Excess material at corners

Posted by GreyMark7650

|

Excess material at corners October 30, 2012 12:44PM |

Registered: 11 years ago Posts: 5 |

Hello All,

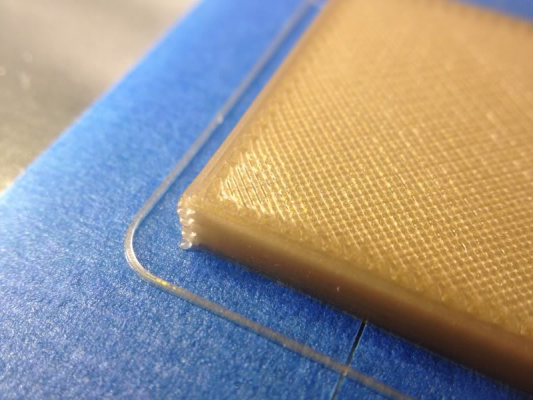

I'm new to 3d printing and have a problem that I can't find a solution to by searching the web and forums. When I print the test block (photo) there seems to be excess material at the corners (where it changes direction). It looks to me like it might be down to the extruder output not slowing down as the head does (just a guess).

I am using a prusa mendel with a 0.5mm J-head, I have the RAMPS 1.4 electronics running Merlin firmware and I'm trying to print using ABS.

I have tried various temperature settings for the heatbed and extruder as well as playing with the settings in both firmware and software (Slic3r) which have improved printing, but nothing I have found changes this material at the corners.

Any pointers as to where to look would be appreciated.

Regards,

MarkW

I'm new to 3d printing and have a problem that I can't find a solution to by searching the web and forums. When I print the test block (photo) there seems to be excess material at the corners (where it changes direction). It looks to me like it might be down to the extruder output not slowing down as the head does (just a guess).

I am using a prusa mendel with a 0.5mm J-head, I have the RAMPS 1.4 electronics running Merlin firmware and I'm trying to print using ABS.

I have tried various temperature settings for the heatbed and extruder as well as playing with the settings in both firmware and software (Slic3r) which have improved printing, but nothing I have found changes this material at the corners.

Any pointers as to where to look would be appreciated.

Regards,

MarkW

|

Re: Excess material at corners October 30, 2012 01:23PM |

Registered: 11 years ago Posts: 560 |

From the side wall warping it looks like you are printing too hot. Print surface, bed temp, and extruder temp on this print? I'm running ABS at 220-230c with a bed temp of 110c directly on glass build platform.

Corner blobs can come from laying down too much material overall, or from too much retraction. When retracting too much, it causes a longer pause in the XY movement and the nozzle will actually ooze a bit at the retraction point. Retracting more actually won't eliminate the blobs.

I've found that when the extrusion flow rate is correct, that retraction doesn't need to be much more than 1mm.

Edited 1 time(s). Last edit at 10/30/2012 01:27PM by Dirty Steve.

Corner blobs can come from laying down too much material overall, or from too much retraction. When retracting too much, it causes a longer pause in the XY movement and the nozzle will actually ooze a bit at the retraction point. Retracting more actually won't eliminate the blobs.

I've found that when the extrusion flow rate is correct, that retraction doesn't need to be much more than 1mm.

Edited 1 time(s). Last edit at 10/30/2012 01:27PM by Dirty Steve.

|

Re: Excess material at corners October 31, 2012 05:42AM |

Registered: 11 years ago Posts: 5 |

|

Re: Excess material at corners October 31, 2012 06:25PM |

|

Re: Excess material at corners October 31, 2012 06:38PM |

Registered: 11 years ago Posts: 939 |

I would verify you're actual hotend temperature with a thermo couple I agree with the first reply that looks like you're printing very hot, and probably with too high an extrusion rate.

I base the temperature comment on the side wall warping and the discoloration at the top of the print.

You can trivially determine if the issue is retraction related just be turning it off, but I don't think retraction by itself would give the results in the image.

I base the temperature comment on the side wall warping and the discoloration at the top of the print.

You can trivially determine if the issue is retraction related just be turning it off, but I don't think retraction by itself would give the results in the image.

|

Re: Excess material at corners November 01, 2012 05:03AM |

Registered: 11 years ago Posts: 5 |

Thanks for the suggestions. I have done some more work on this and it looks like it may actually still be an adhesion problem. I am printing at those temperatures because if I go lower then it doesn't stick to the hot bed. I calibrated the melting point to be 205 (although I haven't independently calibrated the temperature). I think it is lifting at the corners and the hot-end is then in contact with the material every time it passes the corner and lifts and discolours it some more. Attached is another photo showing one corner printing properly while the others look burnt and lifted.

I am using a PCB heatbed MK1, glass plate and Kapton tape - degreased with glass cleaner (maybe I need to try some of the other degreasing ideas I have seen around).

Regards,

MarkW

I am using a PCB heatbed MK1, glass plate and Kapton tape - degreased with glass cleaner (maybe I need to try some of the other degreasing ideas I have seen around).

Regards,

MarkW

|

Re: Excess material at corners November 01, 2012 12:50PM |

Registered: 11 years ago Posts: 5 |

Here is a further update. I just changed to PLA instead of ABS and managed to print a part after just a few tweaks to the slicing.

I am now fairly convinced that most of this problem is caused by lack of adhesion between the part and the bed. Not sure how to fix it yet, but for now I think I'll stick (no pun) with PLA until I am happy with the print quality from that.

Thanks.

MarkW

I am now fairly convinced that most of this problem is caused by lack of adhesion between the part and the bed. Not sure how to fix it yet, but for now I think I'll stick (no pun) with PLA until I am happy with the print quality from that.

Thanks.

MarkW

|

Re: Excess material at corners November 01, 2012 12:52PM |

Registered: 11 years ago Posts: 939 |

If your printing ABS wipe the surface down with Acetone.

Or just use a small amount of ABS disolved in aceton on top of the tape or just the glass.

IME Kapton doesn't last very long before it needs to be replaced.

Start by printing a single walled test piece, with no retraction.

If you can't get that to come out clean and measuring accurately printing anything else is a waste of plastic.

Or just use a small amount of ABS disolved in aceton on top of the tape or just the glass.

IME Kapton doesn't last very long before it needs to be replaced.

Start by printing a single walled test piece, with no retraction.

If you can't get that to come out clean and measuring accurately printing anything else is a waste of plastic.

|

Re: Excess material at corners November 01, 2012 01:11PM |

Registered: 11 years ago Posts: 560 |

That still looks way way too hot, I'd check the actual hot end temperature with an IR Thermometer.

I had a hot end thermocouple fail on mine, but my temperature dropped from thermocouple value.

If your hot end is hotter than what the thermocouple is outputting you could be over melting previous layers from the following layer pass and pulling material up from the bed.

I only see burning/scorching in the ABS that gets stuck to the side of my nozzle and cooks there for several hours, never in my prints.

I would eliminate the heated bed while trouble shooting this as well, print on blue painters tape, or a coating of ABS juice on a cold glass bed. Adhesion issues would not cause warping like that. Poor adhesion causes squashing in the z-axis where the part is curling up.

If you can't do anything with your thermocouple due to the way you have it mounted/cemented in your hot end, I would run test prints dropping 10c on each print to find the best print temp. My first themocouple was off by about 10c actual temperature from thermocouple value.

I can run abs from about 200 to 250, poor adhesion on the low end, excessive warp on the high end.

What does your filament come out like if you just extrude in air? It should flow out smooth from the nozzle and be a smooth surface on the extruded ABS and have a surface quality and flexability similar to your unextruded supply filament. Over temp will tend to be kind of crunchy and brittle and curl to the side of the nozzle when extruding.

Where did you get your ABS from? I know this sounds like a dumb question, but are you sure it is ABS? That material almost looks like HDPE, what plastic milk jugs are made of.

Edited 3 time(s). Last edit at 11/01/2012 01:23PM by Dirty Steve.

I had a hot end thermocouple fail on mine, but my temperature dropped from thermocouple value.

If your hot end is hotter than what the thermocouple is outputting you could be over melting previous layers from the following layer pass and pulling material up from the bed.

I only see burning/scorching in the ABS that gets stuck to the side of my nozzle and cooks there for several hours, never in my prints.

I would eliminate the heated bed while trouble shooting this as well, print on blue painters tape, or a coating of ABS juice on a cold glass bed. Adhesion issues would not cause warping like that. Poor adhesion causes squashing in the z-axis where the part is curling up.

If you can't do anything with your thermocouple due to the way you have it mounted/cemented in your hot end, I would run test prints dropping 10c on each print to find the best print temp. My first themocouple was off by about 10c actual temperature from thermocouple value.

I can run abs from about 200 to 250, poor adhesion on the low end, excessive warp on the high end.

What does your filament come out like if you just extrude in air? It should flow out smooth from the nozzle and be a smooth surface on the extruded ABS and have a surface quality and flexability similar to your unextruded supply filament. Over temp will tend to be kind of crunchy and brittle and curl to the side of the nozzle when extruding.

Where did you get your ABS from? I know this sounds like a dumb question, but are you sure it is ABS? That material almost looks like HDPE, what plastic milk jugs are made of.

Edited 3 time(s). Last edit at 11/01/2012 01:23PM by Dirty Steve.

|

Re: Excess material at corners November 07, 2012 05:34AM |

Registered: 11 years ago Posts: 5 |

Hi,

Thanks for all of the input. I have now switched to using PLA and I am getting very good results. I think I will work with this for a while unitl I am sure that this is working as well as it can before switching back to try ABS.

It does seem like it is something to do with temperature, but I haven't been able to figure out what. I still suspect adhesion issues will turn out to be the root cause of the problem, but I will have to fix the adhesion problem before I can turn down the temperature and still get prints.

Regards,

MarkW

Thanks for all of the input. I have now switched to using PLA and I am getting very good results. I think I will work with this for a while unitl I am sure that this is working as well as it can before switching back to try ABS.

It does seem like it is something to do with temperature, but I haven't been able to figure out what. I still suspect adhesion issues will turn out to be the root cause of the problem, but I will have to fix the adhesion problem before I can turn down the temperature and still get prints.

Regards,

MarkW

|

Re: Excess material at corners November 18, 2012 04:29PM |

Registered: 12 years ago Posts: 122 |

Dirty Steve Wrote:

-------------------------------------------------------

> From the side wall warping it looks like you are

> printing too hot. Print surface, bed temp, and

> extruder temp on this print? I'm running ABS at

> 220-230c with a bed temp of 110c directly on glass

> build platform.

>

> Corner blobs can come from laying down too much

> material overall, or from too much retraction.

> When retracting too much, it causes a longer pause

> in the XY movement and the nozzle will actually

> ooze a bit at the retraction point. Retracting

> more actually won't eliminate the blobs.

>

> I've found that when the extrusion flow rate is

> correct, that retraction doesn't need to be much

> more than 1mm.

@DirtySteve - Thanks for this great tip!

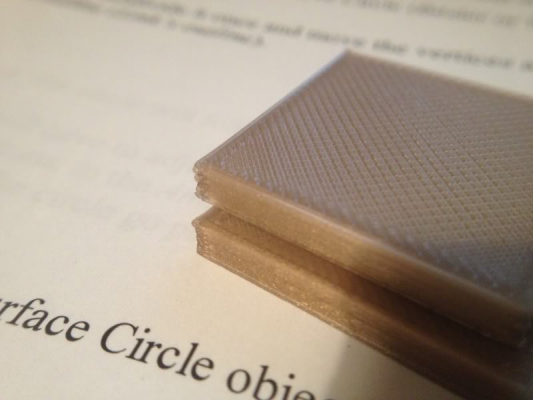

I had my settings pretty much dialed in with a nice smooth top layer on a test cube printed with 100% infill.

The only remaining problem was that the corners were bulging everywhere.

My retract was set to 2.5 mm at quite a slow 20 mm/s. I reduced this to 1 mm, as per your suggestion.

The new copy is on the bottom here, with the original on top.

Not perfect yet but much better.

richgain

-------------------------------------------------------

> From the side wall warping it looks like you are

> printing too hot. Print surface, bed temp, and

> extruder temp on this print? I'm running ABS at

> 220-230c with a bed temp of 110c directly on glass

> build platform.

>

> Corner blobs can come from laying down too much

> material overall, or from too much retraction.

> When retracting too much, it causes a longer pause

> in the XY movement and the nozzle will actually

> ooze a bit at the retraction point. Retracting

> more actually won't eliminate the blobs.

>

> I've found that when the extrusion flow rate is

> correct, that retraction doesn't need to be much

> more than 1mm.

@DirtySteve - Thanks for this great tip!

I had my settings pretty much dialed in with a nice smooth top layer on a test cube printed with 100% infill.

The only remaining problem was that the corners were bulging everywhere.

My retract was set to 2.5 mm at quite a slow 20 mm/s. I reduced this to 1 mm, as per your suggestion.

The new copy is on the bottom here, with the original on top.

Not perfect yet but much better.

richgain

Sorry, only registered users may post in this forum.