Extruder cooling/layer smash

Posted by Ohmarinus

|

Extruder cooling/layer smash April 15, 2013 04:13PM |

Admin Registered: 11 years ago Posts: 3,096 |

Hi guys, I'm facing a case of very bad layer smash, it has been around the past few days and gradually getting worse.

Now today I tried printing my extruder again, and now the extruder I am printing with is becoming SO hot again during printing, I notice the smashed layers are getting far worse now that my all the parts above my my hotend are getting ridiculously hot.

Can a too hot extruder cause something similar to layer smash? Also some layers are not stuck together well at all.

I haven't had this before.

Should I post pictures about the ordeal? I am currently awaiting my print to finish before I can take any close-up picture.

Now today I tried printing my extruder again, and now the extruder I am printing with is becoming SO hot again during printing, I notice the smashed layers are getting far worse now that my all the parts above my my hotend are getting ridiculously hot.

Can a too hot extruder cause something similar to layer smash? Also some layers are not stuck together well at all.

I haven't had this before.

Should I post pictures about the ordeal? I am currently awaiting my print to finish before I can take any close-up picture.

|

Re: Extruder cooling/layer smash April 15, 2013 04:40PM |

Admin Registered: 11 years ago Posts: 3,096 |

I noticed it almost disappeared after turning off the heated bed.

What can I do to prevent the heatbed PCB to move up and down by heating? The temperature doesn't fluctuate. It stays around 110º constantly.

Currently sporting an MDF bottom plate, maybe I should replace it for a 2mm aluminum bottom plate? I don't trust wood and heat.

Edited 1 time(s). Last edit at 04/15/2013 04:41PM by Ohmarinus.

What can I do to prevent the heatbed PCB to move up and down by heating? The temperature doesn't fluctuate. It stays around 110º constantly.

Currently sporting an MDF bottom plate, maybe I should replace it for a 2mm aluminum bottom plate? I don't trust wood and heat.

Edited 1 time(s). Last edit at 04/15/2013 04:41PM by Ohmarinus.

|

Re: Extruder cooling/layer smash April 16, 2013 01:54AM |

Registered: 11 years ago Posts: 254 |

|

Re: Extruder cooling/layer smash April 16, 2013 05:24AM |

Admin Registered: 11 years ago Posts: 3,096 |

Hey thanks, it kind of confirms my findings.

However, my heatbed is connected with screws that have springs under them, so there should be enough room for expansion as they are not tightly fixed to the bottom plate that holds the Y-carriage to the smooth rods with LM8UU bearings.

I will surely try PID PWM heating for the heatbed. Also I have some kind of insulation material underneath the bed now I will try to print without it.

The best option would be to come up with a second aluminium bottom plate using aluminium instead of the MDF wood I'm using now.

My printbed is aluminium which is hard to bend already so I think the heatbed is instead deforming the MDF plate that holds it all together.

Gerard Choinka Wrote:

-------------------------------------------------------

> if the bed is heating it expands, you can do 2

> things

> 1. loosen the screws, if it expands in x and y

> direction and it tighten to the plate, it bends

> 2. turn PID PWM for heat bed in firmware on, this

> will give the heat bed are more uniform heating

However, my heatbed is connected with screws that have springs under them, so there should be enough room for expansion as they are not tightly fixed to the bottom plate that holds the Y-carriage to the smooth rods with LM8UU bearings.

I will surely try PID PWM heating for the heatbed. Also I have some kind of insulation material underneath the bed now I will try to print without it.

The best option would be to come up with a second aluminium bottom plate using aluminium instead of the MDF wood I'm using now.

My printbed is aluminium which is hard to bend already so I think the heatbed is instead deforming the MDF plate that holds it all together.

Gerard Choinka Wrote:

-------------------------------------------------------

> if the bed is heating it expands, you can do 2

> things

> 1. loosen the screws, if it expands in x and y

> direction and it tighten to the plate, it bends

> 2. turn PID PWM for heat bed in firmware on, this

> will give the heat bed are more uniform heating

|

Re: Extruder cooling/layer smash April 16, 2013 01:13PM |

Admin Registered: 11 years ago Posts: 3,096 |

|

Re: Extruder cooling/layer smash April 16, 2013 03:54PM |

Admin Registered: 11 years ago Posts: 3,096 |

I have discovered my Hotend isn't firmly in place, the clamp mechanism that 'should' hold it in place doesn't do it's job well enough. After my current print I will force it to be fixed in height. Now whenever the extruder retracts, it moves the hotend up and down.

Edit:

And my extruder loses grip sometimes. That hobbed bolt is so shitty...

Gonna order a new one from ebay or something.

Edit 2:

I have added 2 filling rings of metal into the hole of my extruder on top of the hotend, it is fitting now and working much better already.

However, these mechanical problems have surely shown me that I really need to get a better X-carriage and maybe a J-head, I need the compatible stuff, and I want something that simply just 'works'. I have also fixed the heatbed, no problems with is leveling up or down anymore when it's on temperature.

Edited 2 time(s). Last edit at 04/16/2013 07:53PM by Ohmarinus.

Edit:

And my extruder loses grip sometimes. That hobbed bolt is so shitty...

Gonna order a new one from ebay or something.

Edit 2:

I have added 2 filling rings of metal into the hole of my extruder on top of the hotend, it is fitting now and working much better already.

However, these mechanical problems have surely shown me that I really need to get a better X-carriage and maybe a J-head, I need the compatible stuff, and I want something that simply just 'works'. I have also fixed the heatbed, no problems with is leveling up or down anymore when it's on temperature.

Edited 2 time(s). Last edit at 04/16/2013 07:53PM by Ohmarinus.

|

Re: Extruder cooling/layer smash April 16, 2013 11:46PM |

Registered: 12 years ago Posts: 174 |

Did you see the final entries under At wit's end. Terrible print quailty ?

His PCB was deflecting as the heater cycled and he thinks that adding a glass plate on top of the PCB may have fixed it.

That is if your affixing extruder did not solve the whole issue.

Edited 1 time(s). Last edit at 04/16/2013 11:47PM by rrr7.

His PCB was deflecting as the heater cycled and he thinks that adding a glass plate on top of the PCB may have fixed it.

That is if your affixing extruder did not solve the whole issue.

Edited 1 time(s). Last edit at 04/16/2013 11:47PM by rrr7.

|

Re: Extruder cooling/layer smash April 17, 2013 04:11AM |

Admin Registered: 11 years ago Posts: 3,096 |

Yes I am having that topic open in a special tab for the last days already  Thanks for mentioning it though.

Thanks for mentioning it though.

I currently sport a 1mm aluminum plate on top of the PCB, but I think I am going to invest in a 2mm aluminum construction with a PCB that 'hangs' against it and floats freely and isn't attached in a fixed mechanical way at all. Also thinking of keeping the MDF bottom plate out of the design to lighten the load on the Y-motor even more.

But to be honest.. I'm not that far yet in my development, but I am certain that using the four-corner holes in the PCB for fixing it to the carriage is not a good idea at all.

rrr7 Wrote:

-------------------------------------------------------

> Did you see the final entries under At wit's end.

> Terrible print quailty ?

> His PCB was deflecting as the heater cycled and he

> thinks that adding a glass plate on top of the PCB

> may have fixed it.

> That is if your affixing extruder did not solve

> the whole issue.

Thanks for mentioning it though.

Thanks for mentioning it though.I currently sport a 1mm aluminum plate on top of the PCB, but I think I am going to invest in a 2mm aluminum construction with a PCB that 'hangs' against it and floats freely and isn't attached in a fixed mechanical way at all. Also thinking of keeping the MDF bottom plate out of the design to lighten the load on the Y-motor even more.

But to be honest.. I'm not that far yet in my development, but I am certain that using the four-corner holes in the PCB for fixing it to the carriage is not a good idea at all.

rrr7 Wrote:

-------------------------------------------------------

> Did you see the final entries under At wit's end.

> Terrible print quailty ?

> His PCB was deflecting as the heater cycled and he

> thinks that adding a glass plate on top of the PCB

> may have fixed it.

> That is if your affixing extruder did not solve

> the whole issue.

|

Re: Extruder cooling/layer smash April 21, 2013 03:14PM |

Admin Registered: 11 years ago Posts: 3,096 |

Meanwhile, my problems are sometimes there, and sometimes gone.

I posted this in another post:

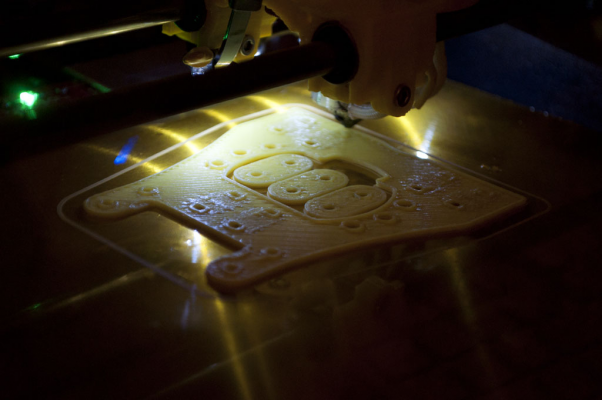

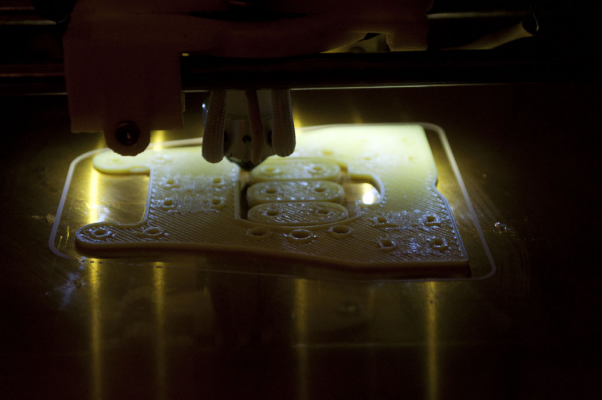

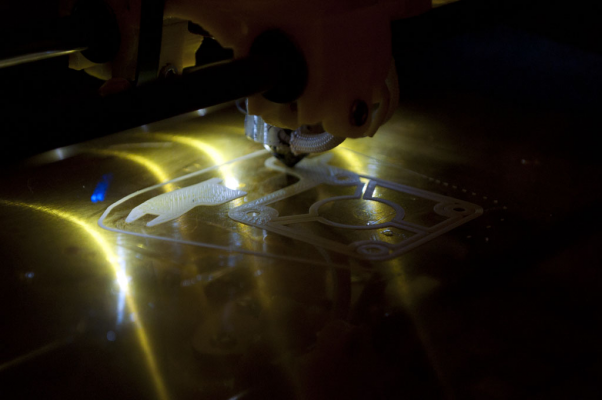

Here some pictures:

Edited 4 time(s). Last edit at 04/21/2013 03:18PM by Ohmarinus.

I posted this in another post:

Quote

Okay, I have solved most things, but now all of a sudden sometimes, I have the idea the Z-axis skips a few steps? It doesnt get hot, it doesn't really have much friction in going up or down, but just randomly it sometimes doesnt move up when it should and this means it prints two layers on the same height which means that small gaps are immediately closed up and the next layer it moves up, so it's actually 3 layers squashed in the area for 2 layers. It takes 2 more layers for the squashed layers to normalise again.

I don't know why this is happening, the motors don't shut off, and I can just manually move the Z-axis as much as I want.

I bought a digital caliper to calibrate my axes and I am sure that my axes are correctly configured. I have the values all with maximum of 5 decimals.

Should I maybe set even less decimals in my firmware, or can it be that there is a different problem?

I have locked my hotend completely, no movement up nor down, left nor right. The heatbed doesn't just jump up or anything, I have been constantly measuring and I sometimes can print nicely and sometimes randomly it just messes up a few layers.

This is driving me nuts.

Here some pictures:

Edited 4 time(s). Last edit at 04/21/2013 03:18PM by Ohmarinus.

|

Re: Extruder cooling/layer smash April 27, 2013 01:27PM |

Admin Registered: 11 years ago Posts: 3,096 |

The layer sass-squash is still following me through the woods..

Sometimes it goes pretty well, like the 'Chitzen Itza' building I printed today from Thingiverse, but then again I am printing a new X-carriage and the LM8UU bearing holder just doesn't want to print well... Always some layers squashed.

I have re-designed my printbed this week. I now have a great printbed, but somehow the Z-height still varies! Can it be that my X-carriage deforms from the heat coming up from the hotend? I am completely going nuts!

Sometimes it goes pretty well, like the 'Chitzen Itza' building I printed today from Thingiverse, but then again I am printing a new X-carriage and the LM8UU bearing holder just doesn't want to print well... Always some layers squashed.

I have re-designed my printbed this week. I now have a great printbed, but somehow the Z-height still varies! Can it be that my X-carriage deforms from the heat coming up from the hotend? I am completely going nuts!

|

Re: Extruder cooling/layer smash April 27, 2013 01:58PM |

Registered: 12 years ago Posts: 174 |

Yes, nophead has commented on the heat retained by the x-axis and the long term damage it did to his mendel in his blog, so something like that could cause you issues. I just read through that last night, it is in July 2010. HydraRaptor

(sass-squash through the woods.... funny! )

)

(sass-squash through the woods.... funny!

)

)

|

Re: Extruder cooling/layer smash April 27, 2013 07:47PM |

Admin Registered: 11 years ago Posts: 3,096 |

Okay, I am not sure if it is my X-carriage, but I will try to reprint parts tomorrow and replace my current carriage with a new one to see if I can get rid of that sass-squash

Always fun to make fun of stuff that goes wrong.

Edit:

I built a extruder-cooler also, but the layer smash stays... buuhuuhuuu

BUT Yay! I managed to finally print my final part for the new X-carriage after some 15 tries, the part is still of terrible quality, but I can use it and hope it helps improve my prints..

Otherwise I will:

- Cry

- Order a complete newly-printed Extruder and X-carriage from someone on ebay..

rrr7 Wrote:

-------------------------------------------------------

> Yes, nophead has commented on the heat retained by

> the x-axis and the long term damage it did to his

> mendel in his blog, so something like that could

> cause you issues. I just read through that last

> night, it is in July 2010. HydraRaptor

> (sass-squash through the woods.... funny! )

)

Edited 1 time(s). Last edit at 04/28/2013 08:21AM by Ohmarinus.

Always fun to make fun of stuff that goes wrong.

Edit:

I built a extruder-cooler also, but the layer smash stays... buuhuuhuuu

BUT Yay! I managed to finally print my final part for the new X-carriage after some 15 tries, the part is still of terrible quality, but I can use it and hope it helps improve my prints..

Otherwise I will:

- Cry

- Order a complete newly-printed Extruder and X-carriage from someone on ebay..

rrr7 Wrote:

-------------------------------------------------------

> Yes, nophead has commented on the heat retained by

> the x-axis and the long term damage it did to his

> mendel in his blog, so something like that could

> cause you issues. I just read through that last

> night, it is in July 2010. HydraRaptor

> (sass-squash through the woods.... funny!

)

)Edited 1 time(s). Last edit at 04/28/2013 08:21AM by Ohmarinus.

|

Re: Extruder cooling/layer smash April 28, 2013 06:02PM |

Admin Registered: 11 years ago Posts: 3,096 |

I have been looking at my Z-couplings. They do not slip, but it looks as if sometimes, they don't make a full turn, they just move a small bit. Sometimes it even moves back a small part after moving a bit in the right direction.

I have already improved the stepper drivers power, so this cannot be it. Is there another way my Z-axis doesn't make the full turn it needs to make to get correct layer height?

When I move my Z-axis up down and up and down, it never pauses, it just runs smoothly and my stepsticks never pause and/or overheat. I am getting very frustrated with this problem. I can't print anything already for weeks because my Z-axis simply is unreliable...

Edited 1 time(s). Last edit at 04/28/2013 07:05PM by Ohmarinus.

I have already improved the stepper drivers power, so this cannot be it. Is there another way my Z-axis doesn't make the full turn it needs to make to get correct layer height?

When I move my Z-axis up down and up and down, it never pauses, it just runs smoothly and my stepsticks never pause and/or overheat. I am getting very frustrated with this problem. I can't print anything already for weeks because my Z-axis simply is unreliable...

Edited 1 time(s). Last edit at 04/28/2013 07:05PM by Ohmarinus.

|

Re: Extruder cooling/layer smash April 28, 2013 11:53PM |

Registered: 12 years ago Posts: 198 |

|

Re: Extruder cooling/layer smash April 29, 2013 05:02AM |

Admin Registered: 11 years ago Posts: 3,096 |

Yes, ofcourse  I have switched out the stepper drivers, checked the connectors, everything, I have wiggled the connector while giving the motors a 'move 100mm up' command to see if it would lose connection sometimes...

I have switched out the stepper drivers, checked the connectors, everything, I have wiggled the connector while giving the motors a 'move 100mm up' command to see if it would lose connection sometimes...

Clueless!

Ok, it went 'ok' for a moment, but now after some 30 minutes of printing, suddenly it started doing the same again. WHAAAAAT!? I punched the machine...

Almost ready to skip the holidays and buy another machine from the holiday money..

So here is what causes my flattened layers:

Normally the screw turns about 1/4th of a circle when moving up a layer. After some time, suddenly the motor doesn't spin 1/4th but more like 1/40th of the circle, it's like it's not getting enough power, but when I give the machine the order to move the Z-axis up, it does it without overheating and without any problem for hundreds of millimeters of movement.

How can I solve this!?

Something to add is that I have printed for a month without any problems.

Komb' Wrote:

-------------------------------------------------------

> Just a random thought,

>

> Have you checked the connector pins?

Edited 2 time(s). Last edit at 04/29/2013 07:38AM by Ohmarinus.

I have switched out the stepper drivers, checked the connectors, everything, I have wiggled the connector while giving the motors a 'move 100mm up' command to see if it would lose connection sometimes...

I have switched out the stepper drivers, checked the connectors, everything, I have wiggled the connector while giving the motors a 'move 100mm up' command to see if it would lose connection sometimes...Clueless!

Ok, it went 'ok' for a moment, but now after some 30 minutes of printing, suddenly it started doing the same again. WHAAAAAT!? I punched the machine...

Almost ready to skip the holidays and buy another machine from the holiday money..

So here is what causes my flattened layers:

Normally the screw turns about 1/4th of a circle when moving up a layer. After some time, suddenly the motor doesn't spin 1/4th but more like 1/40th of the circle, it's like it's not getting enough power, but when I give the machine the order to move the Z-axis up, it does it without overheating and without any problem for hundreds of millimeters of movement.

How can I solve this!?

Something to add is that I have printed for a month without any problems.

Komb' Wrote:

-------------------------------------------------------

> Just a random thought,

>

> Have you checked the connector pins?

Edited 2 time(s). Last edit at 04/29/2013 07:38AM by Ohmarinus.

|

Re: Extruder cooling/layer smash April 29, 2013 10:31AM |

Registered: 13 years ago Posts: 485 |

Sticky screws? I seem to remember having lost some Z axis moves to unlubricated screws. Usually it would move, sometimes it wouldn't. Simple hex nuts on simple threaded rod will wear and cause random stickiness. Some places the steppers can get started, other places they can't. Once started, traversing the whole axis is relatively easy.

I had some bicycle chain lube handy, so I ran some of that down the screws and ran the Z up and down a couple times to distribute it. Problem solved until next time (probably somewhere over 100 hours print time).

I had some bicycle chain lube handy, so I ran some of that down the screws and ran the Z up and down a couple times to distribute it. Problem solved until next time (probably somewhere over 100 hours print time).

|

Re: Extruder cooling/layer smash April 29, 2013 12:45PM |

Admin Registered: 11 years ago Posts: 3,096 |

Hey, like I said, there is nothing I can find mechanically, so it must be electrical/firmware/sanguinololu problem.

I have been printing for two months now and the past three/four weeks it's been constantly going wrong. I have lubricated the rods nicely and I can even put a LOT of pressure on the carriage and the stepper motors will still pull it up so it's definately nothing mechanical.

The stepper just doesn't turn sometimes, while I can have it move 100mm's in one go even when I apply much downforce on the X-carriage. So I am sure it's not low power or mechanical friction.

Maybe I should open a new thread in electronical forum?

Can a Stepper driver overheat when it's in idle?

Can the heat of lower stepper drivers rise up through the air and help overheat the stepperdrivers above it?

I am now testing with a cooling fan on my Sanguino. I have passive cooling elements on my polulu stepper drivers, so I hope the squashed layers now go away.

I am testing this with by printing a fan holder that you can put on the sanguino board, so if it helps, I have created the solution during the test.

This one: [www.thingiverse.com]

Edited 1 time(s). Last edit at 04/29/2013 03:29PM by Ohmarinus.

I have been printing for two months now and the past three/four weeks it's been constantly going wrong. I have lubricated the rods nicely and I can even put a LOT of pressure on the carriage and the stepper motors will still pull it up so it's definately nothing mechanical.

The stepper just doesn't turn sometimes, while I can have it move 100mm's in one go even when I apply much downforce on the X-carriage. So I am sure it's not low power or mechanical friction.

Maybe I should open a new thread in electronical forum?

Can a Stepper driver overheat when it's in idle?

Can the heat of lower stepper drivers rise up through the air and help overheat the stepperdrivers above it?

I am now testing with a cooling fan on my Sanguino. I have passive cooling elements on my polulu stepper drivers, so I hope the squashed layers now go away.

I am testing this with by printing a fan holder that you can put on the sanguino board, so if it helps, I have created the solution during the test.

This one: [www.thingiverse.com]

Edited 1 time(s). Last edit at 04/29/2013 03:29PM by Ohmarinus.

|

Re: Extruder cooling/layer smash April 30, 2013 06:59AM |

Admin Registered: 11 years ago Posts: 3,096 |

Okay, I think I have solved the problem for now.

The stepper was apparently overheating when in IDLE. I had no idea that could happen, I am suspecting convection heating from the surrounding stepper drivers might have helped causing the problem.

I have one small 40mm fan now hanging in front of the stepper drivers, it's not connected to any special hinge, it's just hanging at the approximate position of the Z-stepper and hanging there.

The prints come out better now. However, I have messed up my calibration slightly because I tried solving this problem in other ways before. Also, the right M8 rod of my Z-axis is not entirely straight on the lowest part. This is causing a line profile on the sides of my prints. I will fix this later.

Meanwhile I've taken the freedom to order a set of RAMPS with all additional electronics, so I will replace my current electronic setup and try to integrate the ramps.

After this I will try to build a completely new printer (maybe my own design, maybe a MendelMax, just because I think MendelMax is very sexay), this way I have one printer with which I can tinker and one I can use to reproduce parts that break down on the other one. (Though I haven't had any part break down yet).

So, the problem was overheating of the stepper driver in IDLE. This is very 'uncool'. Hehe. At least it's solved for now

The stepper was apparently overheating when in IDLE. I had no idea that could happen, I am suspecting convection heating from the surrounding stepper drivers might have helped causing the problem.

I have one small 40mm fan now hanging in front of the stepper drivers, it's not connected to any special hinge, it's just hanging at the approximate position of the Z-stepper and hanging there.

The prints come out better now. However, I have messed up my calibration slightly because I tried solving this problem in other ways before. Also, the right M8 rod of my Z-axis is not entirely straight on the lowest part. This is causing a line profile on the sides of my prints. I will fix this later.

Meanwhile I've taken the freedom to order a set of RAMPS with all additional electronics, so I will replace my current electronic setup and try to integrate the ramps.

After this I will try to build a completely new printer (maybe my own design, maybe a MendelMax, just because I think MendelMax is very sexay), this way I have one printer with which I can tinker and one I can use to reproduce parts that break down on the other one. (Though I haven't had any part break down yet).

So, the problem was overheating of the stepper driver in IDLE. This is very 'uncool'. Hehe. At least it's solved for now

|

Re: Extruder cooling/layer smash April 30, 2013 11:27PM |

Registered: 12 years ago Posts: 198 |

|

Re: Extruder cooling/layer smash May 01, 2013 05:52AM |

Admin Registered: 11 years ago Posts: 3,096 |

It is really weird that this overheating suddenly became a problem, especially since I haven't changed anything.. I even made the Y-carriage lighter.

I noticed some other properties of the machine have also changed, the hotend is now outputting more material, at least it looks like that.

Printing 3.05mm ABS with a 0.4mm nozzle, on a 0.32mm layer height. First layer is also 0.32mm so it squashes a bit and adheres nicely.

Extrusion rate is configured perfectly, BUT the machine now hits the printed material with the nozzle, and is 'scratches' it's solid layer prints a little bit. So I am thinking of putting the mm/s feedrate in Marlin back to the 'theoretical' 2560. It is now slightly higher, and it's what I measured and calculated with the webtool, but apparently now it outputs too much material and I don't want to change it in Slic3r because I have a new firm belief that you need to get to the core of a problem and solve it there instead of solving the symptoms like I am doing all the time now.

I noticed some other properties of the machine have also changed, the hotend is now outputting more material, at least it looks like that.

Printing 3.05mm ABS with a 0.4mm nozzle, on a 0.32mm layer height. First layer is also 0.32mm so it squashes a bit and adheres nicely.

Extrusion rate is configured perfectly, BUT the machine now hits the printed material with the nozzle, and is 'scratches' it's solid layer prints a little bit. So I am thinking of putting the mm/s feedrate in Marlin back to the 'theoretical' 2560. It is now slightly higher, and it's what I measured and calculated with the webtool, but apparently now it outputs too much material and I don't want to change it in Slic3r because I have a new firm belief that you need to get to the core of a problem and solve it there instead of solving the symptoms like I am doing all the time now.

|

Re: Extruder cooling/layer smash May 01, 2013 06:33PM |

Registered: 12 years ago Posts: 174 |

|

Re: Extruder cooling/layer smash May 01, 2013 07:25PM |

Admin Registered: 11 years ago Posts: 3,096 |

Haha, okay, I didn't realize..

Now it's time for some serious calibrating finally!

Am getting some very poor printing results lately, so I should get myself a straight M8 rod, I should finish the heatbed improvements (replace the bottom MDF for an aluminum one) and start printing parts for moving the Z-motors to the bottom!

Do others also have a up- and down moving printbed?

Now it's time for some serious calibrating finally!

Am getting some very poor printing results lately, so I should get myself a straight M8 rod, I should finish the heatbed improvements (replace the bottom MDF for an aluminum one) and start printing parts for moving the Z-motors to the bottom!

Do others also have a up- and down moving printbed?

|

Re: Extruder cooling/layer smash May 02, 2013 06:25PM |

Admin Registered: 11 years ago Posts: 3,096 |

Hey guys, I just wanted to show that my prints have improved radically when I added a cooling fan to cool my stepper drivers. I guess the cooling elements just weren't enough...

Check out these pictures

More calibration needed! (layer height etc.).

Check out these pictures

More calibration needed! (layer height etc.).

|

Re: Extruder cooling/layer smash May 03, 2013 02:04PM |

Admin Registered: 11 years ago Posts: 3,096 |

Putting back the Z-steps/mm to 2560 instead of a measured distance, made my prints even nicer. Printing on layer height of 0.325 with a 0.4mm nozzle. First layer height 0.30mm.

More pictures soon, I try to make as many as possible. I am now printing a dodecahedron as a test, so far this is the NICEST print I've ever have gotten out of the machine, I hope it finishes well (And I hope I don't Jinx it now..).

(And I hope I don't Jinx it now..).

More pictures soon, I try to make as many as possible. I am now printing a dodecahedron as a test, so far this is the NICEST print I've ever have gotten out of the machine, I hope it finishes well

(And I hope I don't Jinx it now..).

(And I hope I don't Jinx it now..).

|

Re: Extruder cooling/layer smash May 06, 2013 01:29PM |

Registered: 11 years ago Posts: 469 |

|

Re: Extruder cooling/layer smash May 06, 2013 04:20PM |

Admin Registered: 11 years ago Posts: 3,096 |

Hi, thanks for the hint, I had already set my layer height to 0.325 and it works good now

I have now discovered that one of my Z-axis threaded rods isn't straight! What a pain.

Still having some printing problems, I will make a new topic for it, because it's entirely different.

bigfilsing Wrote:

-------------------------------------------------------

> you might want to read up on only using a layer

> height that coincides with whole steps.

> 1mm = 2560 steps

> 0.3 mm = 768 steps

> 0.325 = 832 steps

> 0.33 = 844.8<<

>

> so if ( for whatever reason) you change your Z

> steps ..remember to chose a layer height that

> "works" with your Z steps

> good luck

I have now discovered that one of my Z-axis threaded rods isn't straight! What a pain.

Still having some printing problems, I will make a new topic for it, because it's entirely different.

bigfilsing Wrote:

-------------------------------------------------------

> you might want to read up on only using a layer

> height that coincides with whole steps.

> 1mm = 2560 steps

> 0.3 mm = 768 steps

> 0.325 = 832 steps

> 0.33 = 844.8<<

>

> so if ( for whatever reason) you change your Z

> steps ..remember to chose a layer height that

> "works" with your Z steps

> good luck

Sorry, only registered users may post in this forum.