E3D Titan grooves filament way too much

Posted by nikko4913

|

E3D Titan grooves filament way too much February 10, 2019 08:38AM |

Registered: 8 years ago Posts: 33 |

Hello.

I just purchased the E3D Titan extruder to be used on my new CoreXY printer. I bought it because of the versatile mounting options, and because it can be used easily with both the V6 and a bowden-style setup... or so I thought. I've followed the exact assembly instructions on the E3D website, however, whenever I try to extrude (even with the idler pressure on the lowest possible setting), the filament gets too grooved to pass freely in the bowden tube. In fact, just heating the hotend to 210 degrees (the recommended setting from the manufacturer of the filament) and attempting to extrude a small amount of 1.75mm PLA will result in the extruder grinding away on the filament because it simply cannot push it through the bowden tubing.

I know that this is the problem because taking a 20 cm piece of filament that has gone through the extruder, and attempting to push it through a 20cm piece of tubing (even without a hotend on the other side) is very challenging. The filament is simply too grooved and grinded.

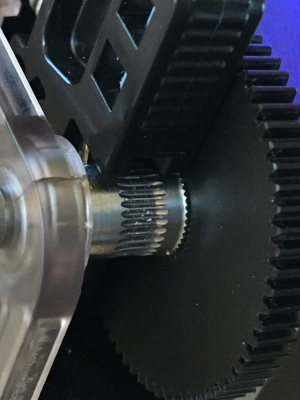

I have attached a few images of the filament after going through the extruder, and also of the extruders hobbed "bolt"/gear.

Has anyone else experienced anything like this? What have you done/what can you suggest?

I have thought about grinding down the gears "teeth" a bit, so they won't cut into the filament as much, but I don't know if that will work and I don't want to damage the extruder...

BTW the filament is white InnoFil 1.75mm PLA.

Thanks in advance!

I just purchased the E3D Titan extruder to be used on my new CoreXY printer. I bought it because of the versatile mounting options, and because it can be used easily with both the V6 and a bowden-style setup... or so I thought. I've followed the exact assembly instructions on the E3D website, however, whenever I try to extrude (even with the idler pressure on the lowest possible setting), the filament gets too grooved to pass freely in the bowden tube. In fact, just heating the hotend to 210 degrees (the recommended setting from the manufacturer of the filament) and attempting to extrude a small amount of 1.75mm PLA will result in the extruder grinding away on the filament because it simply cannot push it through the bowden tubing.

I know that this is the problem because taking a 20 cm piece of filament that has gone through the extruder, and attempting to push it through a 20cm piece of tubing (even without a hotend on the other side) is very challenging. The filament is simply too grooved and grinded.

I have attached a few images of the filament after going through the extruder, and also of the extruders hobbed "bolt"/gear.

Has anyone else experienced anything like this? What have you done/what can you suggest?

I have thought about grinding down the gears "teeth" a bit, so they won't cut into the filament as much, but I don't know if that will work and I don't want to damage the extruder...

BTW the filament is white InnoFil 1.75mm PLA.

Thanks in advance!

|

Re: E3D Titan grooves filament way too much February 10, 2019 09:19AM |

Registered: 11 years ago Posts: 5,780 |

Are you sure the nozzle isn't blocked? Try bumping up the temperature.

The drive gear teeth should bite into the filament deeply so that they don't cause stripping- the divot you caved in the filament when you reduced the pinch roller pressure. That reduced pressure setting is for flexible filaments.

I used Titans on a few printers for the last few years and have started converting to BondTech BMGs. The Titans are OK but there are some design flaws that make them less than ideal. The mounting system is pretty bad- one screw is behind the hot-end, and the screw that goes through the drive gear can't be tightened because if you do you'll bend the front plastic piece and tilt the drive gear bearing. Once the thing is assembled with a V6 hot-end, the hot-end can rotate easily (more of a poor hot-end design that has no anti rotation features) which means the heater block will rotate with it and it will melt your print cooling duct/nozzle if you have one and it isn't oversized. Loading filament is always a little bit of a thread-the-needle event and sometime it's difficult to find the hole. The problem is that the filament feeds through the pinch roller lever that you have to move back in order to feed the filament in.

The BMG extruder is much more solidly made. Tightening screws doesn't distort the plastic, and there are no hidden screws. It pushes filament from two sides so doesn't need to bite as deeply. The feed hole is very close to the top of the extruder so loading filament is done simply by telling it to extrude and then inserting a piece of filament into the top of the extruder- it grabs it and feeds it into the hot-end every time. The BMG grips a V6 hot-end tightly and it can't rotate. The only problem I've run into is with unloading filament. The little knob on the end of the filament that comes out of the heater block sometimes gets caught in the feed tube. I've found that the surest way to unload filament is either to grab it and pull it out quickly by hand, or just cut the old filament and feed it through, pushing it with the new filament.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The drive gear teeth should bite into the filament deeply so that they don't cause stripping- the divot you caved in the filament when you reduced the pinch roller pressure. That reduced pressure setting is for flexible filaments.

I used Titans on a few printers for the last few years and have started converting to BondTech BMGs. The Titans are OK but there are some design flaws that make them less than ideal. The mounting system is pretty bad- one screw is behind the hot-end, and the screw that goes through the drive gear can't be tightened because if you do you'll bend the front plastic piece and tilt the drive gear bearing. Once the thing is assembled with a V6 hot-end, the hot-end can rotate easily (more of a poor hot-end design that has no anti rotation features) which means the heater block will rotate with it and it will melt your print cooling duct/nozzle if you have one and it isn't oversized. Loading filament is always a little bit of a thread-the-needle event and sometime it's difficult to find the hole. The problem is that the filament feeds through the pinch roller lever that you have to move back in order to feed the filament in.

The BMG extruder is much more solidly made. Tightening screws doesn't distort the plastic, and there are no hidden screws. It pushes filament from two sides so doesn't need to bite as deeply. The feed hole is very close to the top of the extruder so loading filament is done simply by telling it to extrude and then inserting a piece of filament into the top of the extruder- it grabs it and feeds it into the hot-end every time. The BMG grips a V6 hot-end tightly and it can't rotate. The only problem I've run into is with unloading filament. The little knob on the end of the filament that comes out of the heater block sometimes gets caught in the feed tube. I've found that the surest way to unload filament is either to grab it and pull it out quickly by hand, or just cut the old filament and feed it through, pushing it with the new filament.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.