a troublshooting-faq ??? / my extruder blocks after 30 minutes :'(

Posted by roland

|

a troublshooting-faq ??? / my extruder blocks after 30 minutes :'( December 18, 2012 02:13PM |

Registered: 14 years ago Posts: 65 |

i don't like these forums, where all the know how gets lost and you better search with google worldwide anyway..

There should be a nice troubleshooting-faq on reprap.org.

With keywords on the parts making trouble and keywords on the problem.

[reprap.org] is surely not enough.

I could easily setup such a keyword-faq on my loser-site reprob.org.

But maybe you have a better idea.

My problem right now:

The extruder jams after about 30 minutes.

It is a 4 hours print and i don't have the time to supervise it.

When i have a look at it, it is always already to late and the extruder is extruding emptiness some 10 layers up in the air.

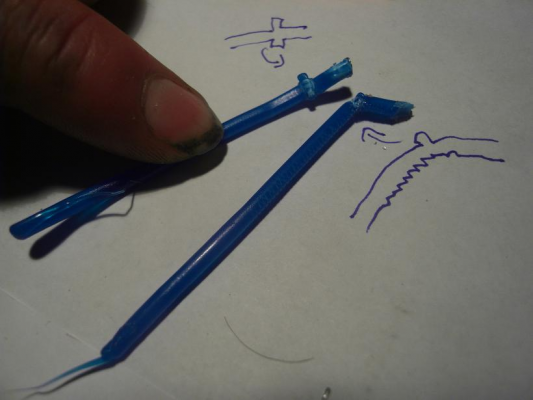

After fastening the hobbed bolt, the bolt pressed the pla so hard into the extruder, that it bent beneath the hobbed bolt.

After i have removed the crushed pla, i can easily inject a new filament.

I guess, for a short time, the temperature of the extruder drops below melting point for some reason, the pla inside the extruder gets hard, the hobbed bolt mills away the 3mm filament and when the extruder heats up again, the hobbed bolt no longer has any grip to push the pla forwards.

but sprinter / pronterface should stop printing, when the temperature drops below 185°C ?

The 3mm pla looks fine to me and is easily fed to the printer.

roland

dasRoland.de

ideas welcome.

There should be a nice troubleshooting-faq on reprap.org.

With keywords on the parts making trouble and keywords on the problem.

[reprap.org] is surely not enough.

I could easily setup such a keyword-faq on my loser-site reprob.org.

But maybe you have a better idea.

My problem right now:

The extruder jams after about 30 minutes.

It is a 4 hours print and i don't have the time to supervise it.

When i have a look at it, it is always already to late and the extruder is extruding emptiness some 10 layers up in the air.

After fastening the hobbed bolt, the bolt pressed the pla so hard into the extruder, that it bent beneath the hobbed bolt.

After i have removed the crushed pla, i can easily inject a new filament.

I guess, for a short time, the temperature of the extruder drops below melting point for some reason, the pla inside the extruder gets hard, the hobbed bolt mills away the 3mm filament and when the extruder heats up again, the hobbed bolt no longer has any grip to push the pla forwards.

but sprinter / pronterface should stop printing, when the temperature drops below 185°C ?

The 3mm pla looks fine to me and is easily fed to the printer.

roland

dasRoland.de

ideas welcome.

|

Re: a troublshooting-faq ??? / my extruder blocks after 30 minutes :'( December 18, 2012 04:55PM |

Admin Registered: 17 years ago Posts: 7,879 |

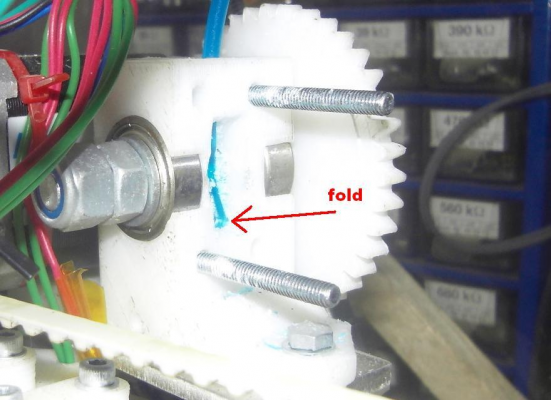

I don't know what sort of extruder you have, but the plastic should not be able to bend between the hobbed bolt and the entrance to the hot end. It should be guided all the way by a channel not much bigger than the filament. Something like this: [4.bp.blogspot.com]

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: a troublshooting-faq ??? / my extruder blocks after 30 minutes :'( December 19, 2012 03:22AM |

Registered: 14 years ago Posts: 65 |

Hi Nophead, nice you answer me :-)

Yes, that is my extruder, you printed it :-))

I got that ABSPrusa [www.youtube.com] and am that loser who thinks python programmers to be stupid :-/

There are about 5mm space between the hobbed bolt and the entrance to the hotend. And the strong extruder stepper was able to fold the 3mm filament just before the entrance.

Yes, really strange. Otherwise i would not write about it.

I want to leave tomorrow dasRoland.de and don't have the time to play with the broken reprap.

Would be nice if there were a logging-function in pronterface...

main topic:

Once such a topic in this board is solved, someone could summerize the solution and simply add the line "keywords: x y z" to the message. Then one could search the messages with the "all words" option and would "only" get solved problems.

And I could program a spider that would update a troubleshooting-page in the reprap-wiki that would contain a keyword sorted link list.

dasRoland.de

first two rules: you always speak yes.

(to "speak yes" is rather the opposite of "to say yes")

Yes, that is my extruder, you printed it :-))

I got that ABSPrusa [www.youtube.com] and am that loser who thinks python programmers to be stupid :-/

There are about 5mm space between the hobbed bolt and the entrance to the hotend. And the strong extruder stepper was able to fold the 3mm filament just before the entrance.

Yes, really strange. Otherwise i would not write about it.

I want to leave tomorrow dasRoland.de and don't have the time to play with the broken reprap.

Would be nice if there were a logging-function in pronterface...

main topic:

Once such a topic in this board is solved, someone could summerize the solution and simply add the line "keywords: x y z" to the message. Then one could search the messages with the "all words" option and would "only" get solved problems.

And I could program a spider that would update a troubleshooting-page in the reprap-wiki that would contain a keyword sorted link list.

dasRoland.de

first two rules: you always speak yes.

(to "speak yes" is rather the opposite of "to say yes")

|

Re: a troublshooting-faq ??? / my extruder blocks after 30 minutes :'( December 19, 2012 09:08AM |

Registered: 11 years ago Posts: 39 |

yes, too soft pla seems to be causing the trouble.

As i usualy do not heat this room, i built a tent that i heat with a 50 watt tealight.

The pla roll is at the topmost place inside the tent and temperature rises above 30°C.

When the bearing is pressing too hard against the hobbed bolt, the pla might get deformed

and than it no longer fits into the entrance to the hotend.

I will try ABS now. should use abs for my 139 tooth underwater pulley anyway.

roland

As i usualy do not heat this room, i built a tent that i heat with a 50 watt tealight.

The pla roll is at the topmost place inside the tent and temperature rises above 30°C.

When the bearing is pressing too hard against the hobbed bolt, the pla might get deformed

and than it no longer fits into the entrance to the hotend.

I will try ABS now. should use abs for my 139 tooth underwater pulley anyway.

roland

|

Re: a troublshooting-faq ??? / my extruder blocks after 30 minutes :'( December 28, 2012 10:37PM |

Registered: 11 years ago Posts: 16 |

Is there any way you could take more detailed pictures of the contact surface of the feeding unit and the plastic itself?

After reading all of the posts I have a couple ideas that need pictures to eliminate..here's one of them.

Are the teeth that grip/feed the filament sharp enough? This normally shouldn't be a problem if spaced correctly, but not all units are spaced properly for the varying diameters of filament. The difference between 1.75mm filament and 1.80 is a lot to gripping/feeding something steadily.

Also, I really do prefer a feeding mechanism that has actual biting gears versus just a hobbed bolt. The difference is how easily the hobbed bolt can get "caked" with the plastic it's feeding because of the angle of the feed and the chip size that's formed. The valley in the pitch of the hobbed bolt which you rely on for grip strength gets filled and it can no longer grip everywhere it should, slipping at certain points in the rotation.

Please post more pics so we can get an actual solution for this issue.

After reading all of the posts I have a couple ideas that need pictures to eliminate..here's one of them.

Are the teeth that grip/feed the filament sharp enough? This normally shouldn't be a problem if spaced correctly, but not all units are spaced properly for the varying diameters of filament. The difference between 1.75mm filament and 1.80 is a lot to gripping/feeding something steadily.

Also, I really do prefer a feeding mechanism that has actual biting gears versus just a hobbed bolt. The difference is how easily the hobbed bolt can get "caked" with the plastic it's feeding because of the angle of the feed and the chip size that's formed. The valley in the pitch of the hobbed bolt which you rely on for grip strength gets filled and it can no longer grip everywhere it should, slipping at certain points in the rotation.

Please post more pics so we can get an actual solution for this issue.

|

Re: a troublshooting-faq ??? / my extruder blocks after 30 minutes :'( January 15, 2013 05:44AM |

Registered: 11 years ago Posts: 251 |

|

Re: a troublshooting-faq ??? / my extruder blocks after 30 minutes :'( January 21, 2013 01:06PM |

Registered: 14 years ago Posts: 65 |

sorry, can not post new photos. Ron Bombadil is living on the rivers again: [www.liebwink.de]

i guess, not heating the roll of pla did help. but other things went wrong and i was not able to finish another print.

i guess, not heating the roll of pla did help. but other things went wrong and i was not able to finish another print.

Sorry, only registered users may post in this forum.