adhesion problem and poor printing quality

Posted by dont_go_away

|

adhesion problem and poor printing quality December 19, 2016 05:04AM |

Registered: 9 years ago Posts: 111 |

Hi everybody,

first of all sorry for my english.

I try to explain my problem:

I have a problem with the adhesion of filament to the heated bed. I don't know what the problem, I tried of everything, but the problem is always the same.

I tried to search my problem in the forum, but I don't found an answer.

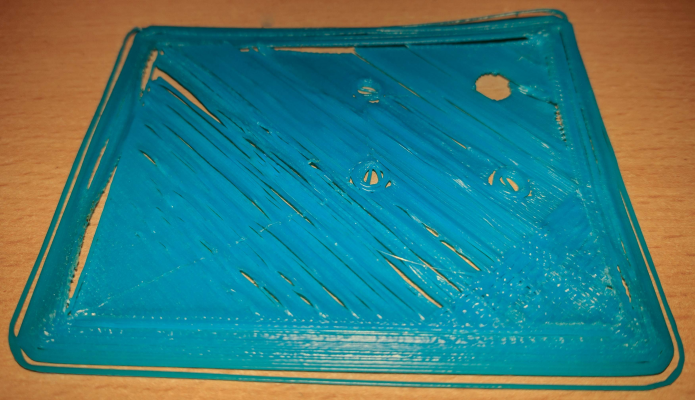

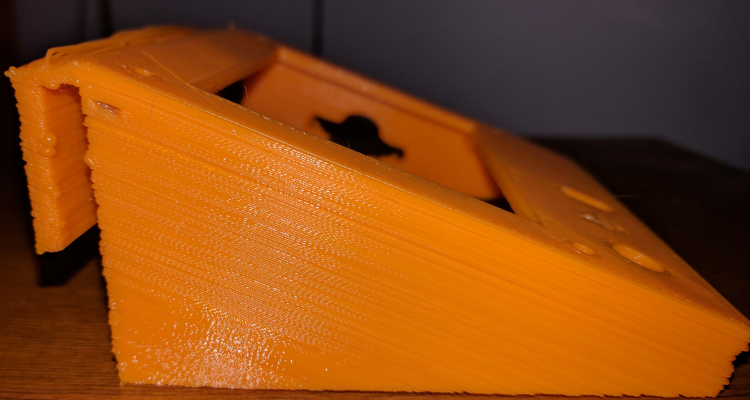

I show you a photo of a ABS filament which I printed at 230° for layers with bed at 110° first layer and 105° others:

I have a problem especially at the beginning of the print, because the filament touch the heated bed but it doesn't remains attached and I think I have a problem with a temperature of extruder because isn't normal that the filament is full of bubbles like the photo.

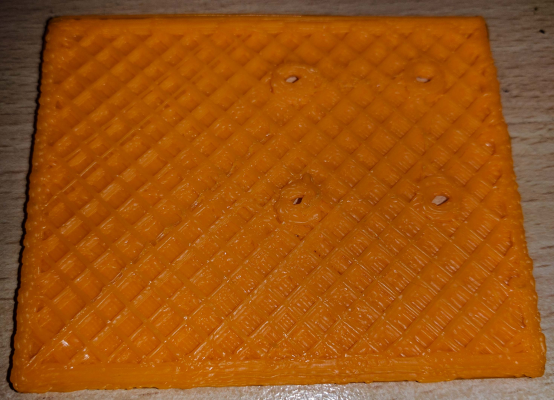

So, I tried to lower the temperature and set first layer temperature to 205° and others to 200° and the result is much better, but the anomaly is that the filament is ABS, but the printing temperature which I setted are for PLA:

So,I checked if the filament is a real ABS filament with the acetone method and it has melted, so I think it is a ABS.

Then, thinking that the problem was the extruder thermistor, I changed it and I tried a new print but the problem is the same.

So, I tried to change filament, I bought a PLA filament and I printed at 200° first layer and 195° others with the bed at 70°. The result is slightly improved:

But I have the problem with adhesion of the filament, the skirt and brim are raised just touching the surface and I don't know why.

Furthermore, after some layers, I must stop the print because the extruder scratch on the irregolar surface and even the perimeters starts to become irregular.

I changed temperature, thermistor, filament, nozzle, but I couldn't solve the problem.

My printing surface is the heated bed with kapton and hair spray.

Help me, please

Thanks to all!

Edited 1 time(s). Last edit at 12/19/2016 05:07AM by dont_go_away.

Stampante: Anycubic 4Max Pro --- Estrusore diretto --- Nozzle: 0,4 --- Software: Cura 4.4.1 --- Materiale: PLA 1,75mm

first of all sorry for my english.

I try to explain my problem:

I have a problem with the adhesion of filament to the heated bed. I don't know what the problem, I tried of everything, but the problem is always the same.

I tried to search my problem in the forum, but I don't found an answer.

I show you a photo of a ABS filament which I printed at 230° for layers with bed at 110° first layer and 105° others:

I have a problem especially at the beginning of the print, because the filament touch the heated bed but it doesn't remains attached and I think I have a problem with a temperature of extruder because isn't normal that the filament is full of bubbles like the photo.

So, I tried to lower the temperature and set first layer temperature to 205° and others to 200° and the result is much better, but the anomaly is that the filament is ABS, but the printing temperature which I setted are for PLA:

So,I checked if the filament is a real ABS filament with the acetone method and it has melted, so I think it is a ABS.

Then, thinking that the problem was the extruder thermistor, I changed it and I tried a new print but the problem is the same.

So, I tried to change filament, I bought a PLA filament and I printed at 200° first layer and 195° others with the bed at 70°. The result is slightly improved:

But I have the problem with adhesion of the filament, the skirt and brim are raised just touching the surface and I don't know why.

Furthermore, after some layers, I must stop the print because the extruder scratch on the irregolar surface and even the perimeters starts to become irregular.

I changed temperature, thermistor, filament, nozzle, but I couldn't solve the problem.

My printing surface is the heated bed with kapton and hair spray.

Help me, please

Thanks to all!

Edited 1 time(s). Last edit at 12/19/2016 05:07AM by dont_go_away.

Stampante: Anycubic 4Max Pro --- Estrusore diretto --- Nozzle: 0,4 --- Software: Cura 4.4.1 --- Materiale: PLA 1,75mm

|

Re: adhesion problem and poor printing quality December 19, 2016 09:34AM |

Registered: 10 years ago Posts: 770 |

|

Re: adhesion problem and poor printing quality December 19, 2016 09:43AM |

Registered: 7 years ago Posts: 181 |

Above all the surface that you are printing on must be completely free from oil and grease (including that on your hands and fingers). This requires that the surface is cleaned with alcohol, but I wouldn't recommend that you do this to the bed surface itself, since this may remove part of the protective coating. I see you have covered the bed with Kapton tape, this surface can then be cleaned without worrying about damaging it.

You need to clean any filament from the nozzle and then thoroughly go through the bed levelling proceedure recommended for you printer. You need to do this at least once, even if your machine is set up for auto-levelling. Then set the nozzle height accurately.

For ensuring that the print adheres then super-hold hairspray is OK, make sure that you achieve a good layer of hairspray or consider using an ABS slurry. Have a look around the forum for how to make and use the slurry. For ABS printing you need the bed temperature to be at least 100c and set the extruder to the temperature recommended for your filament. The filament starts to cool the instant that it leaves the nozzle, so if it is not hot enough it will start to set rather than stick to the bed. Also the area in which your printer is set up must be free of draughts otherwise the print will cool too quickly.

For ABS the print cooling fan (not the extruder cooling fan) must be OFF at all times. Don't set too big a first layer thickness - not more than 0.2mm for a 0.4mm nozzle and print the first layer at reduced speed to give the filament a chance to adhere to the bed, say 15 to 20 mm/s. Print with a brim or raft.

Try a simple print of say a 30 x 30 x 3mm block while experimenting with temperatures to avoid wasting large amounts of filament.

Edited 3 time(s). Last edit at 12/19/2016 09:53AM by Supermec.

You need to clean any filament from the nozzle and then thoroughly go through the bed levelling proceedure recommended for you printer. You need to do this at least once, even if your machine is set up for auto-levelling. Then set the nozzle height accurately.

For ensuring that the print adheres then super-hold hairspray is OK, make sure that you achieve a good layer of hairspray or consider using an ABS slurry. Have a look around the forum for how to make and use the slurry. For ABS printing you need the bed temperature to be at least 100c and set the extruder to the temperature recommended for your filament. The filament starts to cool the instant that it leaves the nozzle, so if it is not hot enough it will start to set rather than stick to the bed. Also the area in which your printer is set up must be free of draughts otherwise the print will cool too quickly.

For ABS the print cooling fan (not the extruder cooling fan) must be OFF at all times. Don't set too big a first layer thickness - not more than 0.2mm for a 0.4mm nozzle and print the first layer at reduced speed to give the filament a chance to adhere to the bed, say 15 to 20 mm/s. Print with a brim or raft.

Try a simple print of say a 30 x 30 x 3mm block while experimenting with temperatures to avoid wasting large amounts of filament.

Edited 3 time(s). Last edit at 12/19/2016 09:53AM by Supermec.

|

Re: adhesion problem and poor printing quality December 19, 2016 10:30AM |

Registered: 9 years ago Posts: 111 |

Quote

Floyd

Looks like your printing too high for the first layers and maybe the rest of the layers.

What is your nozzle size?

What is your layer height?

Hi, thanks for the answer.

My nozzle size is 0.4. Also I had thought that the problem could be the layers height and I did some tests: I tried to set at 0.3 first layer and 0.25 others, then I lowered the height to 0.25 and 0.20 and then I lowered to 0.20 and 0.15 but the problem is always the same. I have an inductive sensor and after the auto bed leveling, I Did a paper test and the paper passes under the nozzle slightly scratching.

Supermec, when I print in ABS the fan are off, only the extruder fan is on, and I cleaned the surface before the first print. My problem is only with the medium and big size objects, with a small objects, print quality is decent. This is a photo of a small object that I print in ABS 250° first layer and 240° others with bed at 110°:

and this is a photo of a small object that I print in ABS 205° first layer and 200° others with bed at 110°:

But when I print a bigger object, I have that problem.

Stampante: Anycubic 4Max Pro --- Estrusore diretto --- Nozzle: 0,4 --- Software: Cura 4.4.1 --- Materiale: PLA 1,75mm

|

Re: adhesion problem and poor printing quality December 19, 2016 10:57AM |

Registered: 8 years ago Posts: 34 |

|

Re: adhesion problem and poor printing quality December 19, 2016 07:04PM |

Registered: 9 years ago Posts: 111 |

I tried to fix auto bed leveling also, but the auto bed is ok.Quote

sliceheart

If small is OK then the bed is not leveled

After the G29, the nozzle touch the surface and the paper passes under the nozzle scratching slightly.

Tomorrow I'll try again with a small object and i will post the result.

Thank you!

Stampante: Anycubic 4Max Pro --- Estrusore diretto --- Nozzle: 0,4 --- Software: Cura 4.4.1 --- Materiale: PLA 1,75mm

|

Re: adhesion problem and poor printing quality December 20, 2016 02:13AM |

Registered: 8 years ago Posts: 916 |

Your nozzle is too high. You need to lower it a bit. If paper passes underneath the nozzle when it's at 0 height, then it's too high. I'd lower it by 0.08 mm or so.

If using Repetier you can get a perfect first layer by adjusting the babysteps while printing the skirt. This is easy to do. After a couple of prints you'll get a good feel for how far the nozzle needs to be lowered, you do that by adjusting the Z probe height in firmware.

If using Repetier you can get a perfect first layer by adjusting the babysteps while printing the skirt. This is easy to do. After a couple of prints you'll get a good feel for how far the nozzle needs to be lowered, you do that by adjusting the Z probe height in firmware.

|

Re: adhesion problem and poor printing quality December 20, 2016 02:14AM |

Registered: 8 years ago Posts: 916 |

|

Re: adhesion problem and poor printing quality December 20, 2016 02:19AM |

Registered: 8 years ago Posts: 916 |

This print shows clearly why the old advice to "never use a fan when printing ABS" is wrong. You need a fan to be on when printing fast layers.

Here are my settings for the fan speed on ABS. Depending on the part you can also keep the fan always on, but ensure that the speed is set so that the fan is just ticking over.

Fan speed:

Min: 10, max 50

Bridges fan speed 8

Disable fan for the first 4 layers.

Enable fan if layer print time is below 10 seconds

Slow down if layer print time is 8 seconds

Min print speed 10 mm/s

Edited 1 time(s). Last edit at 12/20/2016 02:20AM by nebbian.

|

Re: adhesion problem and poor printing quality December 20, 2016 03:47AM |

Registered: 12 years ago Posts: 2,470 |

Sorry, but no. This is just a matter of giving the part time to cool before printing the next layer. Using a fan might work if you have only a small tip of an object left to print, but if it is only a local element the fan will wrack havoc. The old method of just pausing between layers to give the part a minimum time to cool is enough.Quote

nebbian

This print shows clearly why the old advice to "never use a fan when printing ABS" is wrong. You need a fan to be on when printing fast layers.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: adhesion problem and poor printing quality December 20, 2016 04:42AM |

Registered: 9 years ago Posts: 111 |

Thanks to all for the answers!

I try to explain my steps for the autobed leveling.

- I setted the offset to 0.90mm on Marlin FW

- G28: Auto home

- G29: auto bed leveling

After this, for testing, I set on the LCD the height of first layer (that I setted at 0.25mm in Slicer) and I try to pass the paper under the nozzle, and the zozzle scratching slightly on the paper.

Is this the right procedure?

I tried to print a ABS with fan at the beginning, but the object is rised from the heated bed, after some layers. With fan off I print the same object perfectly, so I don't think that is a fan problem, but this evening a will try your advices, especially first layer extrusion width at 0.6mm (now is setted to 170%).

You think that is a auto bed leveling problem? Because, actually, I haven't idea what kind of problem causes this issues

Thanks!

Edited 1 time(s). Last edit at 12/20/2016 04:44AM by dont_go_away.

Stampante: Anycubic 4Max Pro --- Estrusore diretto --- Nozzle: 0,4 --- Software: Cura 4.4.1 --- Materiale: PLA 1,75mm

I try to explain my steps for the autobed leveling.

- I setted the offset to 0.90mm on Marlin FW

- G28: Auto home

- G29: auto bed leveling

After this, for testing, I set on the LCD the height of first layer (that I setted at 0.25mm in Slicer) and I try to pass the paper under the nozzle, and the zozzle scratching slightly on the paper.

Is this the right procedure?

Quote

nebbian

Here are my settings for the fan speed on ABS. Depending on the part you can also keep the fan always on, but ensure that the speed is set so that the fan is just ticking over.

Fan speed:

Min: 10, max 50

Bridges fan speed 8

Disable fan for the first 4 layers.

Enable fan if layer print time is below 10 seconds

Slow down if layer print time is 8 seconds

Min print speed 10 mm/s

I tried to print a ABS with fan at the beginning, but the object is rised from the heated bed, after some layers. With fan off I print the same object perfectly, so I don't think that is a fan problem, but this evening a will try your advices, especially first layer extrusion width at 0.6mm (now is setted to 170%).

You think that is a auto bed leveling problem? Because, actually, I haven't idea what kind of problem causes this issues

Thanks!

Edited 1 time(s). Last edit at 12/20/2016 04:44AM by dont_go_away.

Stampante: Anycubic 4Max Pro --- Estrusore diretto --- Nozzle: 0,4 --- Software: Cura 4.4.1 --- Materiale: PLA 1,75mm

|

Re: adhesion problem and poor printing quality December 20, 2016 05:26AM |

Registered: 8 years ago Posts: 22 |

|

Re: adhesion problem and poor printing quality December 20, 2016 05:38AM |

Registered: 9 years ago Posts: 111 |

No, it's a good idea!

I setted the first layers speed at 25mm/s and I always thought was the right speed for the first layer, but I'll try to lower it to 20mm/s.

When I get home, I'll try your advices and I will post the tests, attaching my speed settings in Slicer.

Thanks!

Edited 1 time(s). Last edit at 12/20/2016 05:38AM by dont_go_away.

Stampante: Anycubic 4Max Pro --- Estrusore diretto --- Nozzle: 0,4 --- Software: Cura 4.4.1 --- Materiale: PLA 1,75mm

I setted the first layers speed at 25mm/s and I always thought was the right speed for the first layer, but I'll try to lower it to 20mm/s.

When I get home, I'll try your advices and I will post the tests, attaching my speed settings in Slicer.

Thanks!

Edited 1 time(s). Last edit at 12/20/2016 05:38AM by dont_go_away.

Stampante: Anycubic 4Max Pro --- Estrusore diretto --- Nozzle: 0,4 --- Software: Cura 4.4.1 --- Materiale: PLA 1,75mm

|

Re: adhesion problem and poor printing quality December 20, 2016 05:59AM |

Registered: 8 years ago Posts: 22 |

|

Re: adhesion problem and poor printing quality December 20, 2016 06:58AM |

Registered: 9 years ago Posts: 1,873 |

If you're printing directly onto a pcb heatbed, or onto the heatbed with kapton tape, it is very unlikely to be flat enough for large prints. You can either try to increase the flatness by adding a sheet of glass (or other flat material) on top of the heatbed, or seeing as you have abl you could try the distortion compensation in newer versions of repetier firmware which is quite effective.

|

Re: adhesion problem and poor printing quality December 20, 2016 07:53AM |

Registered: 8 years ago Posts: 413 |

I don't use autoleveling or Marlin but just check you have the offsets set correctly.

The sensor to nozzle z offset is particular for the auto levelling but not related to the 1st layer height.

However the Z offset in slicer is the distance between the nozzle and the bed at 0 height. Slicer compensates for this in calculating the Z height it will request in the Gcode. If Marlin has an equivalent offset then I would expect you need to set the slicer value to 0 to avoid double counting. So if slicer has 0 offset then a 0.25 layer height should be at position 0.25mm. This implies it is possible for the nozzle to touch the bed which is not desirable.

If you set the z height via the controller to 0.25 (same as layer requested in slicer) then this will not include slicers z offset - check what is in slicer (including the sign).

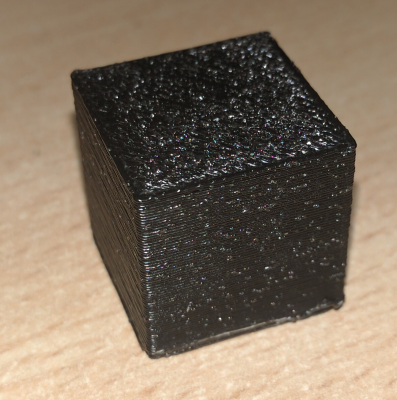

I also have black parts that have similar lumps on them so don't panic - its a combination of the material and water absorption - that's another story.

Your early photos looked like you had something loose as the layers don't seem repeatable. newer picks seem OK.

The sensor to nozzle z offset is particular for the auto levelling but not related to the 1st layer height.

However the Z offset in slicer is the distance between the nozzle and the bed at 0 height. Slicer compensates for this in calculating the Z height it will request in the Gcode. If Marlin has an equivalent offset then I would expect you need to set the slicer value to 0 to avoid double counting. So if slicer has 0 offset then a 0.25 layer height should be at position 0.25mm. This implies it is possible for the nozzle to touch the bed which is not desirable.

If you set the z height via the controller to 0.25 (same as layer requested in slicer) then this will not include slicers z offset - check what is in slicer (including the sign).

I also have black parts that have similar lumps on them so don't panic - its a combination of the material and water absorption - that's another story.

Your early photos looked like you had something loose as the layers don't seem repeatable. newer picks seem OK.

|

Re: adhesion problem and poor printing quality December 20, 2016 08:18AM |

Registered: 7 years ago Posts: 759 |

|

Re: adhesion problem and poor printing quality December 20, 2016 10:42AM |

Registered: 9 years ago Posts: 111 |

Quote

MCcarman

I don't use autoleveling or Marlin but just check you have the offsets set correctly.

The sensor to nozzle z offset is particular for the auto levelling but not related to the 1st layer height.

However the Z offset in slicer is the distance between the nozzle and the bed at 0 height. Slicer compensates for this in calculating the Z height it will request in the Gcode. If Marlin has an equivalent offset then I would expect you need to set the slicer value to 0 to avoid double counting. So if slicer has 0 offset then a 0.25 layer height should be at position 0.25mm. This implies it is possible for the nozzle to touch the bed which is not desirable.

If you set the z height via the controller to 0.25 (same as layer requested in slicer) then this will not include slicers z offset - check what is in slicer (including the sign).

I also have black parts that have similar lumps on them so don't panic - its a combination of the material and water absorption - that's another story.

Your early photos looked like you had something loose as the layers don't seem repeatable. newer picks seem OK.

At the beginning, I setted the offset in Marlin and I type G28 and then G29, but after the bed leveling, the nozzle was eighter than the offset and didn't touch the heated bed, indeed when I printed, the filament didn't adhere to the plate. I did various tests:

offset in Marlin -------- Z after G28 -----------Z after G29

0.78 ----------------------------10.78 ---------------------9.52

0.82 ----------------------------10.82 ---------------------9.56

0.86 ----------------------------10.86 ---------------------9.56

After this result I decide to set the offset lower and I solve the problem with the small objects, now the issue is with the medium and large objects, as you can see in the previous photos.

JamesK: When I didin't have an inductive sensor, I had a glass on the heated bed, but the inductive sensor don't reveal the metal if I put the glass between the bed and the sensor, so I must print directly on heatbed

obewan: if it was a temperature problem, if I lowered the temp, should be better?

Stampante: Anycubic 4Max Pro --- Estrusore diretto --- Nozzle: 0,4 --- Software: Cura 4.4.1 --- Materiale: PLA 1,75mm

|

Re: adhesion problem and poor printing quality December 20, 2016 02:09PM |

Registered: 7 years ago Posts: 181 |

|

Re: adhesion problem and poor printing quality December 21, 2016 05:22PM |

Registered: 9 years ago Posts: 111 |

Quote

Jan-Willem

Have you tried printing the first layer a bit slower? Then you give it a bit more time to bond to the bed.

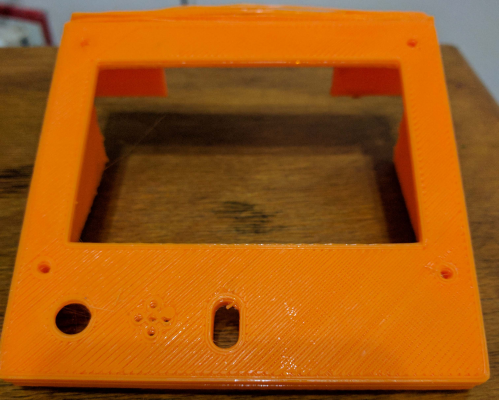

Great! I did same tests with lowered speed and, after setting the speeds in attached file, the result is this:

This is PLA that I printed at 200° first layer, 195° other layers and bed at 70° first layer and 65° other layers.

The print is finished and this is a great archievement!

Now, as the photos show, I have same problems with the layers that are misaligned, averyone have any idea to solve it?

I tried to tighten the belt of x axis and y axis, but I haven't solved the problem.

Thanks to all for the help!!!

Edited 1 time(s). Last edit at 12/21/2016 05:25PM by dont_go_away.

Stampante: Anycubic 4Max Pro --- Estrusore diretto --- Nozzle: 0,4 --- Software: Cura 4.4.1 --- Materiale: PLA 1,75mm

|

Re: adhesion problem and poor printing quality December 22, 2016 04:59AM |

Registered: 8 years ago Posts: 22 |

Great that you are now able to print. I think you still have some strange first layer settings. In your first picture I can see the second layer as well so it is definitely under extruded. Which software do you use and can you make a screenshot of your setting page?

Since I don't have a pic of your prusa i3 it is hard to say. But I can try.

Is there any play in your hotend mounting?

How straight are your z axis? I replaced my 5mm threaded rod with M8 acme rod and that made it a lot better.

I think you can lower your temperature a bit. I print pla at around 180 degrees. Again adjust the temperature during printing and see what happens. Also try changing print speeds during printing, then you will learn what impact temp and speed on your prints and you will recognize problems better in future.

Jan-Willem

Since I don't have a pic of your prusa i3 it is hard to say. But I can try.

Is there any play in your hotend mounting?

How straight are your z axis? I replaced my 5mm threaded rod with M8 acme rod and that made it a lot better.

I think you can lower your temperature a bit. I print pla at around 180 degrees. Again adjust the temperature during printing and see what happens. Also try changing print speeds during printing, then you will learn what impact temp and speed on your prints and you will recognize problems better in future.

Jan-Willem

|

Re: adhesion problem and poor printing quality December 22, 2016 08:07AM |

Registered: 9 years ago Posts: 111 |

Quote

Jan-Willem

Great that you are now able to print. I think you still have some strange first layer settings. In your first picture I can see the second layer as well so it is definitely under extruded. Which software do you use and can you make a screenshot of your setting page?

Since I don't have a pic of your prusa i3 it is hard to say. But I can try.

Is there any play in your hotend mounting?

How straight are your z axis? I replaced my 5mm threaded rod with M8 acme rod and that made it a lot better.

I think you can lower your temperature a bit. I print pla at around 180 degrees. Again adjust the temperature during printing and see what happens. Also try changing print speeds during printing, then you will learn what impact temp and speed on your prints and you will recognize problems better in future.

Jan-Willem

Hi Jan,

thanks for the support!

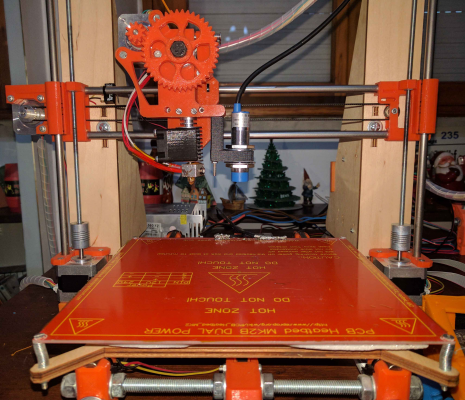

This is my Prusa i3

I have 5mm threaded rod but I just bought the 8mm acme rod and I also bought the E3d Titan v6 to replace my J-head V5 extruder.

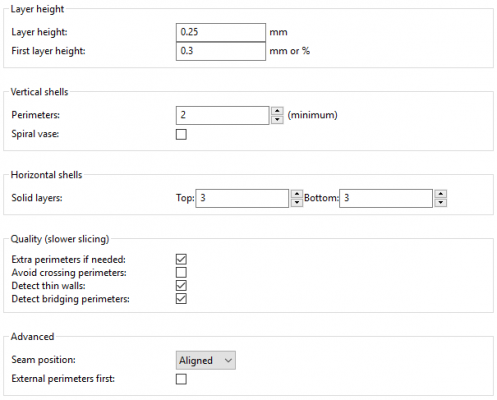

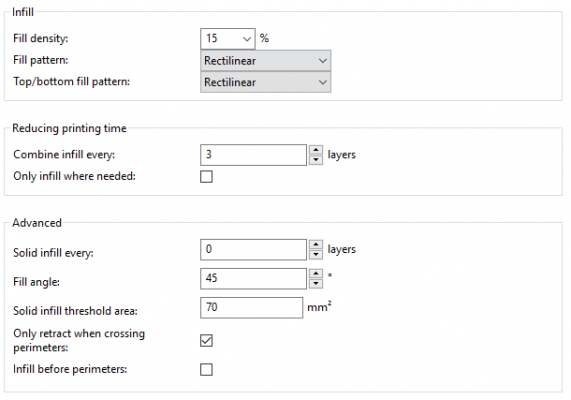

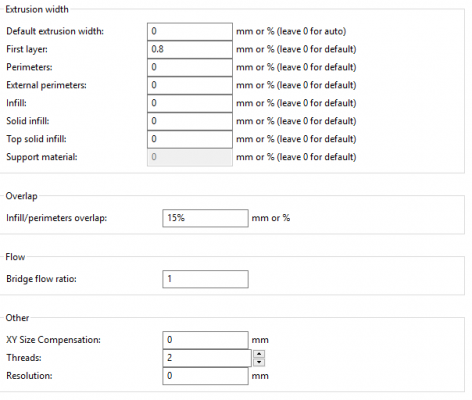

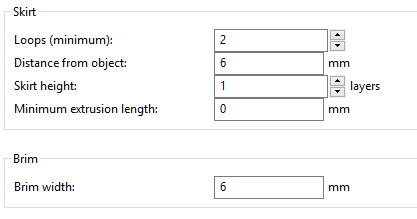

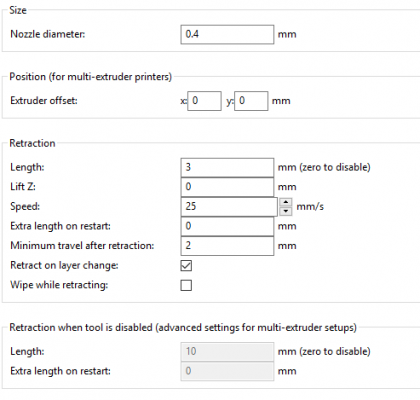

For printing I use Repetier-Host with Slicer, and this is my settings:

This evening I'll try to lower the speed and temperature during the print and see the effects. Then I'll try to raise the extrusion width for the first layer, what do you think?

Thanks!

Edited 2 time(s). Last edit at 12/22/2016 08:11AM by dont_go_away.

Stampante: Anycubic 4Max Pro --- Estrusore diretto --- Nozzle: 0,4 --- Software: Cura 4.4.1 --- Materiale: PLA 1,75mm

|

Re: adhesion problem and poor printing quality December 22, 2016 10:57AM |

Registered: 8 years ago Posts: 22 |

ok, What are your results with first layer set to default?(so 0->200% extrusion)

I found this thing really helpful to reduce the z wobble: [www.thingiverse.com] but then modified for a M8 nut. If you send me your email via pm I'll sent you my file.

I found this thing really helpful to reduce the z wobble: [www.thingiverse.com] but then modified for a M8 nut. If you send me your email via pm I'll sent you my file.

|

Re: adhesion problem and poor printing quality December 22, 2016 01:48PM |

Registered: 9 years ago Posts: 111 |

Quote

Jan-Willem

ok, What are your results with first layer set to default?(so 0->200% extrusion)

I found this thing really helpful to reduce the z wobble: [www.thingiverse.com] but then modified for a M8 nut. If you send me your email via pm I'll sent you my file.

I always setted the extrusion width lower then the 200% because many users in the italian forum suggested me this, but if you suggest me that I can set the extrusion width to 200%, i'll try this test.

Thanks fort your help, I'll send you my e-mail in PM, I'll print your object and I'll post the result.

Thanks again!

Stampante: Anycubic 4Max Pro --- Estrusore diretto --- Nozzle: 0,4 --- Software: Cura 4.4.1 --- Materiale: PLA 1,75mm

Sorry, only registered users may post in this forum.