Intermittent PLA filament problem

Posted by leadinglights

|

Intermittent PLA filament problem October 04, 2013 07:59AM |

Registered: 12 years ago Posts: 1,450 |

While my hot end and extruder produce fine prints with ABS, I have occasional problems with PLA: prints become more and more sparse. This may occur after a couple of days of printing or a couple of weeks of printing. So far, nothing unusual - clean the nozzle with a drill bit and it is good to go again - but here is where the freaky bit starts: Now it will start blocking after only a day and, with more nozzle cleaning it may only be good for a few layers.

O.K., I have been doing this for long enough to know some tricks - clean the filament drive gear, increase the temperature, sell that roll of PLA to an acquaintance etc., but the only thing that works is to strip down the extruder, burn out the old PLA and use drills to clean the chamber and nozzle followed by a soak in various solvents and cleaning in an ultrasonic bath.

Having exhausted any good ideas, I think that it is time to see if anybody recognises the problem. Attached photos below show clean filament from an extruder which has just been cleaned with a drill bit and the same after an hour of printing. The regularity of that spiral pattern must mean something - but what?

A short section of a filament which had almost stopped flowing. This has some yellow inclusions which make me suspect that I am extruding too hot (210C), but using a lower temperature doesn't help.

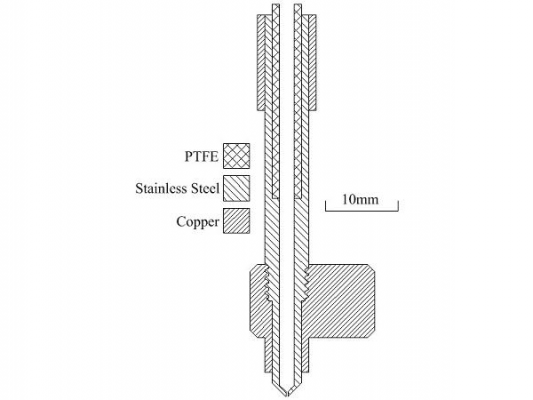

A cross section drawing of the hot end/nozzle. Has anybody any thoughts on whether the melt chamber is too short or too long or if the the angle to the final (0.45mm) nozzle hole is too blunt? The top of the nozzle is mounted in a force cooled heatsink and the top of the melt chamber/bottom of the PTFE maintains about 60 to 80C.

Any thoughts or input greatfully received.

Mike

Edited 1 time(s). Last edit at 10/04/2013 08:15AM by leadinglights.

O.K., I have been doing this for long enough to know some tricks - clean the filament drive gear, increase the temperature, sell that roll of PLA to an acquaintance etc., but the only thing that works is to strip down the extruder, burn out the old PLA and use drills to clean the chamber and nozzle followed by a soak in various solvents and cleaning in an ultrasonic bath.

Having exhausted any good ideas, I think that it is time to see if anybody recognises the problem. Attached photos below show clean filament from an extruder which has just been cleaned with a drill bit and the same after an hour of printing. The regularity of that spiral pattern must mean something - but what?

A short section of a filament which had almost stopped flowing. This has some yellow inclusions which make me suspect that I am extruding too hot (210C), but using a lower temperature doesn't help.

A cross section drawing of the hot end/nozzle. Has anybody any thoughts on whether the melt chamber is too short or too long or if the the angle to the final (0.45mm) nozzle hole is too blunt? The top of the nozzle is mounted in a force cooled heatsink and the top of the melt chamber/bottom of the PTFE maintains about 60 to 80C.

Any thoughts or input greatfully received.

Mike

Edited 1 time(s). Last edit at 10/04/2013 08:15AM by leadinglights.

|

Re: Intermittent PLA filament problem October 04, 2013 10:06AM |

Registered: 10 years ago Posts: 7 |

|

Re: Intermittent PLA filament problem October 04, 2013 12:38PM |

Registered: 12 years ago Posts: 1,450 |

It is possible that it is too hot, but that by itself doesn't explain why the nozzle gets blocked, or why it flows very cleanly initialy. Removing the idler from the extruder and pushing the 1.75mm filament through by hand gives very little back pressure with a freshly cleaned nozzle, but a lot of back pressure a little later - when the output filament is becoming rough. With the temperature down at 190C the back pressure starts high and the layer to layer adhesion is not too good. The best temperature seems to be very variable between different rolls of plastic, different prints and even different people.

As I have done a complete clean on a nozzel I will try a big print at 200C.

Mike

As I have done a complete clean on a nozzel I will try a big print at 200C.

Mike

|

Re: Intermittent PLA filament problem October 10, 2013 04:31AM |

Registered: 12 years ago Posts: 1,450 |

Having done some extensive trials I have come to the conclusion that a setting of 210C on my hot ends is about right. However, the problems seems to be getting worse on PLA - ABS is still pretty much perfect.

To rehash the problem:

The extruder (Airtrippers) generally does not get clogged and excessive back pressure used to cause the stepper to be intermittetently driven backwards by ca 45 degrees - this no longer happens. My suspicion is that the stepper motor is not keeping up; but this happens without any of the usual sound effects or lack of smoothness.

Although I have started to design an extruder to use a Phidgets geared Nema17 stepper with a bowden drive, I don't think that this will answer the primary problem.

As usual, any help, sugestions, sympathy such as "I feel your pain brother" greatfully received

Mike

To rehash the problem:

- PLA prints with this hot end and extruder used to be acceptable to perfect.

- Prints started to become sparse at highter speeds but improved with cleaning the nozzle

- Cleaning the nozzle stopped helpint and all passages in the hot end needed to be cleaned before a print would complete O.K.

- Nozzle now gets blocked shortly after starting a print - even a full strip down and clean doesn't help.

- Detectable back pressure from pushing the filament manually is good with a freshly cleaned nozzle but rapidly gets worse.

The extruder (Airtrippers) generally does not get clogged and excessive back pressure used to cause the stepper to be intermittetently driven backwards by ca 45 degrees - this no longer happens. My suspicion is that the stepper motor is not keeping up; but this happens without any of the usual sound effects or lack of smoothness.

Although I have started to design an extruder to use a Phidgets geared Nema17 stepper with a bowden drive, I don't think that this will answer the primary problem.

As usual, any help, sugestions, sympathy such as "I feel your pain brother" greatfully received

Mike

|

Re: Intermittent PLA filament problem October 14, 2013 03:35AM |

Registered: 12 years ago Posts: 1,450 |

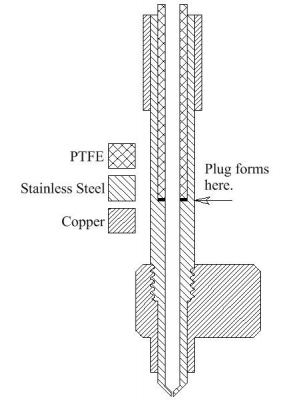

At long last, the inexplicable is expliked! On removing my hot end and redrilling the 2mm passage and the 0.45mm nozzle, I also drilled the 4mm dia bit where the PTFE liner goes and hit paydirt more than 2mm before I should have reached metal. Every time I had cleaned it before I had drilled out the main passages in the hope of removing the blockage while thr real culprit was waiting in the wings.

Mike

Mike

Sorry, only registered users may post in this forum.