannot heal those even bigger roundings)

So because of the above 2, it turned out that the Repair Corner feature only useful on the perimeter, not on the loops.

Pros:

- raster-offsetting performance depends on rough mesh surface area and not on mesh complexity. (That's why a simple dog bowl takes as long as an complex MRI skull.)

- numerically stable: Needs no reconstruction and healing after an offset operation. The answer to the question "Which side of a line am I standing?" is always trivial.

Cons:

- Sharp edges are rounded, and when they rare close to each other, or not that sharp, they're difficult/impossible to repair.

- Surfaces close together tend to stick to each other similar like metaball demo effect. Because of this, it is unable to slice a working ball-bearing.

Solution:

- An option to use vector offsetting algorithm. The masking and the toolpath generator will be the same, so it will be a hybrid thing.

When:

- Unfortunately there are other more important priorities like tons of bugs and a usable slicing-settings interface, and also multiplatform support. So it must be scheduled later.

* Could you maybe make an option to also deactivate all "reflection" (Lightspot)

I've made an option to disable environmentMapping for gcode viewer and for the Editor. But do you mean the perpixel phong light effect? (that's some kind of a reflection too) What kind of scene you see when you encounter this slow FPS? Is it a hipoly scene? I think the bottleneck is rather vertex count based, as the pixel shader is quite simple (compared to games).

* Multitouch Support would be cool

Good idea, landed on the Todo list, but after multiplatform support.

5-mal bearbeitet. Zuletzt am 30.07.14 16:43.

* build volume settings is crap now.

Yes, I've noticed this. The other error report I got is also from a win8 system, so someone of us must upgrade in order to catch this bug. Until that I'll manually set the size of the forms, not with Qt's adtjustSize() thing.

* Corners at the inner loops of a square hole are still round.

I think it's time for some technical explanation: CraftWare uses an experimental method for polygon offsetting: it works in raster space instead of the traditional vector space. Every slice is represented as a 8bit black/white image. The offsetting operation is performed with a blur image effect followed by a threshold operation at a specific intensity level. Then a contour detection algorithm follows that produces an outline (basically an iso-contour) which is composed of ExtrusionWidth/3 length vector-segments. And finally here comes an area based path optimizer algorithm which builds longer segments of those small segments based on the PathSmoothing parameter.

Because of blur, as processing loops:

- 90deg corners on the outside will collapse into somewhat round corners but the rounding will not exceed ExtrusionWidth. (RepairCornes can heal those)

- 90deg corners on the inside (holes) will grow to even rounder shapes, in the end they will become circles. (RepairCornes cannot heal those even bigger roundings)

So because of the above 2, it turned out that the Repair Corner feature only useful on the perimeter, not on the loops.

Pros:

- raster-offsetting performance depends on rough mesh surface area and not on mesh complexity. (That's why a simple dog bowl takes as long as an complex MRI skull.)

- numerically stable: Needs no reconstruction and healing after an offset operation. The answer to the question "Which side of a line am I standing?" is always trivial.

Cons:

- Sharp edges are rounded, and when they rare close to each other, or not that sharp, they're difficult/impossible to repair.

- Surfaces close together tend to stick to each other similar like metaball demo effect. Because of this, it is unable to slice a working ball-bearing.

Solution:

- An option to use vector offsetting algorithm. The masking and the toolpath generator will be the same, so it will be a hybrid thing.

When:

- Unfortunately there are other more important priorities like tons of bugs and a usable slicing-settings interface, and also multiplatform support. So it must be scheduled later.

* Could you maybe make an option to also deactivate all "reflection" (Lightspot)

I've made an option to disable environmentMapping for gcode viewer and for the Editor. But do you mean the perpixel phong light effect? (that's some kind of a reflection too) What kind of scene you see when you encounter this slow FPS? Is it a hipoly scene? I think the bottleneck is rather vertex count based, as the pixel shader is quite simple (compared to games).

* Multitouch Support would be cool

Good idea, landed on the Todo list, but after multiplatform support.

5-mal bearbeitet. Zuletzt am 30.07.14 16:43.

|

Re: CraftWare 30. July 2014 16:48 |

Registrierungsdatum: 12 Jahre zuvor Beiträge: 799 |

Ok then i`ll have to wait for the new hybrid engine to replace my SK but i`m still testing the beta`s until then

Its already with the relative small Bottle Opener that the movements are not running smooth anymore.

mfg Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

Its already with the relative small Bottle Opener that the movements are not running smooth anymore.

mfg Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

|

Re: CraftWare 03. August 2014 02:23 |

Registrierungsdatum: 10 Jahre zuvor Beiträge: 4 |

Any testing news from the new CraftWare 1.04 beta compare to cura (Ulitmaker)?

I can not find a feature change log on [craftunique.com]

I can not find a feature change log on [craftunique.com]

|

Re: CraftWare 03. August 2014 08:18 |

Registrierungsdatum: 10 Jahre zuvor Beiträge: 1.103 |

Der Changelog ist doch direkt neben dem Download-Tab:

Grüße

Marco

Thingiverse

CraftWare 1.04 beta - 2014.08.01

IMPORTANT:

You must reinstall 1.04 because all the dll files have been replaced due to the upgrade from Qt 5.1.1 to 5.3.1. The update.exe file can only replace the main executable file but not the required dll files, it's unfortunately not enough for this update.

Features:

InfillThicknes: Stronger infill walls can be made of more than one extruded line (Basic settings/Infill/Thickness).

FirstLayerExtrusionRation: Extrusion override for the first layer.

FirstLayerDrawSpeed: Speed override for the first layer. Works along with the InitialLayerSpeed/Count settings.

SlicerForm: Import/Export preset. File extension is ".cwsp" (CW Slicer Preset). It's saved in a human readable JSON format.

BugFixes:

SlicerForm text in the controls turns green when their values are different from the current preset/profile.

Slicer: Retract bug. Sometimes the program did not allow Far Travels (alongside retracting) when they would be necessary.

Slicer: RepairCorners functionality was bugged (crashed) with complex meshes like Thingiverse/Dragonfly Wing Set.

Popup Forms: form size is no longer restricted. During form creation the function "adjustSize()" is used, you can still resize the form if it fails (because Qt doesn't like warped text labels and such)

Preview display is now aware of the current Raft configuration.

CraftWare v1.03 beta - 2014.07.25

Known bugs

When PolygonFillStyle is set to "Odd" there are some perimeter artifacts.

When StartAtLayer is not equal to LastPosition. This setting will be ignored until corrected.

Slicer form is closeable while slicing is in progress.

Options/NumCPU setting doesn't effect actual CPU core usage.

Rare random crashes.

There are a few (1-5) random bright pixels on the screen.

Features and bug fixes

Shell Thickness calculated fields: LayerHeight and ExtrusionWidth values were swapped.

An option to turn off environment mapping in both object and support view in unison.

Tab order corrections

Brim has been completely redesigned. (Although the previous ''fishing net'' feature will return in the future, I think it's simple and practical with a heated bed to strengthen the supports)

Crashes while adjusting the brim/skirt fixed.

MakerBot M132 is not interpreted by the gcode viewer as a sign that the XY is centered at 0,0. Use Options/BuildVolume instead.

New circular build platform option.

gcode decoder: Now it understands comments in KISS, MakerWare, Cura gcodes and uses appropriate colors based on the segment type.

gcode text display is available in the gcode viewer.

Popup form resolutions are maximized to 1000x700 pixels.

Models bigger than 4M triangles will not crash (there is a GPU limit on the VBO size), rather they will be drawn incomplete.

Slicer Form: inappropriate CPU usage (10-20%) reduced. Now it is more careful when changing widget stylesheets.

CraftWare v1.02 beta - 2014.07.18

Features and bug fixes

RepairCorners default is now 0

RepairCorners works for more than one loops. Although it's not necessary because outer corners are automatically collapse to sharp corners and inner corners (in holes) are tend to grow into big circles that can't be repaired.

Slightly improved RepairCorners: No need to increment PathSmoothing from default 0.08 to 0.1.

Installer runs vcredist in /quiet mode.

Slicing crash caused by the performance monitor thing is fixed.

Bug: "I wasn't able to load Stored presets yet? Only when saving the project and reloading it again." -> presets are now saved into the registry.

Selectable Polygon Filler Algorithm: You can choose between fast or error-prone methods.

Shell Thickness auto-calculated fields.

Layer start position is selectable: Sequential, Random, North, South, East, West. Sequential is slow, but minimizes travel between adjacent layers.

My misunderstanding of Raft is renamed to Brim (sorry ABS people)

Raft 'sandwich' configuration thing is established in the Slicer UI. But in the application, only the Raft Enable checkbox is working. Just expect a flexible Raft generator tool in the future.

CraftWare v1.01 beta - 2014.07.14

Features and bug fixes

Options/Build Volume config is now working. You can configure it for Delta machines.

Maximum speeds are now raised to 500mm/s

Open/Save folder bug fixed: It doesn't remember the folder when you not save and only shows home folder when you freshly install the app.

Slicer form: Fill Angles are now configurable: Infill angle & layer increment, HShell angle & layer increment, Raft angle. The only exception is Support angles.

Slicer form: Fan settings are accessible.

Slicer form: HShell density now affects extruded flow as it should.

Slicer form: Vertical speed and retract/prime speed.

Slicer form: There is now a Repair Corners option. It fixes rounded corners caused by the raster-offset algorithm.

Form maximized state is stored in the ini (registry).

There is now a basic interface to set up filament meter prices in the options form. It is displayed on the GCode viewer and it has a button to toggle.

CraftWare v1.00 beta - 2014.07.07

Grüße

Marco

Thingiverse

|

Re: CraftWare 08. August 2014 15:02 |

Registrierungsdatum: 9 Jahre zuvor Beiträge: 2 |

Quote

hjani1970

Hello,

* build volume settings is crap now.

Yes, I've noticed this. The other error report I got is also from a win8 system, so someone of us must upgrade in order to catch this bug. Until that I'll manually set the size of the forms, not with Qt's adtjustSize() thing.

* Corners at the inner loops of a square hole are still round.

I think it's time for some technical explanation: CraftWare uses an experimental method for polygon offsetting: it works in raster space instead of the traditional vector space. Every slice is represented as a 8bit black/white image. The offsetting operation is performed with a blur image effect followed by a threshold operation at a specific intensity level. Then a contour detection algorithm follows that produces an outline (basically an iso-contour) which is composed of ExtrusionWidth/3 length vector-segments. And finally here comes an area based path optimizer algorithm which builds longer segments of those small segments based on the PathSmoothing parameter.

Because of blur, as processing loops:

- 90deg corners on the outside will collapse into somewhat round corners but the rounding will not exceed ExtrusionWidth. (RepairCornes can heal those)

- 90deg corners on the inside (holes) will grow to even rounder shapes, in the end they will become circles. (RepairCornes cannot heal those even bigger roundings)

So because of the above 2, it turned out that the Repair Corner feature only useful on the perimeter, not on the loops.

Pros:

- raster-offsetting performance depends on rough mesh surface area and not on mesh complexity. (That's why a simple dog bowl takes as long as an complex MRI skull.)

- numerically stable: Needs no reconstruction and healing after an offset operation. The answer to the question "Which side of a line am I standing?" is always trivial.

Cons:

- Sharp edges are rounded, and when they rare close to each other, or not that sharp, they're difficult/impossible to repair.

- Surfaces close together tend to stick to each other similar like metaball demo effect. Because of this, it is unable to slice a working ball-bearing.

Solution:

- An option to use vector offsetting algorithm. The masking and the toolpath generator will be the same, so it will be a hybrid thing.

When:

- Unfortunately there are other more important priorities like tons of bugs and a usable slicing-settings interface, and also multiplatform support. So it must be scheduled later.

* Could you maybe make an option to also deactivate all "reflection" (Lightspot)

I've made an option to disable environmentMapping for gcode viewer and for the Editor. But do you mean the perpixel phong light effect? (that's some kind of a reflection too) What kind of scene you see when you encounter this slow FPS? Is it a hipoly scene? I think the bottleneck is rather vertex count based, as the pixel shader is quite simple (compared to games).

* Multitouch Support would be cool

Good idea, landed on the Todo list, but after multiplatform support.

just throwing some ideas out there....before or after the blur filter is applied, run a corner detection algorithm to pick out the corners (since they have some very unique features), and then close it when you do edge/contour detection.

|

Re: CraftWare 23. February 2015 09:54 |

Registrierungsdatum: 10 Jahre zuvor Beiträge: 1.103 |

Es gibt eine neue Version: [www.craftunique.com]

Damit sollten bald die runden Ecken verschwunden sein

[www.youtube.com]

Grüße

Marco

Thingiverse

Damit sollten bald die runden Ecken verschwunden sein

[www.youtube.com]

Grüße

Marco

Thingiverse

|

Re: CraftWare 21. May 2015 00:54 |

Registrierungsdatum: 12 Jahre zuvor Beiträge: 799 |

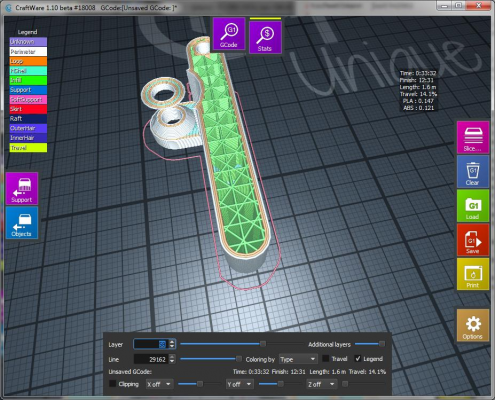

Gestern erst entdeckt das es wieder eine neue Version gibt (Craftware 1.10 beta).

Hab gestern abend nen kurzen Testdruck gemacht war echt ein top Ergebnis (Besser als Cura mit weniger Settings gefummel), auch ein paar andere geslicte Teile sahen super und Fehlerfrei aus.

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

Hab gestern abend nen kurzen Testdruck gemacht war echt ein top Ergebnis (Besser als Cura mit weniger Settings gefummel), auch ein paar andere geslicte Teile sahen super und Fehlerfrei aus.

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

|

Re: CraftWare 21. June 2015 14:18 |

Registrierungsdatum: 10 Jahre zuvor Beiträge: 501 |

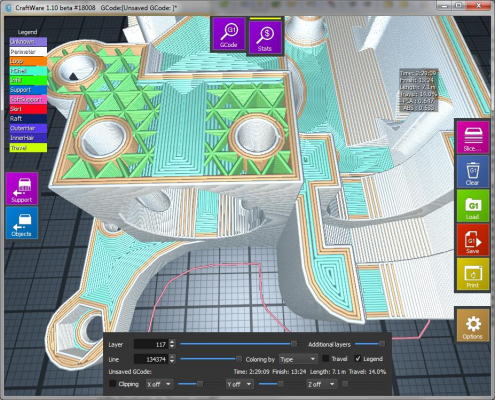

Nach längerer Zeit hatte ich letztes WE mal wieder aktuelle Slicer geladen, insbesondere auf deren Verträglichkeit mit nicht spieletauglicher Hardware.

Ich habe sie ausnahmslos auf meinem Notebook installiert und oberflächlich gecheckt.

So u.a. auch die aktuelle Version von Craftware.

Im Gegensatz zu meinem letztjährigen Versuch ließ sie sich problemlos installieren und starten, immerhin.

Ein wenig störrisch verhielt sie sich beim Entfernen der voreingestellten Demos, ein einfaches Clear henügte nicht,

die Objekte mussten einzeln vernichtet werden.

Das gleiche galt auch für alle weiteren geladenen Objekte.

Die Oberfläche ist Geschmackssache, ich finde sie schlichtweg überladen.

Sie macht auf mich den Eindruck, als wäre sie als alleiniges Fenster auf einem zugehörigen Bedienterminal vorgesehen.

Wie auch immer, sie verrichtet ihre Aufgaben, und das nicht einmal schlecht.

Im Gegenteil, mit meinen Testobjekten sogar richtig gut.

Legte ich ausschließlich meinen Kurztest zugrunde, befindet sie sich auf Cura-Niveau,

sowohl bezgl. Slicegeschwindigkeit, erzeugtem Code und Materialverbrauch.

Sie hat sogar zwei Vorteile, der Slicer rennt nicht unmittelbar los und die visuelle Darstellung ist aussagekräftiger.

Leider hat diese Darstellung auch einen immensen Nachteil, sie ist zu verspielt und frisst zuviel Resourcen.

Ein simples Notebook ist damit völlig überfordert, auch mein höherwertiges Dell mit Zusatzgraka ist da ebenfalls am Ende.

Eigentlich schade, da der Slicer eindeutig zu den schnelleren seiner Zunft gehört.

Eine Objektverschiebung bei leichtem Zoom fördert ca. ein Bild so alle 2-10 Sekunden.

Ausgeklügelte Beleuchtung mag nett anzusehen sein, ebenso ein transparenter Extruder.

Einen informellen Mehrwert liefern sie nicht, weg damit! MIndestens aber abschaltbar...

Autoplatzieren klappt meistens, hat ein Modell mehrere "gerade" Seiten, wird es auf die erstbeste mit der größten Fläche gelegt.

Da dies nicht immer stimmen muss, kann es zu "Luft"-Extrusionen kommen.

Die Einstellungsvielvalt übertrifft Cura deutlich, sie reicht in Teilen an Slic3R heran.

Perimeter sind in der Craftwaresprache nur die äußere Bahn einer sogenannten Loop.

Das hat den Vorteil, dass Craftware sind absolut keine Probleme damit hat, wenn eine Wand dünner ist als die vorgegebene

"Mindestdicke" aufgrund der Perimeterzahl. Ein Punkt, bei dem Slic3R regelmäßig streikt.

Bei den Infillvarianten habe ich eine Wabenstruktur vermisst, parallele Linien und Quadrate sind m.E. unnötig, da im Regelfall unzureichend stabil.

Es bleibt praktisch nur die Trianglevariante übrig, bei allen getesteten Objekten zeigt sie einwandfreie Ergebnisse.

Sollte da doch einmal etwas nicht so recht passen hat man noch drei Optionen mit unregelmäßigen Dreiecken: 45°, 36° und 30°.

Brauchbaren Code liefern alle.

Für Grund- und Deckflächen gibt es zwei Varianten: Linien und konzentrische Gebilde.

Letztere erzeugen eine sehr ansehnliche Oberfläche.

Leider sind alle Lagen gleich aufgebaut, bei einem gekreuzten Linienunterbau wäre die Stabilität wohl noch besser.

Zu guter Letzt wurde noch ein Dünnwand-Arrangement in Druckschichten zerlegt.

Von 6 LM8UU Varianten wurden 5 mit Bravour abgeliefert, nur bei einem hat sich das Proggie verschluckt.

Trotz unzulässiger Perimeter- bzw. Loopvorgabe sind die äußeren Flächen jedenfalls in Ordnung.

Ein weiterer Pluspunkt: Ein Versuch, ein Objekt zu platzieren, welches vollständig unterhalb der Druckfläche liegt, endet mit einer

Fehlermeldung. Andere Slicer zeigen statt dessen einfach gar nichts an.

Summasummarum bei entspechender Hardwareausstattung (3D) ein wirklich tolles Programm.

Ich habe sie ausnahmslos auf meinem Notebook installiert und oberflächlich gecheckt.

So u.a. auch die aktuelle Version von Craftware.

Im Gegensatz zu meinem letztjährigen Versuch ließ sie sich problemlos installieren und starten, immerhin.

Ein wenig störrisch verhielt sie sich beim Entfernen der voreingestellten Demos, ein einfaches Clear henügte nicht,

die Objekte mussten einzeln vernichtet werden.

Das gleiche galt auch für alle weiteren geladenen Objekte.

Die Oberfläche ist Geschmackssache, ich finde sie schlichtweg überladen.

Sie macht auf mich den Eindruck, als wäre sie als alleiniges Fenster auf einem zugehörigen Bedienterminal vorgesehen.

Wie auch immer, sie verrichtet ihre Aufgaben, und das nicht einmal schlecht.

Im Gegenteil, mit meinen Testobjekten sogar richtig gut.

Legte ich ausschließlich meinen Kurztest zugrunde, befindet sie sich auf Cura-Niveau,

sowohl bezgl. Slicegeschwindigkeit, erzeugtem Code und Materialverbrauch.

Sie hat sogar zwei Vorteile, der Slicer rennt nicht unmittelbar los und die visuelle Darstellung ist aussagekräftiger.

Leider hat diese Darstellung auch einen immensen Nachteil, sie ist zu verspielt und frisst zuviel Resourcen.

Ein simples Notebook ist damit völlig überfordert, auch mein höherwertiges Dell mit Zusatzgraka ist da ebenfalls am Ende.

Eigentlich schade, da der Slicer eindeutig zu den schnelleren seiner Zunft gehört.

Eine Objektverschiebung bei leichtem Zoom fördert ca. ein Bild so alle 2-10 Sekunden.

Ausgeklügelte Beleuchtung mag nett anzusehen sein, ebenso ein transparenter Extruder.

Einen informellen Mehrwert liefern sie nicht, weg damit! MIndestens aber abschaltbar...

Autoplatzieren klappt meistens, hat ein Modell mehrere "gerade" Seiten, wird es auf die erstbeste mit der größten Fläche gelegt.

Da dies nicht immer stimmen muss, kann es zu "Luft"-Extrusionen kommen.

Die Einstellungsvielvalt übertrifft Cura deutlich, sie reicht in Teilen an Slic3R heran.

Perimeter sind in der Craftwaresprache nur die äußere Bahn einer sogenannten Loop.

Das hat den Vorteil, dass Craftware sind absolut keine Probleme damit hat, wenn eine Wand dünner ist als die vorgegebene

"Mindestdicke" aufgrund der Perimeterzahl. Ein Punkt, bei dem Slic3R regelmäßig streikt.

Bei den Infillvarianten habe ich eine Wabenstruktur vermisst, parallele Linien und Quadrate sind m.E. unnötig, da im Regelfall unzureichend stabil.

Es bleibt praktisch nur die Trianglevariante übrig, bei allen getesteten Objekten zeigt sie einwandfreie Ergebnisse.

Sollte da doch einmal etwas nicht so recht passen hat man noch drei Optionen mit unregelmäßigen Dreiecken: 45°, 36° und 30°.

Brauchbaren Code liefern alle.

Für Grund- und Deckflächen gibt es zwei Varianten: Linien und konzentrische Gebilde.

Letztere erzeugen eine sehr ansehnliche Oberfläche.

Leider sind alle Lagen gleich aufgebaut, bei einem gekreuzten Linienunterbau wäre die Stabilität wohl noch besser.

Zu guter Letzt wurde noch ein Dünnwand-Arrangement in Druckschichten zerlegt.

Von 6 LM8UU Varianten wurden 5 mit Bravour abgeliefert, nur bei einem hat sich das Proggie verschluckt.

Trotz unzulässiger Perimeter- bzw. Loopvorgabe sind die äußeren Flächen jedenfalls in Ordnung.

Ein weiterer Pluspunkt: Ein Versuch, ein Objekt zu platzieren, welches vollständig unterhalb der Druckfläche liegt, endet mit einer

Fehlermeldung. Andere Slicer zeigen statt dessen einfach gar nichts an.

Summasummarum bei entspechender Hardwareausstattung (3D) ein wirklich tolles Programm.

In diesem Forum dürfen leider nur registrierte Teilnehmer schreiben.