Insulating hotend to contain radiation heat?

Posted by Ohmarinus

|

Insulating hotend to contain radiation heat? May 24, 2013 01:49PM |

Admin Registered: 11 years ago Posts: 3,096 |

Hi, I have a Budaschnozzle and am printing 3mm ABS with a 0.4mm nozzle. The heat-barrier above the hotend is cooled by a directional 40mm fan and this works great for keeping the hot air away from the extruder.

When I print high things with a small diameter, I notice that the ABS stays hot because the hotend is radiating heat onto the printed material.

I would like to attempt to insulate the heating block and part of the nozzle to contain the heat really inside just that area.

Now I've seen people insulate their hotends with some kind of fiber-glass fabric wrapped in Kapton tape. Would this also help keeping the radiation heat down?

I want to prevent having to use a cooler on the printed ABS because it promotes severe warping.

Some example I've found online:

[bukobot.com]

I am wondering what I could use for the thermal insulation besides that heat-resistant ceramic fibreglass wool stuff.

Any good common materials available?

When I print high things with a small diameter, I notice that the ABS stays hot because the hotend is radiating heat onto the printed material.

I would like to attempt to insulate the heating block and part of the nozzle to contain the heat really inside just that area.

Now I've seen people insulate their hotends with some kind of fiber-glass fabric wrapped in Kapton tape. Would this also help keeping the radiation heat down?

I want to prevent having to use a cooler on the printed ABS because it promotes severe warping.

Some example I've found online:

[bukobot.com]

I am wondering what I could use for the thermal insulation besides that heat-resistant ceramic fibreglass wool stuff.

Any good common materials available?

|

Re: Insulating hotend to contain radiation heat? May 25, 2013 04:06AM |

Registered: 11 years ago Posts: 173 |

I used cuttlefish bone - cut it in 2-3 mm pieces and used high temperature silicone on the outside corners to secure the cuttlefish bone to the heater block.

Only problem - could not remove the nozzle without destroying the insulation.

Got the idea here - [forums.reprap.org]

Wikipedia page - [en.wikipedia.org]

I could touch the outside of the insulation with my fingers when the hotend registered 230 degrees C

The best insulation material would be Aerogel - if you can get it.

Aerogel : [en.wikipedia.org]

Buy it here - [www.buyaerogel.com]

Ohmarinus Wrote:

-------------------------------------------------------

> Hi, I have a Budaschnozzle and am printing 3mm ABS

> with a 0.4mm nozzle. The heat-barrier above the

> hotend is cooled by a directional 40mm fan and

> this works great for keeping the hot air away from

> the extruder.

>

> When I print high things with a small diameter, I

> notice that the ABS stays hot because the hotend

> is radiating heat onto the printed material.

>

> I would like to attempt to insulate the heating

> block and part of the nozzle to contain the heat

> really inside just that area.

>

> Now I've seen people insulate their hotends with

> some kind of fiber-glass fabric wrapped in Kapton

> tape. Would this also help keeping the radiation

> heat down?

> I want to prevent having to use a cooler on the

> printed ABS because it promotes severe warping.

>

> Some example I've found online:

> [bukobot.com]

>

> I am wondering what I could use for the thermal

> insulation besides that heat-resistant ceramic

> fibreglass wool stuff.

> Any good common materials available?

Edited 2 time(s). Last edit at 05/25/2013 04:52AM by Xabbax.

Only problem - could not remove the nozzle without destroying the insulation.

Got the idea here - [forums.reprap.org]

Wikipedia page - [en.wikipedia.org]

I could touch the outside of the insulation with my fingers when the hotend registered 230 degrees C

The best insulation material would be Aerogel - if you can get it.

Aerogel : [en.wikipedia.org]

Buy it here - [www.buyaerogel.com]

Ohmarinus Wrote:

-------------------------------------------------------

> Hi, I have a Budaschnozzle and am printing 3mm ABS

> with a 0.4mm nozzle. The heat-barrier above the

> hotend is cooled by a directional 40mm fan and

> this works great for keeping the hot air away from

> the extruder.

>

> When I print high things with a small diameter, I

> notice that the ABS stays hot because the hotend

> is radiating heat onto the printed material.

>

> I would like to attempt to insulate the heating

> block and part of the nozzle to contain the heat

> really inside just that area.

>

> Now I've seen people insulate their hotends with

> some kind of fiber-glass fabric wrapped in Kapton

> tape. Would this also help keeping the radiation

> heat down?

> I want to prevent having to use a cooler on the

> printed ABS because it promotes severe warping.

>

> Some example I've found online:

> [bukobot.com]

>

> I am wondering what I could use for the thermal

> insulation besides that heat-resistant ceramic

> fibreglass wool stuff.

> Any good common materials available?

Edited 2 time(s). Last edit at 05/25/2013 04:52AM by Xabbax.

|

Re: Insulating hotend to contain radiation heat? May 25, 2013 05:10AM |

Admin Registered: 11 years ago Posts: 3,096 |

Thanks, cuttlefishbone looks very interesting! However, the ceramic fiber-fabric kind of looking stuff is easier to work with I think. And cleaner, but I will give it a try.

Also, I have a roll of 100mm x 33m Kapton tape, so I was thinking of making 'packages' with aluminum foil that have air inside and then wrapping it in 2 layers of kapton, to make sure it cannot short anything out. And see if I can make a 'jacket' with that wrapped aluminum foil. I don't know if it will work, but it's worth a try.

The whole problem is that in my country, it's very hard as a consumer to find industrial products. My country feels like a stoneage country sometimes, only when it comes to getting a hold on more industrial-type products. They sell some kinds of products as if it comes out of 'recently developed production processess', while it's actually already widely available in other countries for years..

I have also been pondering on making something like this:

[umforum.ultimaker.com]

There products like this that are also interesting:

[store.qu-bd.com]

Yet, there is nothing like that ceramic insulation available. And theres only a few shops that sell it and it costs about a factor 10 of the price of the qu-bd store, and I have to buy quantities..

Ok, I ordered the 2 feet of ceramic tape from the QU-BD shop. It was only $1.61 postage cost, in total it only cost me 3.17 euros.

I am still wondering, will insulating the heatend help with printing high small objects? I have the idea the ABS stays too hot and therefor doesn't keep shape while printing, thats why I'm insulating the hotend.

Edited 3 time(s). Last edit at 05/26/2013 07:45AM by Ohmarinus.

Also, I have a roll of 100mm x 33m Kapton tape, so I was thinking of making 'packages' with aluminum foil that have air inside and then wrapping it in 2 layers of kapton, to make sure it cannot short anything out. And see if I can make a 'jacket' with that wrapped aluminum foil. I don't know if it will work, but it's worth a try.

The whole problem is that in my country, it's very hard as a consumer to find industrial products. My country feels like a stoneage country sometimes, only when it comes to getting a hold on more industrial-type products. They sell some kinds of products as if it comes out of 'recently developed production processess', while it's actually already widely available in other countries for years..

I have also been pondering on making something like this:

[umforum.ultimaker.com]

There products like this that are also interesting:

[store.qu-bd.com]

Yet, there is nothing like that ceramic insulation available. And theres only a few shops that sell it and it costs about a factor 10 of the price of the qu-bd store, and I have to buy quantities..

Ok, I ordered the 2 feet of ceramic tape from the QU-BD shop. It was only $1.61 postage cost, in total it only cost me 3.17 euros.

I am still wondering, will insulating the heatend help with printing high small objects? I have the idea the ABS stays too hot and therefor doesn't keep shape while printing, thats why I'm insulating the hotend.

Edited 3 time(s). Last edit at 05/26/2013 07:45AM by Ohmarinus.

|

Re: Insulating hotend to contain radiation heat? June 08, 2013 08:12PM |

Admin Registered: 11 years ago Posts: 3,096 |

Finally received my QU-BD strip of ceramic insulation! Yes

And I can tell it works well.

What I do now is insulate the heater block so the heat is radiated less to other parts of the machine and also the hotend has a more stable temperature.

And, third, the heat has less travel upwards to other printer parts like the extruder carriage. I am already using a fan to cool down the upper part of the hotend (Budaschnozzle) but this insulation material really helps with containing the heat even more!

Now just trying out another quick Z-axis stress test by printing a tower 5x5mm and about 25mm height.

And I can tell it works well.

What I do now is insulate the heater block so the heat is radiated less to other parts of the machine and also the hotend has a more stable temperature.

And, third, the heat has less travel upwards to other printer parts like the extruder carriage. I am already using a fan to cool down the upper part of the hotend (Budaschnozzle) but this insulation material really helps with containing the heat even more!

Now just trying out another quick Z-axis stress test by printing a tower 5x5mm and about 25mm height.

|

Re: Insulating hotend to contain radiation heat? June 09, 2013 06:33AM |

Admin Registered: 11 years ago Posts: 3,096 |

|

Re: Insulating hotend to contain radiation heat? May 26, 2016 05:34AM |

Registered: 8 years ago Posts: 17 |

|

Re: Insulating hotend to contain radiation heat? May 26, 2016 05:50AM |

Registered: 12 years ago Posts: 2,470 |

I tried a few things, so far the best solution i found is this

[b.bonkers.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[b.bonkers.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Insulating hotend to contain radiation heat? May 26, 2016 07:07AM |

Registered: 8 years ago Posts: 17 |

|

Re: Insulating hotend to contain radiation heat? May 26, 2016 07:09AM |

Registered: 8 years ago Posts: 778 |

Here we go agin with the old discussion about insulating a hotend....

1. If the heater cartridge is the right size and working properly it makes no difference at all if you insulate or not - only weak heaters and badly designed hotend require it.

2. Where is the heat actually escaping to ? Right! The higher the speed the more heat is lost to the filament melting - again if the heater is too weak insulating is nothing but patchwork.

3. Insulating something is usually done to prevent heat loss - again only required if the heater or entire hotend is rubbish.

If you want something insulated then simply use a hotend designed that way, like some of the direct heated ones from china (despite their other problems).

Or do you go ahead and insulate your BBQ so the steaks are ready faster?

1. If the heater cartridge is the right size and working properly it makes no difference at all if you insulate or not - only weak heaters and badly designed hotend require it.

2. Where is the heat actually escaping to ? Right! The higher the speed the more heat is lost to the filament melting - again if the heater is too weak insulating is nothing but patchwork.

3. Insulating something is usually done to prevent heat loss - again only required if the heater or entire hotend is rubbish.

If you want something insulated then simply use a hotend designed that way, like some of the direct heated ones from china (despite their other problems).

Or do you go ahead and insulate your BBQ so the steaks are ready faster?

|

Re: Insulating hotend to contain radiation heat? May 26, 2016 07:31AM |

Registered: 11 years ago Posts: 5,780 |

I agree with Downunder35m. Specifically, the budaschnozzle is a terrible hot-end. There are plywood parts near the heater block (!) and the heatsink fins are mounted on a piece of teflon tubing (!), and there is no heat-break- just a large cross section threaded aluminum (!) tube. I think it was designed by someone who thought it would look cool without any understanding of what a hot-end does or how it is supposed to function.

Get a real hot-end.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Get a real hot-end.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Insulating hotend to contain radiation heat? May 26, 2016 08:28AM |

Registered: 8 years ago Posts: 17 |

Well, except you both misunderstood why I do want to do this. But you've assumed a lot, and decided to boldly bash the idea.

Thank you for that not really useful opinion.

My "not real" hot end have no problem getting to 280C and keeping it that way. This is not an issue.

And no, Im not printing abs at 280+ ,) just tested if it will.

Now go and read this: [forums.reprap.org]

I used that glass woll, seem to fix curling for me. Yes, I know enclosing the printer in a heated chamber might be better - it wouldnt curl because it wouldnt shrink cooling too much, but that's not the option for me right now. Will probably do that in the future.

Thank you for that not really useful opinion.

My "not real" hot end have no problem getting to 280C and keeping it that way. This is not an issue.

And no, Im not printing abs at 280+ ,) just tested if it will.

Now go and read this: [forums.reprap.org]

I used that glass woll, seem to fix curling for me. Yes, I know enclosing the printer in a heated chamber might be better - it wouldnt curl because it wouldnt shrink cooling too much, but that's not the option for me right now. Will probably do that in the future.

|

Re: Insulating hotend to contain radiation heat? May 26, 2016 08:42AM |

Registered: 8 years ago Posts: 778 |

It does not matter what is written in your link as it won't address the physical issues and realities - a badly designed hotend is crap not matter if it is insulated or not - a good hotend does not require any insulation to produce good and reliable prints.

If that would not be true all hotends would be insulated and not just the crappy ones

There are people still printing with totally outdated J-head hotends and they still get good prints, so what exactly could be the goal or gain by adding insulation where none is required?

Edited 1 time(s). Last edit at 05/26/2016 08:43AM by Downunder35m.

If that would not be true all hotends would be insulated and not just the crappy ones

There are people still printing with totally outdated J-head hotends and they still get good prints, so what exactly could be the goal or gain by adding insulation where none is required?

Edited 1 time(s). Last edit at 05/26/2016 08:43AM by Downunder35m.

|

Re: Insulating hotend to contain radiation heat? May 26, 2016 09:58AM |

Registered: 8 years ago Posts: 177 |

Quote

Ohmarinus

When I print high things with a small diameter, I notice that the ABS stays hot because the hotend is radiating heat onto the printed material.

I am going to ignore the argument about good/bad hotend and address at least part of the original post.....

The quoted statement is largely wrong..... yep wrong, the ABS is not staying hot because the hotend is radiating heat it is simply staying hot because you are adding hot ABS faster than it can naturally cool, made worse once you enclose and run heated bed at correct temps....

The simplest thing to do for small ABS parts is to print multiples at the same time with the aim of allowing each part enough cool down between layers, the smaller the part the more items you print

|

Re: Insulating hotend to contain radiation heat? May 26, 2016 03:14PM |

Registered: 10 years ago Posts: 1,401 |

|

Re: Insulating hotend to contain radiation heat? May 26, 2016 08:28PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Insulating hotend to contain radiation heat? May 26, 2016 08:38PM |

Registered: 11 years ago Posts: 5,780 |

In this case insulating the block won't solve the problem. The problem is that the previous layer of plastic doesn't have time to cool before the nozzle comes along and plops some more hot plastic down on it. The result is blobby yuck. You have to give the previous layer time to cool before the nozzle deposits the next layer. There are different ways to do it, such a printing multiple copies of the object or printing a sacrificial part that you throw away after the main print is finished. I often use cylinders 15-20 mm in diameter, and a little taller than the print. Space it out on the bed so the nozzle takes a little while to traverse between the print and the sacrificial part. Reduce travel speed. Etc.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Insulating hotend to contain radiation heat? May 26, 2016 08:55PM |

Registered: 9 years ago Posts: 1,873 |

There are two parts to this thread, the original question from 2013, and the recent update today. For today's part of the thread we seem to have got into a discussion not about how to solve the OP's problem but whether or not we should bother insulating the heat block at all. I'm firmly in the "it's obvious you should insulate the heat block" camp and struggle to see why any one wouldn't, other than it's less work. Even regarding the OP's question about radiant heat, I would suggest that an un-insulated heat block can only make the situation worse. Whatever rate the filament cools down at, it can only be less if it is simultaneously receiving IR from the heat block at 200+C. The problem is compounded for physically small layers with complex geometry where the head lingers in the same vicinity for long times. It's one of the things that makes it difficult to come up with generic cooling schemes that work for all prints, because the amount of cooling required depends not just on layer time but also on layer shape.

|

Re: Insulating hotend to contain radiation heat? May 26, 2016 09:36PM |

Registered: 11 years ago Posts: 5,780 |

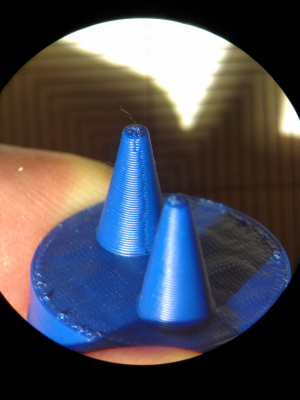

Moving the nozzle away from the print for a while works perfectly:

That's ABS printed with an uninsulated heater block. I printed 4 of these parts simultaneously, spread about 50 mm apart on the bed, IRIC. The tips of the cones are 2mm and the bases are 6 mm diameter.

Adding insulation to the heater block makes basic maintenance of the hot-end even more of a PITA than it already is. The PID controller maintains a constant temperature just fine without any insulation. If you have a print cooling fan that blows some air over the block, you might have an easier time maintaining a constant temperature by adding insulation, but it would be better fix the fan duct so it doesn't blow air over the heater block.

Edited 1 time(s). Last edit at 05/26/2016 09:46PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

That's ABS printed with an uninsulated heater block. I printed 4 of these parts simultaneously, spread about 50 mm apart on the bed, IRIC. The tips of the cones are 2mm and the bases are 6 mm diameter.

Adding insulation to the heater block makes basic maintenance of the hot-end even more of a PITA than it already is. The PID controller maintains a constant temperature just fine without any insulation. If you have a print cooling fan that blows some air over the block, you might have an easier time maintaining a constant temperature by adding insulation, but it would be better fix the fan duct so it doesn't blow air over the heater block.

Edited 1 time(s). Last edit at 05/26/2016 09:46PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Insulating hotend to contain radiation heat? May 26, 2016 09:50PM |

Registered: 9 years ago Posts: 1,873 |

Yes, agreed you can work around almost any problem. But what if you only wanted one copy of your part? You could add a sacrificial part just to move the head away, but that's a waste of filament. Cura has an option (amongst it's bizarrely difficult cooling settings) to move the head away for small layers, but that dramatically increases print time. Perhaps the biggest issue is predicting when you are going to run into problems before you have a wasted print - it's difficult to guess for non-trivial shapes, and if insulating the hot-end only makes it slightly less likely to happen you still win.

On the other hand, you're completely right about the maintenance issue. If the throat/nozzle joint leaks you won't know about it with an insulated nozzle until it's already made a horrible mess.

Everyone is entitled to their own opinions, but I think it's worth avoiding any uncontrolled sources of heat. If I want ambient heat I'll add an enclosure heater.

On the other hand, you're completely right about the maintenance issue. If the throat/nozzle joint leaks you won't know about it with an insulated nozzle until it's already made a horrible mess.

Everyone is entitled to their own opinions, but I think it's worth avoiding any uncontrolled sources of heat. If I want ambient heat I'll add an enclosure heater.

|

Re: Insulating hotend to contain radiation heat? May 26, 2016 10:03PM |

Registered: 11 years ago Posts: 5,780 |

The problem with just moving the nozzle away is that it starts to drool. When it moves back to the print it leaves a blob of plastic. By giving it something to do while it's away from the print you don't have that problem. It wastes plastic in the sense that you're printing an extra part you don't need, but it prevents waste by eliminating the need to have to reprint a part that failed because fine details came out blobby. It isn't waste, it's just doing what's necessary to get an acceptable print.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Insulating hotend to contain radiation heat? May 26, 2016 10:37PM |

Registered: 10 years ago Posts: 1,401 |

I agree with James, I don't like the idea of printing multiple copies if I just want one, it's just a waste of filament.

Lowering the printing speed to allow proper cooling of the printed part in conjunction with an insulated block have the same effect and don't waste filament or energy.

Lowering the printing speed to allow proper cooling of the printed part in conjunction with an insulated block have the same effect and don't waste filament or energy.

|

Re: Insulating hotend to contain radiation heat? May 26, 2016 10:50PM |

Registered: 10 years ago Posts: 466 |

I am in the insulate the block group. not because of an under powered heat cartridge, but for heat management. The way others make it sound if I were to develop a hotend that needed the heat block insulated, it would be deemed crap because it was not designed correctly. pure and simple I do it to keep heat where it is needed.

|

Re: Insulating hotend to contain radiation heat? May 27, 2016 01:57AM |

Registered: 12 years ago Posts: 2,470 |

I already had one situation where the silicone cover prevented more trouble.

[b.bonkers.de]

Yes, you can work around the heat buildup in the printed part, but isolating the hotend ist much simpler and just works.

Since humans can't see infrared i found it a good idea to isolate the hotend so unsuspecting inquiering fingers of visitors don't get blisters.

I just don't see any reason to not insulate it.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[b.bonkers.de]

Yes, you can work around the heat buildup in the printed part, but isolating the hotend ist much simpler and just works.

Since humans can't see infrared i found it a good idea to isolate the hotend so unsuspecting inquiering fingers of visitors don't get blisters.

I just don't see any reason to not insulate it.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Insulating hotend to contain radiation heat? October 07, 2016 02:56PM |

Registered: 7 years ago Posts: 73 |

Wait, u meen if a big aluminum block is exposed to atmosphere. The heat escapes to atmosphere???

Now that saying my Dad has makes sense..."Colorado is an expensive state to heat."

Srsrly though: If one of the tenants of the RepRap is to have machines making machines, and universality of dispersion...Lowering thermal escape, in turn lowers power consumption and minimum requirements to operate said machines. More energy savings will be found in lowering heating costs than designing a new 3.3v board

Although the HeatBed still remains the #1 American.

Also, as far as heatblock goes. If you relate it to a wood fired boiler system (?any boiler?), it depends where you want that heat to escape. Wood fired tend to be outside and store outside/underground, so thermally insulating the storage provides more volume of heat to be retained for later use. A boiler in the basement of an East Coast building may not, however be insulated. Different ends/ different means. In heating terms, you only need to equal the Btu that is escaping, to maintain a temperature. It doesn't mean you are being efficient about it.

If your goal was to lower power consumption you'd be looking at lowering heat requirements (bed and hotend) as first priority. Since system self regulates temperature, we don't see inefficiency of non-insulation.

I'll probably try some rockwool as I won't have to wait for the boat from China.

Edited 4 time(s). Last edit at 10/07/2016 04:16PM by VonRansak.

Now that saying my Dad has makes sense..."Colorado is an expensive state to heat."

Srsrly though: If one of the tenants of the RepRap is to have machines making machines, and universality of dispersion...Lowering thermal escape, in turn lowers power consumption and minimum requirements to operate said machines. More energy savings will be found in lowering heating costs than designing a new 3.3v board

Although the HeatBed still remains the #1 American.

Also, as far as heatblock goes. If you relate it to a wood fired boiler system (?any boiler?), it depends where you want that heat to escape. Wood fired tend to be outside and store outside/underground, so thermally insulating the storage provides more volume of heat to be retained for later use. A boiler in the basement of an East Coast building may not, however be insulated. Different ends/ different means. In heating terms, you only need to equal the Btu that is escaping, to maintain a temperature. It doesn't mean you are being efficient about it.

If your goal was to lower power consumption you'd be looking at lowering heat requirements (bed and hotend) as first priority. Since system self regulates temperature, we don't see inefficiency of non-insulation.

I'll probably try some rockwool as I won't have to wait for the boat from China.

Edited 4 time(s). Last edit at 10/07/2016 04:16PM by VonRansak.

Sorry, only registered users may post in this forum.