Printing PVDF

Posted by runninfarmer

|

Printing PVDF July 29, 2018 10:17PM |

Registered: 10 years ago Posts: 105 |

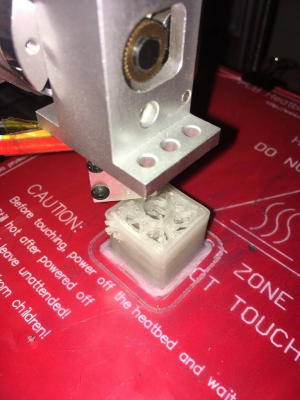

I've recently extruded some Kyna PVDF plastic and now I'm having the joy of trying to dial in my printer. I'm having some issues and will welcome some pointers. PVDF is a slow extruding plastic so print speeds have to be slow, I already have all speeds at 20 mm/s and non print moves at 80 mm/s. I have a 1:5 ratio geared extruder (all metal hotend) running at 260C. I can get the print to stick well with elmers glue, despite PVDF being in the teflon family, but I'm having the most issues with infill. The infill wants to curl up and out of the perimeter. Has anyone ever experienced this phenomenon with any type of plastic and how did you rectify it? Here's a pic of the issue:

PS, I have 100g or more quantities of PVDF to sell if anyone's interested. Thanks for the help!

PS, I have 100g or more quantities of PVDF to sell if anyone's interested. Thanks for the help!

|

Re: Printing PVDF July 30, 2018 12:03AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Printing PVDF July 30, 2018 12:10PM |

Registered: 8 years ago Posts: 413 |

What infill patern are you using?

The linear version only sits on the previous layer where it crosses so a lot of the time its bridging. If you try something like honeycomb patern it sits on the previous layer so it should behave like the perimeters.

Obviously doesn't address the fundamental issue but may get you usefull prints.

I tend to print slower with honeycombe as the rapid changes in direction can cause a lot of vibration.

The linear version only sits on the previous layer where it crosses so a lot of the time its bridging. If you try something like honeycomb patern it sits on the previous layer so it should behave like the perimeters.

Obviously doesn't address the fundamental issue but may get you usefull prints.

I tend to print slower with honeycombe as the rapid changes in direction can cause a lot of vibration.

|

Re: Printing PVDF July 30, 2018 04:16PM |

Registered: 10 years ago Posts: 105 |

Thanks for the suggestions, I'll tweak both infill layer width and pattern to see if I can dial it in. I had issues with honeycomb so I'll give rectilinear a try. I've also had it running at full bed temp (87°C), so I'll try it where I lower the bed temp to 50-60°C after the first layer. Also, here's a video I took when I took the above pic:

[www.youtube.com]

[www.youtube.com]

|

Re: Printing PVDF August 03, 2018 08:40AM |

Registered: 8 years ago Posts: 318 |

havent used PVDF but have used PETG quite a bit.

Can confirm that infill peeling issues can be solved by making the extrusions wider and shorter (ie honeycomb instead of rectilinear) both help in addition to inceasing the infill overlap in your slicer (maybe as high as 40%?)

What would someone use a teflon like printed plastic for? Do its printed properties make a good choice for plastic on plastic wear?

Can confirm that infill peeling issues can be solved by making the extrusions wider and shorter (ie honeycomb instead of rectilinear) both help in addition to inceasing the infill overlap in your slicer (maybe as high as 40%?)

What would someone use a teflon like printed plastic for? Do its printed properties make a good choice for plastic on plastic wear?

|

Re: Printing PVDF August 03, 2018 08:57PM |

Registered: 10 years ago Posts: 105 |

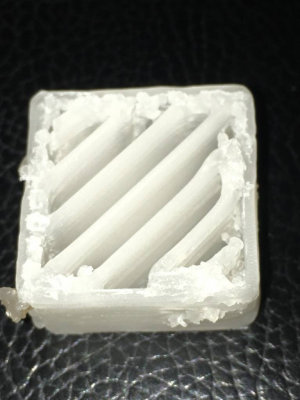

I can try wider extrusions but now I've narrowed the issue down to layer changes. I tried disabling retraction, but it's like on every layer change it under extrudes on the interior perimeter, even with retraction disabled. Once it's started the external perimeter it's good again. I'm using aligned rectilinear fill pattern and that looks really good. I took a video and will get a YouTube link posted soon. Here's a pic of the latest cal cube:

Like teflon, PVDF will be good in any wear application. With its low friction and low surface energy, I think it'd work well for plastic on plastic wear. I'm mainly interested in it for its high chemical resistance at high temps. Basically resists any chemical (except strong bases, acetone and other ketones) up to 150C.

Edited 2 time(s). Last edit at 08/03/2018 09:00PM by runninfarmer.

Like teflon, PVDF will be good in any wear application. With its low friction and low surface energy, I think it'd work well for plastic on plastic wear. I'm mainly interested in it for its high chemical resistance at high temps. Basically resists any chemical (except strong bases, acetone and other ketones) up to 150C.

Edited 2 time(s). Last edit at 08/03/2018 09:00PM by runninfarmer.

|

Re: Printing PVDF August 04, 2018 10:35PM |

Registered: 8 years ago Posts: 318 |

Yup at that small of a print size rectilinear is not an issue. Problems may arrise if you print something 4x or bigger than that layer size though.

That chemical resistance is quite interesting indeed, Im sure ill be pondering its applications.

Could it be recovering from a wipe movement at the end of the last layer that is causing the under extrusion of the inner perimeter?

That chemical resistance is quite interesting indeed, Im sure ill be pondering its applications.

Could it be recovering from a wipe movement at the end of the last layer that is causing the under extrusion of the inner perimeter?

|

Re: Printing PVDF August 09, 2018 02:22AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Printing PVDF August 10, 2018 09:36AM |

Registered: 10 years ago Posts: 105 |

Hahaha, I thought that was a real random post. I'm curious more about the wipe movements you mentioned DaGameFace. Is that something customizeable in any/all of the common slicers out there? Contemplating swapping to a smaller nozzle and trying that. Going to be changing my z-axis to belt drive so that'll put that machine down for a while. I have a Flashforge that I could try it on again, had issues with low extruder torque though.

Sorry, only registered users may post in this forum.