Problem with "setting the number of stepper steps per millimetre of filament fed for a single-material machine"

Posted by Jasinka

|

Problem with "setting the number of stepper steps per millimetre of filament fed for a single-material machine" October 02, 2013 11:51AM |

Registered: 10 years ago Posts: 14 |

Hello,

I am new right here. So sorry if posting same here.... I can't found way fix it.

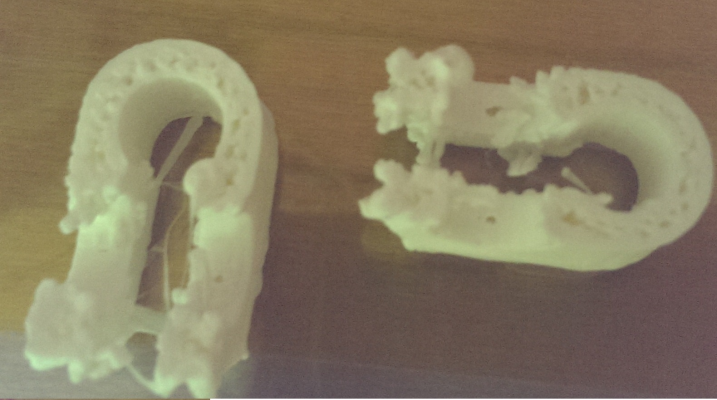

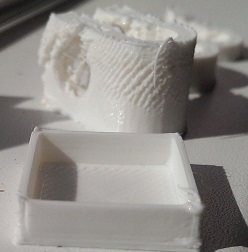

Please check at my photos.

I played with slicer and exported many times with different settings.

Example, no space between lines, filament speed about 130, and etc. And always the same.

Maybe someone can explane my problem?

Thank you very much in advance.

Regards.

I am new right here. So sorry if posting same here.... I can't found way fix it.

Please check at my photos.

I played with slicer and exported many times with different settings.

Example, no space between lines, filament speed about 130, and etc. And always the same.

Maybe someone can explane my problem?

Thank you very much in advance.

Regards.

|

Re: Problem with "setting the number of stepper steps per millimetre of filament fed for a single-material machine" June 30, 2015 01:51PM |

Registered: 10 years ago Posts: 14 |

|

Re: Problem with "setting the number of stepper steps per millimetre of filament fed for a single-material machine" June 30, 2015 03:30PM |

Registered: 10 years ago Posts: 770 |

|

Re: Problem with "setting the number of stepper steps per millimetre of filament fed for a single-material machine" July 01, 2015 11:42AM |

Registered: 8 years ago Posts: 183 |

|

Re: Problem with "setting the number of stepper steps per millimetre of filament fed for a single-material machine" September 14, 2015 04:16PM |

Registered: 10 years ago Posts: 14 |

Thanks for your helpings. And sorry for my late respond.

I tested (fixed) steps per unit and looks good. Maybe on 100mm +- 1mm just. It' can be problem or maybe need look more?

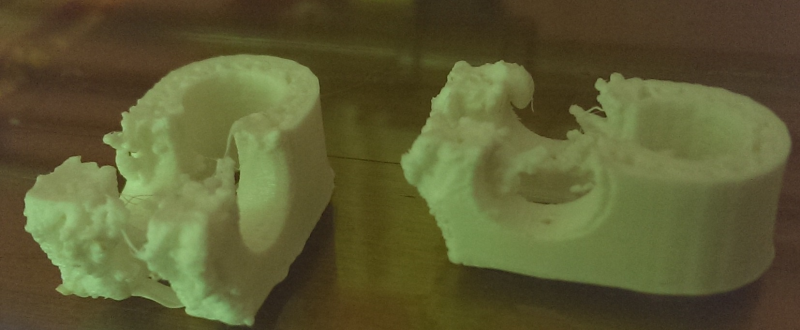

New couple tested parts with different settings. Thanks for helping.

Edited 1 time(s). Last edit at 09/14/2015 04:19PM by Jasinka.

I tested (fixed) steps per unit and looks good. Maybe on 100mm +- 1mm just. It' can be problem or maybe need look more?

New couple tested parts with different settings. Thanks for helping.

Edited 1 time(s). Last edit at 09/14/2015 04:19PM by Jasinka.

|

Re: Problem with "setting the number of stepper steps per millimetre of filament fed for a single-material machine" September 14, 2015 04:29PM |

Registered: 10 years ago Posts: 770 |

|

Re: Problem with "setting the number of stepper steps per millimetre of filament fed for a single-material machine" September 14, 2015 05:52PM |

Registered: 8 years ago Posts: 183 |

|

Re: Problem with "setting the number of stepper steps per millimetre of filament fed for a single-material machine" September 15, 2015 01:11AM |

Registered: 10 years ago Posts: 14 |

|

Re: Problem with "setting the number of stepper steps per millimetre of filament fed for a single-material machine" September 15, 2015 01:48AM |

Registered: 8 years ago Posts: 778 |

Do temp and speed test with a simple shape, like a long and flar box.

Lower the tep until you notice layer seperation when bending the part.

Increase the temp by at least 5°C after that.

Similar story for the speed:

Take the same thing and start with speeds around 40mm/s.

Work your way up until the print no longer looks 100% good.

Note this as the max speed for simple parts.

Now use some small cones and print them with the newly found settings for a final check.

Print 3 or 4 at once to avoid temp problems on the tip of the cone.

They should come out even and with a fine surface and tip.

Once you are happy with the basics try again on more complex parts to finetune the speed for perimeters, infill and bridging.

Lower the tep until you notice layer seperation when bending the part.

Increase the temp by at least 5°C after that.

Similar story for the speed:

Take the same thing and start with speeds around 40mm/s.

Work your way up until the print no longer looks 100% good.

Note this as the max speed for simple parts.

Now use some small cones and print them with the newly found settings for a final check.

Print 3 or 4 at once to avoid temp problems on the tip of the cone.

They should come out even and with a fine surface and tip.

Once you are happy with the basics try again on more complex parts to finetune the speed for perimeters, infill and bridging.

|

Re: Problem with "setting the number of stepper steps per millimetre of filament fed for a single-material machine" September 15, 2015 09:40AM |

Registered: 10 years ago Posts: 770 |

|

Re: Problem with "setting the number of stepper steps per millimetre of filament fed for a single-material machine" September 15, 2015 10:18AM |

Registered: 10 years ago Posts: 14 |

Thank you for suggestions. I will try play with temp. Now tested just speed.

Speed increased from 30 to 50 and second time to 60. Looks same. Need play now with temperature.

Changed parts position, so looks like problem not in motors.

Speed increased from 30 to 50 and second time to 60. Looks same. Need play now with temperature.

Changed parts position, so looks like problem not in motors.

|

Re: Problem with "setting the number of stepper steps per millimetre of filament fed for a single-material machine" September 15, 2015 11:33AM |

Registered: 8 years ago Posts: 183 |

|

Re: Problem with "setting the number of stepper steps per millimetre of filament fed for a single-material machine" September 21, 2015 01:55AM |

Registered: 10 years ago Posts: 14 |

Good morning reprapers,

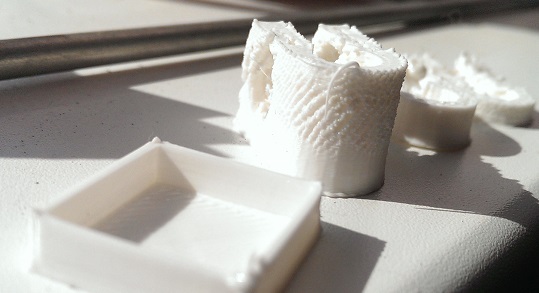

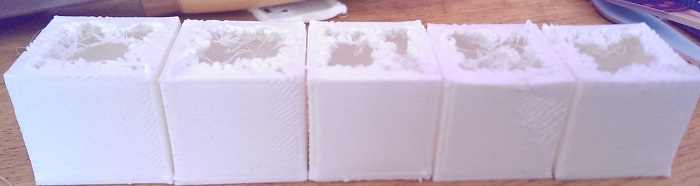

Here is my new tests... With speed and temp. Basic cube looks okay, but little bit complex parts don't looks good.

Maybe i using bad settings? I using default mendel monocolor from RepRap shop.

Thanks for interesting and yours minds.

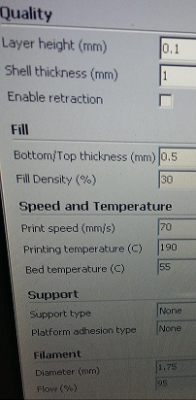

Settings -

And my tests -

Here is my new tests... With speed and temp. Basic cube looks okay, but little bit complex parts don't looks good.

Maybe i using bad settings? I using default mendel monocolor from RepRap shop.

Thanks for interesting and yours minds.

Settings -

And my tests -

|

Re: Problem with "setting the number of stepper steps per millimetre of filament fed for a single-material machine" September 22, 2015 11:38AM |

Registered: 10 years ago Posts: 14 |

Hello,

I tested many option. Looks like now problem just with last top layer.

Maybe someone can help in witch settings i need change? Thanks in advance.

I tested many option. Looks like now problem just with last top layer.

Maybe someone can help in witch settings i need change? Thanks in advance.

|

Re: Problem with "setting the number of stepper steps per millimetre of filament fed for a single-material machine" October 12, 2015 01:11PM |

Registered: 10 years ago Posts: 14 |

|

Re: Problem with "setting the number of stepper steps per millimetre of filament fed for a single-material machine" October 12, 2015 10:04PM |

Registered: 8 years ago Posts: 90 |

I am a new printer myself so take my advice with a grain of salt. I am assuming that your latest prints to be cubes. If so, I don't see any infill. So when attempting to print the top layers the printer can't span the distance. Try setting your slicer to us infill, that will let it span the top and print a surface.

|

Re: Problem with "setting the number of stepper steps per millimetre of filament fed for a single-material machine" October 13, 2015 04:58PM |

Registered: 9 years ago Posts: 752 |

It may still be over extruding, it seems to build up over multiple layers. It seems retractions could improve if it's longer, and/or faster retractions.

Try adjusting bridging speed. Increasing it to the speed at which you do infill/perimeters may help. Try a bridging test object to home in on better settings. I agree with MichaelBrock, if you try to print in 'thin air', it'll improve if it's supported by infill. Also, check if the vertical shells is 3 or more.

Try adjusting bridging speed. Increasing it to the speed at which you do infill/perimeters may help. Try a bridging test object to home in on better settings. I agree with MichaelBrock, if you try to print in 'thin air', it'll improve if it's supported by infill. Also, check if the vertical shells is 3 or more.

Sorry, only registered users may post in this forum.