Home

>

RepRap User Groups

>

Europe

>

Deutschsprachiges Forum

>

Extruder, Hotends & verschiedene Materialien

>

Thema

Formfutura Flexifil, S3D versus Slic3rPE Stringing Wahnsinn

geschrieben von Ghenne

|

Formfutura Flexifil, S3D versus Slic3rPE Stringing Wahnsinn 17. July 2018 16:42 |

Registrierungsdatum: 7 Jahre zuvor Beiträge: 122 |

ich probiere zurzeit Formfutura Flexifil aus. Habe meinen einen Extruder dafür etwas umgebaut und kann damit jetzt TPU und ähnliches drucken.

Heute habe ich zunächst einen Heattower gedruckt. Von Thingiverse hatte ich zuerst den gcode geladen, der laut Header wohl mit S3D erstellt wurde.

Das klappte zunächst auch gut, aber ich musste die Drucke sämtlichst abbrechen, da sie auf meiner Filaprint bei 60-110 Grad sofort gewarpt sind und spätestens nach dem 40igsten Layer abgefallen sind.

Ich habe dann die STL nochmals selbst mit einem breiten Brim gesliced (Slic3rPE) und die Temperaturwechsel wieder eingefügt.

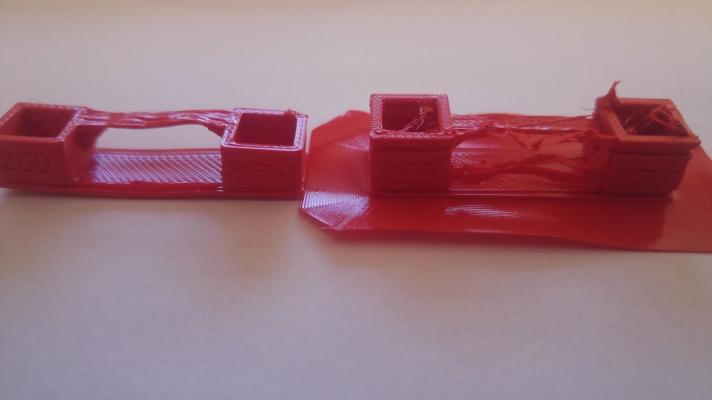

Was ich nun bemerkt habe, der S3D gcode hat praktisch überhaupt kein Stringing produziert, während beim selbstgesliceten das Stringing fast so dick wie eine Bridge wird.

Hier erstmal das Foto, zwei abgebrochene Drucke, links S3D rechts Slic3rPE:

Vielleicht können die Experten mal einen Blick darauf werfen und einen Tip geben (selbst wenn der lautet S3D zu kaufen

Viele Grüße,

Gunnar.

----------------------------------------------------------------------

Hier der S3D Header:

Und hier der vom Slic3r:

2-mal bearbeitet. Zuletzt am 17.07.18 17:20.

Heute habe ich zunächst einen Heattower gedruckt. Von Thingiverse hatte ich zuerst den gcode geladen, der laut Header wohl mit S3D erstellt wurde.

Das klappte zunächst auch gut, aber ich musste die Drucke sämtlichst abbrechen, da sie auf meiner Filaprint bei 60-110 Grad sofort gewarpt sind und spätestens nach dem 40igsten Layer abgefallen sind.

Ich habe dann die STL nochmals selbst mit einem breiten Brim gesliced (Slic3rPE) und die Temperaturwechsel wieder eingefügt.

Was ich nun bemerkt habe, der S3D gcode hat praktisch überhaupt kein Stringing produziert, während beim selbstgesliceten das Stringing fast so dick wie eine Bridge wird.

Hier erstmal das Foto, zwei abgebrochene Drucke, links S3D rechts Slic3rPE:

Vielleicht können die Experten mal einen Blick darauf werfen und einen Tip geben (selbst wenn der lautet S3D zu kaufen

Viele Grüße,

Gunnar.

----------------------------------------------------------------------

Hier der S3D Header:

; G-Code generated by Simplify3D(R) Version 4.0.0 ; Aug 21, 2017 at 10:16:27 AM ; Settings Summary ; processName,Process1 ; applyToModels,220-260PETG Temp Tower ; profileName,Tronxy P802 (modified) ; profileVersion,2017-08-19 17:21:20 ; baseProfile,Default (modified) ; printMaterial,PETG ; printQuality,Medium ; printExtruders, ; extruderName,Primary Extruder ; extruderToolheadNumber,0 ; extruderDiameter,0.4 ; extruderAutoWidth,0 ; extruderWidth,0.4 ; extrusionMultiplier,1 ; extruderUseRetract,1 ; extruderRetractionDistance,1.5 ; extruderExtraRestartDistance,0 ; extruderRetractionZLift,0 ; extruderRetractionSpeed,1800 ; extruderUseCoasting,1 ; extruderCoastingDistance,0.2 ; extruderUseWipe,0 ; extruderWipeDistance,5 ; primaryExtruder,0 ; layerHeight,0.2 ; topSolidLayers,3 ; bottomSolidLayers,3 ; perimeterOutlines,3 ; printPerimetersInsideOut,1 ; startPointOption,2 ; startPointOriginX,0 ; startPointOriginY,0 ; sequentialIslands,0 ; spiralVaseMode,0 ; firstLayerHeightPercentage,90 ; firstLayerWidthPercentage,100 ; firstLayerUnderspeed,0.5 ; useRaft,0 ; raftExtruder,0 ; raftTopLayers,3 ; raftBaseLayers,2 ; raftOffset,3 ; raftSeparationDistance,0.14 ; raftTopInfill,100 ; aboveRaftSpeedMultiplier,0.3 ; useSkirt,1 ; skirtExtruder,0 ; skirtLayers,1 ; skirtOutlines,4 ; skirtOffset,4 ; usePrimePillar,0 ; primePillarExtruder,999 ; primePillarWidth,12 ; primePillarLocation,7 ; primePillarSpeedMultiplier,1 ; useOozeShield,0 ; oozeShieldExtruder,999 ; oozeShieldOffset,2 ; oozeShieldOutlines,1 ; oozeShieldSidewallShape,1 ; oozeShieldSidewallAngle,30 ; oozeShieldSpeedMultiplier,1 ; infillExtruder,0 ; internalInfillPattern,Rectilinear ; externalInfillPattern,Rectilinear ; infillPercentage,20 ; outlineOverlapPercentage,15 ; infillExtrusionWidthPercentage,100 ; minInfillLength,5 ; infillLayerInterval,1 ; internalInfillAngles,45,-45 ; overlapInternalInfillAngles,0 ; externalInfillAngles,45,-45 ; generateSupport,0 ; supportExtruder,0 ; supportInfillPercentage,30 ; supportExtraInflation,0 ; supportBaseLayers,0 ; denseSupportExtruder,0 ; denseSupportLayers,0 ; denseSupportInfillPercentage,70 ; supportLayerInterval,1 ; supportHorizontalPartOffset,0.3 ; supportUpperSeparationLayers,1 ; supportLowerSeparationLayers,1 ; supportType,0 ; supportGridSpacing,4 ; maxOverhangAngle,45 ; supportAngles,0 ; temperatureName,Primary Extruder,Headed bed ; temperatureNumber,0,1 ; temperatureSetpointCount,9,1 ; temperatureSetpointLayers,1,39,73,106,140,174,207,241,275,1 ; temperatureSetpointTemperatures,260,255,250,245,240,235,230,225,220,80 ; temperatureStabilizeAtStartup,1,1 ; temperatureHeatedBed,0,1 ; temperatureRelayBetweenLayers,0,0 ; temperatureRelayBetweenLoops,0,0 ; fanLayers,1,2 ; fanSpeeds,0,50 ; blipFanToFullPower,0 ; adjustSpeedForCooling,1 ; minSpeedLayerTime,15 ; minCoolingSpeedSlowdown,20 ; increaseFanForCooling,0 ; minFanLayerTime,45 ; maxCoolingFanSpeed,100 ; increaseFanForBridging,0 ; bridgingFanSpeed,100 ; use5D,1 ; relativeEdistances,0 ; allowEaxisZeroing,1 ; independentExtruderAxes,0 ; includeM10123,0 ; stickySupport,1 ; applyToolheadOffsets,0 ; gcodeXoffset,0 ; gcodeYoffset,0 ; gcodeZoffset,-0.05 ; overrideMachineDefinition,0 ; machineTypeOverride,0 ; strokeXoverride,200 ; strokeYoverride,200 ; strokeZoverride,200 ; originOffsetXoverride,0 ; originOffsetYoverride,0 ; originOffsetZoverride,0 ; homeXdirOverride,-1 ; homeYdirOverride,-1 ; homeZdirOverride,-1 ; flipXoverride,1 ; flipYoverride,-1 ; flipZoverride,1 ; toolheadOffsets,0,0|0,0|0,0|0,0|0,0|0,0 ; overrideFirmwareConfiguration,0 ; firmwareTypeOverride,RepRap (Marlin/Repetier/Sprinter) ; GPXconfigOverride,r2 ; baudRateOverride,115200 ; overridePrinterModels,0 ; printerModelsOverride ; startingGcode,G28 ;Home,G1 Z15.0 F6000 ;Move the platform down 15mm,G1 E10 F240 ;Extrude 10MM fillament,,, ; layerChangeGcode, ; retractionGcode, ; toolChangeGcode, ; endingGcode,M104 S0,M140 S0,G92 E1,G1 E-1 F300,G28 X0 Y0,M84 ; exportFileFormat,gcode ; celebration,0 ; celebrationSong,Random Song ; postProcessing, ; defaultSpeed,3600 ; outlineUnderspeed,0.5 ; solidInfillUnderspeed,0.8 ; supportUnderspeed,0.8 ; rapidXYspeed,4800 ; rapidZspeed,1002 ; minBridgingArea,50 ; bridgingExtraInflation,0 ; bridgingExtrusionMultiplier,1 ; bridgingSpeedMultiplier,1 ; useFixedBridgingAngle,0 ; fixedBridgingAngle,0 ; applyBridgingToPerimeters,0 ; filamentDiameters,1.75|1.75|1.75|1.75|1.75|1.75 ; filamentPricesPerKg,46|46|46|46|46|46 ; filamentDensities,1.25|1.25|1.25|1.25|1.25|1.25 ; useMinPrintHeight,0 ; minPrintHeight,0 ; useMaxPrintHeight,0 ; maxPrintHeight,0 ; useDiaphragm,0 ; diaphragmLayerInterval,20 ; robustSlicing,1 ; mergeAllIntoSolid,0 ; onlyRetractWhenCrossingOutline,1 ; retractBetweenLayers,1 ; useRetractionMinTravel,0 ; retractionMinTravel,3 ; retractWhileWiping,0 ; onlyWipeOutlines,1 ; avoidCrossingOutline,0 ; maxMovementDetourFactor,3 ; toolChangeRetractionDistance,12 ; toolChangeExtraRestartDistance,-0.5 ; toolChangeRetractionSpeed,600 ; externalThinWallType,0 ; internalThinWallType,2 ; thinWallAllowedOverlapPercentage,10 ; singleExtrusionMinLength,1 ; singleExtrusionMinPrintingWidthPercentage,50 ; singleExtrusionMaxPrintingWidthPercentage,200 ; singleExtrusionEndpointExtension,0.2 ; horizontalSizeCompensation,0

Und hier der vom Slic3r:

; generated by Slic3r 1.31.6-prusa3d-win64 on 2018-07-17 at 20:16:28 ; external perimeters extrusion width = 0.30mm ; perimeters extrusion width = 0.30mm ; infill extrusion width = 0.40mm ; solid infill extrusion width = 0.40mm ; top infill extrusion width = 0.40mm ; filament used = 3193.3mm (7.7cm3) ; avoid_crossing_perimeters = 0 ; bed_shape = 0x0,300x0,300x300,0x300 ; bed_temperature = 0 ; before_layer_gcode = ; bridge_acceleration = 0 ; bridge_fan_speed = 100 ; brim_width = 10 ; complete_objects = 0 ; cooling = 0 ; default_acceleration = 0 ; disable_fan_first_layers = 3 ; duplicate_distance = 6 ; end_gcode = M104 S0 ; turn off extruder temperature\nM140 S0; turn off bed temperature\nG28 X0 Y0; home X axis\nM84 ; disable motors ; extruder_clearance_height = 20 ; extruder_clearance_radius = 20 ; extruder_offset = 0x0,0x0 ; extrusion_axis = E ; extrusion_multiplier = 1,1 ; fan_always_on = 1 ; fan_below_layer_time = 60 ; filament_colour = #FF0000 ; filament_diameter = 1.75,1.75 ; filament_max_volumetric_speed = 0 ; filament_notes = "" ; first_layer_acceleration = 0 ; first_layer_bed_temperature = 0 ; first_layer_extrusion_width = 0.4 ; first_layer_speed = 30 ; first_layer_temperature = 260,260 ; gcode_arcs = 0 ; gcode_comments = 0 ; gcode_flavor = reprap ; infill_acceleration = 0 ; infill_first = 0 ; layer_gcode = ; [layer_z] Hoehe\n; Layer [layer_num]\n; M104 T1 S260 ; max_fan_speed = 100 ; max_print_speed = 80 ; max_volumetric_extrusion_rate_slope_negative = 0 ; max_volumetric_extrusion_rate_slope_positive = 0 ; max_volumetric_speed = 0 ; min_fan_speed = 50 ; min_print_speed = 10 ; min_skirt_length = 0 ; notes = ; nozzle_diameter = 0.4,0.4 ; only_retract_when_crossing_perimeters = 1 ; ooze_prevention = 1 ; output_filename_format = [input_filename_base].gcode ; perimeter_acceleration = 0 ; post_process = ; pressure_advance = 0 ; resolution = 0 ; retract_before_travel = 2,2 ; retract_layer_change = 0,0 ; retract_length = 3,3 ; retract_length_toolchange = 0,0 ; retract_lift = 0,0 ; retract_lift_above = 0,0 ; retract_lift_below = 0,0 ; retract_restart_extra = 0,0 ; retract_restart_extra_toolchange = 0,0 ; retract_speed = 40,40 ; skirt_distance = 6 ; skirt_height = 1 ; skirts = 3 ; slowdown_below_layer_time = 5 ; spiral_vase = 0 ; standby_temperature_delta = -15 ; start_gcode = ;@nosize\nM140 S[first_layer_bed_temperature] ; Bettemp an\nM104 S[first_layer_temperature] ; extruder vorheizen\nG1 X190 Y0 Z1 F2000; D�se in Bettn�he\nM190 S[first_layer_bed_temperature] ; warte auf Betttemp\nM109 S[first_layer_temperature]; warte auf Extrudertemp\nG1 Z0.25 F200\nG92 E0; reset extrusion distance\nG1 X190 Y0\nG1 X190 E5 ;extrudiere\nG1 X145 E10; abstreifen\n;M513 ; FTS Reset\n;@size ; temperature = 260,260 ; threads = 8 ; toolchange_gcode = ; travel_speed = 100 ; use_firmware_retraction = 0 ; use_relative_e_distances = 0 ; use_volumetric_e = 0 ; wipe = 0,0 ; z_offset = 0 ; dont_support_bridges = 1 ; extrusion_width = 0.4 ; first_layer_height = 0.2 ; infill_only_where_needed = 0 ; interface_shells = 0 ; layer_height = 0.2 ; raft_layers = 0 ; seam_position = aligned ; support_material = 0 ; support_material_angle = 0 ; support_material_buildplate_only = 0 ; support_material_contact_distance = 0.2 ; support_material_enforce_layers = 0 ; support_material_extruder = 2 ; support_material_extrusion_width = 0 ; support_material_interface_extruder = 2 ; support_material_interface_layers = 3 ; support_material_interface_spacing = 0 ; support_material_interface_speed = 100% ; support_material_pattern = rectilinear-grid ; support_material_spacing = 2.5 ; support_material_speed = 20 ; support_material_threshold = 0 ; support_material_with_sheath = 0 ; xy_size_compensation = 0 ; bottom_solid_layers = 3 ; bridge_flow_ratio = 1 ; bridge_speed = 30 ; ensure_vertical_shell_thickness = 0 ; external_fill_pattern = rectilinear ; external_perimeter_extrusion_width = 0.3 ; external_perimeter_speed = 50% ; external_perimeters_first = 0 ; extra_perimeters = 1 ; fill_angle = 45 ; fill_density = 20% ; fill_pattern = rectilinear ; gap_fill_speed = 30 ; infill_every_layers = 1 ; infill_extruder = 2 ; infill_extrusion_width = 0.4 ; infill_overlap = 100% ; infill_speed = 30 ; overhangs = 1 ; perimeter_extruder = 2 ; perimeter_extrusion_width = 0.3 ; perimeter_speed = 30 ; perimeters = 3 ; small_perimeter_speed = 30 ; solid_infill_below_area = 70 ; solid_infill_every_layers = 0 ; solid_infill_extruder = 2 ; solid_infill_extrusion_width = 0.4 ; solid_infill_speed = 20 ; thin_walls = 1 ; top_infill_extrusion_width = 0.4 ; top_solid_infill_speed = 20 ; top_solid_layers = 3

2-mal bearbeitet. Zuletzt am 17.07.18 17:20.

|

Re: S3D versus Slic3rPE Stringing Wahnsinn 17. July 2018 17:15 |

Registrierungsdatum: 7 Jahre zuvor Beiträge: 122 |

Hier nochmal der gesamte Heattower, gerade fertig geworden. Das Stringing ist scheinbar fast temperaturunabhängig. Auch wüsste ich jetzt nicht, welche der Temperaturen nun die Beste ist.

Wäre toll, wenn wir das herausfinden könnten...

Grüße,

Gunnar.

Wäre toll, wenn wir das herausfinden könnten...

Grüße,

Gunnar.

|

Re: Formfutura Flexifil, S3D versus Slic3rPE Stringing Wahnsinn 22. July 2018 06:54 |

Registrierungsdatum: 7 Jahre zuvor Beiträge: 349 |

Hast du den Retract angepasst?

Meiner Erfahrung nach, braucht flexibles Filament deutlichst mehr Retract als steifes Filament.

Ganz schlimm wird es in einem Bowden. Bei meinem Hexa fahre ich Extrudr-TPU mit über 8mm Retract...normales Filament liegt irgendwo bei 4,5-4,7mm.

MfG

Torti

______________________________________________________________________________________________________________________________

Hexa V2 mit Merlin-Hotend ; Spindeldelta mit Duet Wifi, V6, 650x300 ; Core 300x300x350 mit Zahnriemen-Z

Meiner Erfahrung nach, braucht flexibles Filament deutlichst mehr Retract als steifes Filament.

Ganz schlimm wird es in einem Bowden. Bei meinem Hexa fahre ich Extrudr-TPU mit über 8mm Retract...normales Filament liegt irgendwo bei 4,5-4,7mm.

MfG

Torti

______________________________________________________________________________________________________________________________

Hexa V2 mit Merlin-Hotend ; Spindeldelta mit Duet Wifi, V6, 650x300 ; Core 300x300x350 mit Zahnriemen-Z

In diesem Forum dürfen leider nur registrierte Teilnehmer schreiben.