first few prints, major issues

Posted by quantize

|

first few prints, major issues December 08, 2012 07:16PM |

Registered: 11 years ago Posts: 7 |

Hey y'all,

Finally got my prusa mendel printing but the first few prints have turned out pretty lame. See attached pictures... I was printing a cube. In addition to the issue of quality, none of the prints finished (at some point extruder stopped extruding because of a jam).

If anyone has some ideas, would really appreciate it!

Some specs/settings:

3MM Blue PLA plastic

.4mm nozzle

230 celcius

repetier firmware & slicer

Slicer Settings

.1mm layer height

5 perimeters

.9 rectilinear fill density

infill every 2 layers, solid infill every layer

default extrusion width: 200%

extrusion multiplier: 5

Finally got my prusa mendel printing but the first few prints have turned out pretty lame. See attached pictures... I was printing a cube. In addition to the issue of quality, none of the prints finished (at some point extruder stopped extruding because of a jam).

If anyone has some ideas, would really appreciate it!

Some specs/settings:

3MM Blue PLA plastic

.4mm nozzle

230 celcius

repetier firmware & slicer

Slicer Settings

.1mm layer height

5 perimeters

.9 rectilinear fill density

infill every 2 layers, solid infill every layer

default extrusion width: 200%

extrusion multiplier: 5

|

Re: first few prints, major issues December 08, 2012 09:01PM |

Registered: 11 years ago Posts: 560 |

|

Re: first few prints, major issues December 11, 2012 08:56AM |

Registered: 11 years ago Posts: 10 |

|

Re: first few prints, major issues December 28, 2012 11:10PM |

Registered: 11 years ago Posts: 16 |

|

Re: first few prints, major issues December 29, 2012 05:22AM |

Registered: 13 years ago Posts: 2,947 |

That actually looks like crystallized PLA which can happen at higher temperatures. I would try lowering the temp to 190c

But the main issue is the 200% width ratio. At 0.1mm layers and a 0.4mm nozzle you would want an extrusion width of 450% to maybe 550%. This is why using any ratios in the setting is completely wrong. When slic3r went to a first layer width ratio of 200% I went why and ??????,, it only works on the default layer height and after that it just makes things not work.

Edited 1 time(s). Last edit at 12/29/2012 09:13PM by Sublime.

But the main issue is the 200% width ratio. At 0.1mm layers and a 0.4mm nozzle you would want an extrusion width of 450% to maybe 550%. This is why using any ratios in the setting is completely wrong. When slic3r went to a first layer width ratio of 200% I went why and ??????,, it only works on the default layer height and after that it just makes things not work.

Edited 1 time(s). Last edit at 12/29/2012 09:13PM by Sublime.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: first few prints, major issues December 29, 2012 07:44PM |

Registered: 12 years ago Posts: 115 |

If you can post some pictures of your machine setup and your nozzle / extruder design, it would also be very helpful. Also, what PLA are you using? Where did you purchase it from? Not all PLA processes the same, some of the cheap stuff from China is really just garbage.

Your heat is WAY to high for PLA. Also, what speeds are you using? The speed you print at will drastically change the temperature your extruder is set at because most printers have a low thermal mass at their nozzle. You end up overcompensating by raising the temperature of you nozzle just to get consistant flow.

At a 0.4mm nozzle, I would recomment only 180-185°C for extruder temp, 60mm/s to 80mm/s for printer speeds, and a 0.3mm layer height for starters. You can always incrementally change your settings to move to your 0.1mm layer height and boost your speeds later. You really need to walk before you can run. Focus on getting consistantly good prints at 0.3mm layer heights first. Also, temperatures that people state are not absolutes, what might be 180° for me might be anywhere from 160° to 200° for other people's extruder designs. Some extruders have the thermocouple just taped to the outside of the nozzle, while others insert it into a small well in the brass hot end. This changes your percieved temperature of your extruder's hot end versus the actual temperature of your melted plastic.

When your hot end comes up to temperature and plastic starts to drool, it should look more like a slow motion toothpaste leaving the tube look, not a quick dump of plastic that looks like a glob of glue on the printer bed. You really only just barely want the plastic to melt, and move like toothpaste from a toothpaste tube. Any hotter and you won't be able to control where plastic ends up. Any colder, and you won't reliably be able to print.

Your heat is WAY to high for PLA. Also, what speeds are you using? The speed you print at will drastically change the temperature your extruder is set at because most printers have a low thermal mass at their nozzle. You end up overcompensating by raising the temperature of you nozzle just to get consistant flow.

At a 0.4mm nozzle, I would recomment only 180-185°C for extruder temp, 60mm/s to 80mm/s for printer speeds, and a 0.3mm layer height for starters. You can always incrementally change your settings to move to your 0.1mm layer height and boost your speeds later. You really need to walk before you can run. Focus on getting consistantly good prints at 0.3mm layer heights first. Also, temperatures that people state are not absolutes, what might be 180° for me might be anywhere from 160° to 200° for other people's extruder designs. Some extruders have the thermocouple just taped to the outside of the nozzle, while others insert it into a small well in the brass hot end. This changes your percieved temperature of your extruder's hot end versus the actual temperature of your melted plastic.

When your hot end comes up to temperature and plastic starts to drool, it should look more like a slow motion toothpaste leaving the tube look, not a quick dump of plastic that looks like a glob of glue on the printer bed. You really only just barely want the plastic to melt, and move like toothpaste from a toothpaste tube. Any hotter and you won't be able to control where plastic ends up. Any colder, and you won't reliably be able to print.

|

Re: first few prints, major issues December 29, 2012 09:26PM |

Registered: 13 years ago Posts: 2,947 |

@ Beekeeper It is interesting you say to start at 0.3 layers as I have never found anything above 0.25 to print worth a damn. I find 0.25 gets good results, 0.2 gives nice parts and 0.1 gives the nicest without wasting to much time printing. (above comments are with either a 0.35mm or 0.5mm nozzle).

But as I said before the issue above is simply trying to print at 0.2mm wide from a 0.4mm nozzle. Printing width should always be an Absolute number and should not be a ratio of the height or you end up with problems like this. Based on NopHeads work the ratio has a bottom limit but that is all, sure he says to always print around 1.5 times the height but he also has never been able to get good results below something like 0.25mm. Once you go below that all the work he did figuring out the optimal is completely useless. If you look at Cura you will see they print close to the nozzle diameter and limit the width based on the nozzle diameter * 1.5 and never do they calculate it in relation to the height (only limit the max height based on nozzle diameter). Same thing with Kisslicer, it recommends using the nozzle diameter as the path width. And guess what both Kisslicer and Cura make far better prints than Slic3r that uses Nopheads math... Hmmmm

But as I said before the issue above is simply trying to print at 0.2mm wide from a 0.4mm nozzle. Printing width should always be an Absolute number and should not be a ratio of the height or you end up with problems like this. Based on NopHeads work the ratio has a bottom limit but that is all, sure he says to always print around 1.5 times the height but he also has never been able to get good results below something like 0.25mm. Once you go below that all the work he did figuring out the optimal is completely useless. If you look at Cura you will see they print close to the nozzle diameter and limit the width based on the nozzle diameter * 1.5 and never do they calculate it in relation to the height (only limit the max height based on nozzle diameter). Same thing with Kisslicer, it recommends using the nozzle diameter as the path width. And guess what both Kisslicer and Cura make far better prints than Slic3r that uses Nopheads math... Hmmmm

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: first few prints, major issues December 30, 2012 06:59AM |

Admin Registered: 17 years ago Posts: 7,879 |

The 1.5 ratio and the die swell area maths I use gives me the upper limits of the extrusion size. I.e. the absolute maximum layer height is sqrt((pi * d^2))/6). That gives me the maximum productivity from my machines and makes strong functional objects. For aesthetic objects, particularly with thin sloping sides, thinner layers are better.

For thinner layers yes you need to keep the width close to the nozzle width. When the layers are high relative to the width the plastic spreads sideways and to limit it to the nozzle width requires stretching it too much. When the layer height is low then it doesn't want to spread sideways because the gap is small, so the width has to tend towards the nozzle width. The ideal value could probably be found by linear interpolation from my maximum values. I.e. when the layer height is zero the width equals the nozzle width.

Slic3r doesn't use my maths because a) it doesn't know the die swell value and b) I don't get the same results slicing the same object with the same layer height.

[www.hydraraptor.blogspot.com]

For thinner layers yes you need to keep the width close to the nozzle width. When the layers are high relative to the width the plastic spreads sideways and to limit it to the nozzle width requires stretching it too much. When the layer height is low then it doesn't want to spread sideways because the gap is small, so the width has to tend towards the nozzle width. The ideal value could probably be found by linear interpolation from my maximum values. I.e. when the layer height is zero the width equals the nozzle width.

Slic3r doesn't use my maths because a) it doesn't know the die swell value and b) I don't get the same results slicing the same object with the same layer height.

[www.hydraraptor.blogspot.com]

|

Re: first few prints, major issues December 30, 2012 02:33PM |

Registered: 12 years ago Posts: 115 |

@ Sublime, I print nearly everything at .3mm in both ABS and PLA with a .5mm nozzle tip, and occasionally with a .35mm nozzle (although I normally drop the layer height to 0.20 to 0.25mm for improved prints for the 0.35mm nozzles). There are a lot of suppliers that print 0.4mm layer heights with a 0.5mm nozzle. Lulzbot does it at least with their Extruder body and their Extruder Idler parts, and they print their extruder gears at 0.3mm. Elderfarrell on ebay prints nearly everything with a 0.4mm layer height. All in all, not bad parts through as every part on the printer I built with his parts was printed at 0.4mm. On a machine I built with his parts, the printed X & Y axis gears have never failed, and I have over 1000 hours print time on that machine.

I've found the die swell of different types of nozzles to vary greatly. In extrusion dies, the die swell is smallest when you have a longer nozzle hole kept at the same diameter when extruding into free air. I would be quite interested to find out if anyone else has seen this.

I've found the die swell of different types of nozzles to vary greatly. In extrusion dies, the die swell is smallest when you have a longer nozzle hole kept at the same diameter when extruding into free air. I would be quite interested to find out if anyone else has seen this.

|

Re: first few prints, major issues December 30, 2012 06:07PM |

Registered: 13 years ago Posts: 2,947 |

@ Nophead I apologize if that came across wrong. Let me try and explain. The work you have done is greatly admired and is some of the best documented work in RepRap. Your print quality has always been an inspiration to people building and working on RepRap. In the end you came up with a style of printing that works really well and influenced Enrique while he wrote Skeinforge. It set in motion what is now a defacto standard in printing. This is what I meant by "your math". Basically a set of standards on how the plastic is extruded (wider than the nozzle) and optimal layer heights (based on max extrusion width). This is what has now influenced how Slic3r predicts its math based on Nozzle diameter. But with Cura and Kisslicer they abandoned your style of printing and went a different way. This other method works 100 times better on a Bowden machine and when used on a non Bowden machine gives excellent results. So now we have two ways of printing, the one you influenced and this other one that I find gives me better results as I have never had a good print using your style of printing regardless of the slicer (mostly Bowden machine experience). This other style of printing gives holes the correct size without compensation, it gives sharp corners with a radius of the nozzle not larger, etc. This is not to say there is anything wrong with your method but rather that there are two completely different ways that give totally different results. I have also noticed that most people that use the RepRap forums use your style of printing but are looking for the results they see from machines like Ultimaker, Printxel, Tantillus, etc . To get these other results you have to completely abandon your style of printing and adopt a new style of printing.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: first few prints, major issues December 31, 2012 03:40AM |

Admin Registered: 17 years ago Posts: 7,879 |

Sorry but I don't see a great divide or revolution here. One can print with any layer height between two limits, the highest being defined by the die swell size and the lowest by the viscosity of the plastic (at some point the gap becomes so small it jams squeezing the plastic through the gap). In between it is a trade off between build speed and resolution.

You should be able to do it with any slicer that allows you to set the height and the width independently. Skeinforge doesn't try to decide the width based on the nozzle size (it doesn't know the nozzle size) so I can't see how it is somehow influenced by my work in such a way as it it isn't suitable for lower layer heights. Its defaults seem to be H = 0.4, W/T = 2.0, which aren't values I have ever used and they wouldn't work on any of my machines. It would need something like a 0.6mm nozzle for ABS and even bigger for PLA.

Slic3r definitely isn't influenced by anything I do because I have never advocated inputting the nozzle diameter into the slicer and trying to use it to determine the width. Again the values it comes up with by default don't match anything I have used.

To get better resolution you have to use lower layer heights. That has always been obvious. I don't see how that is abandoning one style and adopting another. You just type different numbers into your slicer and there is a continuous range in the middle.

What doesn't seem to be well known is how to choose an appropriate width given layer height, nozzle width and die swell as nobody has published a general formula.

Edited 1 time(s). Last edit at 12/31/2012 05:26AM by nophead.

[www.hydraraptor.blogspot.com]

You should be able to do it with any slicer that allows you to set the height and the width independently. Skeinforge doesn't try to decide the width based on the nozzle size (it doesn't know the nozzle size) so I can't see how it is somehow influenced by my work in such a way as it it isn't suitable for lower layer heights. Its defaults seem to be H = 0.4, W/T = 2.0, which aren't values I have ever used and they wouldn't work on any of my machines. It would need something like a 0.6mm nozzle for ABS and even bigger for PLA.

Slic3r definitely isn't influenced by anything I do because I have never advocated inputting the nozzle diameter into the slicer and trying to use it to determine the width. Again the values it comes up with by default don't match anything I have used.

Quote

To get these other results you have to completely abandon your style of printing and adopt a new style of printing.

To get better resolution you have to use lower layer heights. That has always been obvious. I don't see how that is abandoning one style and adopting another. You just type different numbers into your slicer and there is a continuous range in the middle.

What doesn't seem to be well known is how to choose an appropriate width given layer height, nozzle width and die swell as nobody has published a general formula.

Edited 1 time(s). Last edit at 12/31/2012 05:26AM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: first few prints, major issues December 31, 2012 04:23AM |

Registered: 13 years ago Posts: 2,947 |

Well maybe I need to explain it a little different again since you do not seem to understand what I am saying.

You have a huge influence on how people in RepRap have made there decisions. As for SF I can tell you that I have sat and talked with Enrique in person and basically it is written to do what you figured out. Each time I would ask a question about why something was the way it was it came back to something you had done. I am not talking about the defaults but the actual printing style, nothing that could have a mathematical formula attached to it (example: stretch module that is needed for printing with die swell). But rather what people consider correct. I can tell you this because the printing style I have figured out (and Ultimaker owners and Kisslicer) basically go against what you tell people when giving advise, I see it all the time on here. There are two ways of doing things and one is the way you advise along with a great deal of other people in RepRap and then this other way. Even on larger layer heights these other programs don't want to print wider than the nozzle by nearly as much as you advise. this is not to say one is right and one is wrong but rather as I keep saying there are TWO ways of doing things.

When I said Slic3r uses your math I was being much more general. You use the die swell value and Slic3r assumes a die swell value based on the nozzle diameter. But from my experience (and Cura and Kisslicer) the die swell has an effect on print quality and printing close to the nozzle diameter (no die swell) gives sharper corners, more accurate holes, good bridges, low ooze, high speeds without tapering of threads. But limits your max layer height as you can tell by my always recommending printing at layers less than 0.25mm. But as said before this is not way you print and promote which is the way most of the people in RepRap print but not how offshoots of RepRap do.

So we have :

One slicer that prints with an estimated die swell and two that do not.

Then we have:

People that promote printing with die swell in mind and others that promote printing without any die swell.

See how one is your style of printing and one is not? I agree the way I phrased it was wrong as it is not really your math but rather the style of printing your work has encouraged. Again I apologize.

When I read your advise it's often the opposite of what I have found and I usually just stay out of it because I know there are two styles of printing and your advise will give them the same kind of results as you get which are great but not how I do it and as I have recently discovered not the same way these other people that do not participate on the forums have figured out.

Anyway the point I was making in the post above is the width should not be a ratio of the layer height but rather and absolute width with only the max layer height being limited to 66% of the absolute width.

You have a huge influence on how people in RepRap have made there decisions. As for SF I can tell you that I have sat and talked with Enrique in person and basically it is written to do what you figured out. Each time I would ask a question about why something was the way it was it came back to something you had done. I am not talking about the defaults but the actual printing style, nothing that could have a mathematical formula attached to it (example: stretch module that is needed for printing with die swell). But rather what people consider correct. I can tell you this because the printing style I have figured out (and Ultimaker owners and Kisslicer) basically go against what you tell people when giving advise, I see it all the time on here. There are two ways of doing things and one is the way you advise along with a great deal of other people in RepRap and then this other way. Even on larger layer heights these other programs don't want to print wider than the nozzle by nearly as much as you advise. this is not to say one is right and one is wrong but rather as I keep saying there are TWO ways of doing things.

When I said Slic3r uses your math I was being much more general. You use the die swell value and Slic3r assumes a die swell value based on the nozzle diameter. But from my experience (and Cura and Kisslicer) the die swell has an effect on print quality and printing close to the nozzle diameter (no die swell) gives sharper corners, more accurate holes, good bridges, low ooze, high speeds without tapering of threads. But limits your max layer height as you can tell by my always recommending printing at layers less than 0.25mm. But as said before this is not way you print and promote which is the way most of the people in RepRap print but not how offshoots of RepRap do.

So we have :

One slicer that prints with an estimated die swell and two that do not.

Then we have:

People that promote printing with die swell in mind and others that promote printing without any die swell.

See how one is your style of printing and one is not? I agree the way I phrased it was wrong as it is not really your math but rather the style of printing your work has encouraged. Again I apologize.

When I read your advise it's often the opposite of what I have found and I usually just stay out of it because I know there are two styles of printing and your advise will give them the same kind of results as you get which are great but not how I do it and as I have recently discovered not the same way these other people that do not participate on the forums have figured out.

Anyway the point I was making in the post above is the width should not be a ratio of the layer height but rather and absolute width with only the max layer height being limited to 66% of the absolute width.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: first few prints, major issues December 31, 2012 05:58AM |

Admin Registered: 17 years ago Posts: 7,879 |

Quote

Anyway the point I was making in the post above is the width should not be a ratio of the layer height but rather and absolute width with only the max layer height being limited to 66% of the absolute width.

If you keep the width equal to the nozzle width it fails to work for higher layers, hence you say it can't be bigger than 66% of the nozzle width. But one can print higher than that if one wants by not keeping the width absolute. That increases build speed at the expense of resolution, so it shouldn't be dismissed as something one shouldn't do. Yes you get sharper corners with thinner filament, no surprise there, and indeed, why I use thinner layers for gears and pulleys.

When I have a bit of spare time I will attempt come up with a formula that works for all layer heights and then everybody will be happy.

BTW, do you print anything other than PLA?

[www.hydraraptor.blogspot.com]

|

Re: first few prints, major issues December 31, 2012 09:01AM |

Registered: 13 years ago Posts: 2,947 |

nophead Wrote:

-------------------------------------------------------

> If you keep the width equal to the nozzle width it

> fails to work for higher layers, hence you say it

> can't be bigger than 66% of the nozzle width. But

> one can print higher than that if one wants by not

> keeping the width absolute. That increases build

> speed at the expense of resolution, so it

> shouldn't be dismissed as something one shouldn't

> do. Yes you get sharper corners with thinner

> filament, no surprise there, and indeed, why I use

> thinner layers for gears and pulleys.

We have other limits that determine the build time regardless of layer height. Like volume per minute the hotend is able melt. Or the maximum volume of plastic per minute that can be laid down while giving the plastic enough time to cool. Then with firmware that has look-ahead we can actually lay down thin layers at high speeds and still reach those limits while maintaining the finish and accuracy of lower speeds.

> BTW, do you print anything other than PLA?

No I do not. I know a lot of this has to do with the differences between PLA and ABS as well as learning on a Bowden cable machine which requires a different way of approaching things.

-------------------------------------------------------

> If you keep the width equal to the nozzle width it

> fails to work for higher layers, hence you say it

> can't be bigger than 66% of the nozzle width. But

> one can print higher than that if one wants by not

> keeping the width absolute. That increases build

> speed at the expense of resolution, so it

> shouldn't be dismissed as something one shouldn't

> do. Yes you get sharper corners with thinner

> filament, no surprise there, and indeed, why I use

> thinner layers for gears and pulleys.

We have other limits that determine the build time regardless of layer height. Like volume per minute the hotend is able melt. Or the maximum volume of plastic per minute that can be laid down while giving the plastic enough time to cool. Then with firmware that has look-ahead we can actually lay down thin layers at high speeds and still reach those limits while maintaining the finish and accuracy of lower speeds.

> BTW, do you print anything other than PLA?

No I do not. I know a lot of this has to do with the differences between PLA and ABS as well as learning on a Bowden cable machine which requires a different way of approaching things.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: first few prints, major issues December 31, 2012 05:03PM |

Registered: 12 years ago Posts: 88 |

nophead Wrote:

-------------------------------------------------------

> The 1.5 ratio and the die swell area maths I use

> gives me the upper limits of the extrusion size.

> I.e. the absolute maximum layer height is sqrt((pi

> * d^2))/6).

There is one extra parenthesis in the above. Should the '/6' term be inside the sqrt() ?

I regularly print with layer height between 0.2 and 0.6 with a nozzle of 0.4mm and die swell approx 0.8, W/T between 1.5 and 2.5, and am very happy with the results. Higher layers, though worse in resolution, have proven stronger with my setup for large objects, where I don't need a very good finish. I use Skeinforge. I also regularly print at temperatures way higher than those recommended for the plastic, e.g. 285°C for PLA and 305°C for ABS. The trick is to keep the flow of plastic at the maximum possible. Due to the increased flow, the plastic in the melt chamber does not reach the temperature measured by the (displaced) thermistor. Temperature is calculated automatically following a flow vs. temperature graph that I devised for of PLA and ABS for my extruder. I don't claim to have any special understanding on the subject other than that of an average engineer.

I mention the above because I don't see how magic numbers can do good in 3d printing. Yes, there is a need to simplify 3d printing, but it will always remain a rather complex process where engineering calculations are needed if one wants to achieve optimal results for a job in hand (and hope to understand what's going on).

Edited 4 time(s). Last edit at 01/01/2013 01:52PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

-------------------------------------------------------

> The 1.5 ratio and the die swell area maths I use

> gives me the upper limits of the extrusion size.

> I.e. the absolute maximum layer height is sqrt((pi

> * d^2))/6).

There is one extra parenthesis in the above. Should the '/6' term be inside the sqrt() ?

I regularly print with layer height between 0.2 and 0.6 with a nozzle of 0.4mm and die swell approx 0.8, W/T between 1.5 and 2.5, and am very happy with the results. Higher layers, though worse in resolution, have proven stronger with my setup for large objects, where I don't need a very good finish. I use Skeinforge. I also regularly print at temperatures way higher than those recommended for the plastic, e.g. 285°C for PLA and 305°C for ABS. The trick is to keep the flow of plastic at the maximum possible. Due to the increased flow, the plastic in the melt chamber does not reach the temperature measured by the (displaced) thermistor. Temperature is calculated automatically following a flow vs. temperature graph that I devised for of PLA and ABS for my extruder. I don't claim to have any special understanding on the subject other than that of an average engineer.

I mention the above because I don't see how magic numbers can do good in 3d printing. Yes, there is a need to simplify 3d printing, but it will always remain a rather complex process where engineering calculations are needed if one wants to achieve optimal results for a job in hand (and hope to understand what's going on).

Edited 4 time(s). Last edit at 01/01/2013 01:52PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: first few prints, major issues December 31, 2012 07:13PM |

Registered: 12 years ago Posts: 88 |

Happy New Year!

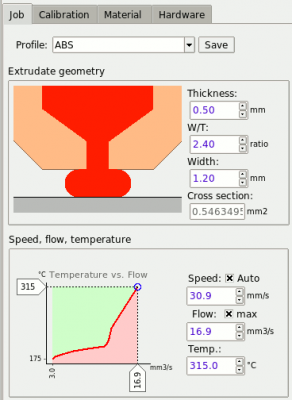

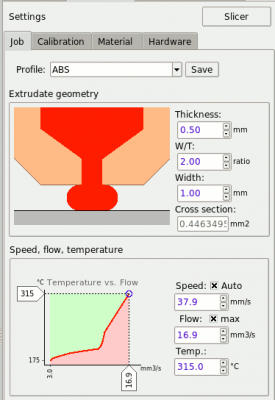

Hoping to aid in understanding how some basic parameters influence 3d printing, triggered by Nopehead's wish to device a set of formulas for setting these parameters, here are two animated gifs from a program I've written to automatically calculate and adjust Skeinforge's parameters for my prints. They show how variation of layer thickness and width/thickess (W/T) influence the shape of the extrudate.

The snapshots where taken with flow fixed to maximum. To get this max flow, I have to set the nozzle temperature to 315°C; this is not the temperature in the melt chamber but the temperature that the thermistor reads. The thermistor is displaced abt 1.0mm from the wall of the melt chamber and therefore reads a different temperature than that of the molten plastic, due to the thermal conductivity of the barrel being less than ideal (i.e. infinite).

This one has W/T varying while keeping layer thickness (T) fixed. Notice the change in speed as the W/T changes and the flow is kept maximum.

This one has layer thickness (height) varying while keeping W/T fixed.

I have not put strict limits to the variation of these values, other than the absolute necessary, like height being larger than die swell and extrudate being thinner than the nozzle diameter. Hopefully, as an outcome of the discussion in this thread, I can impose some tighter limits, like the one mentioned by Nophead above.

EDIT: I just noticed that the flow vs. temperature curve in the animation came from an early test, lacking details.

Edited 9 time(s). Last edit at 01/01/2013 01:56PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

Hoping to aid in understanding how some basic parameters influence 3d printing, triggered by Nopehead's wish to device a set of formulas for setting these parameters, here are two animated gifs from a program I've written to automatically calculate and adjust Skeinforge's parameters for my prints. They show how variation of layer thickness and width/thickess (W/T) influence the shape of the extrudate.

The snapshots where taken with flow fixed to maximum. To get this max flow, I have to set the nozzle temperature to 315°C; this is not the temperature in the melt chamber but the temperature that the thermistor reads. The thermistor is displaced abt 1.0mm from the wall of the melt chamber and therefore reads a different temperature than that of the molten plastic, due to the thermal conductivity of the barrel being less than ideal (i.e. infinite).

This one has W/T varying while keeping layer thickness (T) fixed. Notice the change in speed as the W/T changes and the flow is kept maximum.

This one has layer thickness (height) varying while keeping W/T fixed.

I have not put strict limits to the variation of these values, other than the absolute necessary, like height being larger than die swell and extrudate being thinner than the nozzle diameter. Hopefully, as an outcome of the discussion in this thread, I can impose some tighter limits, like the one mentioned by Nophead above.

EDIT: I just noticed that the flow vs. temperature curve in the animation came from an early test, lacking details.

Edited 9 time(s). Last edit at 01/01/2013 01:56PM by dzach.

--------------------------------------------------------

3D extruder performance tests

dzach's ORDbot Hadron build

|

Re: first few prints, major issues January 01, 2013 05:30PM |

Admin Registered: 17 years ago Posts: 7,879 |

Nice animations.

Yes should be sqrt((pi * d^2)/6). It assumes W/T has to be at least 1.5 to get strong enough bonding.

[www.hydraraptor.blogspot.com]

Quote

There is one extra parenthesis in the above. Should the '/6' term be inside the sqrt() ?

Yes should be sqrt((pi * d^2)/6). It assumes W/T has to be at least 1.5 to get strong enough bonding.

[www.hydraraptor.blogspot.com]

|

Re: first few prints, major issues January 06, 2013 07:24AM |

Registered: 11 years ago Posts: 16 |

|

Re: first few prints, major issues January 23, 2013 02:35AM |

Registered: 13 years ago Posts: 2,947 |

OK I decided to hack up a quick equation that linearly divides the die swell between the max height (nozzle diameter + die swell * .66) and minimum height of 0.08mm at nozzle diameter. It is in my branch of Cura [github.com] along with some other things I feel are needed like path based fan control and single setting skin thickness that automatically sets the layer and perimeter count. Feel free to give it a try and see if the results are what you would expect.

Right now you will need to set the nozzle diameter in the advanced tab and the die swell in the expert settings. The fan control is also in the expert settings right now. It may also be set to use relative extrusion via the expert settings because that is Tantillus's default.

Right now you will need to set the nozzle diameter in the advanced tab and the die swell in the expert settings. The fan control is also in the expert settings right now. It may also be set to use relative extrusion via the expert settings because that is Tantillus's default.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: first few prints, major issues January 23, 2013 06:15AM |

Registered: 11 years ago Posts: 251 |

|

Re: first few prints, major issues January 23, 2013 07:00AM |

Registered: 13 years ago Posts: 2,947 |

konwiddak Wrote:

-------------------------------------------------------

> As a note, I definitely read the only time Slic3r

> uses nozzle width in its calculations is when

> bridging. That would imply its using similar maths

> to kisslicer and Skeinforge.

Actually it use the nozzle diameter to determine the width of all paths using some strange assumptions unless you have the widths set manually via the advanced settings. As for SF and Kisslicer they both have 100% manually set extrusion widths so they are nothing like slic3rs automatic extrusion width math.

-------------------------------------------------------

> As a note, I definitely read the only time Slic3r

> uses nozzle width in its calculations is when

> bridging. That would imply its using similar maths

> to kisslicer and Skeinforge.

Actually it use the nozzle diameter to determine the width of all paths using some strange assumptions unless you have the widths set manually via the advanced settings. As for SF and Kisslicer they both have 100% manually set extrusion widths so they are nothing like slic3rs automatic extrusion width math.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

Sorry, only registered users may post in this forum.