Please help me solve this

Posted by jpan

|

Please help me solve this February 04, 2014 05:23PM |

Registered: 10 years ago Posts: 125 |

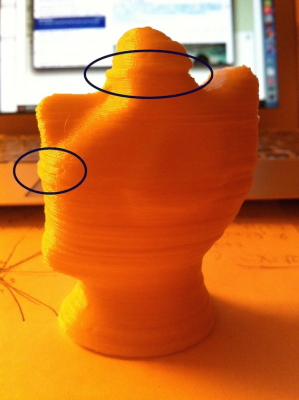

Here are some print that my machine did these days. I do not think it's z-wobble caused by the threaded rods (although I thought so and nearly bought aluminum couplers) after finding out that it's only twisted in the direction of y-axis. And the distances between the "waves" don't match the pitch of my threaded rod.

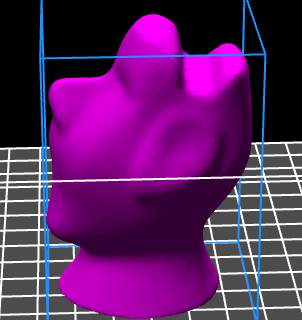

pic token along x-axis.(only it's not on the print bed)

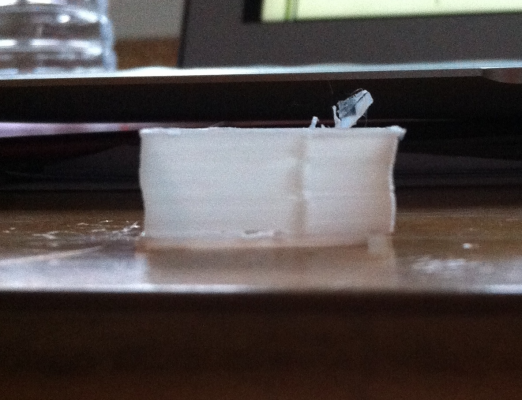

token along the same direction as the one right above

token along the same direction as the ones above

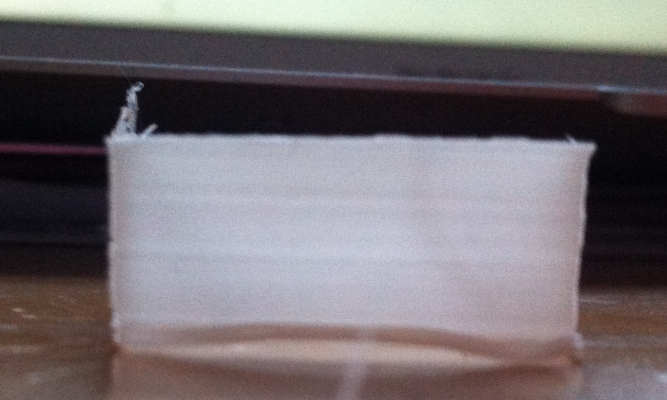

same object but picture token along y-axis, but nicely printed(for me...) from this view.

Since when you see the print panel along x-axis, you actually see y-axis' movement. Therefore I think there's a problem on my y-axis movement. I have no idea on what to do in this kind of situation. I need help!

Any suggestion will be appreciated.

Edited 3 time(s). Last edit at 02/04/2014 07:56PM by jpan.

pic token along x-axis.(only it's not on the print bed)

token along the same direction as the one right above

token along the same direction as the ones above

same object but picture token along y-axis, but nicely printed(for me...) from this view.

Since when you see the print panel along x-axis, you actually see y-axis' movement. Therefore I think there's a problem on my y-axis movement. I have no idea on what to do in this kind of situation. I need help!

Any suggestion will be appreciated.

Edited 3 time(s). Last edit at 02/04/2014 07:56PM by jpan.

|

Re: Please help me solve this February 04, 2014 08:55PM |

Registered: 13 years ago Posts: 1,780 |

You might be printing too fast for those small parts and not giving the lower layers enough time to harden before laying down the next layer. Slow down the print or use the cool option to blow a fan for cooling or slow it down when the time it takes to print each layer is less than 20 or 30 s. You can also print 2 at a time, but that just wastes plastic.

|

Re: Please help me solve this February 04, 2014 09:17PM |

Registered: 10 years ago Posts: 125 |

|

Re: Please help me solve this February 04, 2014 09:20PM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Please help me solve this February 04, 2014 09:30PM |

Registered: 11 years ago Posts: 265 |

|

Re: Please help me solve this February 04, 2014 09:51PM |

Registered: 10 years ago Posts: 125 |

|

Re: Please help me solve this February 05, 2014 01:39AM |

Registered: 13 years ago Posts: 1,797 |

|

Re: Please help me solve this February 05, 2014 08:46AM |

Registered: 10 years ago Posts: 125 |

|

Re: Please help me solve this February 05, 2014 09:23AM |

Registered: 13 years ago Posts: 1,797 |

|

Re: Please help me solve this February 05, 2014 09:26AM |

Admin Registered: 12 years ago Posts: 2,569 |

|

Re: Please help me solve this February 08, 2014 06:23PM |

Registered: 10 years ago Posts: 474 |

|

Re: Please help me solve this February 08, 2014 09:09PM |

Registered: 10 years ago Posts: 125 |

The bearings are fine. Now my electronics are fried, but still I took some pictures.

I also installed something like this (before my Arduino and Aamps being fried =_=III) and didn't have too much good effect. I even sanded it to make it little effective to the linear rod.

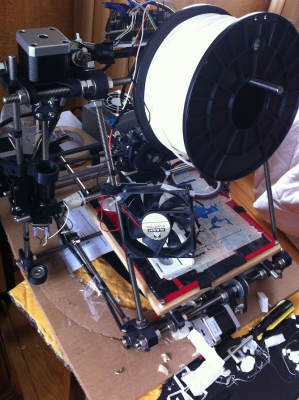

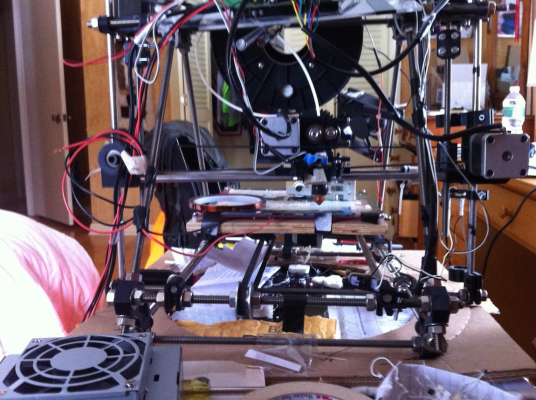

Here's how my machine looks like:

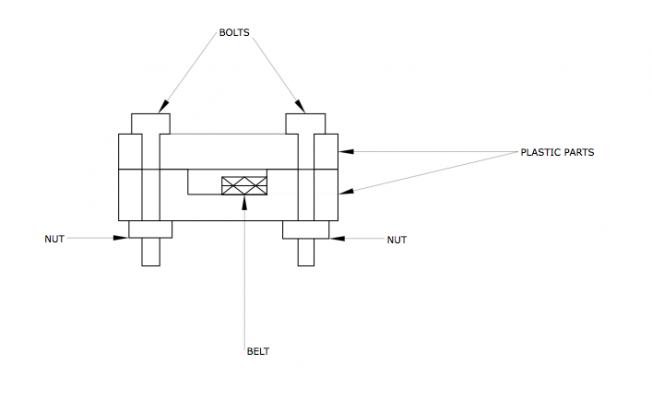

I use 3mm filament. I now suspect the problem might be because misalignment of y-axis belt. When last time I tightened the belt, it wasn't fixed in the center between to space between the two pieces of plastic(as I observed). Although this assumption doesn't make too much sense even to myself.

This is what I mean.

(the belt is fixed there, not that free as shown )

I also installed something like this (before my Arduino and Aamps being fried =_=III) and didn't have too much good effect. I even sanded it to make it little effective to the linear rod.

Here's how my machine looks like:

I use 3mm filament. I now suspect the problem might be because misalignment of y-axis belt. When last time I tightened the belt, it wasn't fixed in the center between to space between the two pieces of plastic(as I observed). Although this assumption doesn't make too much sense even to myself.

This is what I mean.

(the belt is fixed there, not that free as shown )

|

Re: Please help me solve this February 08, 2014 09:41PM |

Registered: 13 years ago Posts: 1,797 |

i would square off z,x,y axis to be sure. also remove all slop from the top bed. I would put springs there instead of spacers. springs allow for the bed to move when it re-sizes from heat and then if compressed enough, reduce motion of the table top, the part that is the heated bed, covered with glass.

also that idler puller on the left is not sized correctly. steps on the left side of bed will have less tension on the belt. make the belt on x axis as level as possible.

Edited 1 time(s). Last edit at 02/08/2014 09:47PM by jamesdanielv.

also that idler puller on the left is not sized correctly. steps on the left side of bed will have less tension on the belt. make the belt on x axis as level as possible.

Edited 1 time(s). Last edit at 02/08/2014 09:47PM by jamesdanielv.

|

Re: Please help me solve this February 09, 2014 08:34AM |

Registered: 10 years ago Posts: 125 |

|

Re: Please help me solve this February 09, 2014 09:23AM |

Registered: 13 years ago Posts: 1,797 |

|

Re: Please help me solve this February 27, 2014 08:45PM |

Registered: 10 years ago Posts: 125 |

I know it's been a long time. I got all electronics replaced, costing me about one hundred bucks. The problem just remains. I adjusted the little screw on the stepper driver and it does make some little differences. But still I cannot get a perfect straight wall whatever numbers of times I tried for.

I also found an interesting phenomenon. The pulley on y-axis motor shaft does not spin around it's center. I guess it's because the tensioned belt is only pulling one end of the pulley.

Is that a possible reason? If so how can I do that?

Any suggestion will be greatly appreciated!

I also found an interesting phenomenon. The pulley on y-axis motor shaft does not spin around it's center. I guess it's because the tensioned belt is only pulling one end of the pulley.

Is that a possible reason? If so how can I do that?

Any suggestion will be greatly appreciated!

|

Re: Please help me solve this February 27, 2014 09:11PM |

Registered: 10 years ago Posts: 1,381 |

Quote

jpan

I also found an interesting phenomenon. The pulley on y-axis motor shaft does not spin around it's center. I guess it's because the tensioned belt is only pulling one end of the pulley.

Is that a possible reason? If so how can I do that?

You need to replace the out of round pulley, less your design is missing a part.

The pulley ideally should have zero circular run out.

Measure the shaft, and the pulley bore diameters, there should be almost no difference.

A small press fit of .0005" (0.013 mm) would be preferable, if you have the means to assemble it.

If you do end up purchasing a replacement pulley, verify that the bore in the pulley is machined to match your shaft diameter,

and not for a range of shaft diameters.

I also noticed that on the back side of the machine, that the Y axis belt is shifted to one side of the pulley.

Possibly a clue that your machine is not square.

|

Re: Please help me solve this February 27, 2014 09:44PM |

Registered: 10 years ago Posts: 125 |

Thanks for reply!

I do have some spare pulleys. I tried them on and once. They work pretty much as well as each other. (Maybe the shape of the pulleys also plays? Doesn't make sense to myself though.)

I am wondering if that little screw adjusting current on stepper drivers (A4988 in my case ) will make any difference if they're turned by only 5 degrees of so. I mean, how accurate are those screws? Cuz now I am adjusting them within a range of 30 degrees in which the motors works better. Don't know if I should narrow this range more.

I do have some spare pulleys. I tried them on and once. They work pretty much as well as each other. (Maybe the shape of the pulleys also plays? Doesn't make sense to myself though.)

I am wondering if that little screw adjusting current on stepper drivers (A4988 in my case ) will make any difference if they're turned by only 5 degrees of so. I mean, how accurate are those screws? Cuz now I am adjusting them within a range of 30 degrees in which the motors works better. Don't know if I should narrow this range more.

|

Re: Please help me solve this February 27, 2014 10:55PM |

Registered: 10 years ago Posts: 1,381 |

Do the teeth of the belt mesh with the pulley, is the pulley bore too big, or is the pulley out of round?

[www.youtube.com]

[www.youtube.com]

You should also verify that the pulley shafts are parallel to each other, and perpendicular to the Y axis, use a square.

[www.starrett.com]

Edited 1 time(s). Last edit at 02/28/2014 07:14AM by A2.

[www.youtube.com]

[www.youtube.com]

You should also verify that the pulley shafts are parallel to each other, and perpendicular to the Y axis, use a square.

[www.starrett.com]

Edited 1 time(s). Last edit at 02/28/2014 07:14AM by A2.

|

Re: Please help me solve this February 28, 2014 07:10AM |

Registered: 10 years ago Posts: 903 |

Quote

jpan

I am wondering if that little screw adjusting current on stepper drivers (A4988 in my case ) will make any difference if they're turned by only 5 degrees of so. I mean, how accurate are those screws? Cuz now I am adjusting them within a range of 30 degrees in which the motors works better. Don't know if I should narrow this range more.

Do you have a multimeter? I'm guessing the answer is no, or you would know how touchy those trim pots are. Even worse, the manufacturer that made mine didn't set them to any default, so there was no starting point for a reference for counting turns without a meter.....

|

Re: Please help me solve this February 28, 2014 08:06AM |

Registered: 10 years ago Posts: 125 |

|

Re: Please help me solve this March 16, 2014 09:03PM |

Registered: 10 years ago Posts: 125 |

Check me newest print out, plz

I now find that my wobble/banding is no in any pattern most of the time. My guess of the root of the problem is the tension of the 3mm filament. When the position of the hot end changes(sort of due to my printer's construction), the tension (both amount and direction) of the filament also changes. Therefore my next step, hopefully the last step, is to switch my filament and hot end to 1.75mm.

Any ideas?

I now find that my wobble/banding is no in any pattern most of the time. My guess of the root of the problem is the tension of the 3mm filament. When the position of the hot end changes(sort of due to my printer's construction), the tension (both amount and direction) of the filament also changes. Therefore my next step, hopefully the last step, is to switch my filament and hot end to 1.75mm.

Any ideas?

|

Re: Please help me solve this March 16, 2014 09:47PM |

Registered: 10 years ago Posts: 474 |

be very careful I would use a plastic screwdriver if you're adjusting this if you short it out you will be buying more electronics. Obviously you need to start with a good square machine everybody here has been trying to help you with this but you need a good machine to start with. Obviously if you pulleys are not running true they are wrong they could even be the wrong pulley for the belt in any case they need to be corrected. Mechanically your machine has to be right first to tune it upQuote

jpan

Well, so I guess the adjusting of current may not be a reason

The first one is my case I think. I'll just try some other pulleys...

The other pulleys that I have are no good, too.

Edited 4 time(s). Last edit at 03/16/2014 09:55PM by cnc dick.

|

Re: Please help me solve this March 21, 2014 10:20AM |

Registered: 10 years ago Posts: 125 |

Thanks for your advice., but I don't even think that matters too much. I am sure that the pulley is the in the right size(GT2). I'll see what would happen after I switch to 1.75 filament. the new extruder and filament are already ordered and shipped so to wait is the only thing that I could do now.

|

Re: Please help me solve this March 31, 2014 08:33PM |

Registered: 10 years ago Posts: 125 |

Switched to 1.75, problem solved (95%, let's say it's solved)

Thank you to everybody who helped. Will post some pictures of newest prints later.

This is really a helpful community. Thank you!

Only thing bad about this experience is the bucks for the fried electronics...... Will learn from it.

Thank you to everybody who helped. Will post some pictures of newest prints later.

This is really a helpful community. Thank you!

Only thing bad about this experience is the bucks for the fried electronics...... Will learn from it.

Sorry, only registered users may post in this forum.

Strange aha?

Strange aha?