Dual extruder drool

Posted by frankvdh

|

Dual extruder drool September 02, 2019 08:36PM |

Registered: 9 years ago Posts: 978 |

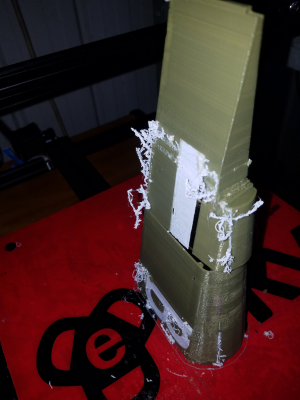

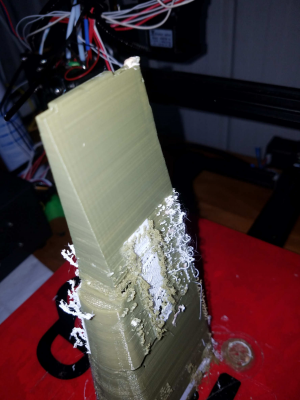

I've just upgraded my new HE3D sky to dual extruders, but I seem to have a huge drool problem (or at least my printer has).

My biggest concern is the white line above the 'B'. It is fused into the green, and I really only want green there!

I could live with the furry bits if I had to... they're easy enough to scrape off. But I suspect that they're another symptom of whatever is causing the blobs on the surface... probably furry bits that have got trapped during green extrusion.

I'm not particularly concerned about the under-extrusion in the white region... I think that's just bad geometry in the position of spool and extruder. And the break in the model at the bottom of the white rectangle is I think because the printer tried to home to [0,0,0] after the print, right through the middle of the model.

In case it's relevant, the white extruder is 18mm to the left of the green one, both printing PLA at 210C, and standby temperature is 175C (the default). I already have 6mm retraction, and I'm reluctant to go higher with that in case of jams. The model itself has 0.8mm thick walls, with some reinforcing inside. Sliced with the latest version of Cura.

Can someone who has dual extruders please give me some pointers? Should I maybe lower the standby temperature? Would Cura's "ooze shield" correct this?

My biggest concern is the white line above the 'B'. It is fused into the green, and I really only want green there!

I could live with the furry bits if I had to... they're easy enough to scrape off. But I suspect that they're another symptom of whatever is causing the blobs on the surface... probably furry bits that have got trapped during green extrusion.

I'm not particularly concerned about the under-extrusion in the white region... I think that's just bad geometry in the position of spool and extruder. And the break in the model at the bottom of the white rectangle is I think because the printer tried to home to [0,0,0] after the print, right through the middle of the model.

In case it's relevant, the white extruder is 18mm to the left of the green one, both printing PLA at 210C, and standby temperature is 175C (the default). I already have 6mm retraction, and I'm reluctant to go higher with that in case of jams. The model itself has 0.8mm thick walls, with some reinforcing inside. Sliced with the latest version of Cura.

Can someone who has dual extruders please give me some pointers? Should I maybe lower the standby temperature? Would Cura's "ooze shield" correct this?

|

Re: Dual extruder drool September 03, 2019 04:13PM |

Registered: 10 years ago Posts: 14,672 |

It's a few years since I used a dual extrusion setup like that, but when I did I used printing temperature 190C and standby temperature 150C, and 10mm retraction for the non printing nozzle. The hot ends in that printer are PTFE lined so they tolerate a lot of retraction. I had zero problems with ooze. There is an entry in my blog for that setup.

Edited 1 time(s). Last edit at 09/03/2019 04:14PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 09/03/2019 04:14PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Dual extruder drool September 04, 2019 05:11PM |

Registered: 7 years ago Posts: 619 |

Quote

frankvdh

I've just upgraded my new HE3D sky to dual extruders, but I seem to have a huge drool problem (or at least my printer has).

[attachment 112643 20190903_072551.jpg][attachment 112644 20190903_072558.jpg]

My biggest concern is the white line above the 'B'. It is fused into the green, and I really only want green there!

I could live with the furry bits if I had to... they're easy enough to scrape off. But I suspect that they're another symptom of whatever is causing the blobs on the surface... probably furry bits that have got trapped during green extrusion.

I'm not particularly concerned about the under-extrusion in the white region... I think that's just bad geometry in the position of spool and extruder. And the break in the model at the bottom of the white rectangle is I think because the printer tried to home to [0,0,0] after the print, right through the middle of the model.

In case it's relevant, the white extruder is 18mm to the left of the green one, both printing PLA at 210C, and standby temperature is 175C (the default). I already have 6mm retraction, and I'm reluctant to go higher with that in case of jams. The model itself has 0.8mm thick walls, with some reinforcing inside. Sliced with the latest version of Cura.

Can someone who has dual extruders please give me some pointers? Should I maybe lower the standby temperature? Would Cura's "ooze shield" correct this?

I have played a LOT with dual color and had a lot of trouble with CURA doing what I wanted. I pretty much stay with Simplify3D which (IMO) has better dual-printing "knobs".

However, you can obviously use CURA to do dual color prints.

Use the breeze wall, drool shield, whatever its called.

Don't use the prime tower, I have never gotten that to work well.

Pull the unused head's filament back 10-12mm and drop the temperature to 165.

Drop your filament temperatures. I like BamTack and Hatchbox filament for my dual-printer. They will want 180-190C temperatures.

Use coasting and retract during the coast (if CURA has that setting).

Write your own tool-change scripts. I never got CURA defaults to behave well here. When I change heads, I retract big (12mm) move the end-effector out of the print entirely, and change hot-end temperatures while away from the print.

Sadly, everything that I have tried with CURA to get a good dual-color print ended up fighting with CURA defaults and gave me weird results. I chalk this up to not understanding all of the "innards" of CURA. Someone really good at driving CURA can probably give better help here. My advice if you do a lot of dual-color printing? Buy Simplify3D, it is stupid-simple to do dual-color with that slicer, but S3D makes you do the tool-change script yourself - However, there are a lot of examples out there that you can start with and tweak to perfection. FULL_DISCLOSURE: The only slicers that I have spent a lot of time with are S3D and CURA. There are others out there.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

Sorry, only registered users may post in this forum.