What causes flat botton finishing?

Posted by fsamir

|

What causes flat botton finishing? December 02, 2012 07:15AM |

Registered: 11 years ago Posts: 112 |

Hi everyone,

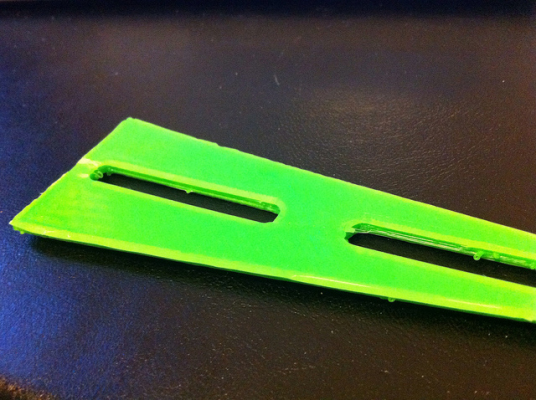

what causes this finishing?

This has been printed with ABS 1.75mm, MKII heated bed at 60C and 3mm glass with Kapton tape. Also, I tried with other 3 filaments and the result is the same.

It seems like the bed is too hot and melting the plastic, but everyone else mentions printing ABS with the bed at 110C. I initially though that my thermistor could not be working properly, then I printed a few parts with 55C to check and it turn out that it didn't stick to the bed.

Any tips?

Franklin Dattein

Cheers,

Franklin Dattein

|

Re: What causes flat botton finishing? December 02, 2012 09:38AM |

Admin Registered: 17 years ago Posts: 7,879 |

Are you sure it is not PLA? Put some in near boiling water and if it goes soft it is not ABS.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: What causes flat botton finishing? December 02, 2012 04:03PM |

Registered: 11 years ago Posts: 112 |

|

Re: What causes flat botton finishing? December 02, 2012 07:24PM |

Admin Registered: 17 years ago Posts: 7,879 |

Well if it ABS the bed temperature is too low so I would expect it not to stick well and it certainly won't melt the plastic.

If you asking why it is a smooth finish, that will always be the case if you extrude it onto a smooth surface and have the first layer height low enough to leave no gaps between the filaments.

[www.hydraraptor.blogspot.com]

If you asking why it is a smooth finish, that will always be the case if you extrude it onto a smooth surface and have the first layer height low enough to leave no gaps between the filaments.

[www.hydraraptor.blogspot.com]

|

Re: What causes flat botton finishing? December 02, 2012 07:37PM |

Registered: 11 years ago Posts: 112 |

|

Re: What causes flat botton finishing? December 02, 2012 11:21PM |

Registered: 11 years ago Posts: 560 |

|

Re: What causes flat botton finishing? December 03, 2012 12:40AM |

Registered: 11 years ago Posts: 112 |

|

Re: What causes flat botton finishing? December 03, 2012 02:08AM |

Registered: 11 years ago Posts: 560 |

|

Re: What causes flat botton finishing? December 03, 2012 03:57AM |

Registered: 11 years ago Posts: 112 |

|

Re: What causes flat botton finishing? December 03, 2012 04:52AM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Franklin,

the bottom layer 'represents' the surface structure of the bed - if it's plain/smooth, the bottom tracks will be plain/smooth too ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

the bottom layer 'represents' the surface structure of the bed - if it's plain/smooth, the bottom tracks will be plain/smooth too ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: What causes flat botton finishing? December 03, 2012 04:57AM |

Admin Registered: 17 years ago Posts: 7,879 |

It is normal to have a fairly smooth bottom. You won't ever get the same finish as the other sides because they aren't pressed against a smooth surface.

To make it gappy make the first layer higher by calibrating so that Z = 0 is higher. You might have problems with it sticking then as the contact area of squashed cylinders tends to zero as you squash them less.

[www.hydraraptor.blogspot.com]

To make it gappy make the first layer higher by calibrating so that Z = 0 is higher. You might have problems with it sticking then as the contact area of squashed cylinders tends to zero as you squash them less.

[www.hydraraptor.blogspot.com]

|

Re: What causes flat botton finishing? December 03, 2012 05:06AM |

Registered: 11 years ago Posts: 112 |

That is good and bad news. Good because it means my printer is finally fully calibrated. Bad because I wish I could print it with the same finishing.

I got a prusa kit from Makergear, the plastic parts are white ABS and they have no flat/smooth finishing. Any idea on how they achieve that?

Cheers,

Franklin Dattein

I got a prusa kit from Makergear, the plastic parts are white ABS and they have no flat/smooth finishing. Any idea on how they achieve that?

Cheers,

Franklin Dattein

|

Re: What causes flat botton finishing? December 03, 2012 06:08AM |

Admin Registered: 16 years ago Posts: 13,884 |

... most common are some breakaway 'raft' layers first, on which the part is printed - then you'll get the 3D-structure of the topmost raft-layer ... but it could be a piece of work to remove all the bits of the raft.

It's something tricky, if you want easier removable bottom layers with gap-width betweeen the tracks and different temperatures for raft and object layers ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

It's something tricky, if you want easier removable bottom layers with gap-width betweeen the tracks and different temperatures for raft and object layers ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: What causes flat botton finishing? December 05, 2012 04:08PM |

Registered: 11 years ago Posts: 120 |

|

Re: What causes flat botton finishing? December 08, 2012 06:18PM |

Registered: 11 years ago Posts: 75 |

wow!? sandblast? that seems like it would bring in a host of other problems? possible that the parts would not stick as well, or that the glass bed would be very hard to clean since there would be a lot of 'pitted' area for the plastic to get into, which may be hard to get out?

Anyone done this? any experiences? could be cool! since u can sandblast one side only and leave the other smooth you could potentially have one glass bed that you can flip over for different finishes!

Anyone done this? any experiences? could be cool! since u can sandblast one side only and leave the other smooth you could potentially have one glass bed that you can flip over for different finishes!

|

Re: What causes flat botton finishing? December 13, 2012 05:07PM |

Registered: 11 years ago Posts: 112 |

Just to close the case, the reason for tha surface finishing was because the nothend was too close of the heated bed.

I was measuring the distance with a business card, very tide, between the hotend and the heated bed.

Fixed the problem by adding an extra 0.2mm distance and now the business card slides without any effort.

Cheers,

Franklin Dattein

I was measuring the distance with a business card, very tide, between the hotend and the heated bed.

Fixed the problem by adding an extra 0.2mm distance and now the business card slides without any effort.

Cheers,

Franklin Dattein

|

Re: What causes flat botton finishing? December 28, 2012 11:06PM |

Registered: 11 years ago Posts: 16 |

Hi there, I've worked profesionally with 3D printers for about 3 years.

What you're talking about the flat bottom is completely normal when you print without a raised raft. Because you're printing with a thermoset that is a liquid that turns to a solid, it naturally takes and saves the physical imperfections/structure of the surface beneath it.

In order to prevent physical imperfections from what is known as the "interface layer", that is to say the first layer of plastic that touches your model that is not the model itself, you have choices;

This assumes you are using a raft that raises the object off the "imperfect platform" that is usually your print bed / tray / glass / etc.

1. Use a slicer program like replicatorG with a custom slicing profile to adjust the exact temperature of the interface layer. This allows the plastic that bonds with your model to be at a different point of crystallization so its' bond strength isn't as high, but still does what it needs to (supports.) This will allow for much easier removal of the model, and can even allow you to use the same material as a support structure (though I wouldn't recommend it, it is not as pretty.)

2. Build in a removable platform that connects to your model that is made to be tossed. This will establish your model layers and model material before your actual object is started, causing the interface layer imperfections to only be visible on your 'pedstal' if you will.

3. If you're having trouble with actual damage from the raft material being removed due to its' bond strength being too great and taking some bits of base model material with it, you're going to need to a soluble support structure. I would suggest pva (polyvinyl alcohol) which is water soluble. You can also get some ABS based solubles but you need to use hydroxide (lye) in a very high concentration.

What you're talking about the flat bottom is completely normal when you print without a raised raft. Because you're printing with a thermoset that is a liquid that turns to a solid, it naturally takes and saves the physical imperfections/structure of the surface beneath it.

In order to prevent physical imperfections from what is known as the "interface layer", that is to say the first layer of plastic that touches your model that is not the model itself, you have choices;

This assumes you are using a raft that raises the object off the "imperfect platform" that is usually your print bed / tray / glass / etc.

1. Use a slicer program like replicatorG with a custom slicing profile to adjust the exact temperature of the interface layer. This allows the plastic that bonds with your model to be at a different point of crystallization so its' bond strength isn't as high, but still does what it needs to (supports.) This will allow for much easier removal of the model, and can even allow you to use the same material as a support structure (though I wouldn't recommend it, it is not as pretty.)

2. Build in a removable platform that connects to your model that is made to be tossed. This will establish your model layers and model material before your actual object is started, causing the interface layer imperfections to only be visible on your 'pedstal' if you will.

3. If you're having trouble with actual damage from the raft material being removed due to its' bond strength being too great and taking some bits of base model material with it, you're going to need to a soluble support structure. I would suggest pva (polyvinyl alcohol) which is water soluble. You can also get some ABS based solubles but you need to use hydroxide (lye) in a very high concentration.

Sorry, only registered users may post in this forum.